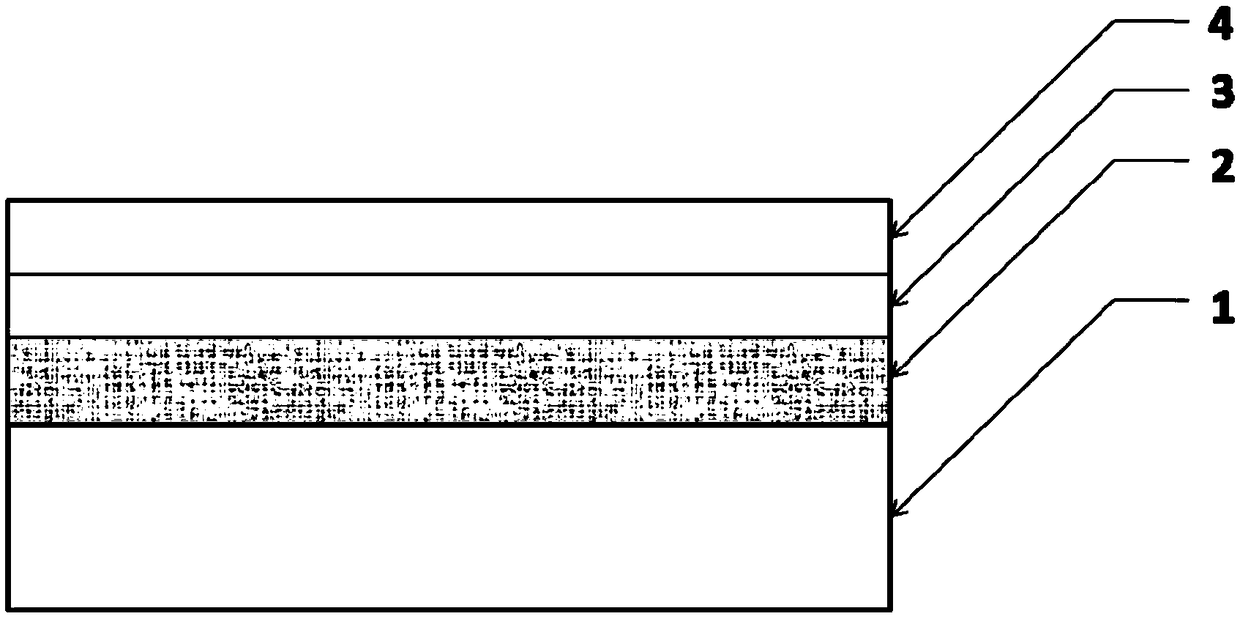

Composite transparent conductive film and preparation method thereof

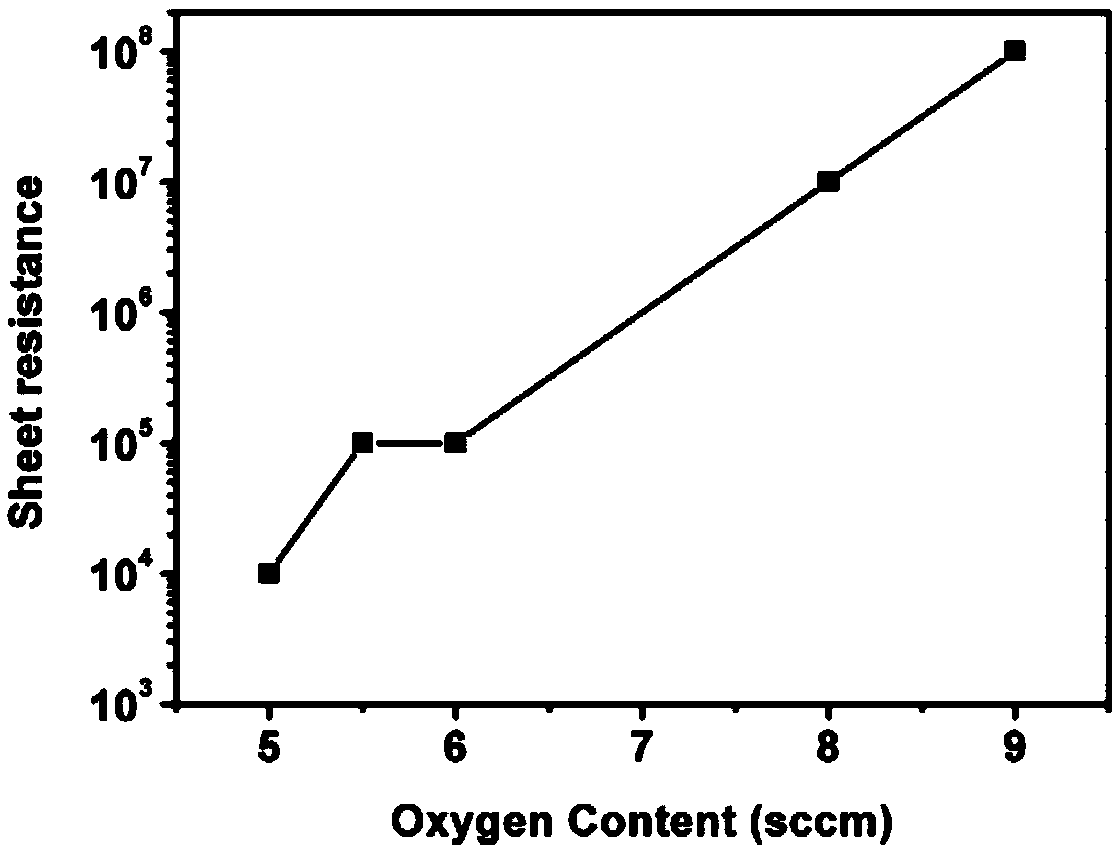

A transparent conductive film and thin film technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problem of poor stability of antistatic fillers, easy failure of antistatic components, and few products of transparent antistatic coatings, etc. problem, to achieve the effect of high surface resistance accuracy, meeting the process window, and convenient process adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare a composite conductive film based on the surface of a plexiglass sample, the steps of the preparation method are as follows:

[0029] (1) Raw materials for preparing transition layer:

[0030] Adopt acrylic polyurethane transparent coating and adopt solution polymerization process, the names and mass percentages of each component are: methyl methacrylate: 20.0% by weight; styrene: 10% by weight; butyl acrylate: 5.0% by weight; trimethylolpropane Triacrylate: 2.0% by weight; initiator (dibenzoyl peroxide): 0.5% by weight and solvent (equal mass mixture of butyl acetate and PMP): 62.5% by weight. During synthesis, first put 15% by weight of monomer (a mixture of methyl methacrylate, styrene, butyl acrylate and trimethylolpropane triacrylate) and 20% by weight of solvent into the kettle, and reflux at 100 ° C Add the mixed solution of the remaining monomer, solvent and 25% by weight of the initiator dropwise at high temperature, drop it for 3 hours, then add the r...

Embodiment 2

[0038] A preparation method based on polycarbonate sample surface composite conductive film, the steps are as follows:

[0039] (1) Raw materials for preparing transition layer

[0040] Polysiloxane coating is used, and the name and mass percentage of each component are: ethyl orthosilicate: 4.7% by weight; methyltriethoxysilane: 50.0% by weight; KH550: 4.7% by weight; hydroxyl silicone oil: 0.2% by weight ; Tetrabutylammonium hydroxide: 0.2% by weight; Isopropanol: 40.2% by weight. When synthesizing, first put the mixture of ethyl orthosilicate and methyltriethoxysilane into the kettle, add a small amount of acetic acid until the pH is 3, raise the temperature to 80°C for reflux reaction for 2 hours, and reflux for cooling. Then add KH550 at 55°C, stir for 2h and cool to room temperature. Finally, isopropanol, hydroxy silicone oil and tetrabutylammonium hydroxide were added exceptionally to obtain polysiloxane clear coatings.

[0041] (2) Preparation of transition layer

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com