A suction type doffer device installed on a nonwoven carding machine

A carding machine and non-woven technology, applied in the field of doffer devices, to achieve good density uniformity, high total utilization rate of raw materials, and expand the use of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

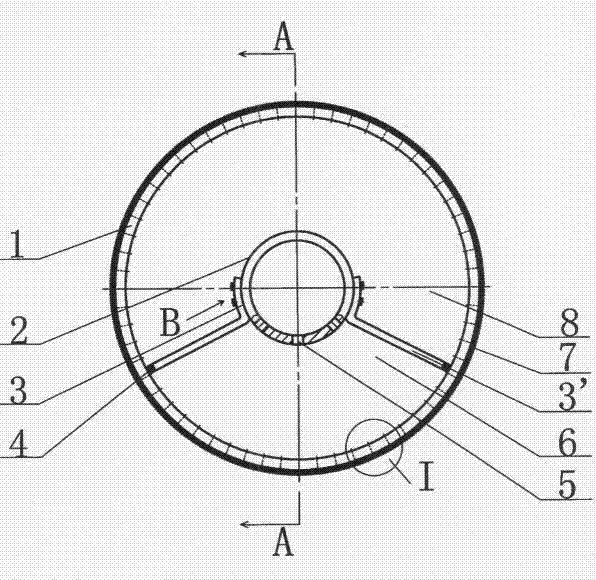

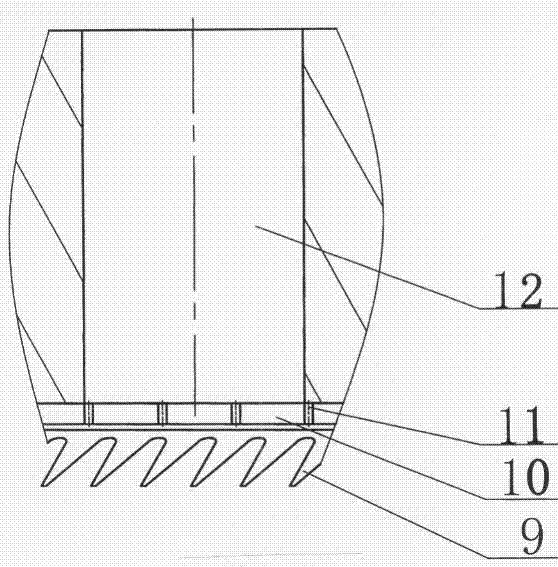

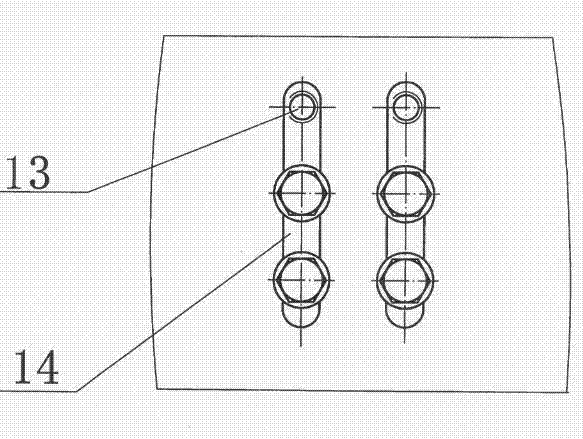

[0049] Process a non-woven material for easy-to-flush wet wipes, use 20% 1.5D×38mm polyester fiber, 50% 1.5D×22mm polyester fiber and 30% 1.5D×16mm viscose fiber to mix, and use the present invention when carding into a web A suction type doffer transfers the fibers from the cylinder to the coalescing rolls. The device is specifically: including roller body 1, mandrel 2, front windshield 3, rear windshield 3', left end cover 15, right end cover 15', card clothing 7, timing pulley 16 and timing belt 17. Parts, the roller body 1 is a steel hollow cylinder with an outer diameter of 700mm, a length of 3800mm, and a wall thickness of 26mm. The diameter of the cylindrical roller air holes 12 on the surface is 8.0mm, and the hole distance is 12.0mm The outer diameter of the mandrel 2 is 240mm, the inner diameter is 200mm, and the length is 4700mm. The bottom of the mandrel 2 part in the inner cavity of the roller body 1 is provided with 3 rows of mandrel suction holes 5 along the dir...

Embodiment 2

[0051] Process a non-woven material for easy-to-flush wet wipes, using 15% 1.5D × 38mm polyester fiber, 50% 1.5D × 22mm polyester fiber and 35% degreased bleached cotton fiber mixed, using the suction type of the present invention when carding into a web The doffer unit transfers the fibers from the cylinder to the coalescing rolls. The device is specifically: composed of roller body 1, mandrel 2, front windshield 3, rear windshield 3', left end cover 15, right end cover 15', card clothing 7, timing pulley 16 and timing belt 17. Composition, the roller body 1 is a steel hollow cylinder with an outer diameter of 600mm, a length of 2500mm, and a wall thickness of 20mm. The diameter of the cylindrical roller air holes 12 on the surface is 5.0mm, and the hole distance is 9.0mm. The outer diameter of the mandrel 2 is 240mm, the inner diameter is 200mm, and the length is 3400mm. The bottom of the mandrel 2 part in the inner cavity of the roller body 1 is provided with 3 rows of mand...

Embodiment 3

[0053]Process a kind of glass wiping non-woven material, adopt 25% 1.5D * 38mm polyester fiber, 45% 1.5D * 38mm viscose fiber and 30% 1.5D * 16mmES two-component fiber to mix, adopt the present invention when carding into a net A suction doffer transfers the fibers from the cylinder to the coalescing rolls. The device is specifically: composed of roller body 1, mandrel 2, front windshield 3, rear windshield 3', left end cover 15, right end cover 15', card clothing 7, timing pulley 16 and timing belt 17. Composition, the roller body 1 is a steel hollow cylinder with an outer diameter of 550mm, a length of 1700mm, and a wall thickness of 17mm. The diameter of the cylindrical roller air hole 12 on the surface is 4.0mm, and the hole distance is 8.0mm The outer diameter of the mandrel 2 is 240mm, the inner diameter is 200mm, and the length is 2800mm; the bottom of the mandrel 2 part located in the inner cavity of the roller body 1 is provided with 3 rows of mandrel suction holes 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com