Patents

Literature

46 results about "Trickle flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The definition of a thin flow or steady drops. An example of a trickle is the flow of drops from a faucet. Trickle is defined as to flow slowly in a thin stream, or fall in steady drops.

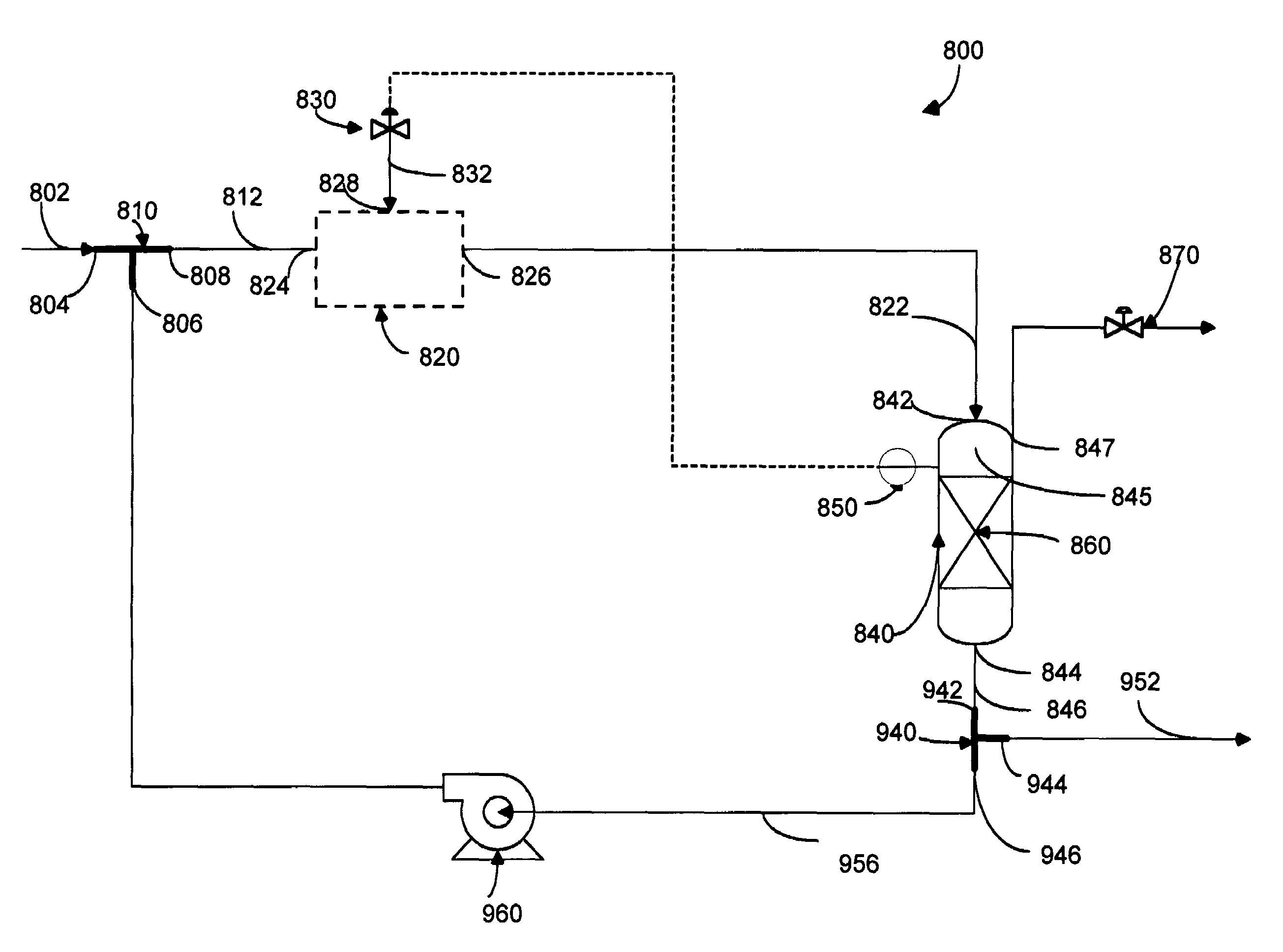

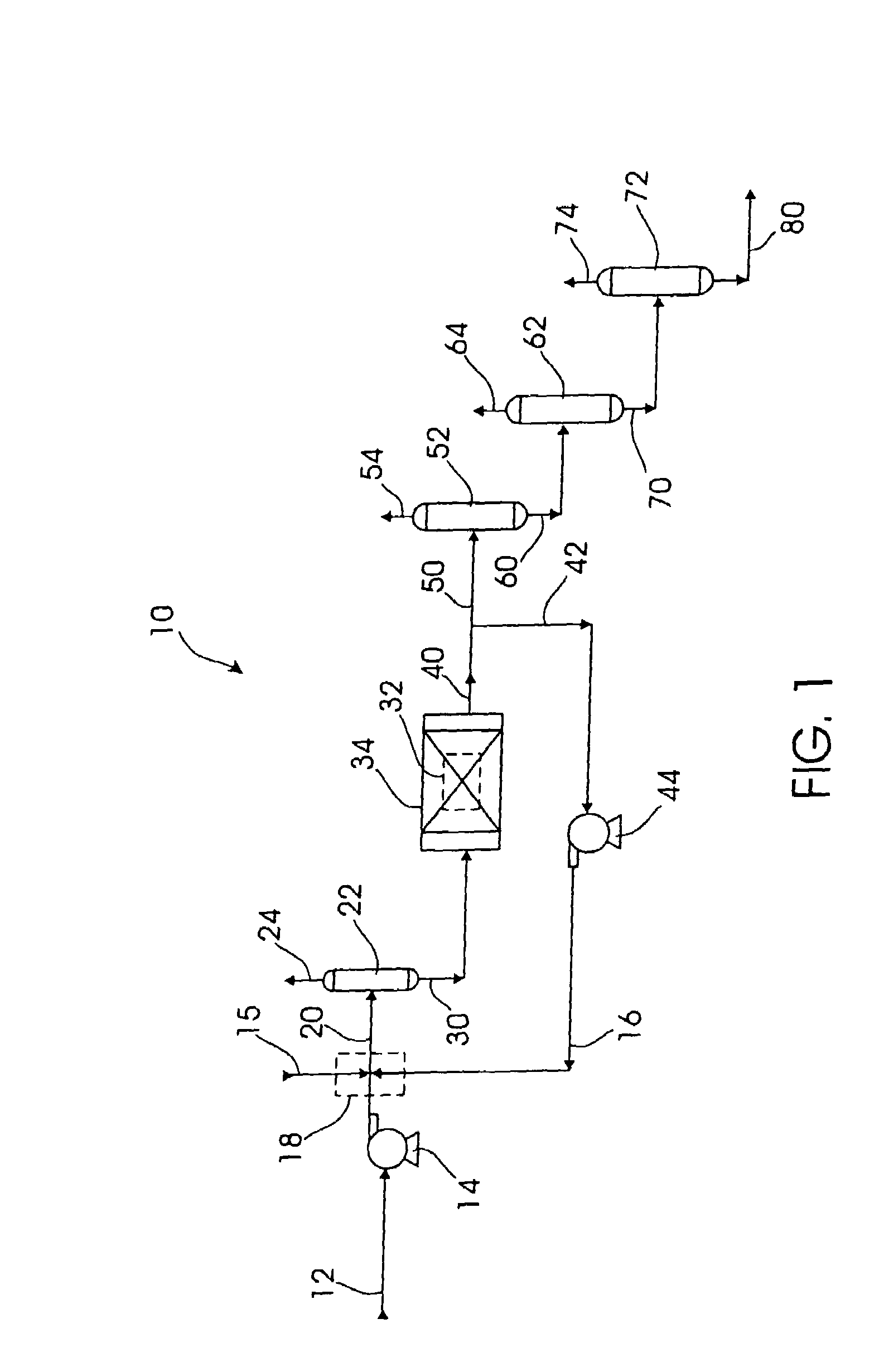

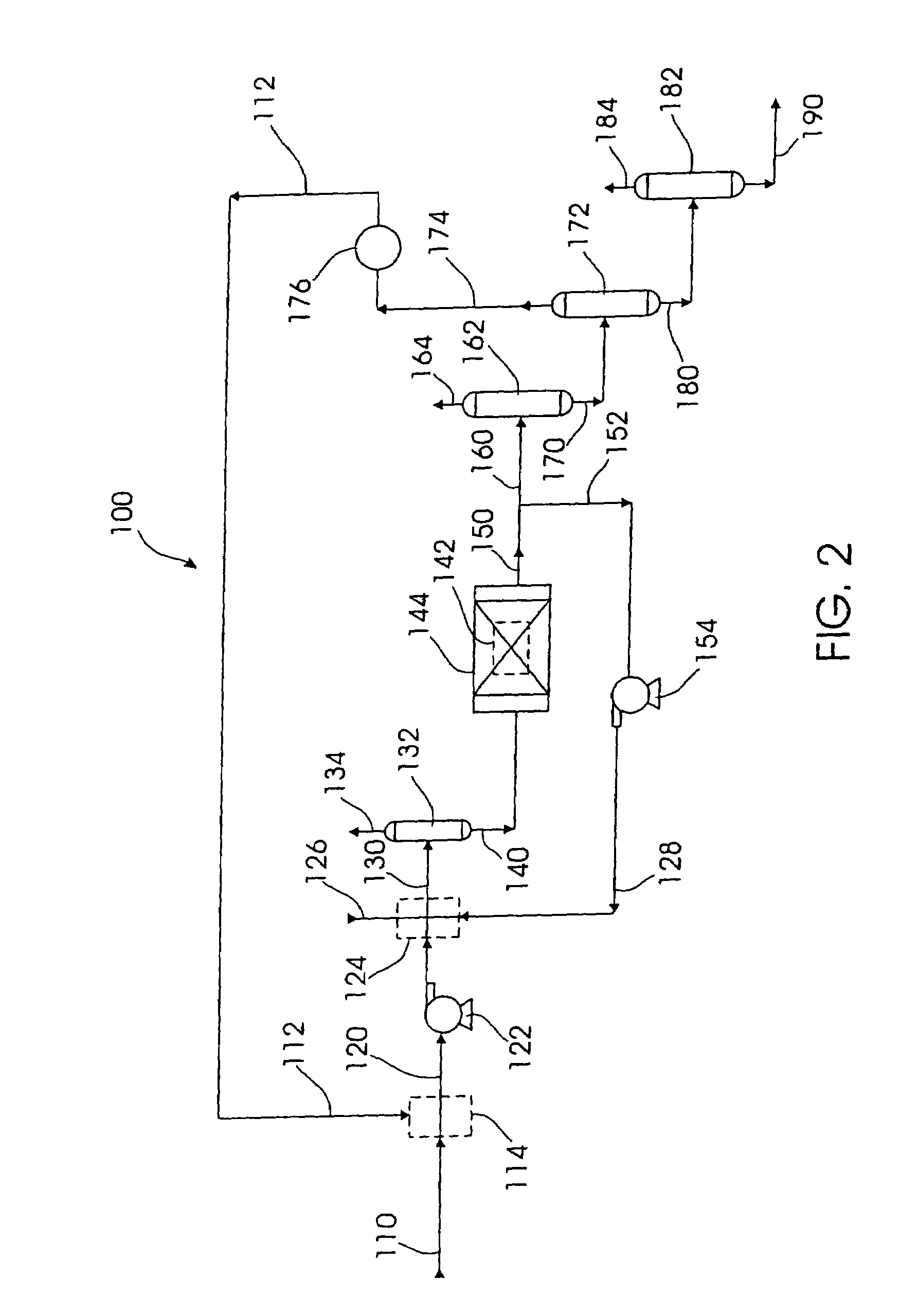

Control system method and apparatus for two phase hydroprocessing

InactiveUS7569136B2Hydrogen solubility is “Eliminate needPhysical/chemical process catalystsHydrocarbon oils treatment control/regulationSolubilityHydrogen

A continuous liquid phase hydroprocessing process, apparatus and process control systems, where the need to circulate hydrogen gas through the catalyst is eliminated. By mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is high relative to the oil feed, all of the hydrogen required in the hydroprocessing reactions may be available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required; therefore, the large trickle bed reactors can be replaced by much smaller tubular reactors. The amount of hydrogen added to the reactor can be used to control the liquid level in the reactor or the pressure in the reactor.

Owner:EI DU PONT DE NEMOURS & CO

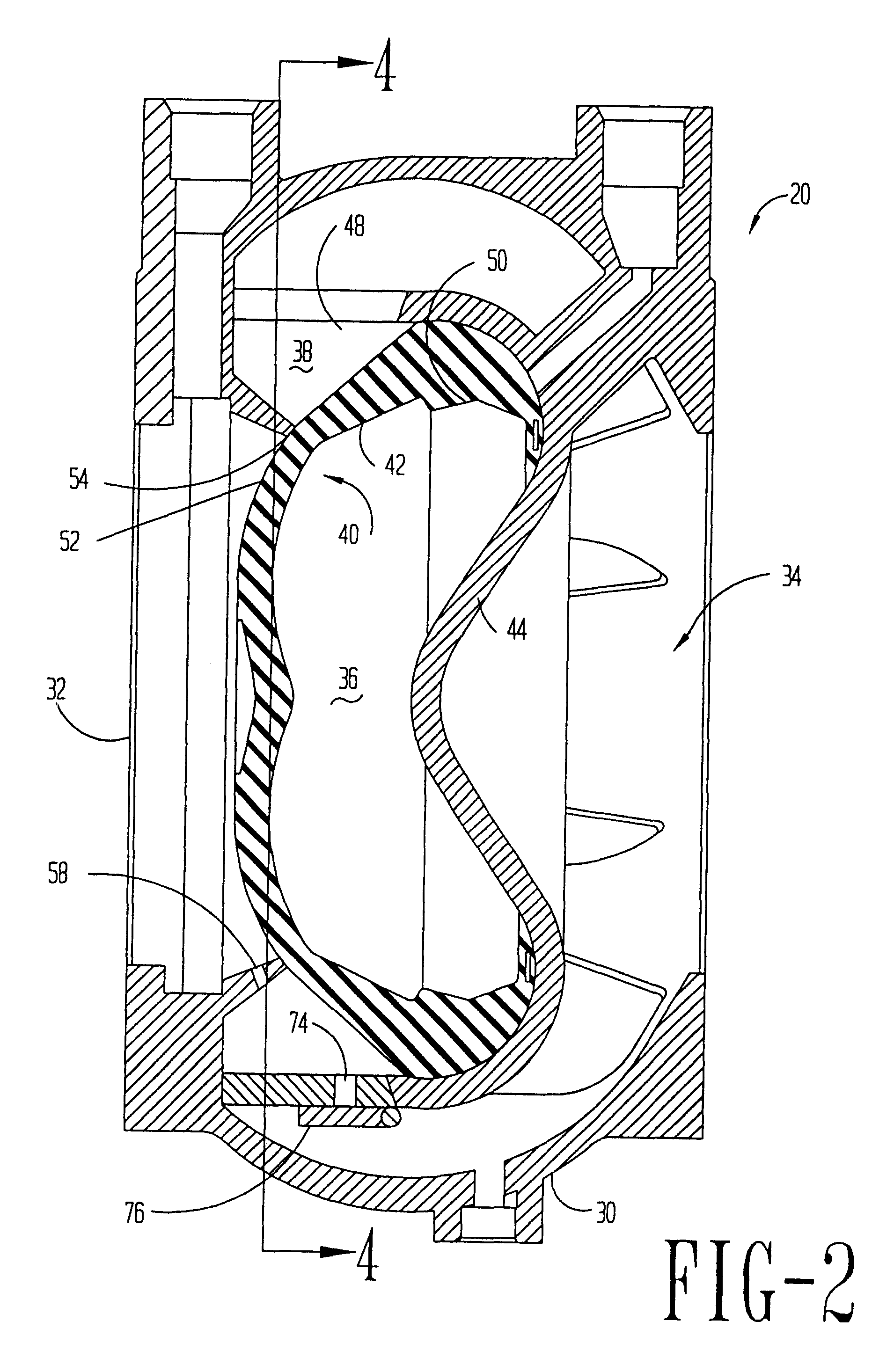

Remote shower actuation and temperature sensing unit

InactiveUS7857234B2Temperature control without auxillary powerOperating means/releasing devices for valvesSteady state temperatureWireless control

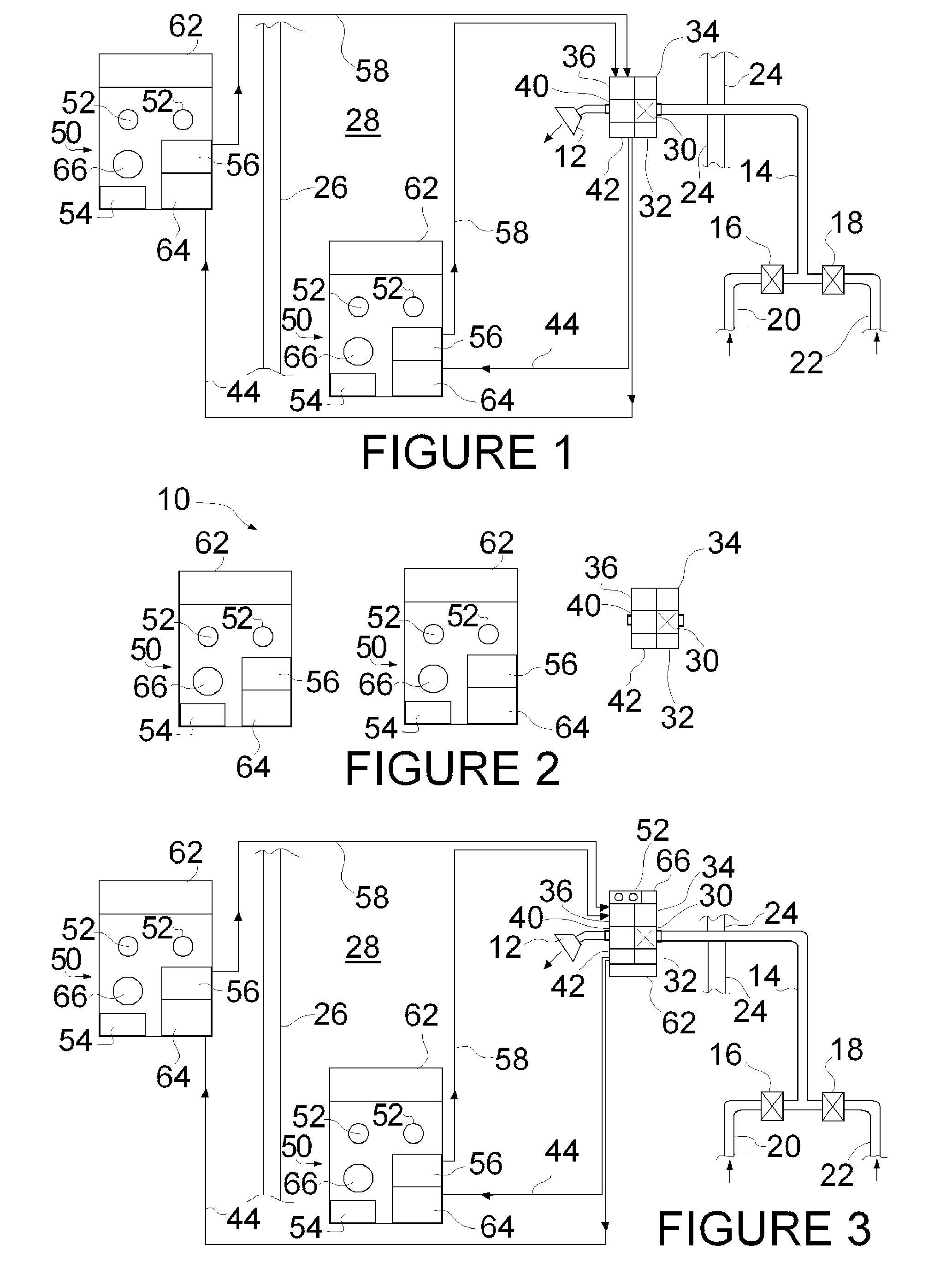

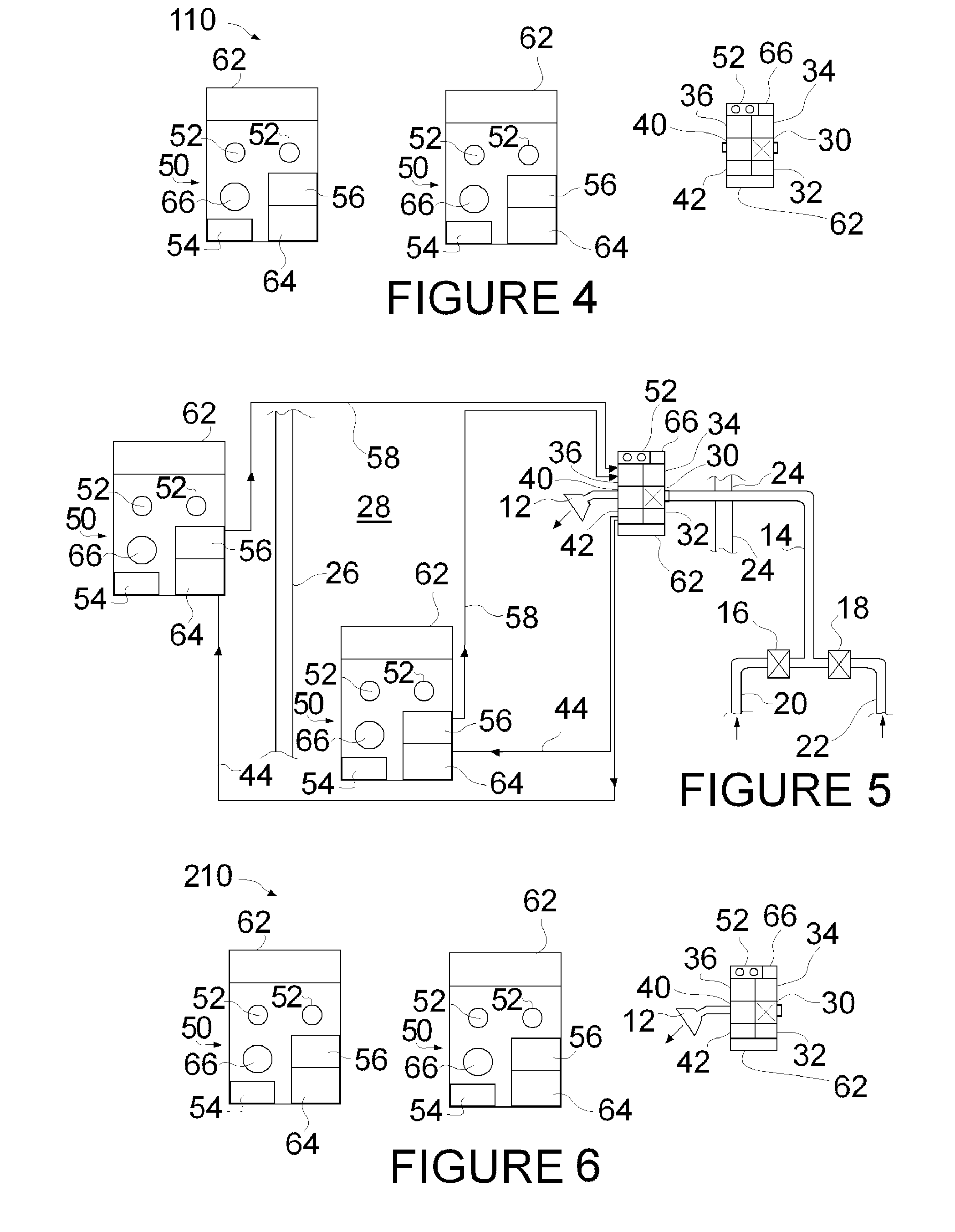

A remote shower actuator and temperature sensing unit installs in a shower having a shower head in a water line that is downstream of hot and cold water mixing for the shower. The shower actuator includes a battery powered wireless actuated blocking valve, a digital temperature sensor mechanism, a temperature indicating mechanism and generally two independent one wireless controllers. The valve may move between a closed position, an open position and a trickle flow position. The trickle flow position is a significantly reduced flow in response to a potentially hazardous temperature reading. The temperature indicating mechanism may be a visible display on the controllers that constantly displays the measured temperatures, or may be a visible or audible indicator on the controllers that identifies that the flowing water temperature has reached an acceptable steady state temperature, or a combination of the two.

Owner:THORLEY INDS

Roll seal control valve

Owner:AUSTIN CARY M

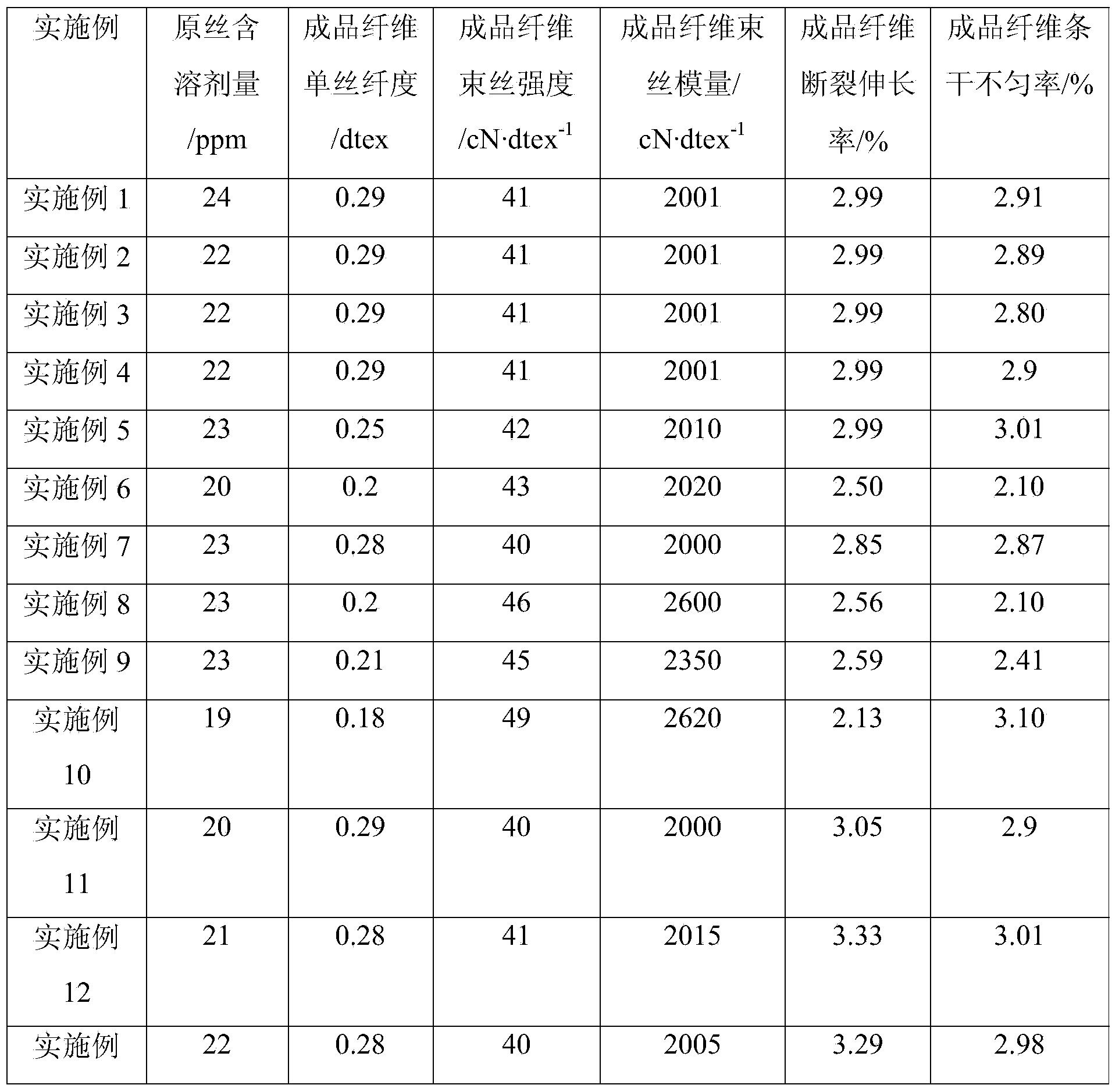

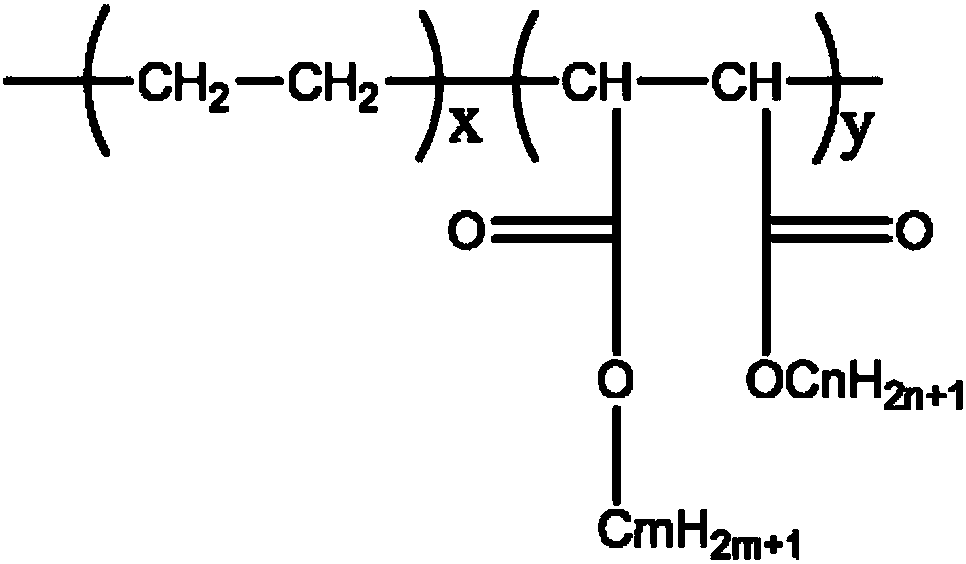

Method for preparing ultra-high molecular weight polyethylene fiber and fiber

ActiveCN104032402AIncrease stickinessImprove cohesionArtificial thread manufacturing machinesArtificial filament washing/dryingPolymer scienceGas phase

The invention discloses a method for preparing an ultra-high molecular weight polyethylene fiber. According to the method, an ultra-high molecular weight polyethylene decahydronaphthalene solution is extruded through a spinneret plate to form a spinning trickle flow; the spinning trickle flow sequentially passes through a gas-phase section, a liquid-phase section, a physical extrusion section, a drying heat tank section and the like to obtain raw filaments; meanwhile, thin spinning filaments exiting from the liquid-phase section have stretching stress, and the raw filaments are subjected to high-power thermal stretching to obtain the ultra-high molecular weight polyethylene fiber of which the single-filament fineness is lower than 0.3dtex. The breaking strength of fiber bundle filaments is not lower than 40cN.dtex<-1>, and the modulus is not lower than 2,000cN.dtex<-1>. The method has the characteristics that the production energy consumption is reduced; the energy is saved, the emission amount is reduced, and the production cost is low. The prepared ultra-high molecular weight polyethylene fiber has excellent quality and is used for preparing public safety protection articles, labor safety products and medical materials such as bulletproof and stab-resistant clothes, explosion-proof blankets, explosion-proof tanks, anti-puncturing shoes, anti-puncturing shoe soles and operation suture lines.

Owner:CHINESE TEXTILE ACAD

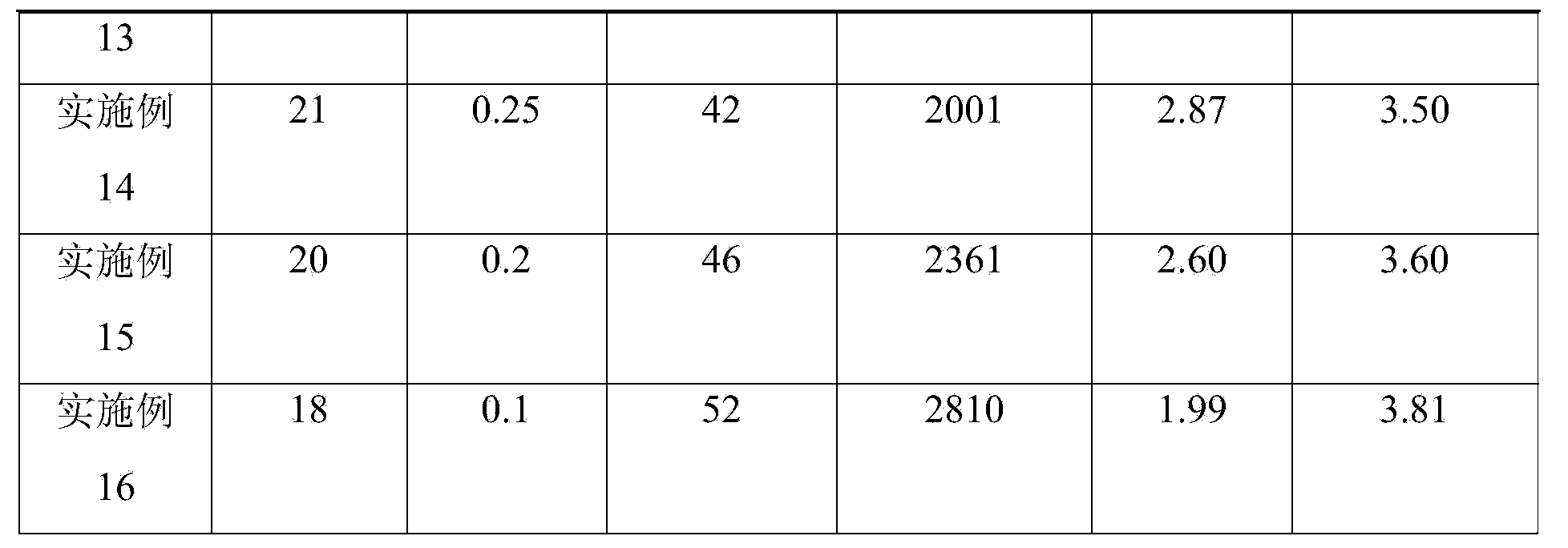

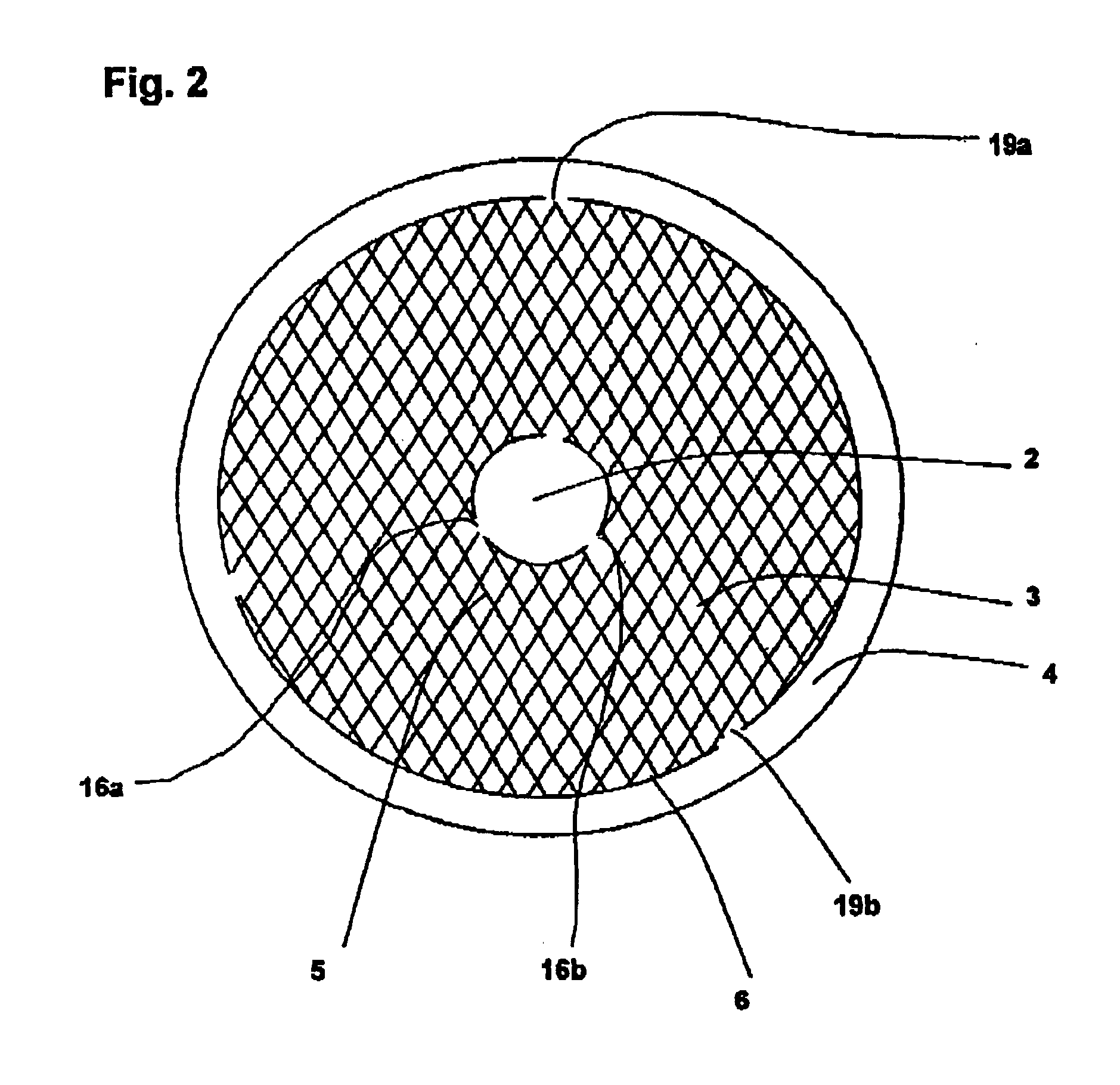

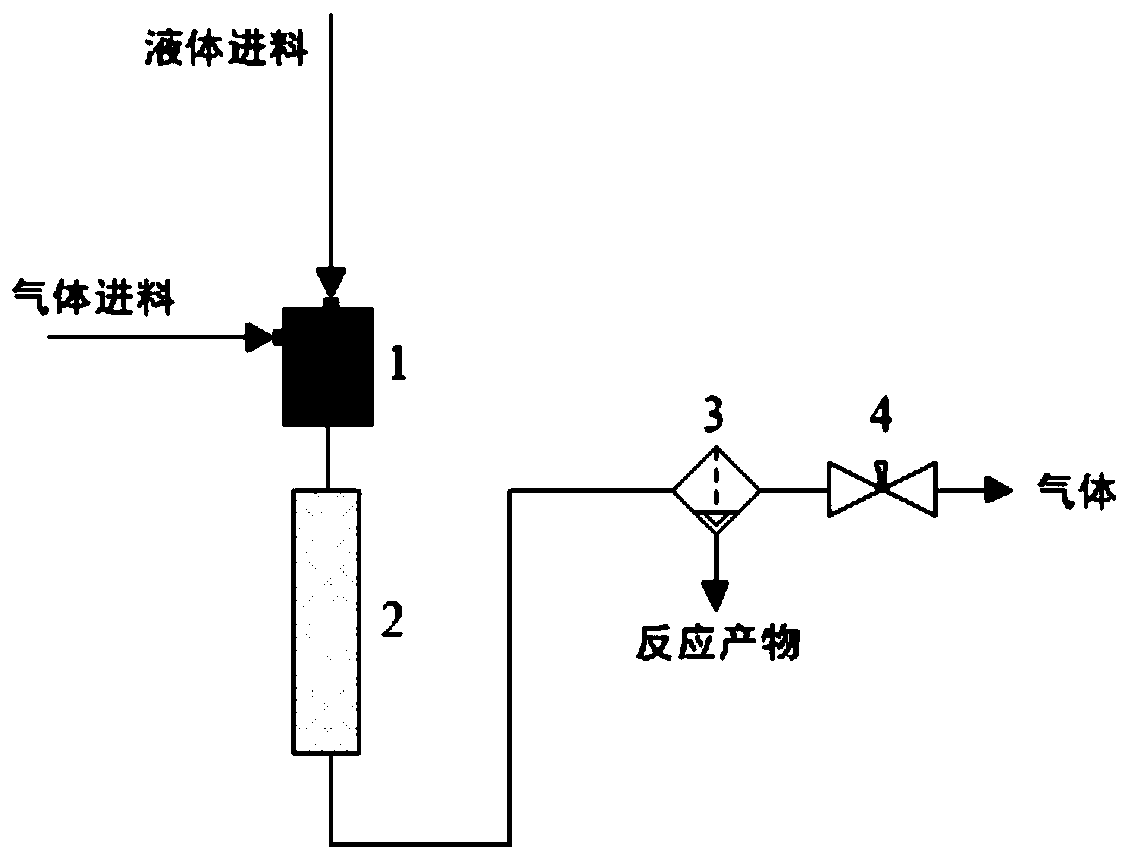

Preparation of hydrogen peroxide from hydrogen and oxygen

InactiveUS6872377B2Reduce pressureIncrease pointsHydrogen peroxideCatalyst activation/preparationHydrogenAlcohol

In a process for preparing an aqueous and / or alcoholic solution of hydrogen peroxide by reaction of hydrogen and oxygen in a trickle-bed reactor over a supported catalyst including a noble metal, the apparent flow direction of the gas stream and the apparent flow direction of the liquid stream are not parallel to one another. The apparent flow direction of the gas stream preferably runs radially from the longitudinal axis to the circumference of the reactor. The process allows high gas throughputs with a small pressure drop.

Owner:BASF AG

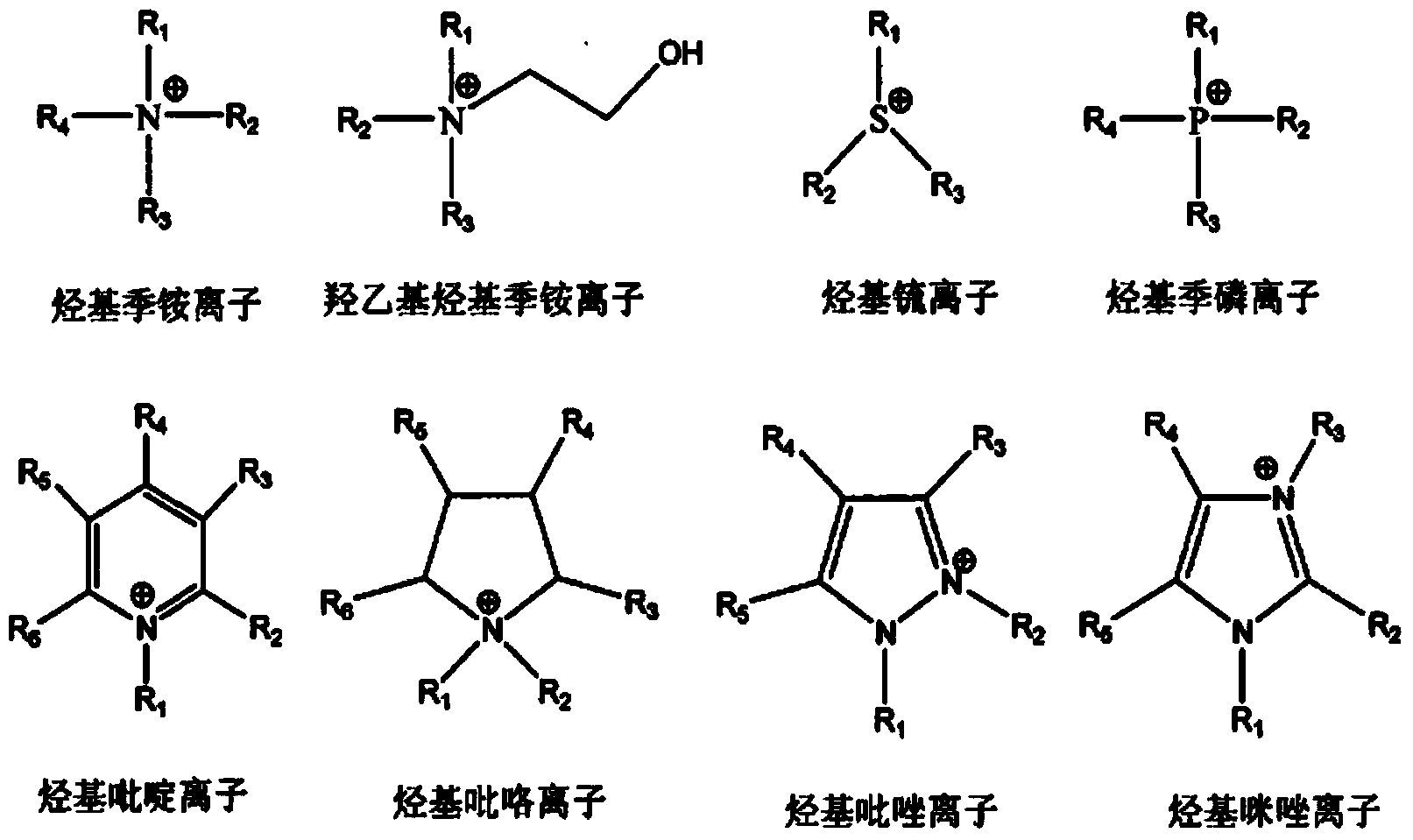

Preparation method of polyacrylonitrile fibres by using protein as modifier

InactiveCN103397400AImprove protectionGood for healthArtificial thread manufacturing machinesArtificial filament washing/dryingTrickle flowHeat setting

The invention relates to a preparation method of polyacrylonitrile fibres by using protein as a modifier. The preparation method comprises the following steps of (1) dissolving protein and polyacrylonitrile in an ionic liquid, and preparing a homogeneous-phase mixed spinning solution; (2) defoaming, filtering and measuring the spinning solution, and then extruding via a spinning jet to form a spinning trickle flow, and passing the spinning trickle flow through a humid air layer and then entering into a coagulating bath, and performing coagulating forming; and (3) performing pre-drawing, drawing, water-washing, drying and heat-setting, and then performing spinning forming, so as to prepare protein-modified polyacrylonitrile filaments or short fibres.

Owner:SUZHOU LONGJIE SPECIAL FIBER

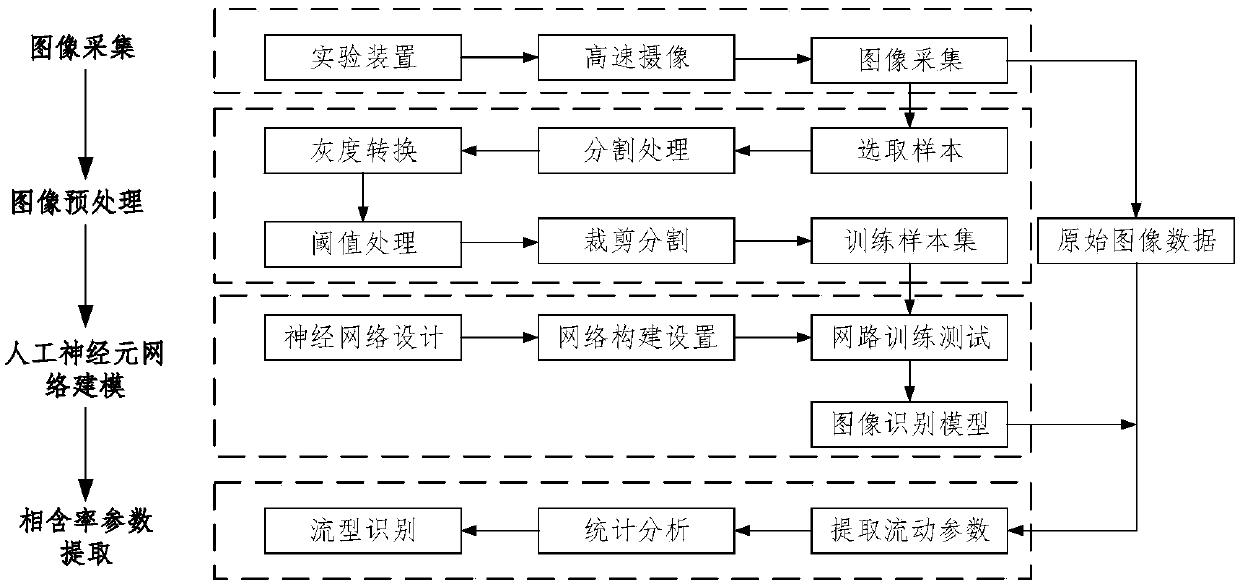

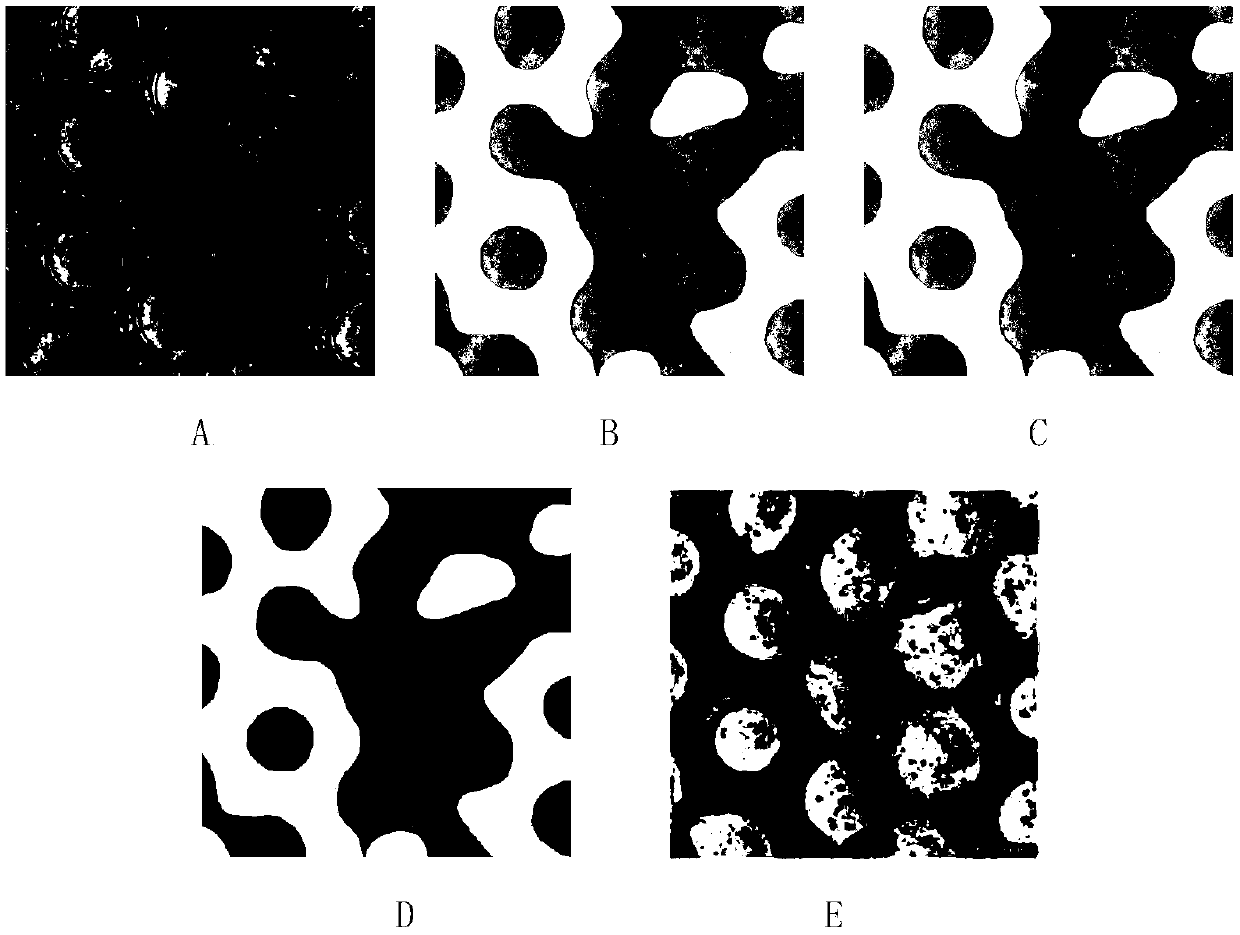

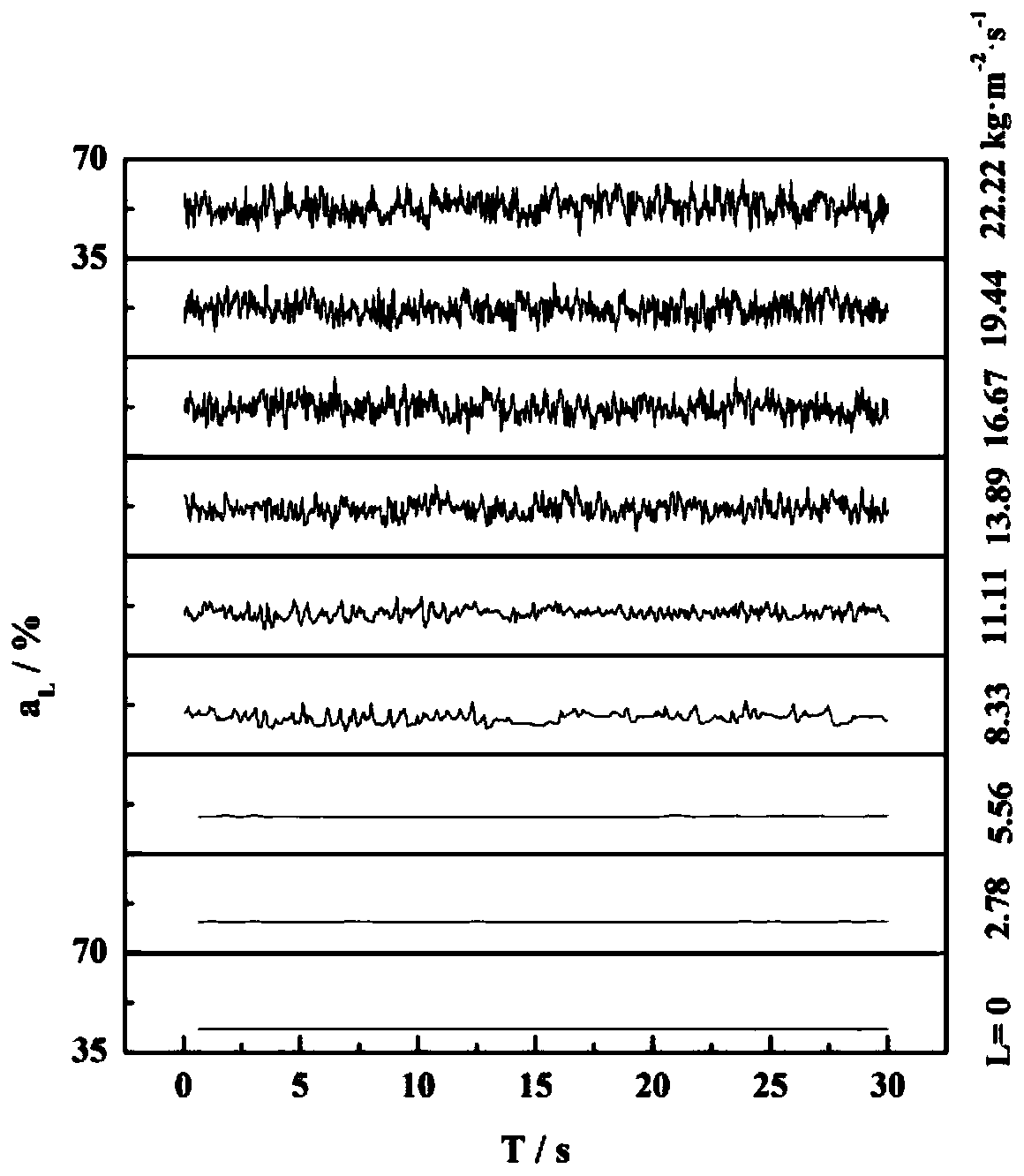

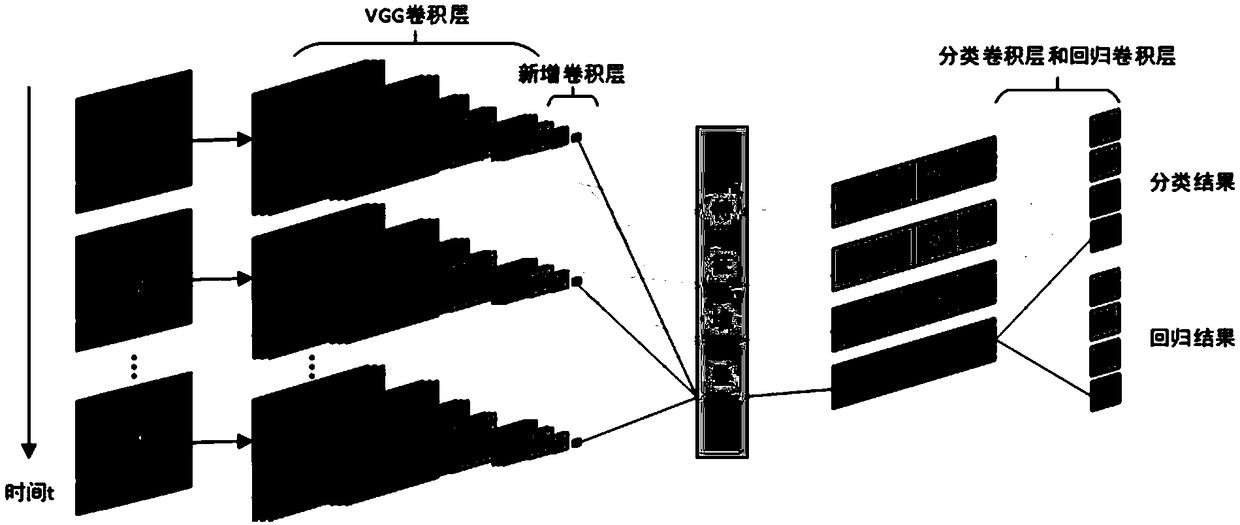

An image measurement method for flow parameters in a gas-liquid-solid three-phase system

ActiveCN109685117AAccurate identificationWith quantitative analysisCharacter and pattern recognitionNeural architecturesStatistical analysisGas phase

The invention discloses an image measurement method for flow parameters in a gas-liquid-solid three-phase system, comprising the steps of image acquisition, image preprocessing, artificial neural network modeling, phase volume fraction parameter extraction and the like, and the flow parameters such as gas phase area, liquid phase area, liquid phase fraction, gas phase fraction and the like can beobtained through the method. Furthermore, the image measurement method processes images at different moments under the same experiment condition to obtain data of the flow parameters changing along with time; Typical flow patterns such as trickle flow, pulse flow and bubbling flow can be identified through statistical analysis. The method can overcome the defects of the existing image recognitiontechnology, breaks through the limitation of extracting quantitative gas-liquid flow parameters by images, and further improves the recognition accuracy of the gas-liquid flow pattern.

Owner:ZHEJIANG UNIV

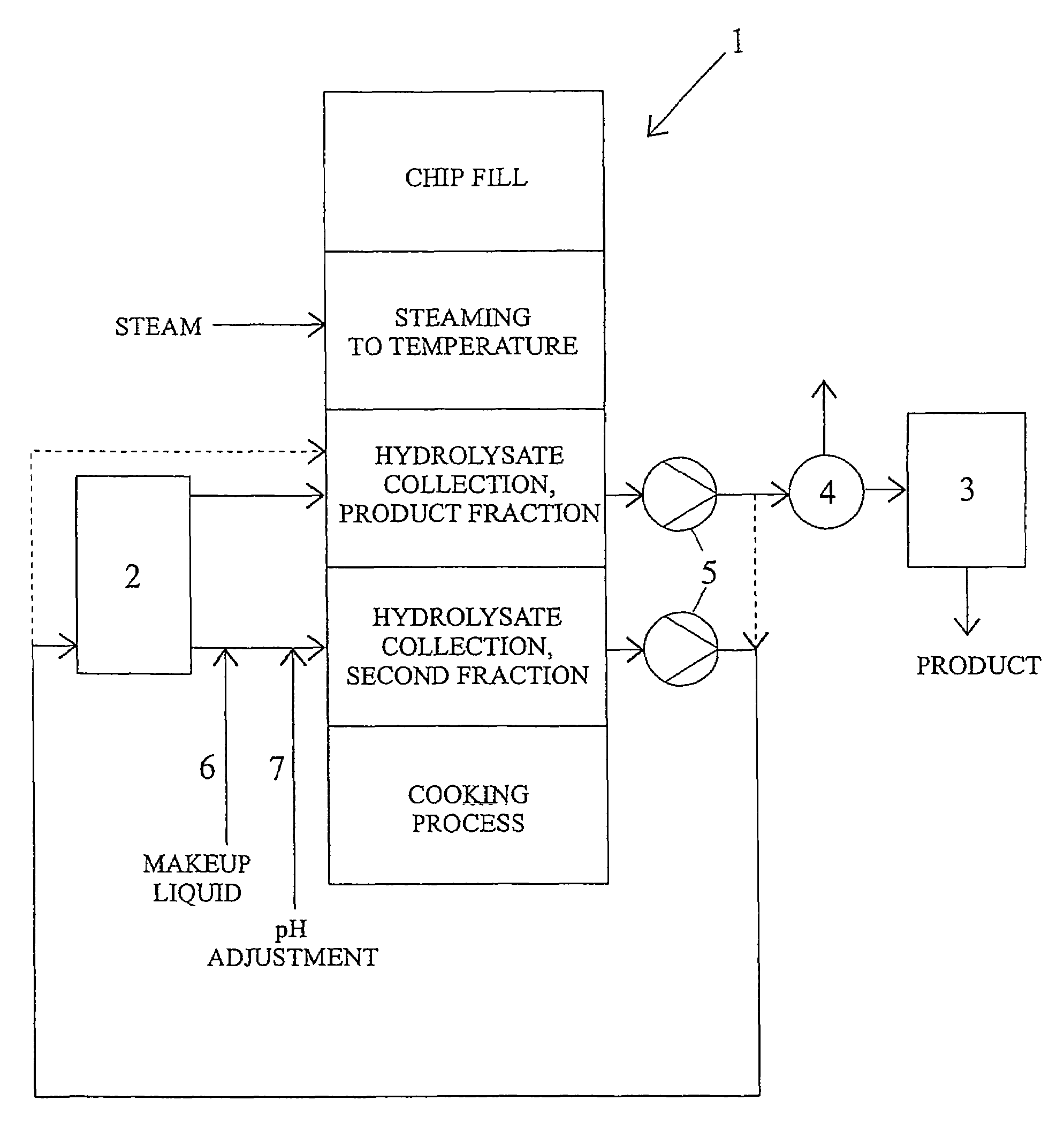

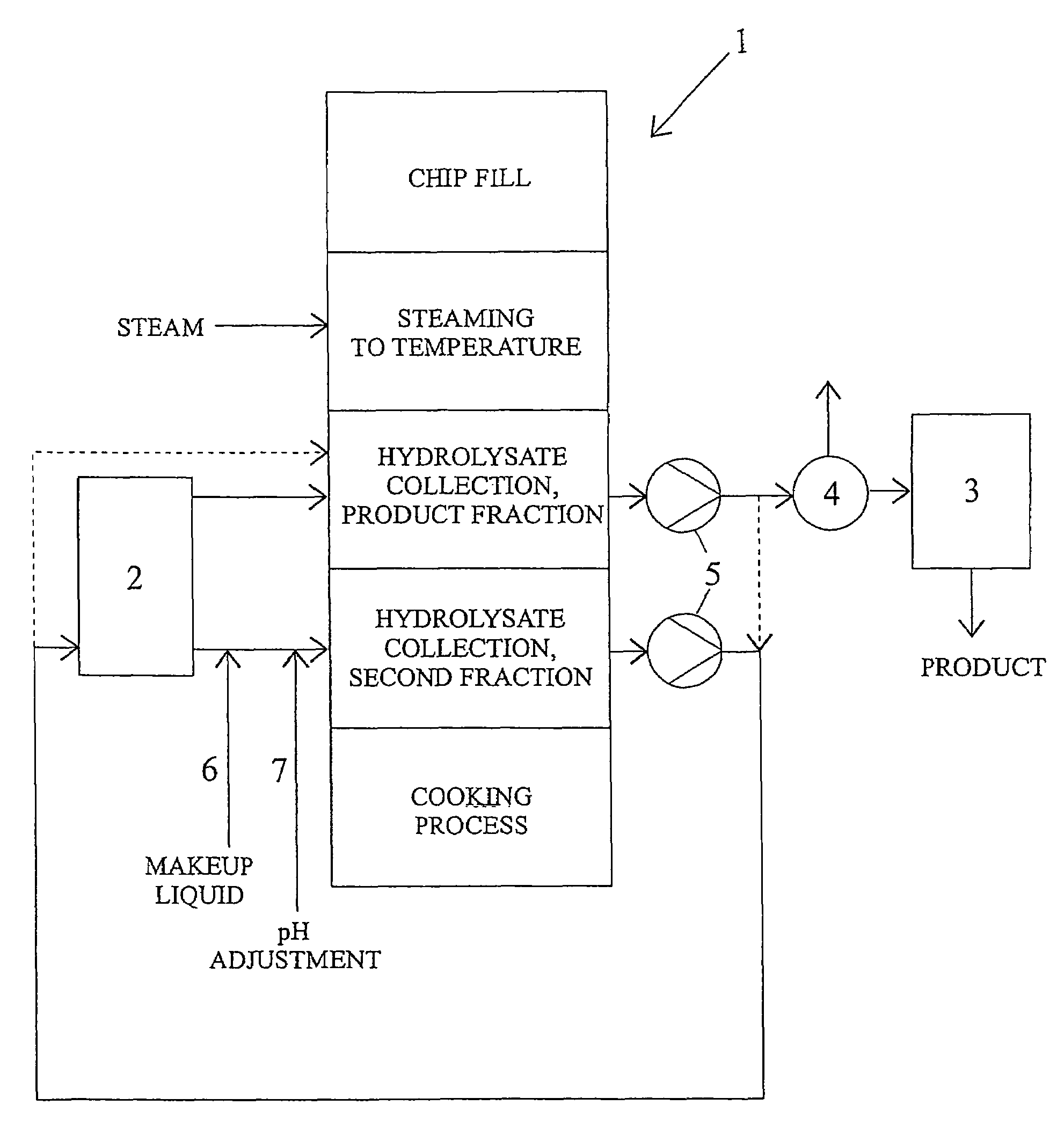

Method for recovering hydrolysis products

InactiveUS8262854B2Improve concentrationSave energyPretreatment with water/steamWashing/displacing pulp-treating liquorsCelluloseHydrolysate

An improved method for treating lignocellulosic material, including a prehydrolysis-mass transfer process, which produces a concentrated hydrolysate volume during the time required for the hydrolysis itself. The improved process comprises the heating of the digester and chip content by direct steam to the required hydrolysis temperature, starting a flow of hot, stored hydrolysate to the top of the chip bed in order to create a trickle-bed type down-flow of hydrolysate, collecting a first fraction of the trickled-down hydrolysate as a product fraction, adding extraction liquid and continuing the trickle flow to collect a second hydrolysate fraction, which will be discharged from the digester to a hot hydrolysate storage tank to be used as the first trickle flow liquid in the next batch.

Owner:VALMET TECH INC

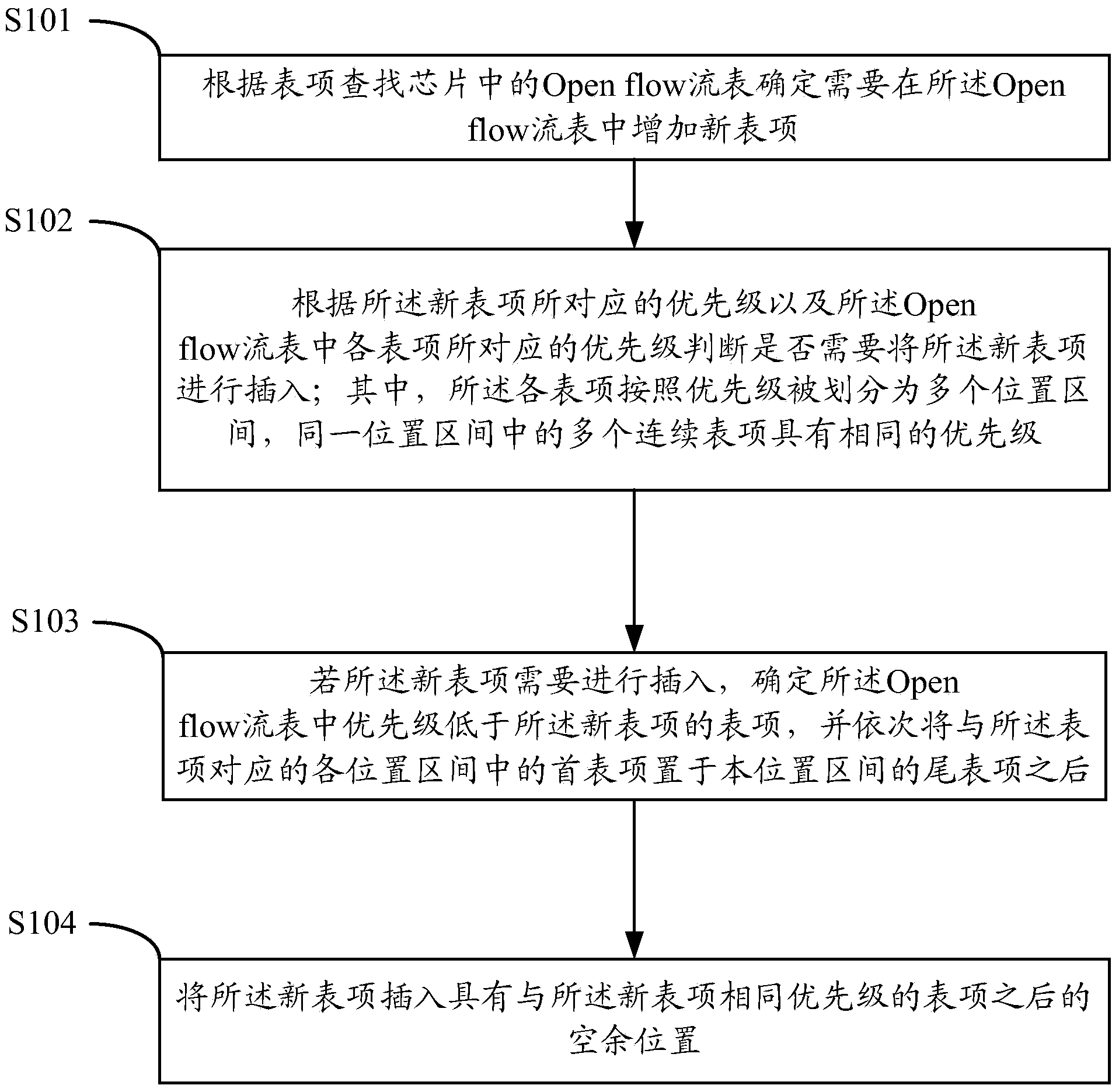

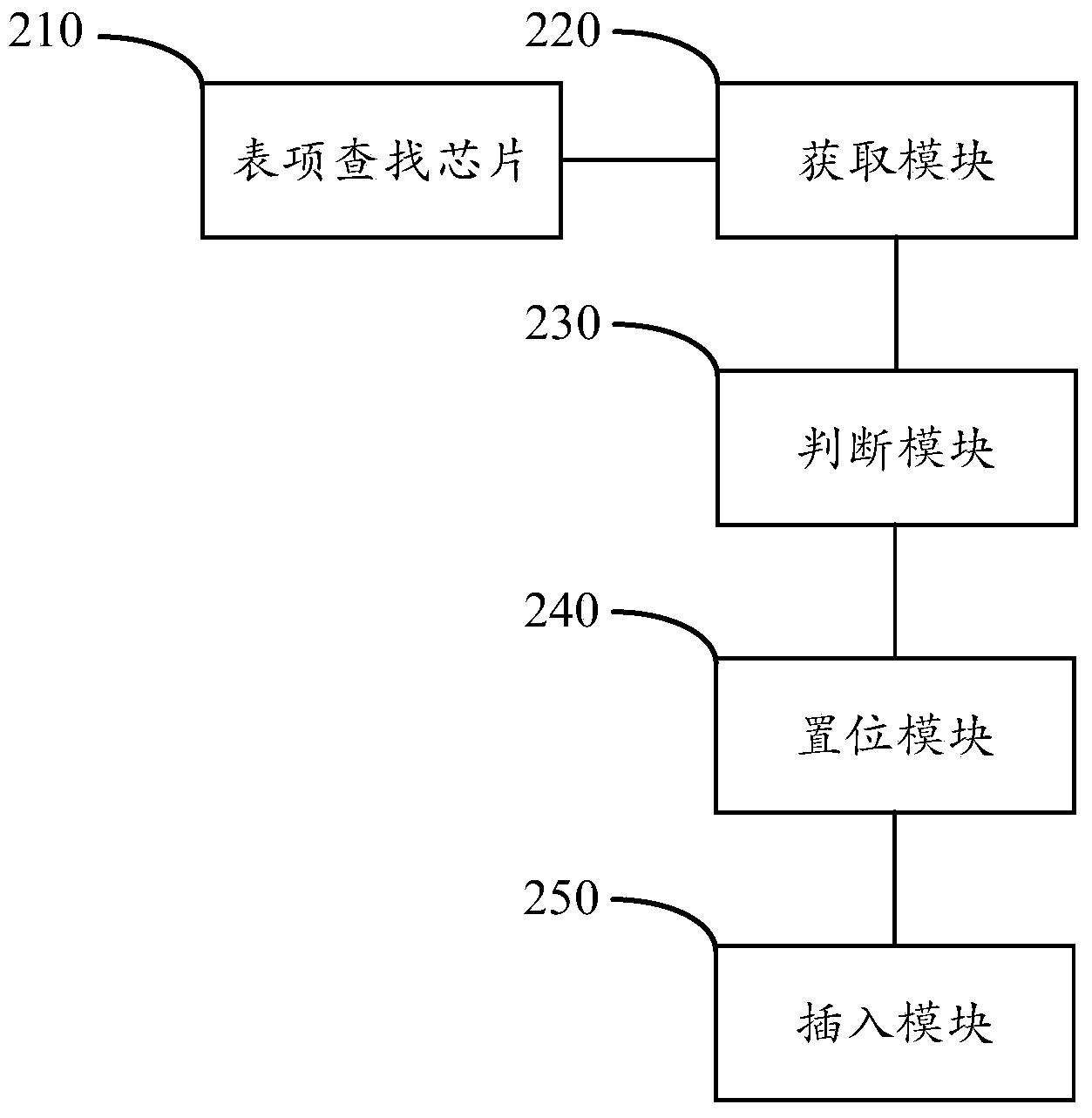

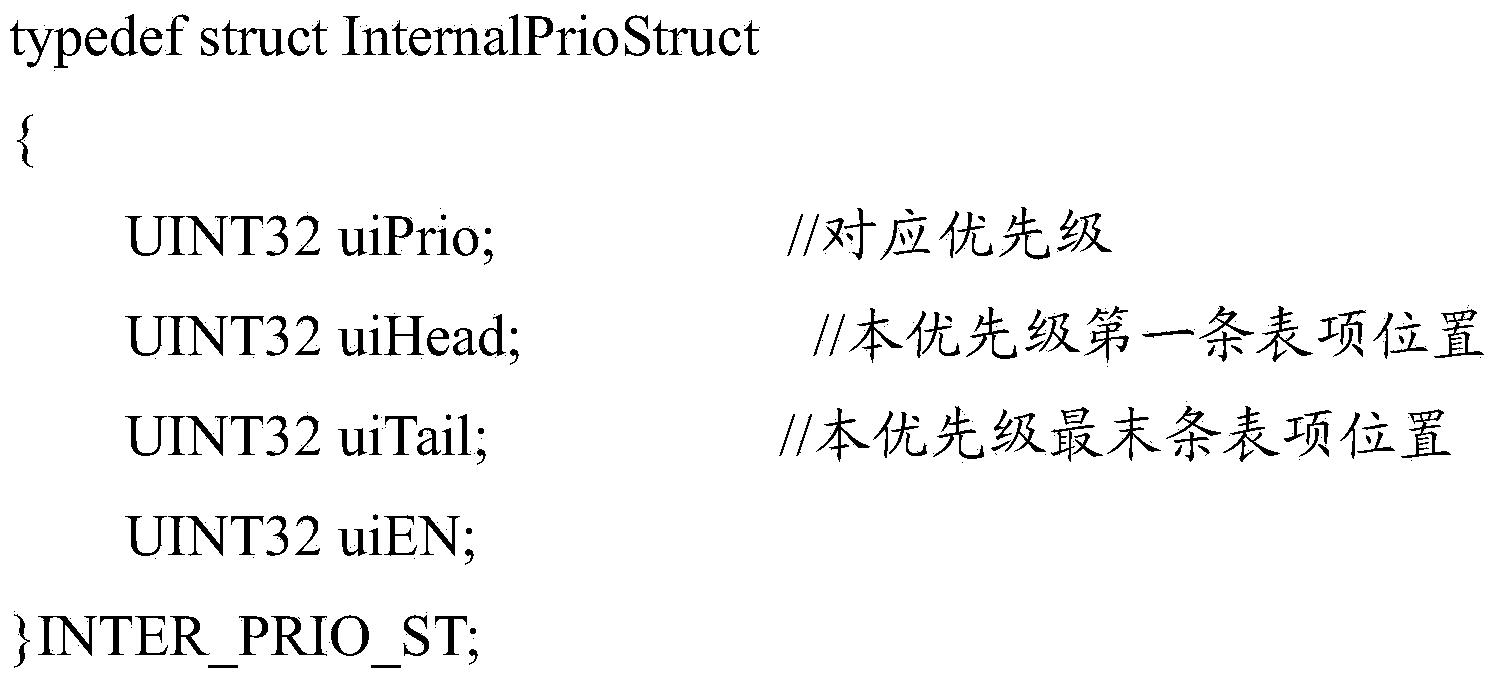

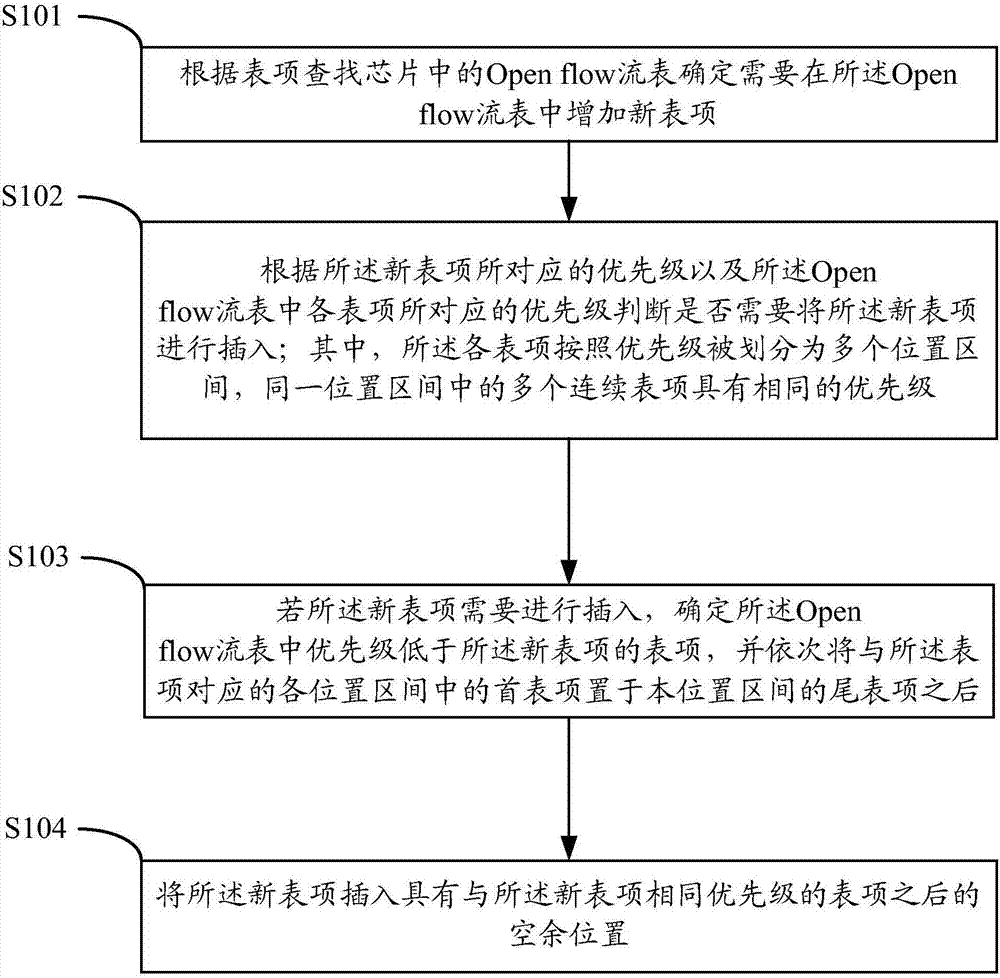

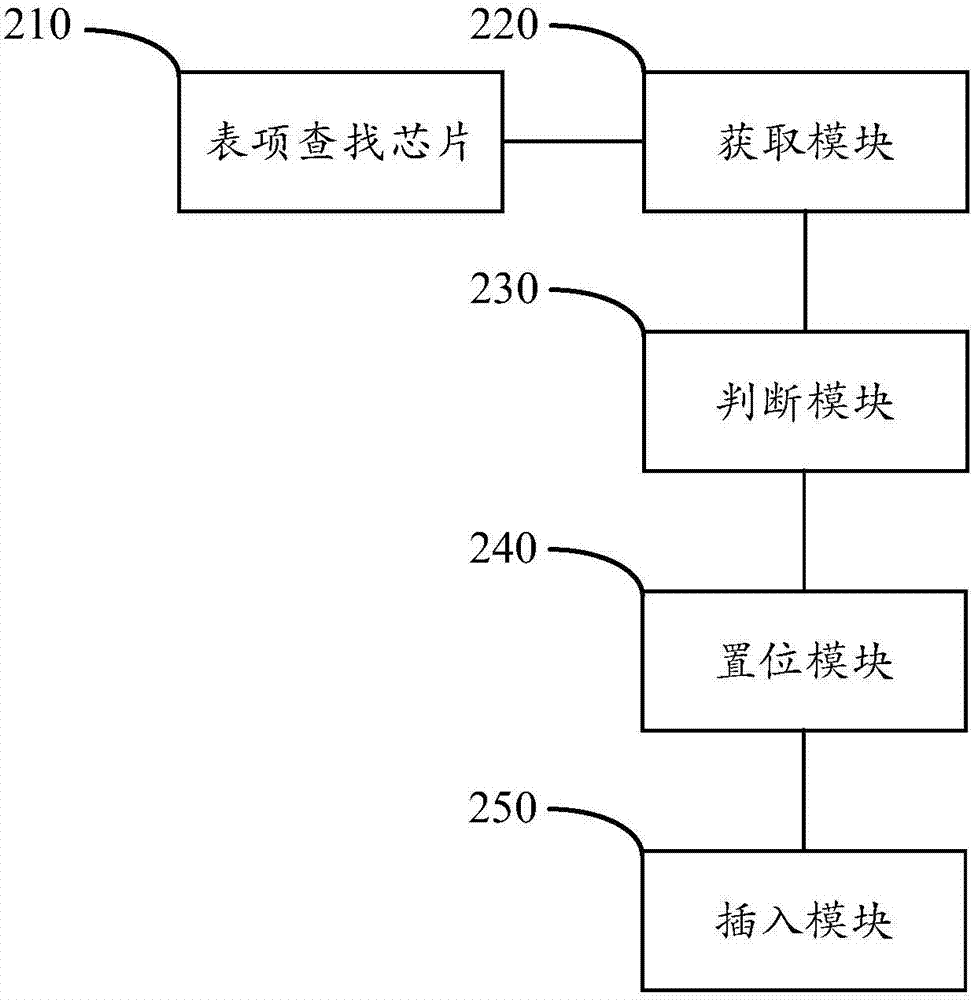

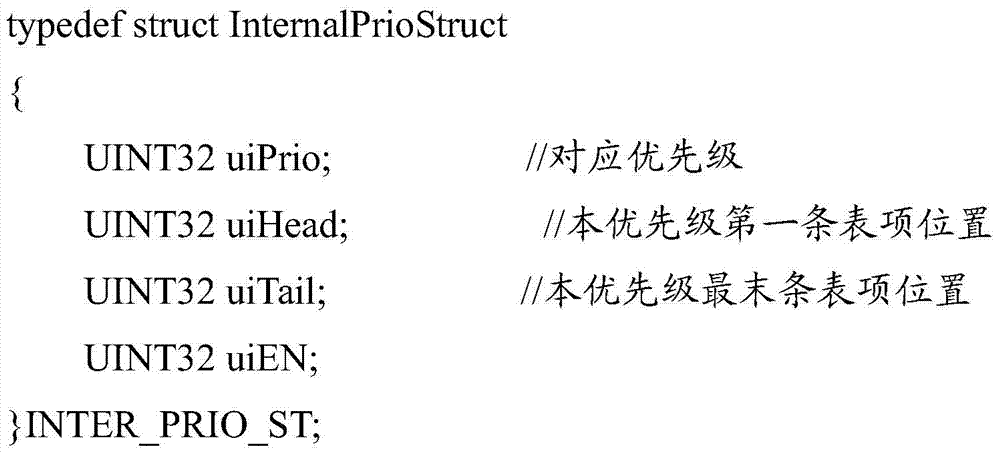

Open flow flow table refreshing method and router device

ActiveCN104038423AImprove update efficiencyGuaranteed processing accuracyData switching networksProgramming languageTrickle flow

The invention discloses an open flow flow table refreshing method. Table items in a table item lookup chip are divided into a plurality of position intervals according to priorities to enable the priorities of the plurality of continuous table items in the same position interval to be equal to each other, the table items of which the priorities are lower than the priority of a new table item in an open flow flow table are determined when whether the new table item needs to be inserted or not is determined and a first table item is placed behind an end table item in every position interval corresponding to the table items in turn, and accordingly the new table item can be inserted into the unoccupied position behind the table items of which the priority is equal to that of the new table item. Accordingly, the updating efficiency of the open flow flow table in the table item lookup chip is effectively improved under the condition that the processing accuracy is ensured.

Owner:NEW H3C TECH CO LTD

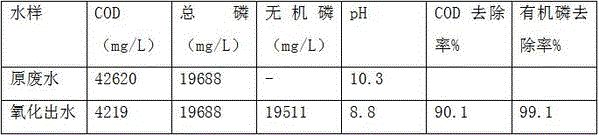

Method for treating waste water generated in glyphosate production process

ActiveCN105948217AHigh removal rateImprove conversion rateWater contaminantsNature of treatment waterPtru catalystGlyphosate

The invention relates to a method for treating waste water generated in a glyphosate production process, and belongs to the technical field of waste water treatment. The method comprises the following steps: preparing a catalyst; and treating the waste water generated in the glyphosate production process in a trickle bed reactor by using the catalyst. Glyphosate waste water is treated by heterogeneous catalysis wet oxidation; and in the method, COD removal rate is high, and organophosphorus conversion rate is also high; the method is environmentally friendly; secondary pollution is avoided; investment and running costs are low; and therefore, the method is suitable for industrial continuous running.

Owner:福华通达化学股份公司

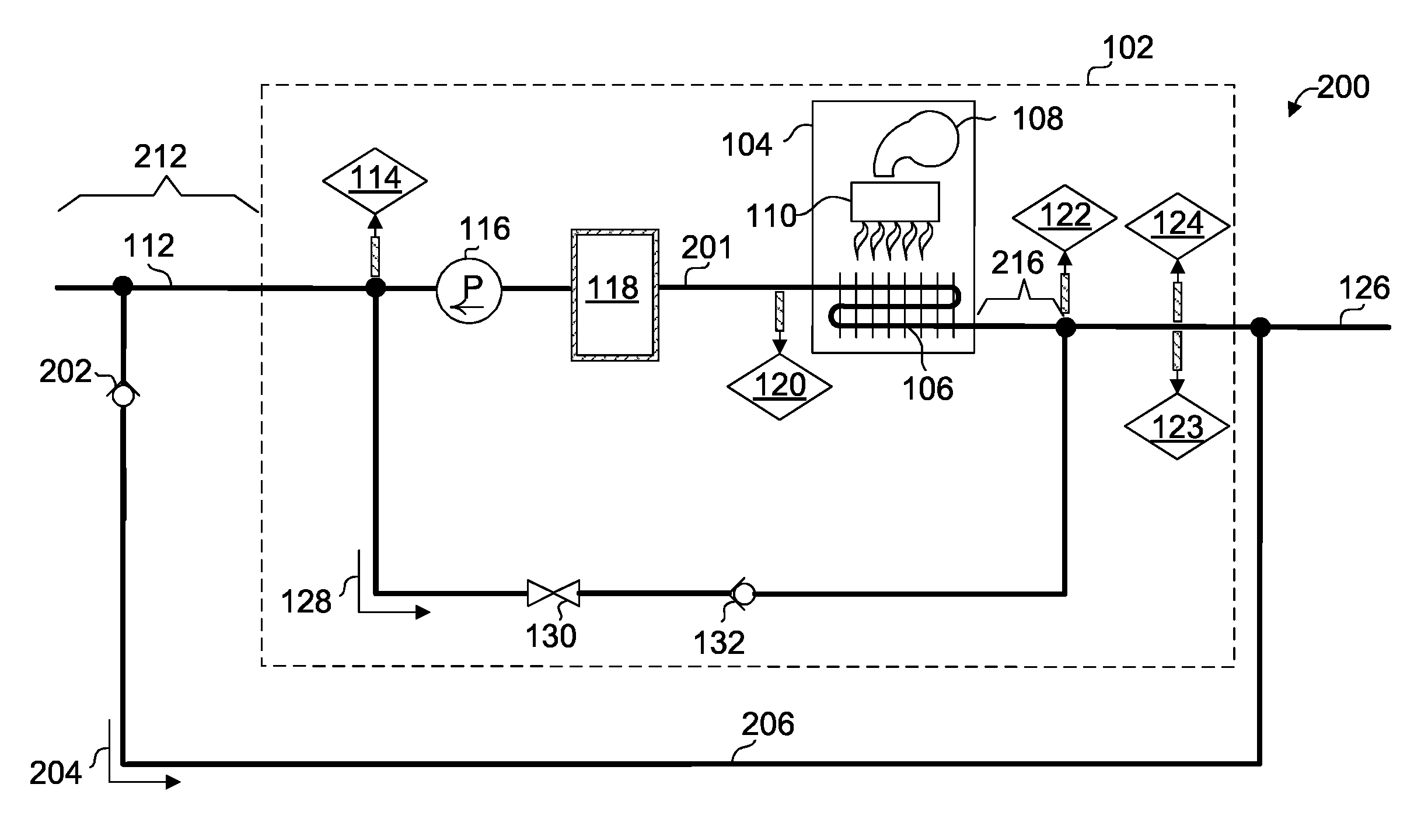

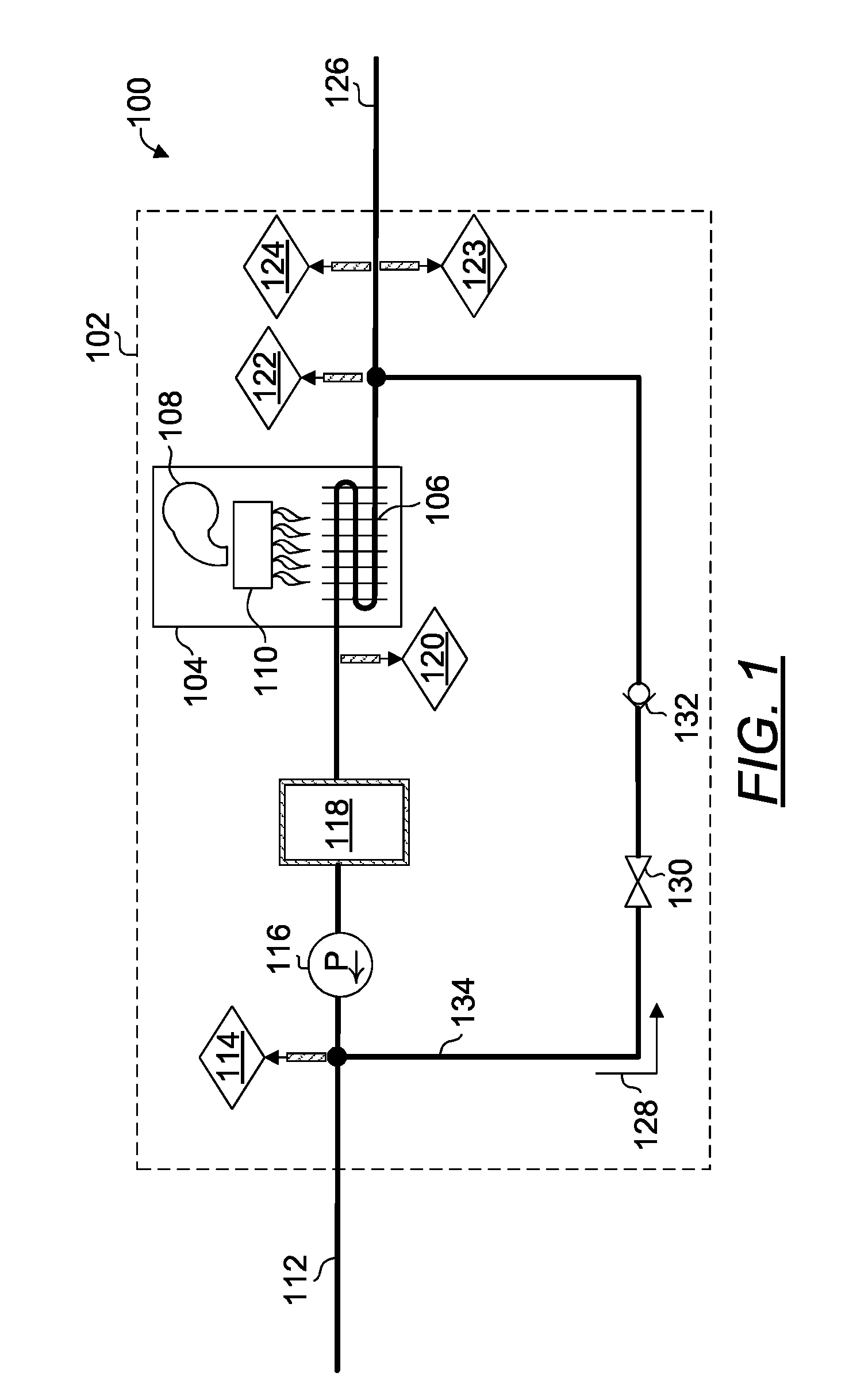

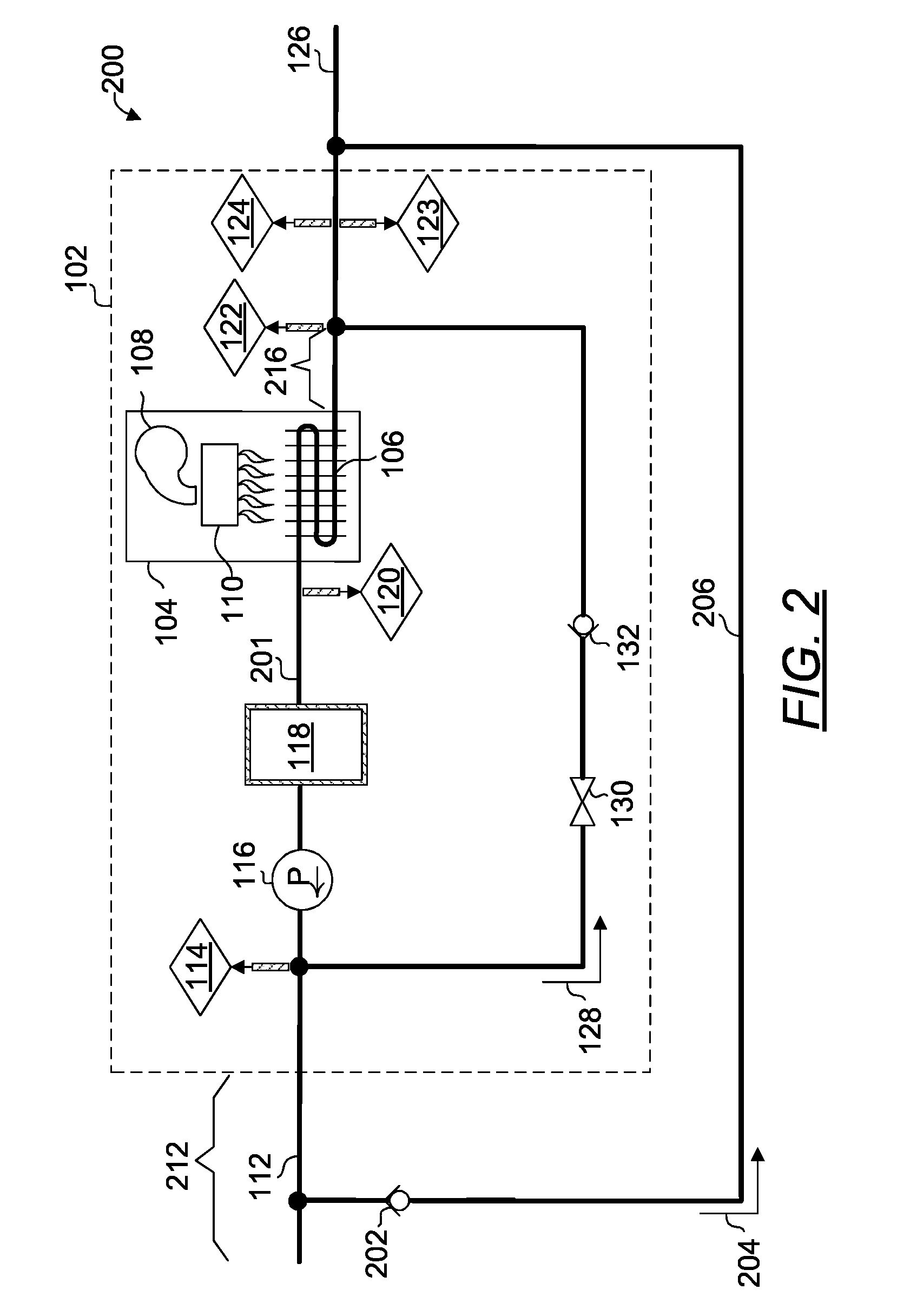

Remote shower actuation and temperature sensing unit

InactiveUS20080060707A1Accurate temperature readingTemperature control without auxillary powerOperating means/releasing devices for valvesSteady state temperatureEngineering

Owner:THORLEY INDS

Process for preparing hydantoin by one-step method

InactiveCN1616435ARealize continuous preparationThe synthesis process is simpleOrganic chemistryCyanideSolid acid

The one-step process of preparing hydantoin is that in a trickle bed reactor hydroxy methyl cyanide, CO2 and ammonia as material and solid acid as stuffing and catalyst are prepared into hydantoin through one-step process. Hydroxy methyl cyanide is made to flow into the trickle bed from the top in the flow rate of 100-300 ml / hr, CO2 and ammonia are made to flow into the trickle bed from the bottom in the flow rate of 0.01-0.1 cu m / hr and 0.005-0.06 cu m / hr separately, and through reaction at 40-120 deg.c for 2-5 hr, the reaction liquid is collected and processed through concentration, crystallization, filtering to obtain initial crystal, recrystallization and drying to obtain hydantoin. The synthesis yield may reach 74.85 %.

Owner:NANJING UNIV OF TECH

Method for preparing 1, 3-butanediol through catalytic hydrogenation

InactiveCN111393259AMild conditionsSolve the separation problemOrganic compound preparationHydroxy compound preparationNickel catalystPtru catalyst

The invention discloses a method for preparing 1, 3-butanediol through catalytic hydrogenation, and belongs to the technical field of catalytic hydrogenation. 3-hydroxybutyraldehyde is taken as a rawmaterial, and catalytic hydrogenation reaction is carried out in a trickle bed reactor in the presence of a supported metal nickel catalyst and an alkaline solvent under the hydrogen atmosphere of 293-3733K and 1.0-8.0MPa. Under optimized conditions, the hydrogenation conversion rate of 3-hydroxybutyraldehyde can reach 86%, and the selectivity of 1, 3-butanediol can reach 88%.

Owner:南京大学淮安高新技术研究院

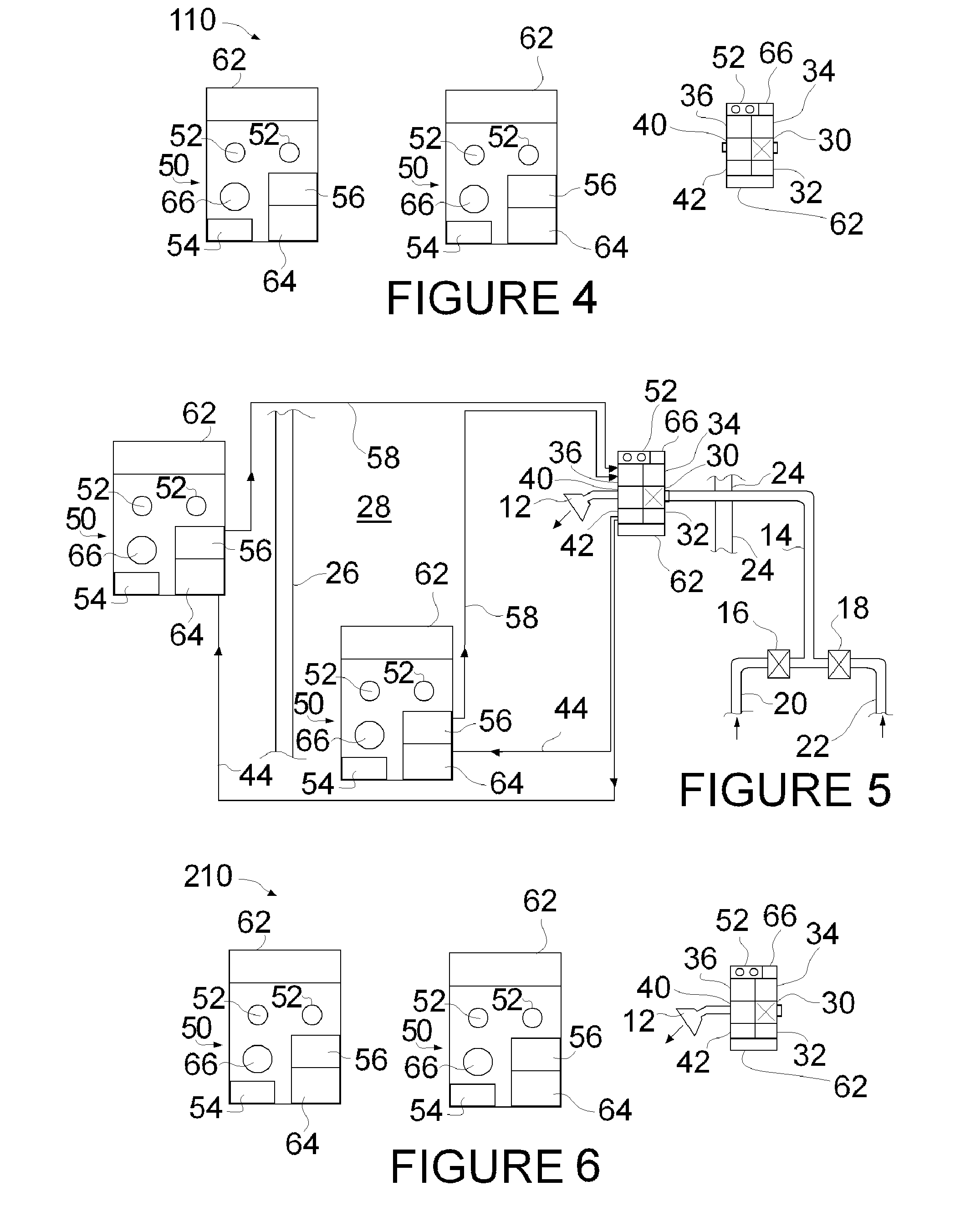

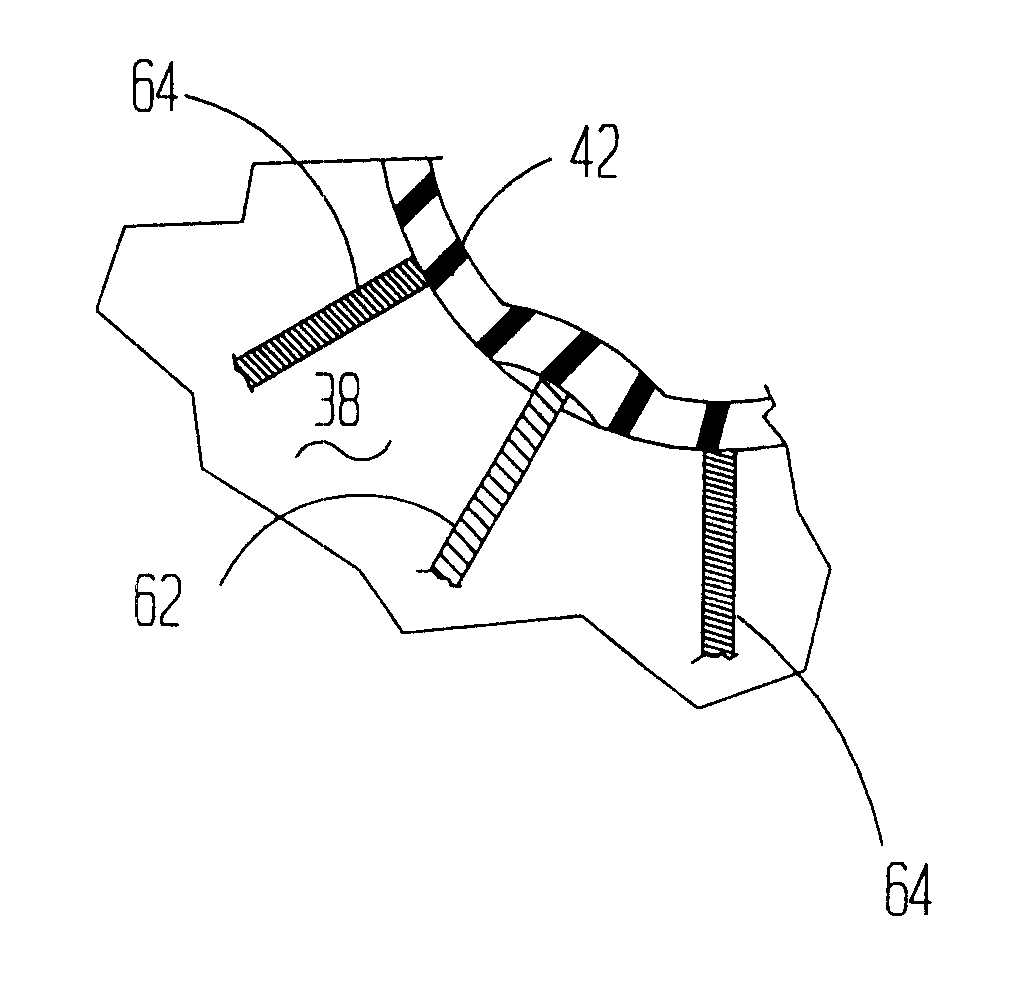

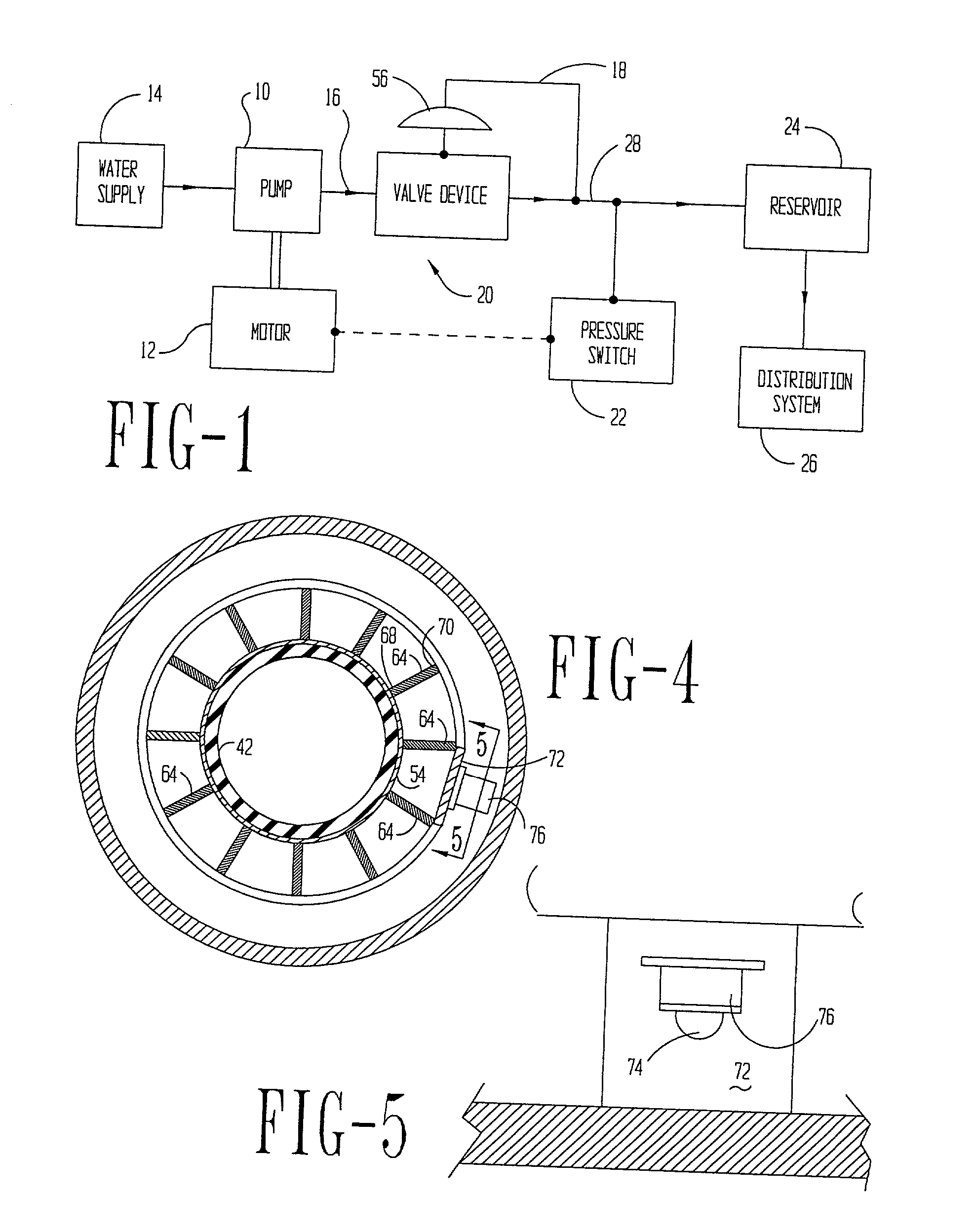

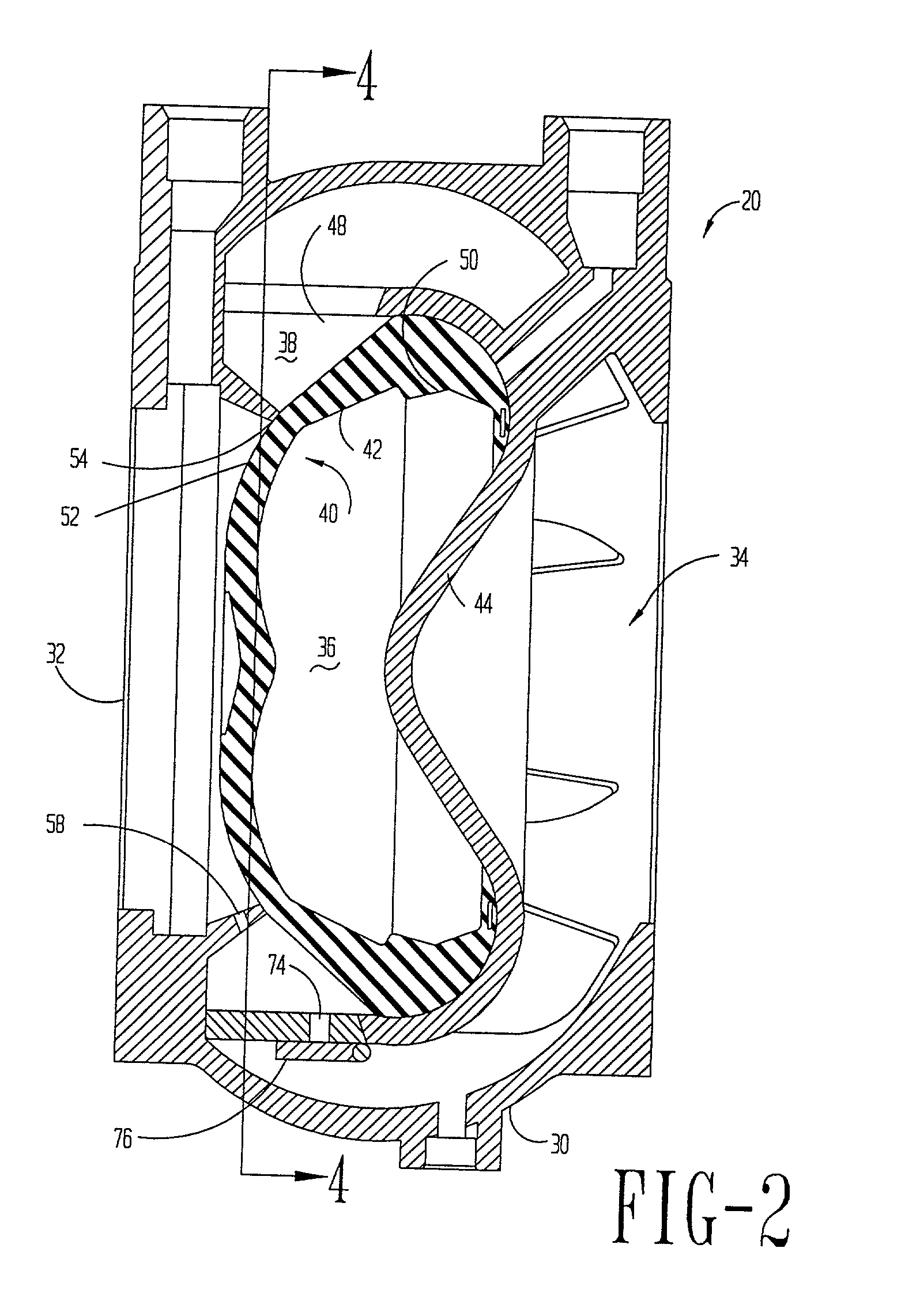

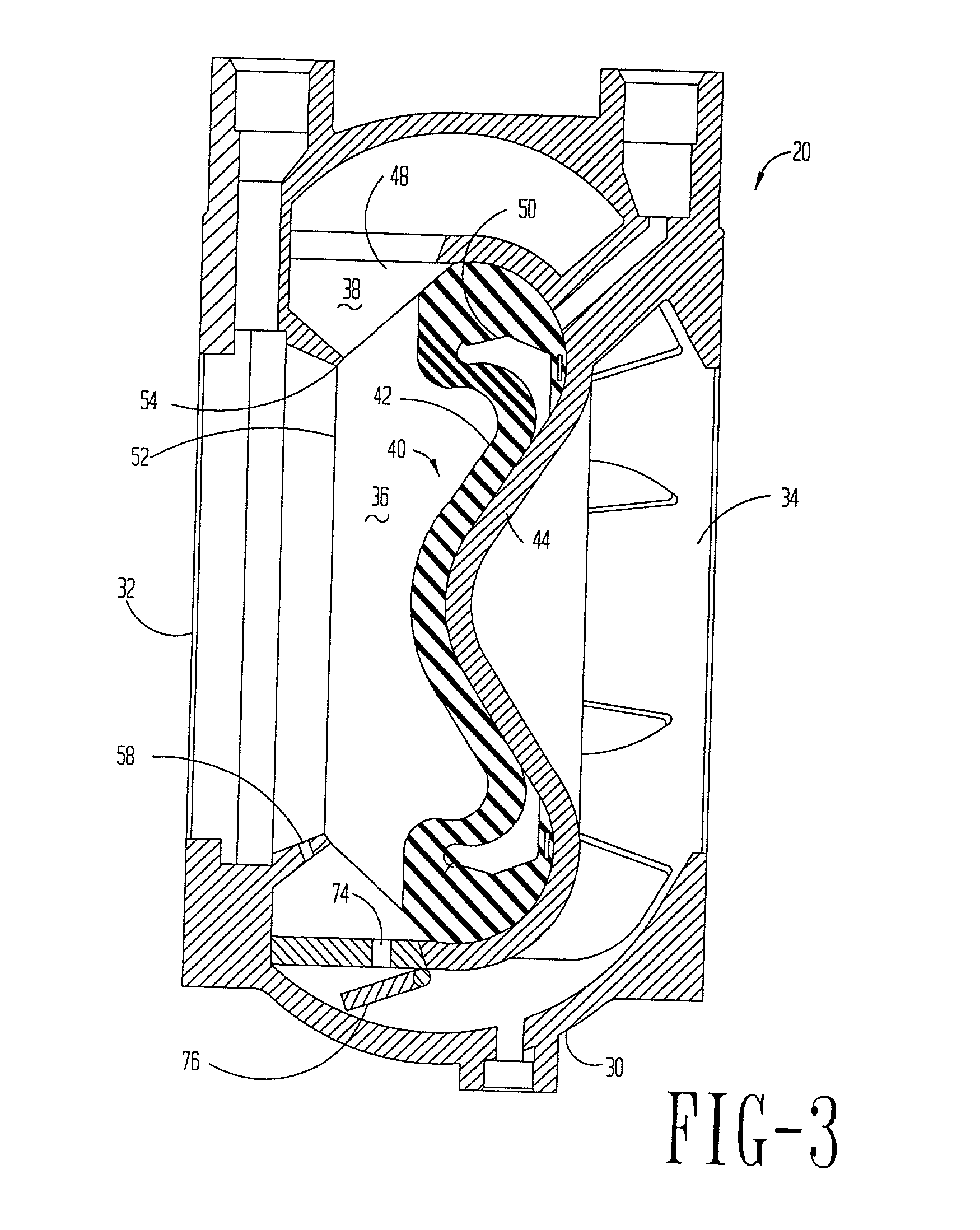

Roll seal control valve

A water system uses a pressure reservoir of an extremely small size. A valve device is placed between a water pump and the pressure reservoir. The valve device has a constant outlet pressure to limit the flow from the pump at high pressures. The pump is turned on and off by a pressure on / off switch. The valve device maintains the pressure to the reservoir at or below the off switch pressure except for a trickle flow. The trickle flow fills the reservoir when there is little or no water usage from the reservoir. The trickle flow is achieved by preventing the surfaces to seal by a projection or notch the valve surfaces of the valve device. Each time the valve opens any debris is washed from the valve surfaces thereby keeping them free of debris.

Owner:AUSTIN CARY M

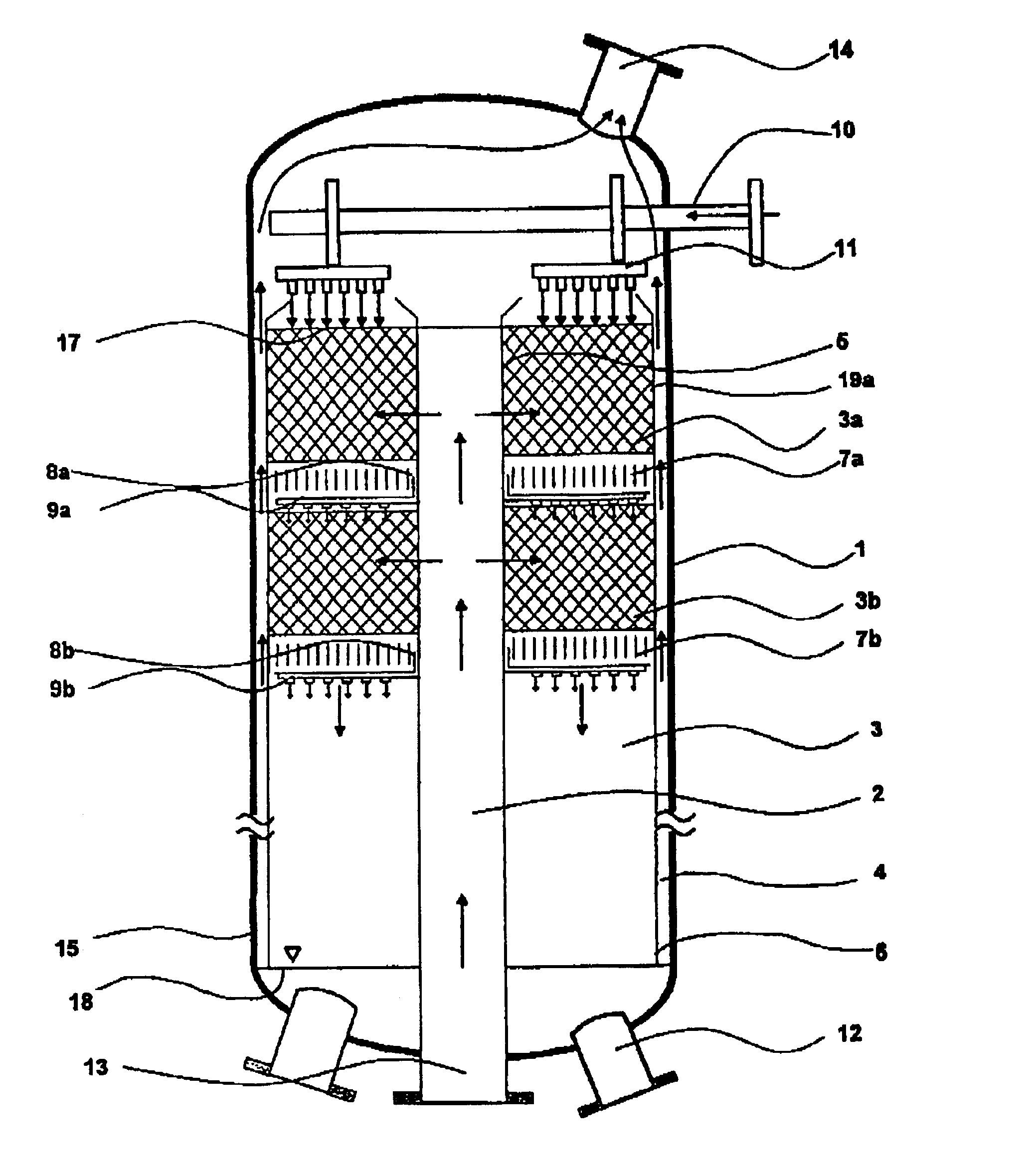

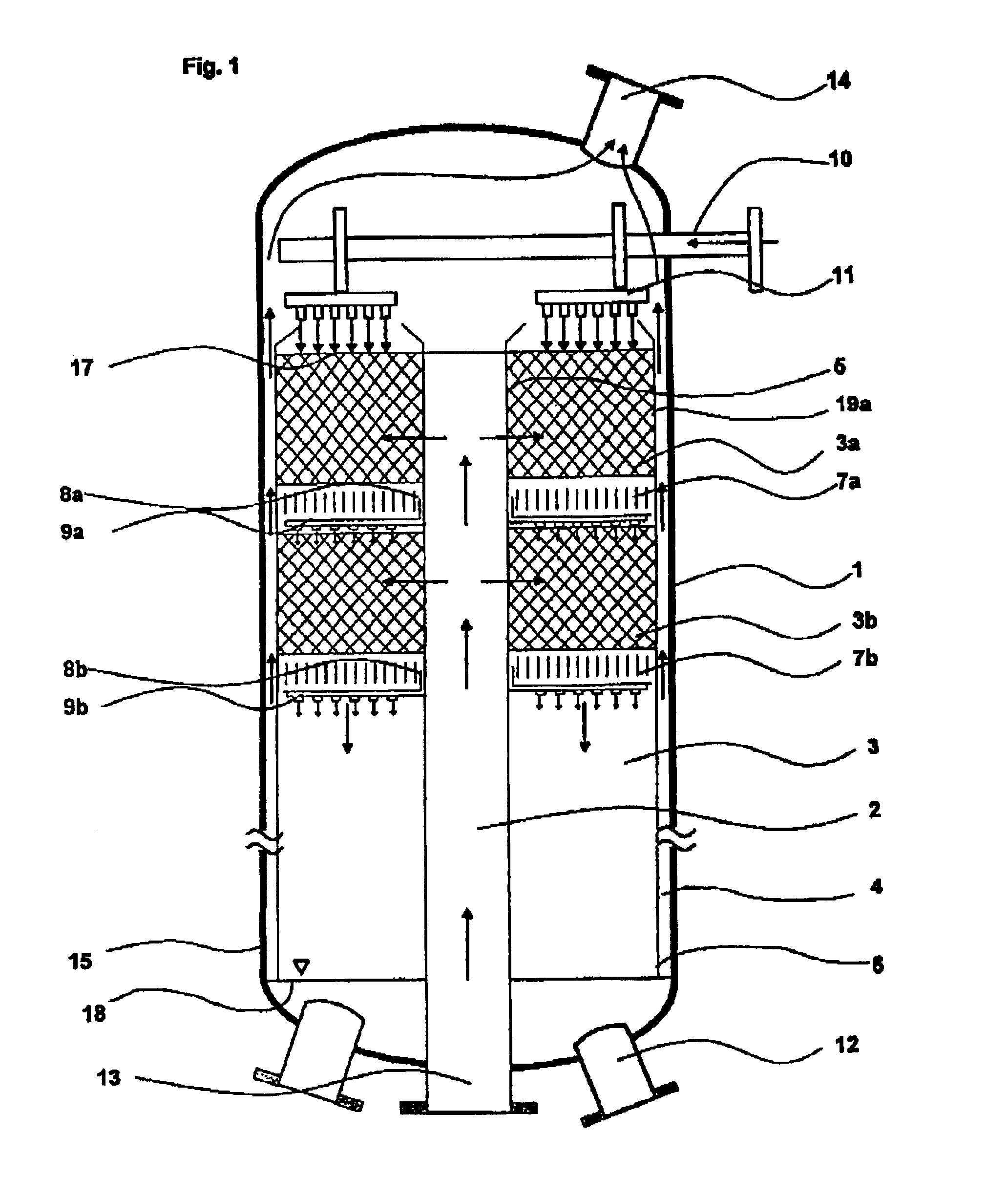

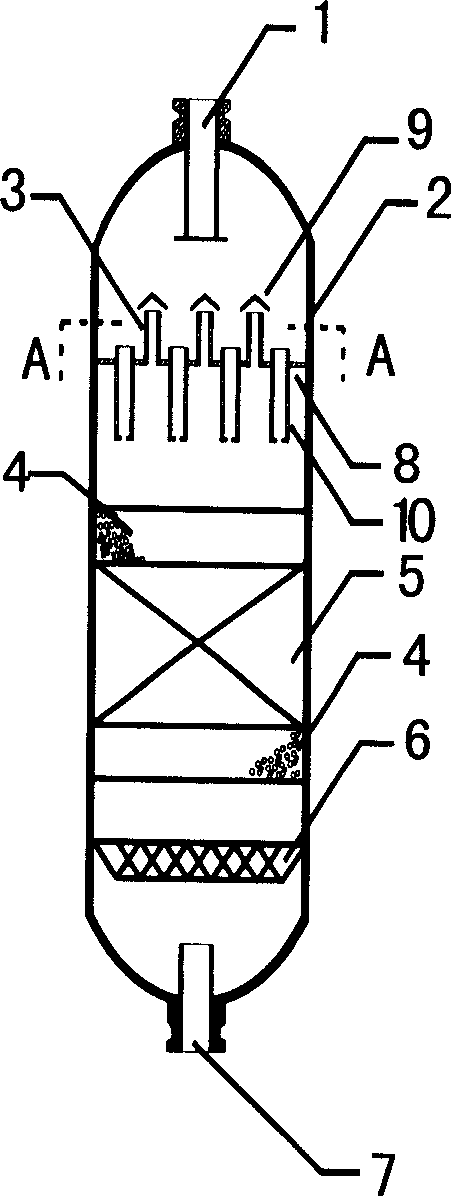

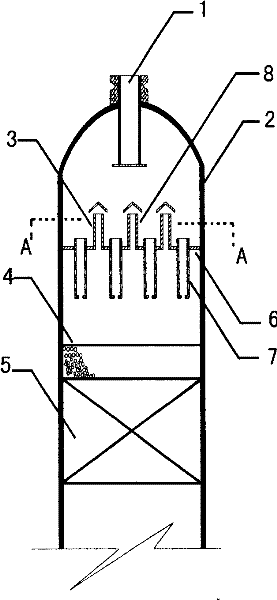

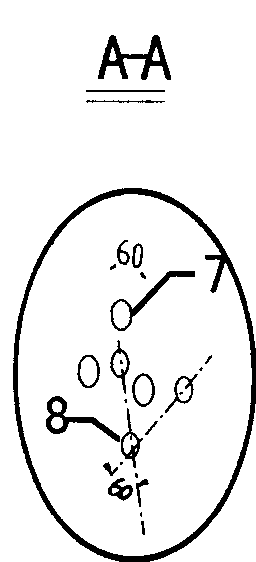

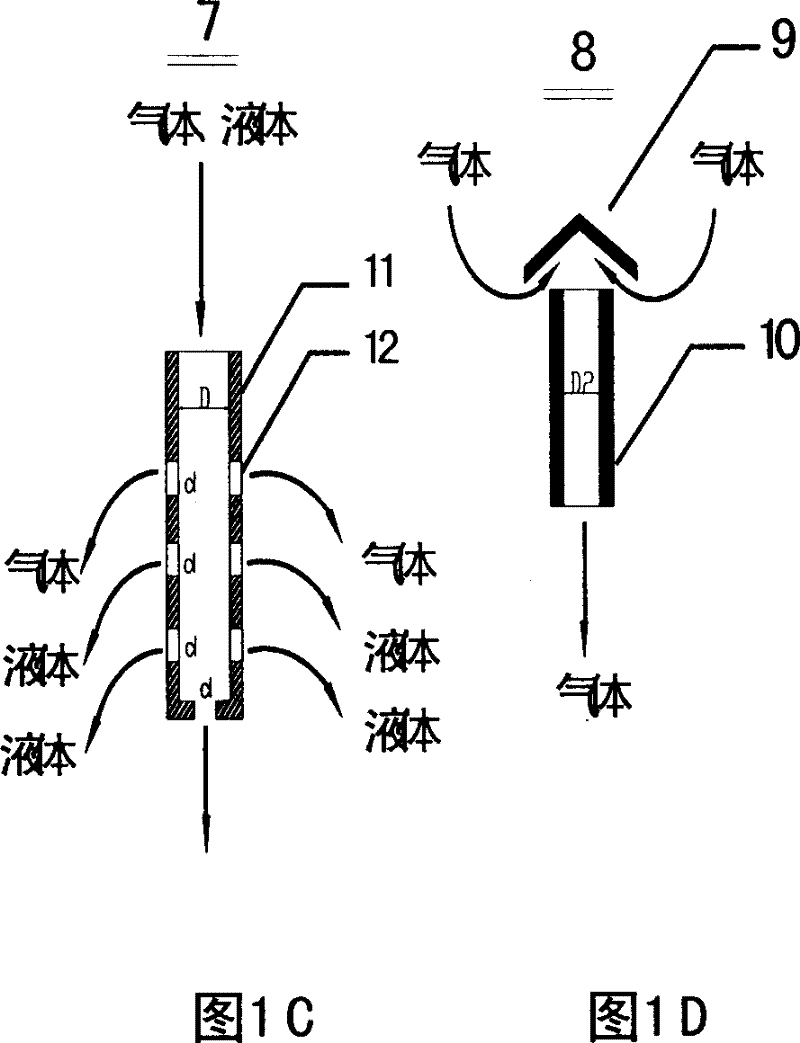

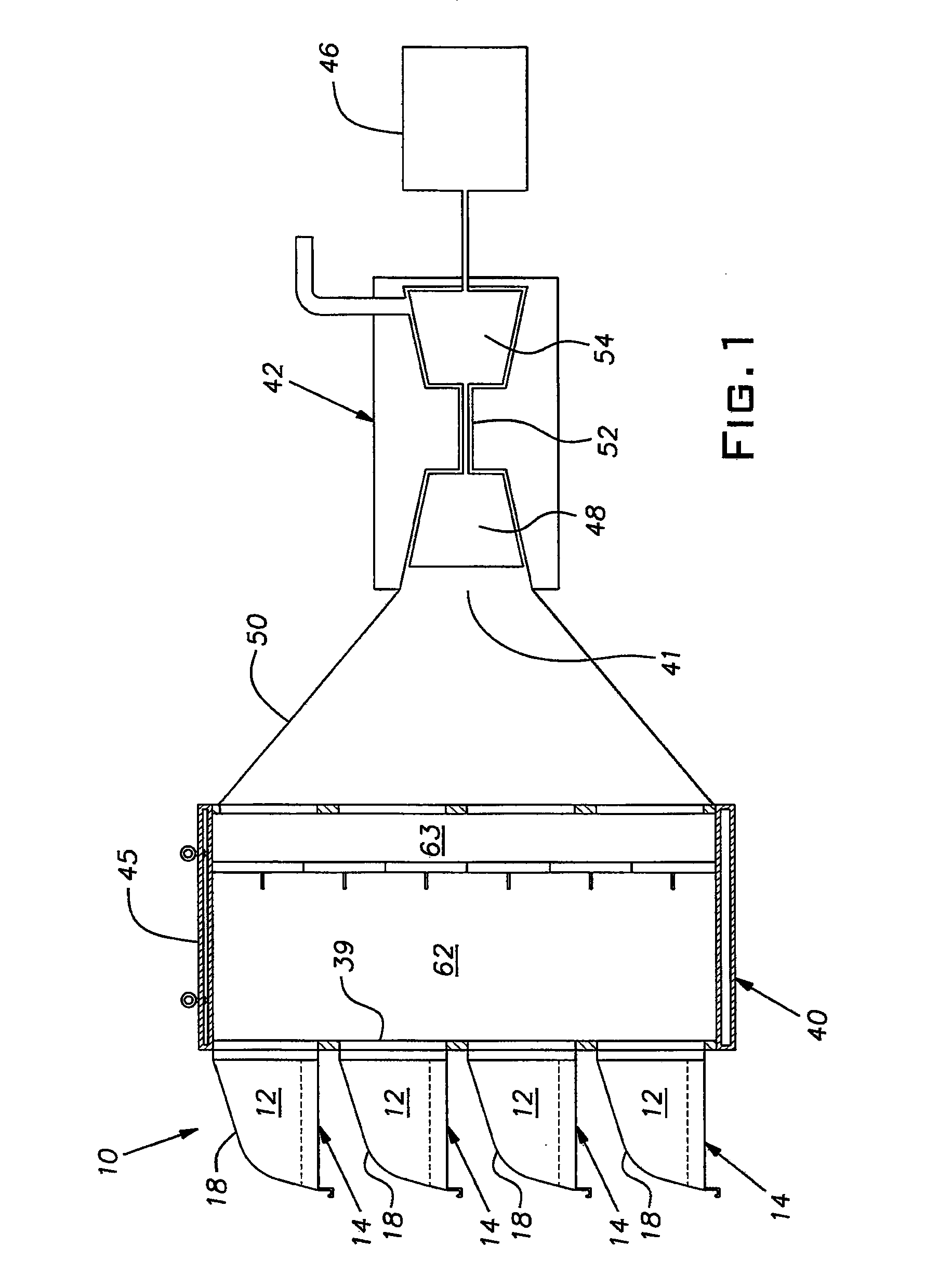

Trickle bed reactor

ActiveCN101279229BImprove gas-liquid distributionImprove reaction efficiencyChemical/physical processesThermodynamicsPtru catalyst

The invention relates to a trickle-bed reactor, which mainly aims at solving the problem that the uneven liquid-gas distribution of the trickle-bed reactor in the prior art results in the bad trickling effect of the reactor and low efficiency of the catalytic reaction. The trickle-bed reactor adopts the technical scheme that the trickle-bed reactor comprises an inlet orifice, a reactor shell, a liquid-gas distributor, a porcelain ball bed layer, a catalyst bed layer and an orifice ring, wherein the liquid-gas distributor is provided with a gas passage pipe and a liquid passage pipe on a distributing plate; the gas passage pipe is composed of a cone roof and a straight nozzle stub; the liquid passage pipe is a vertical nozzle stub with the upper end extending 10 to 100mm out of the upper part of the distributing plate and the lower end extending 200 to 1000mm out of the lower part of the distributing plate; a plurality of pinholes are evenly opened on the cross section at different positions along the axial direction to form the liquid-gas distributor. The technical scheme better solves the problem, greatly improves the reaction efficiency of the trickle-bed reactor and can be applied to various gas liquid and solids three-phase reactors.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

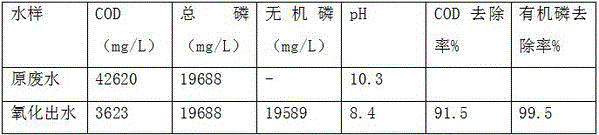

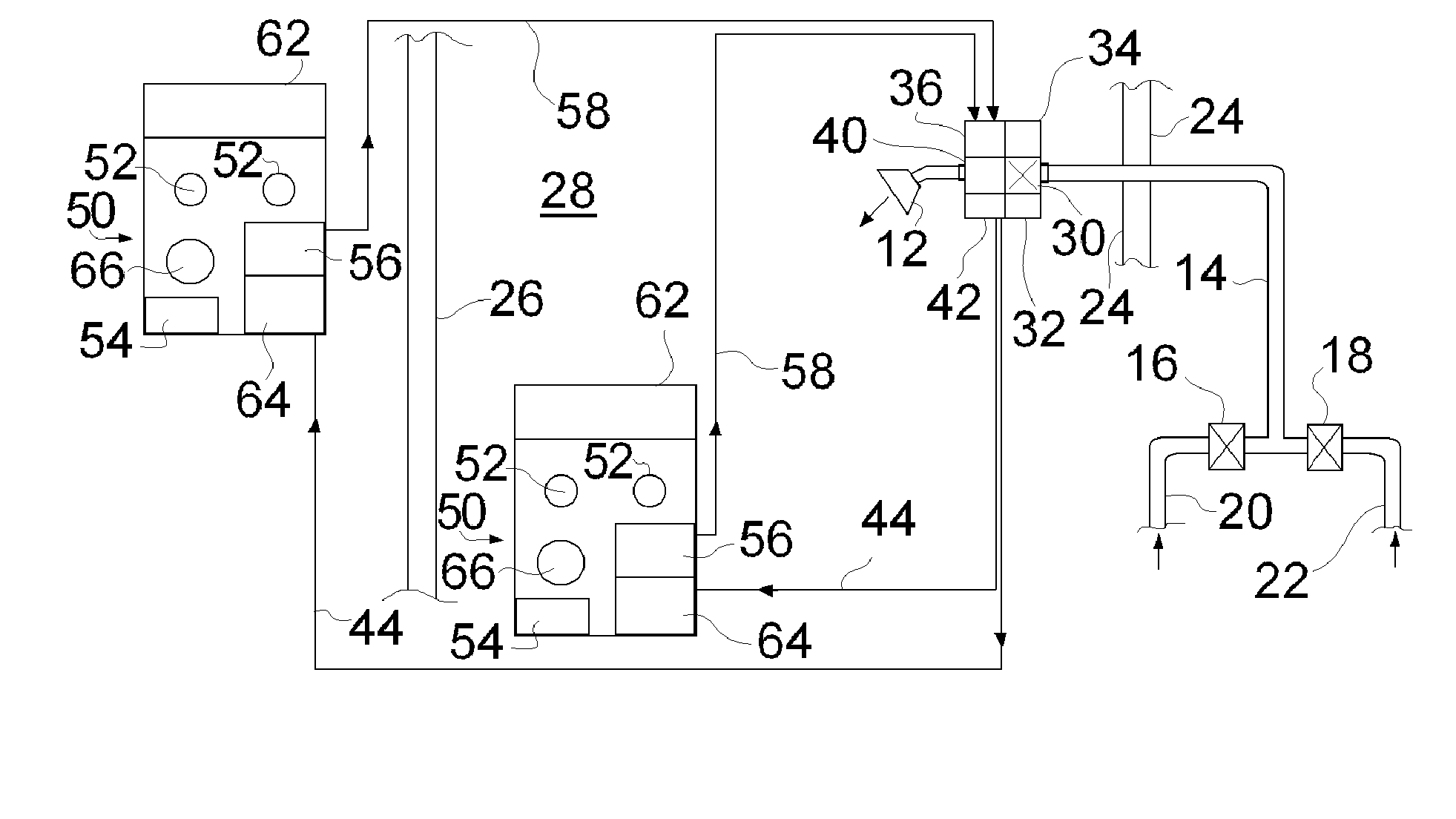

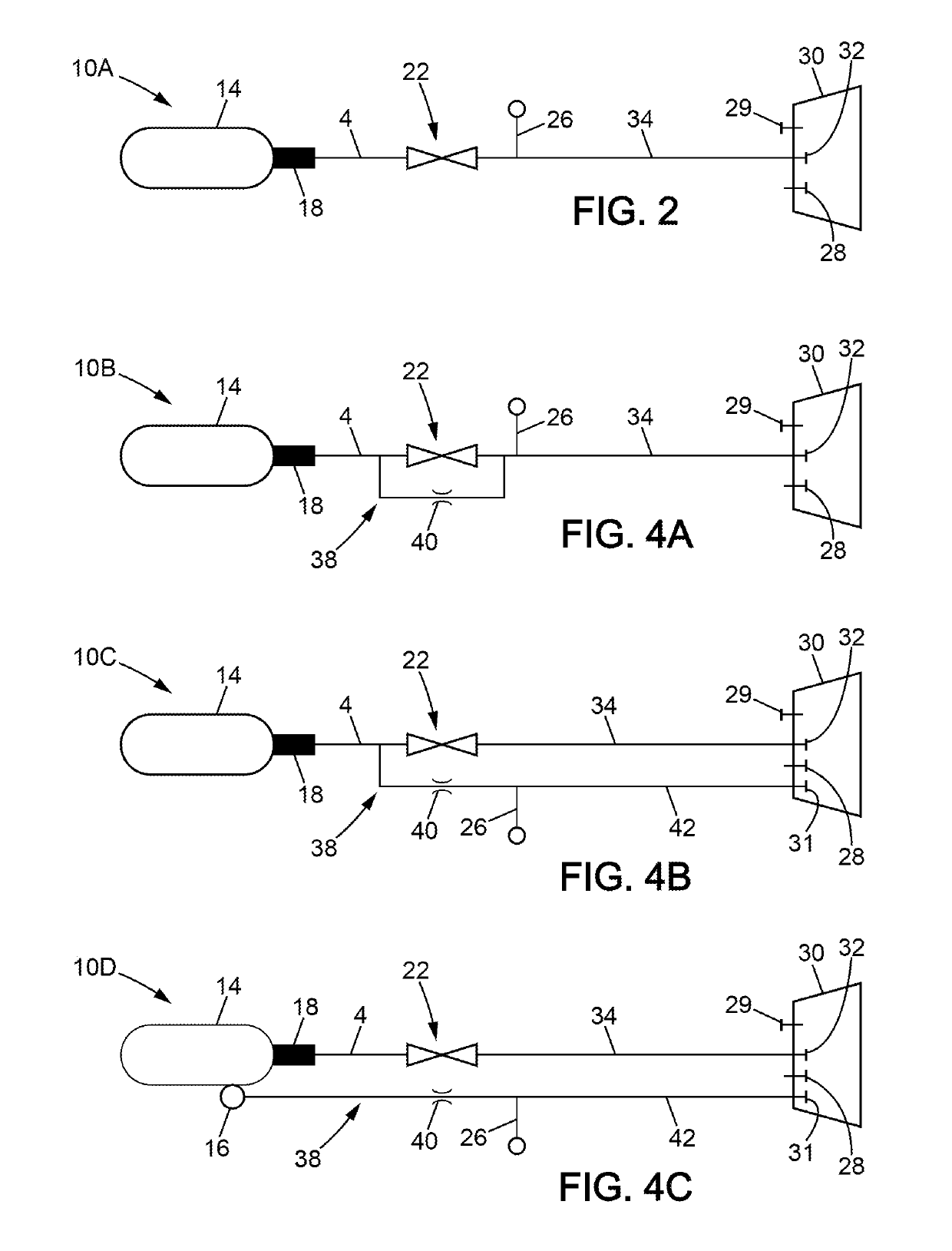

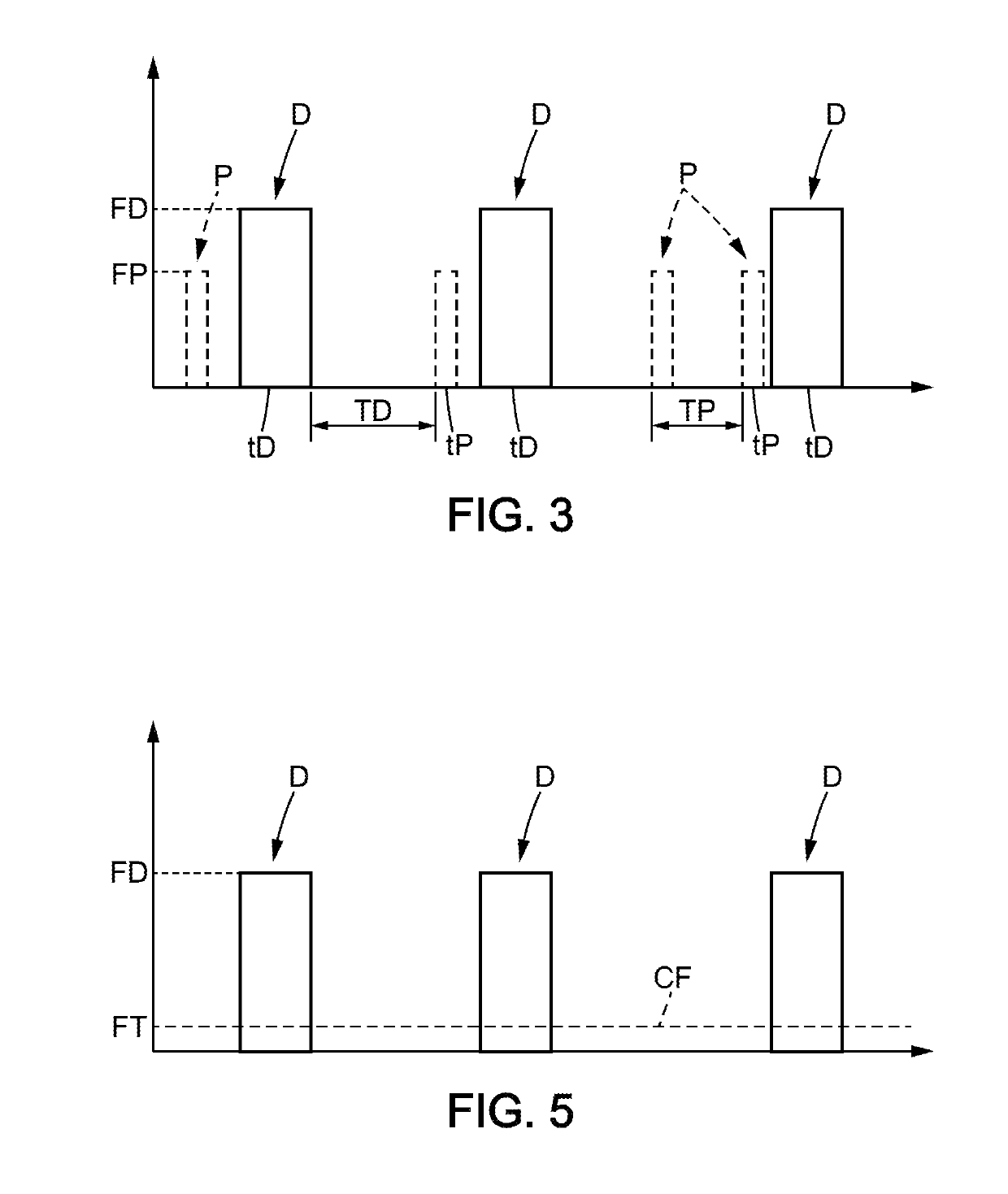

Dosed oxygen systems with delivery tube Anti-blockage features and a method for delivering respiratory gas

ActiveUS20190224505A1Reduce the possibilityAvoid cloggingEmergency oxygen systemsFire rescueBreathing gasOxygen system

Oxygen-delivery systems are described. The systems may supply emergency respiratory gas on demand to aircraft passengers. To reduce risk of blockage of tubes delivering anti-blocking gas to the face masks worn by the passengers, the systems may be designed to provide a continuous trickle flow of respiratory gas, or one or more anti-blocking pulses of gas, into a delivery tube.

Owner:SAFRAN AEROTECHNICS SAS

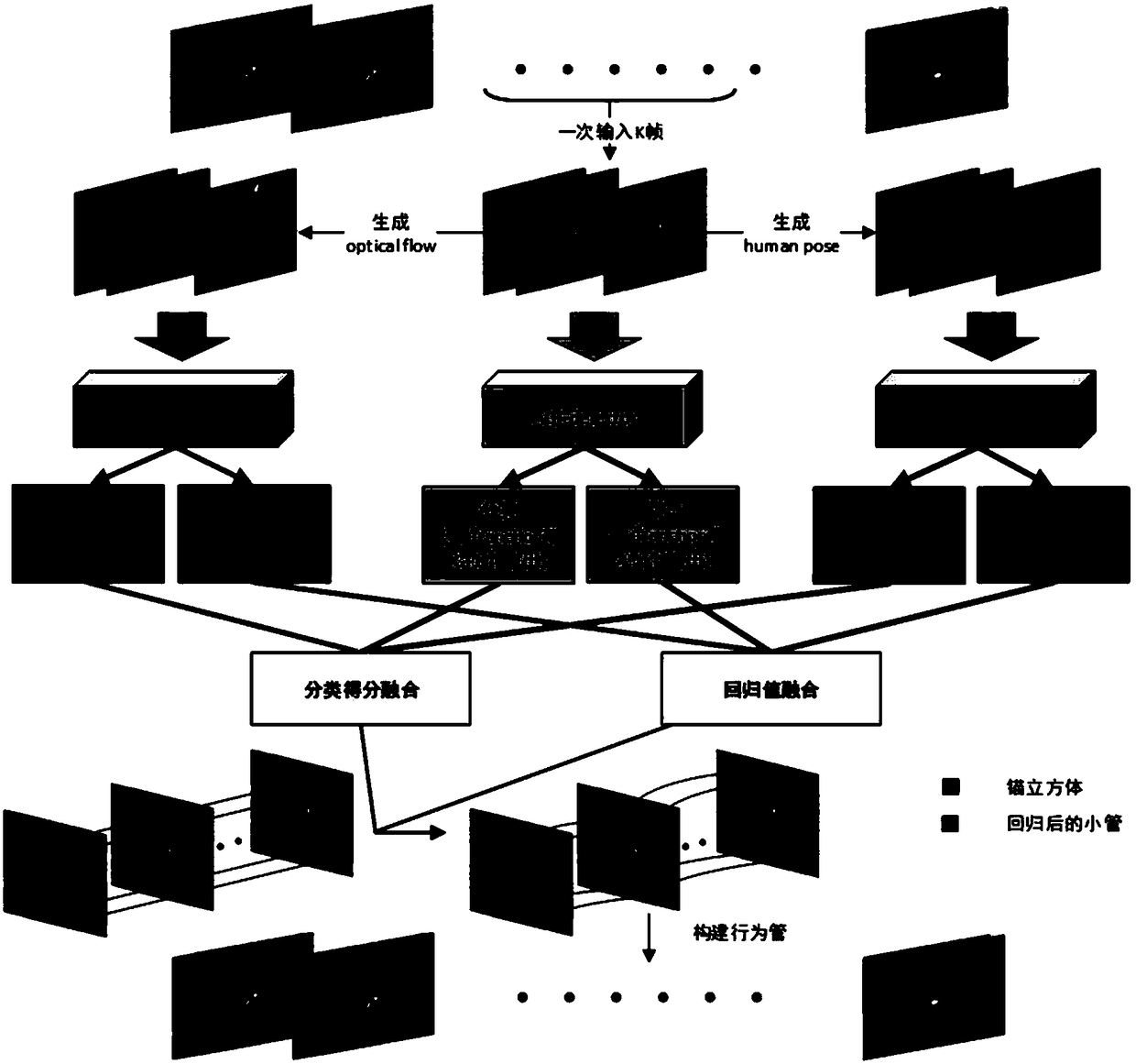

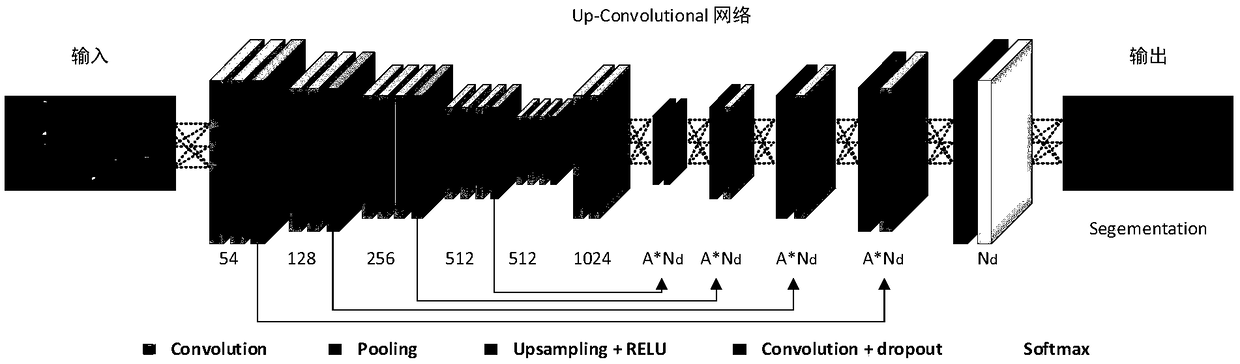

A video-oriented three-stream human motion behavior spatial domain detection method

ActiveCN109284667AThe detection process is fastGuaranteed speedImage enhancementImage analysisPattern recognitionHuman body

The invention relates to a video-oriented three-stream human motion behavior spatial domain detection method, comprising the following steps: an input preparation step of obtaining an input video, obtaining a corresponding optical flow and a human body semantic partition diagram according to an original image to form a three-stream input; a behavior detection step including detecting,at each timestep, that RGB stream, the flow stream and the pose stream by detectors on respective stream to obtain a detection result, wherein the detection result comprises a classification score and a detectiontubular regression value; a three-stream fusion step of fusing the classification scores on the three streams with unequal weights to obtain fusion scores, taking the detection tubular regression value of the original image as a fusion regression value, and combining the fusion score and the fusion regression value to obtain the behavior detection tubular of each time step; a behavior tube construction step connecting the behavior detection tubes at each time step to construct a final video behavior detection tube. Compared with the prior art, the invention has the advantages of high detection speed and high detection accuracy.

Owner:DEEPBLUE TECH (SHANGHAI) CO LTD

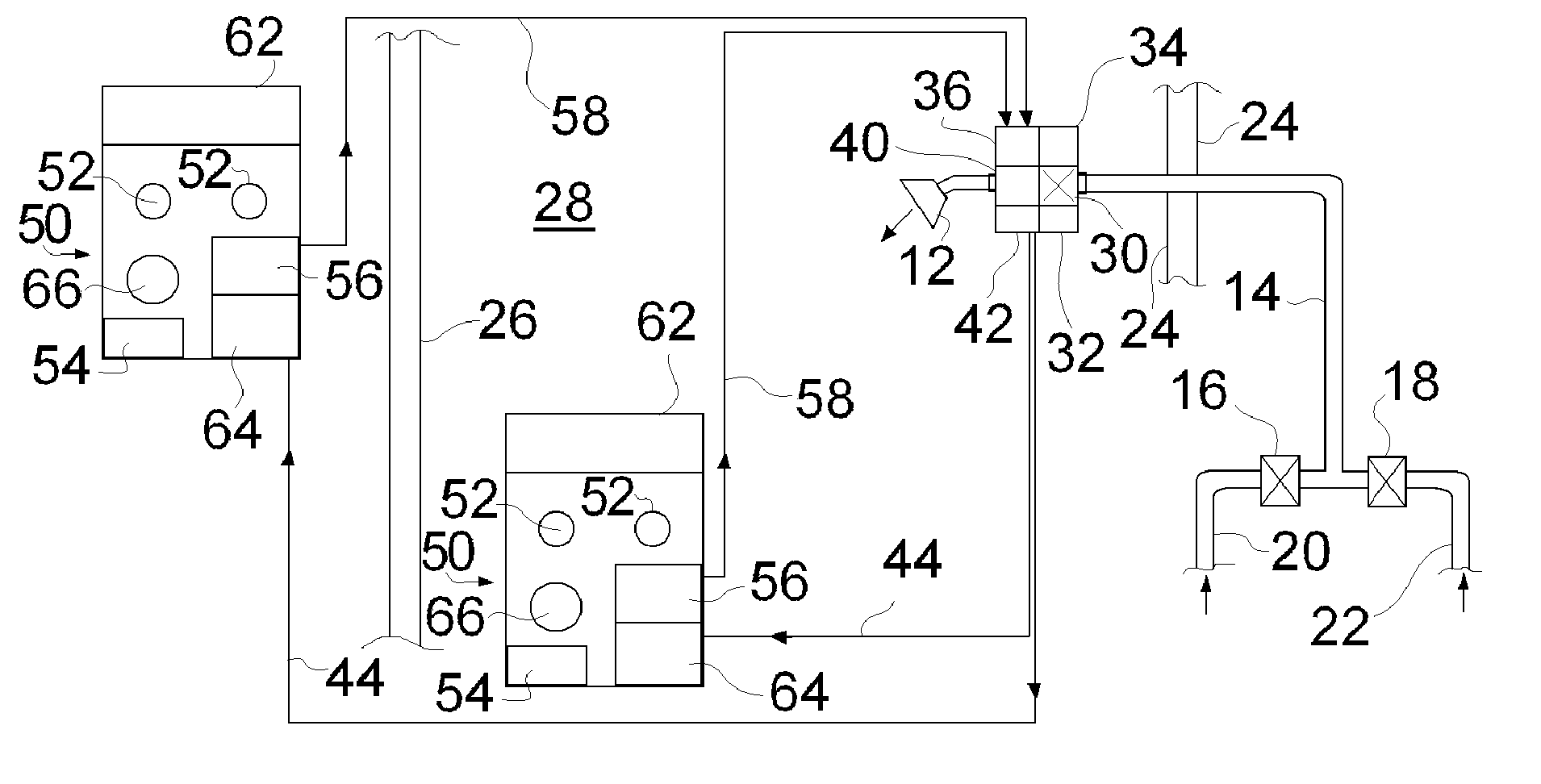

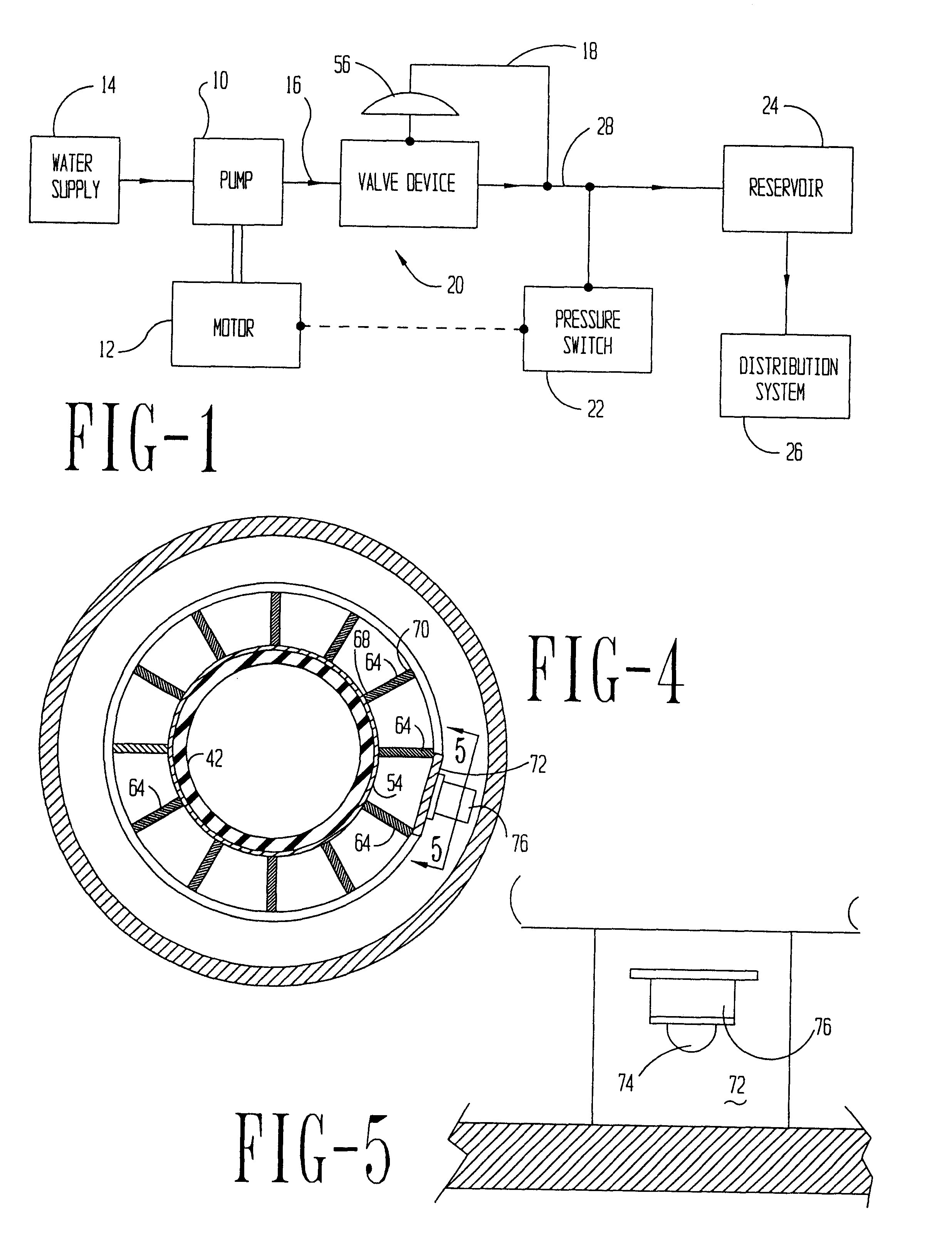

Hot water system configuration, descaling and heating methods therefore

The present invention relates to a user activated hot water heater and control system for processing hot water to hot water output locations, e.g. faucet, shower, or the like, such that temperature fluctuations and delays in hot water delivery are reduced. The present invention provides energy savings resulting from smart activation of internal and / or external recirculation systems. Additionally, trickle flow is detected and responded to based on temperature responses at various points in the main flow line of the present configuration. Simultaneous internal and external recirculations are made possible with advantageous placement of a pump within internal and external recirculation loops and a solenoid valve within the internal recirculation loop. The present system further comprises a means for adjusting the pump action in response to a thermostatic valve, temperature sensors advantageously placed in the main flow line to reduce dead heading.

Owner:INTELLIHOT

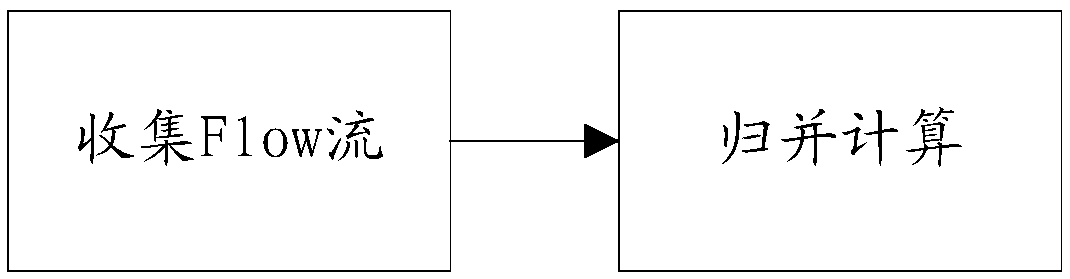

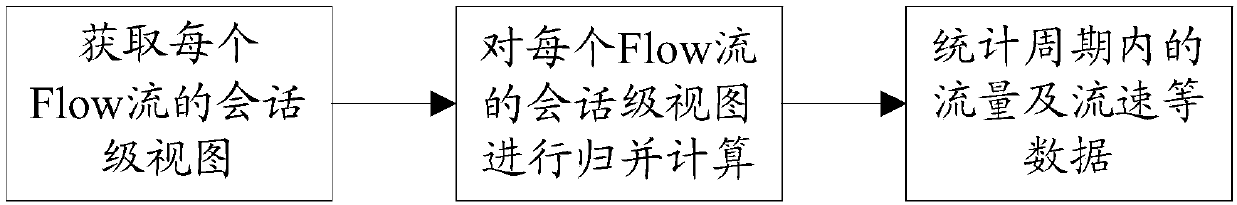

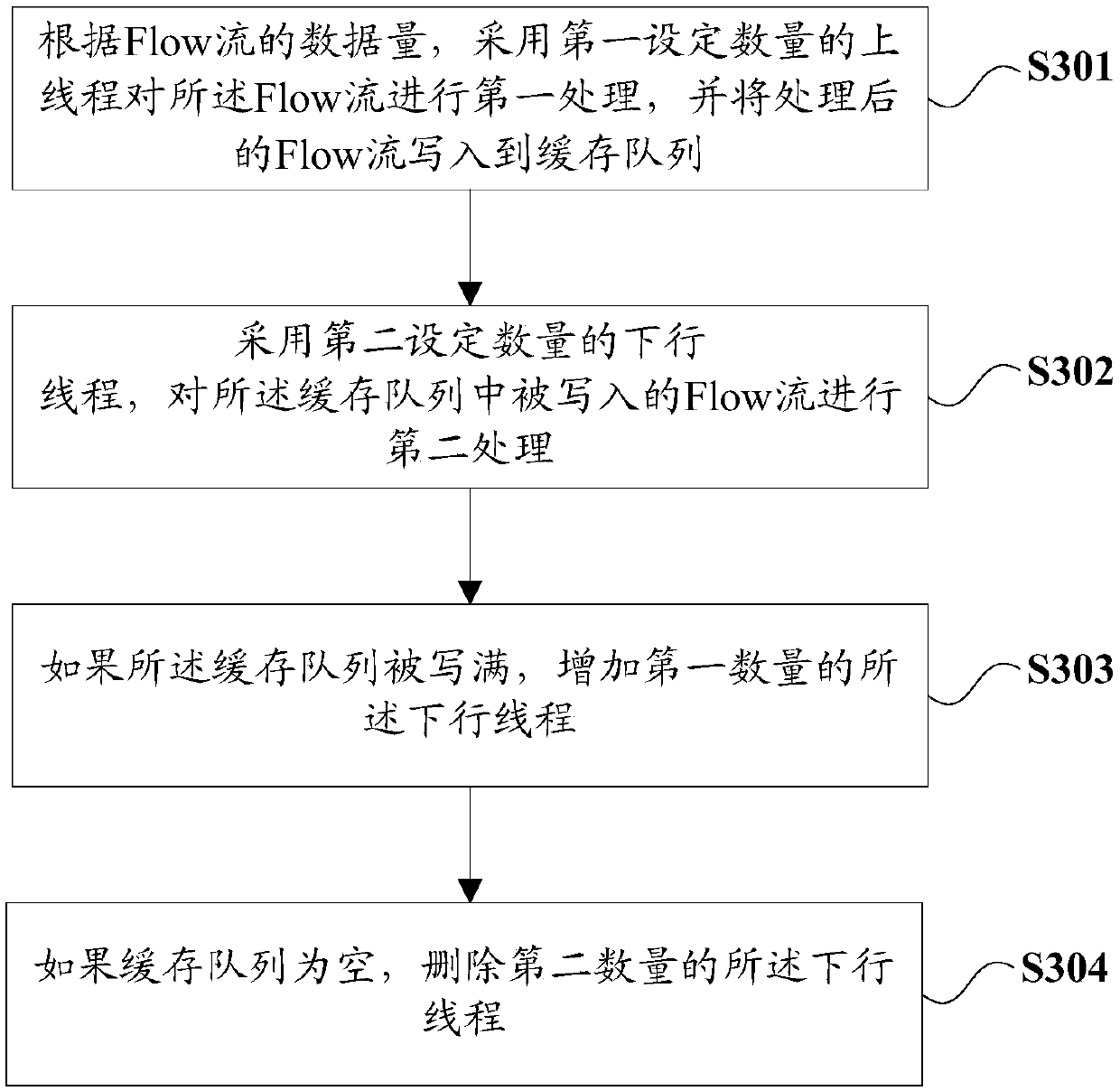

Network flow statistics method and device, electronic equipment and storage medium

ActiveCN110417609AImprove statistical accuracySolve the problem of relative lag in statisticsProgram initiation/switchingData switching networksTraffic capacityParallel computing

The invention provides a network flow statistics method and device, electronic equipment and a storage medium, and the method comprises the steps: carrying out the first processing of a Flow flow through employing a first set number of uplink threads according to the data size of the Flow flow, and writing the processed Flow flow into a cache queue; adopting a second set number of downlink threadsto perform second processing on the Flow flow written in the cache queue, each uplink thread having the same processing capability as each downlink thread; if the cache queue is fully written, addinga first number of downlink threads; and if the cache queue is empty, deleting the second number of downlink threads. According to the method and the device, the thread group is adopted to perform synchronous processing on the Flow flows, and the processing capacity of the thread group is dynamically regulated and controlled by judging whether the cache queue is fully written or empty or not and increasing or decreasing the number of the downlink threads, so that the problems of fixed processing capacity and lack of cooperative cooperation among processing steps in the prior art are solved.

Owner:CHINA MOBILE SUZHOU SOFTWARE TECH CO LTD +1

Production process and process equipment for polyester crimped yarn

InactiveCN102888669ABrightWith super bright flashArtificial thread manufacturing machinesFilament/thread formingYarnOptical property

The invention discloses a production process and process equipment for polyester crimped yarn, wherein the production process is as follows: drying the copolyester chips, putting the dried copolyester chips into an extrusion device, heating and melting the copolyester chips to obtain the copolyester chips melt; pressing the copolyester chips melt into a spinning beam, measuring the flow by a measuring pump and flowing into the spinning components, and then enabling the copolyester chips melt to pass through a spinneret plate of the spinning components, so as to obtain copolyester chips melt trickle flow, and then cooling and solidifying the copolyester chips melt trickle flow through a cooling and solidifying device to obtain the copolyester yarn; treating the copolyester yarn successively by the steps of applying oil via a lubricating nipple, pre-network and heat-setting, and then winding and forming. The process equipment comprises a drying device, an extrusion device, a spinning beam, a cooling and solidifying device and a winding and forming device which are connected in sequence according to the order. The polyester crimped yarn produced by the production process provided by the invention has the characteristics of silk-like sheen and feel, fabric bright sense, elegant and soft silk light perception; the polyester crimped yarn not only has excellent optical properties, but also realizes good air permeability and has a super bright glittery effect.

Owner:ZHONGRUN SCI & TECH

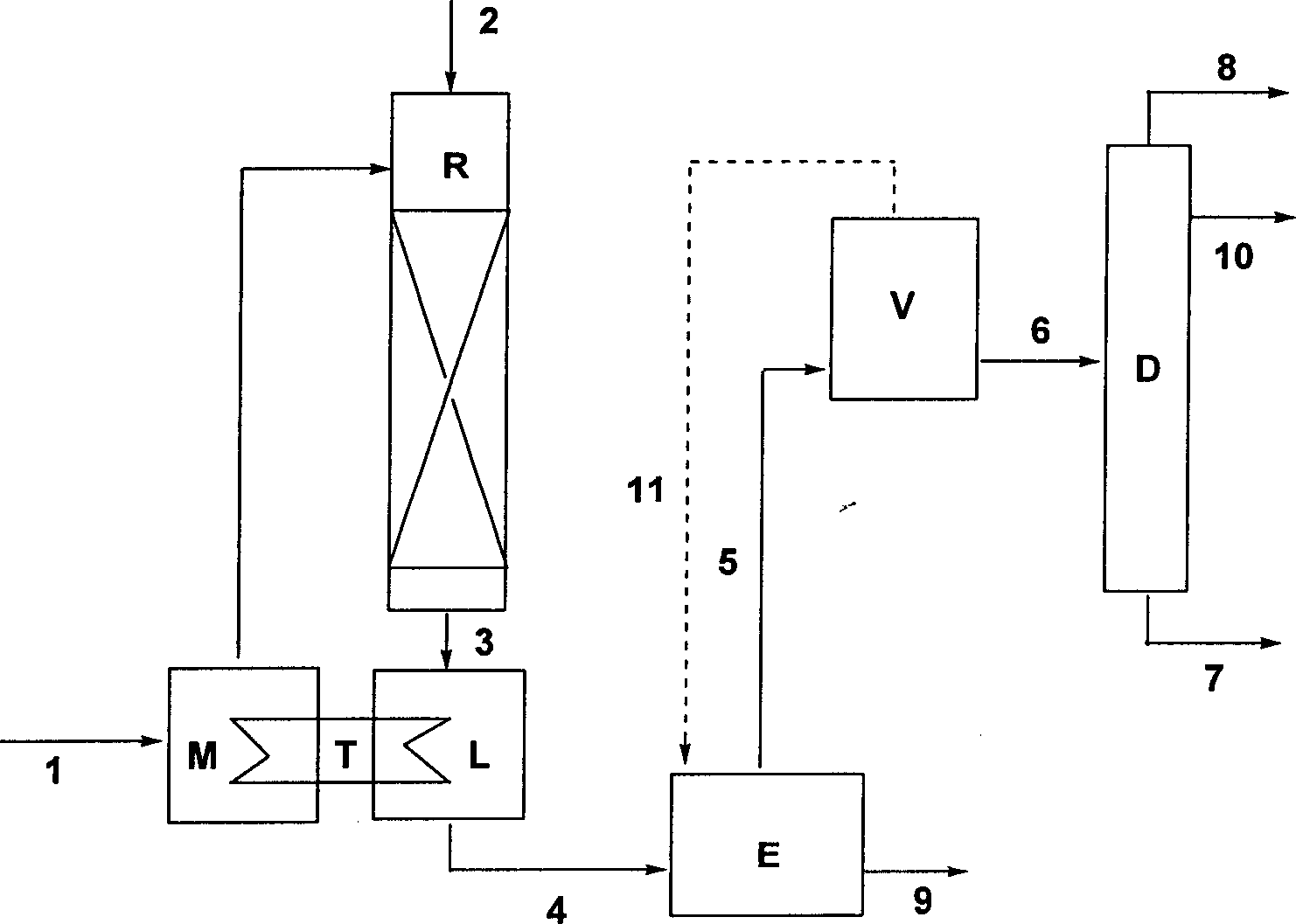

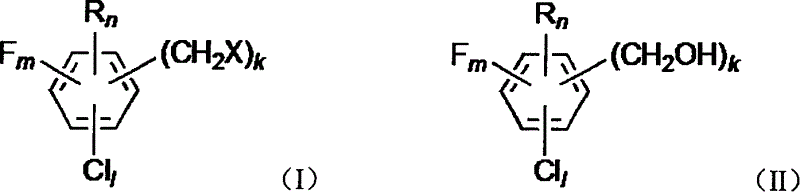

Method for producing substituted benzyl alcohol by continuous process and its apparatus

This invention has disclosed a kind of continuously producing method for substituted benzyl alcohol and its device. Mix substituted benzyl halogen and water, the mixture and steam pass the trickle-bed reactor side-by-side, hydrolyzing and separating continuously, producing substituted benzyl alcohol. This device is trickle-bed reactor, including mixing device, reactor, condenser, heat exchanger, extraction reactor, evaporator, rectification tower. This method is simple and environmental protection, costs little, quality of production is high, could product continuously. This device is of simple structure and easy to operate.

Owner:NANJING UNIV OF TECH

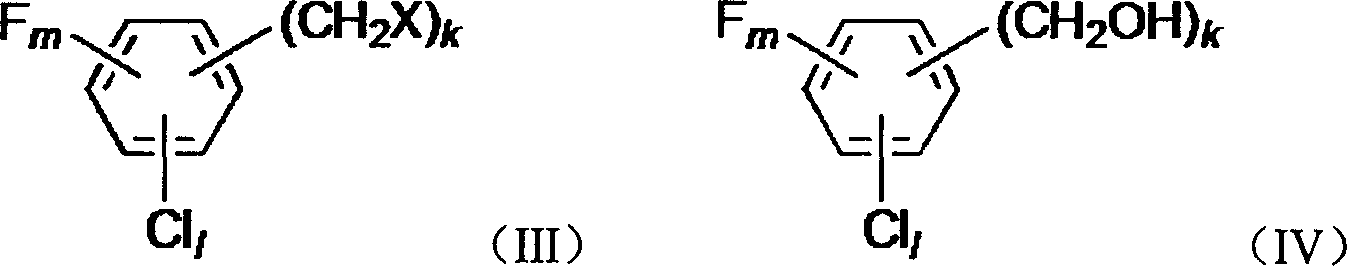

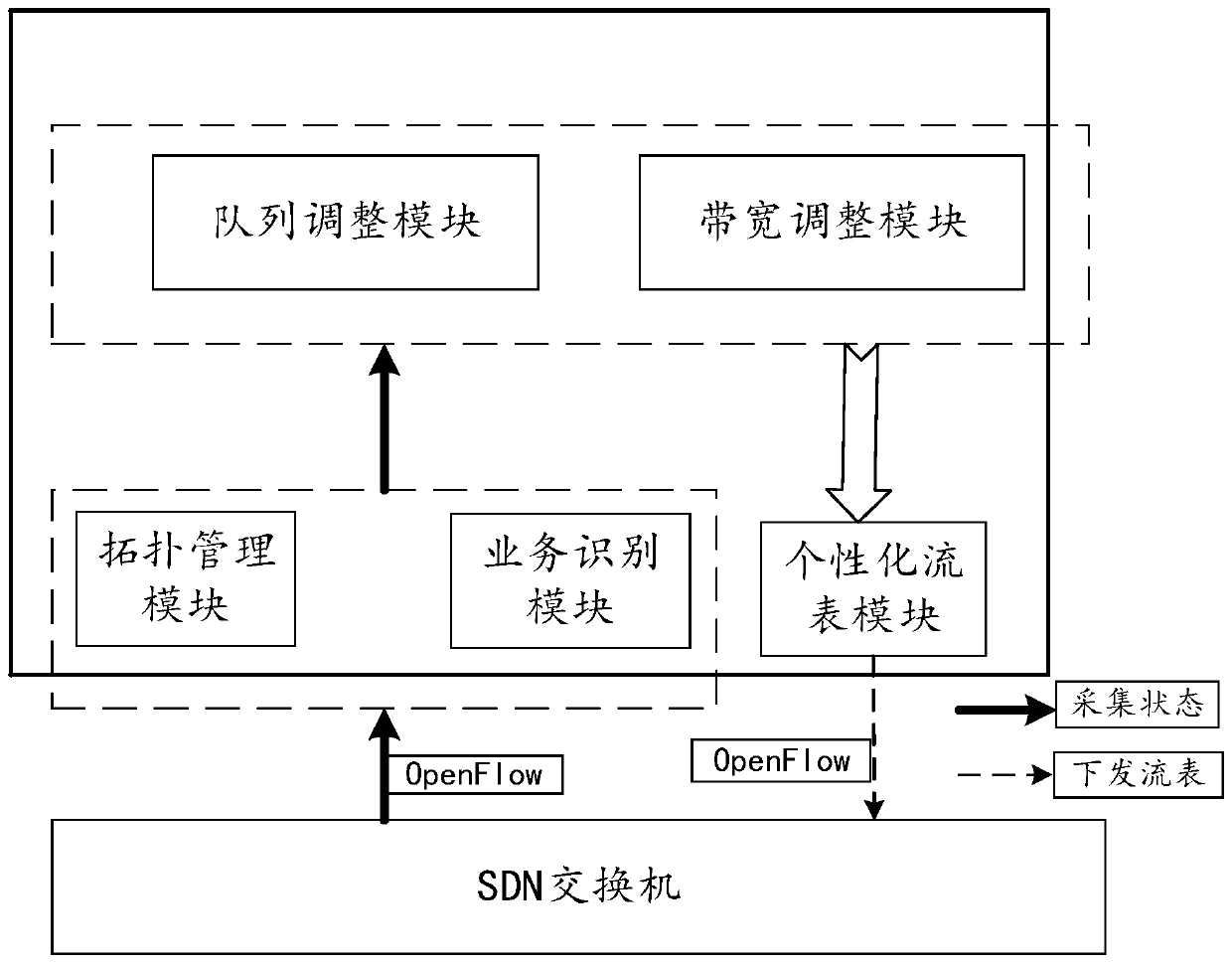

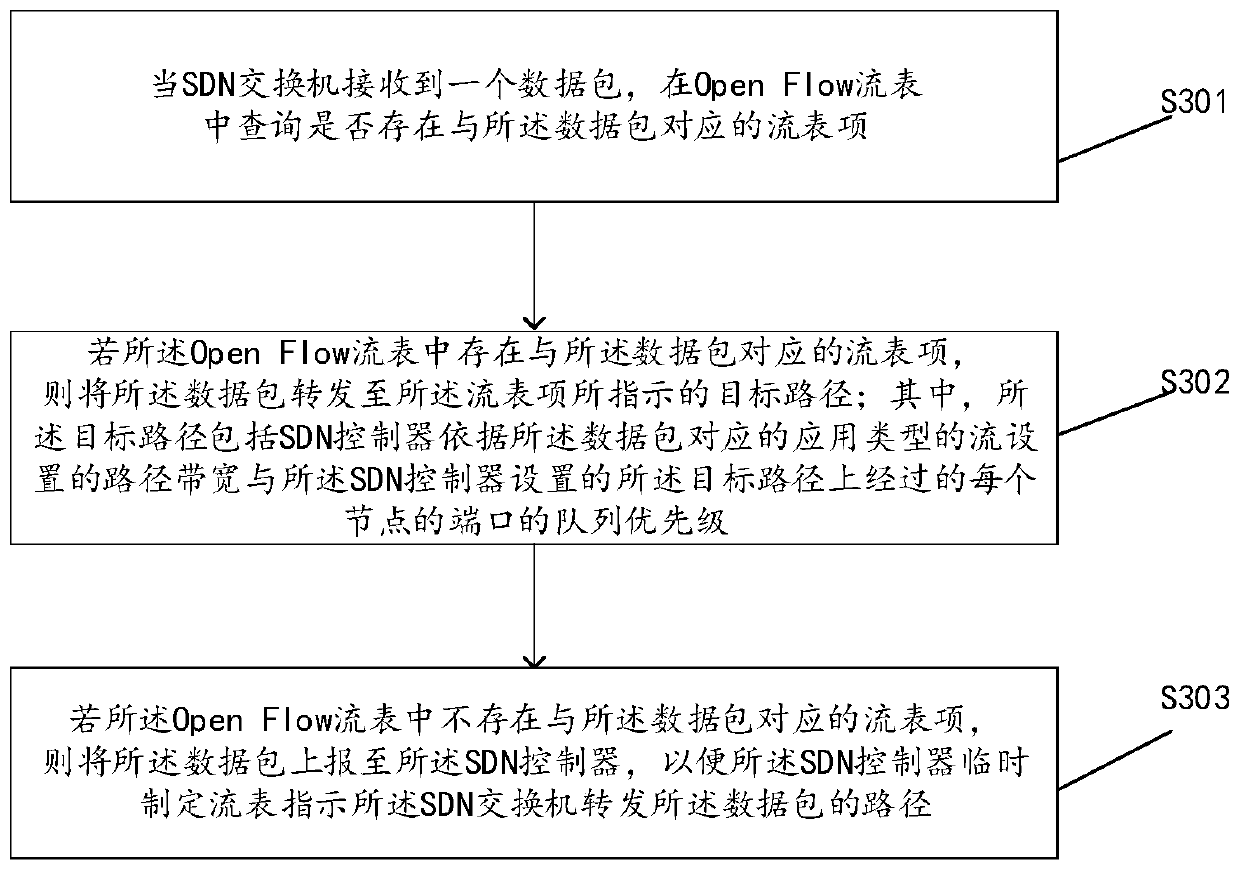

Service quality guarantee system and method based on SDN network

InactiveCN110417656AQuality Assurance Accurate GuaranteeImprove efficiencyData switching networksTrickle flowDistributed computing

The invention discloses a service quality guarantee system and method based on an SDN network. The system comprises: an SDN switch which is used for querying whether a flow table entry corresponding to the data packet exists in an Open Flow flow table or not after receiving the data packet, and forwarding the data packet to a target path indicated by the flow table entry if the flow table entry corresponding to the data packet exists in the Open Flow table; and an SDN controller which is used for setting the path bandwidth of the target path and the queue priority of the port of each node passing through the target path according to the flow of the application type corresponding to the data packet when the flow table entry corresponding to the data packet exists in the Open Flow flow table. According to the system and the method provided by the invention, the QoS guarantee efficiency is improved, the system and the method are easy to implement, and meanwhile, the end-to-end quality service is accurately guaranteed.

Owner:GUANGDONG POWER GRID CO LTD +2

Device and method for carrying out gas-liquid-solid reaction by using micro-foam packed bed

ActiveCN111036148AEasy to replaceEasy to recycleChemical/physical processesPtru catalystThermodynamics

The gas-liquid-solid reaction simultaneously relates to three phase states of gas, liquid and solid, and plays a huge role in the fields of fine chemical engineering, pharmaceutical process, wastewater treatment and the like. Gas-liquid-solid reaction generally depends on a stirring kettle, a bubbling tower, a trickle bed and other traditional multiphase reactors, and the reactors often have the problems of low interface area, poor mass and heat transfer efficiency and the like. The invention provides a device and method for carrying out gas-liquid-solid reaction by using a micro-foam packed bed. As the micro-foam packed bed has the advantages of micron-sized characteristic size, high porosity, small pressure drop and the like, the micro-foam packed bed has the advantages of high mixing efficiency, high reaction speed, quick heat transfer, easiness in catalyst replacement and the like when being used for gas-liquid-solid reaction, and can be widely applied to the fields of fine chemical engineering, medicines, environments and the like.

Owner:TSINGHUA UNIV

Process for the alkylation of aromatic hydrocarbons with C1-C8 alcohols

Process for the alkylation of aromatic hydrocarbons by means of aliphatic alcohols containing from 1 to 8 carbon atoms, which comprises feeding the hydrocarbon and alcohol to the head of a fixed-bed reactor, operating with "trickle flow" regime, containing at least one layer of a catalyst comprising a zeolite selected from medium-pore zeolites and large-pore zeolites.

Owner:VERSALIS SPA

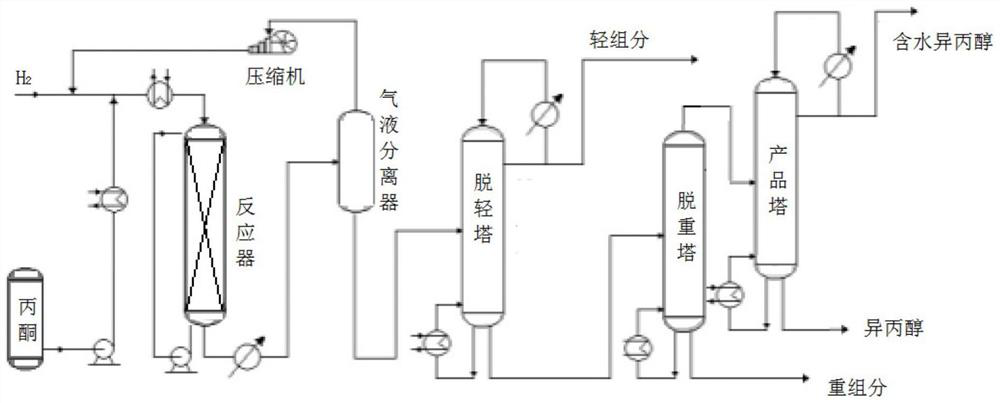

Method for producing isopropanol

ActiveCN113024351ALow reaction temperatureReduce processing energy consumptionOrganic compound preparationHydroxy compound preparationPtru catalystFixed bed

The invention discloses a method for producing isopropanol through acetone hydrogenation. The method comprises the following steps: preheating acetone and the like by using a metering pump, simultaneously introducing hydrogen, preheating the material, feeding the preheated material into a trickle bed reactor filled with a catalyst from the top of the reactor, cooling the product, feeding the cooled product into a hydrogenation high-pressure separation tank for carrying out gas-liquid separation, and returning the hydrogen containing uncondensed components to the reaction system through a circulating hydrogen compressor after fresh hydrogen is supplemented; and reducing the pressure of a liquid phase to be lower than 0.3 MPa in the hydrogenation low-pressure separation tank, cooling a part of reaction products, pumping the reaction products back to the reaction system for heat exchange by using an external circulating pump, feeding the rest reaction products to a separation section, and sequentially passing through a light component removal tower, a heavy component removal tower and a dehydration tower to obtain an isopropanol product with the purity of more than or equal to 99.9%. According to the method, isopropanol is produced through a gas-liquid-solid reaction, acetone does not need to be gasified before the reaction, the reaction temperature is low, the energy consumption is low, and the product selectivity is high. Compared with a shell-and-tube fixed bed reactor, the heat insulation bed reactor made of common stainless steel is low in investment and good in economic benefit.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

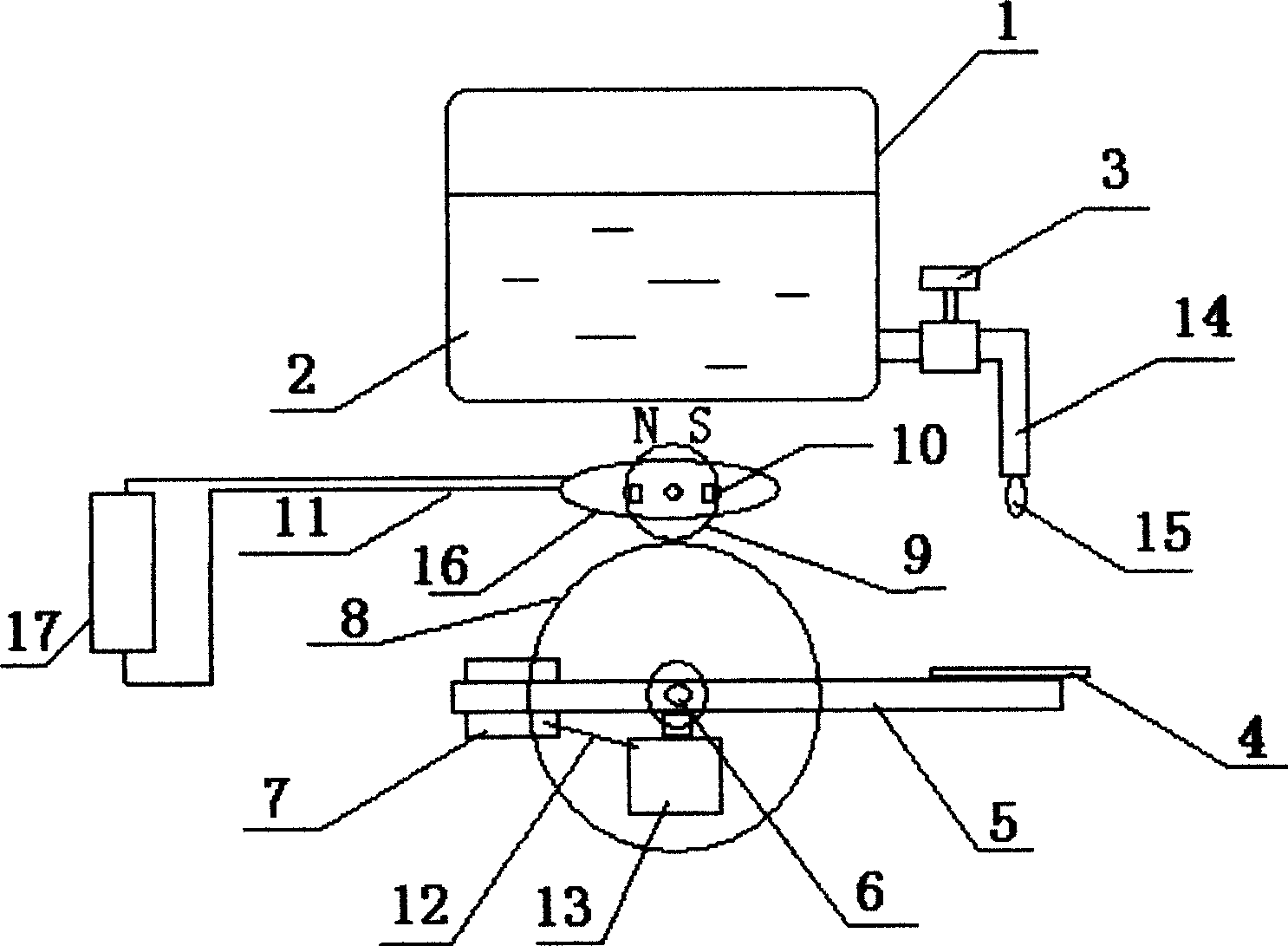

Water drop generating method

InactiveCN101509459ATake advantage ofImprove energy conversion efficiencyMachines/enginesEngine componentsWater pipeHigh energy

The invention relates to a power generation method by water drop, which is characterized in that: power is generated from pushing a generator in a manner that water drop trickles periodically; a water tank (1) is connected with one end of an outlet pipe (14), and the other end of the outlet pipe (14) is connected with a water drop control valve (3) used for generating water drop (15) at the outlet of the outlet pipe (14); a defrosting tray (4) is under the lower end of the free falling of the water drop (15); the defrosting tray (4) is fixed at one end of the level (5), and the other end of the level (5) causes the level (5) to be in a horizontal state via an elastic connecting piece (12); the supporting point of the level (5) is connected with a gearwheel and a pinion via an axis (6), permanent magnets (10) are distributed on the periphery of the pinion and symmetrically form into a N pole and an S pole, and a coil (16) is sheathed around the permanent magnet (10); and the two lead ends of the coil (16) is connected with a load (17). The method has the advantages of high energy conversion efficiency and low cost.

Owner:XIAN XINWEI INFORMATION TECH

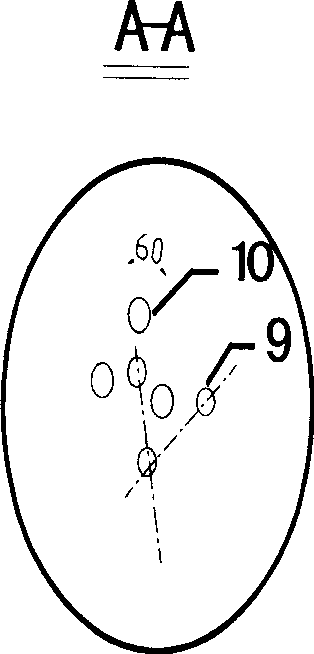

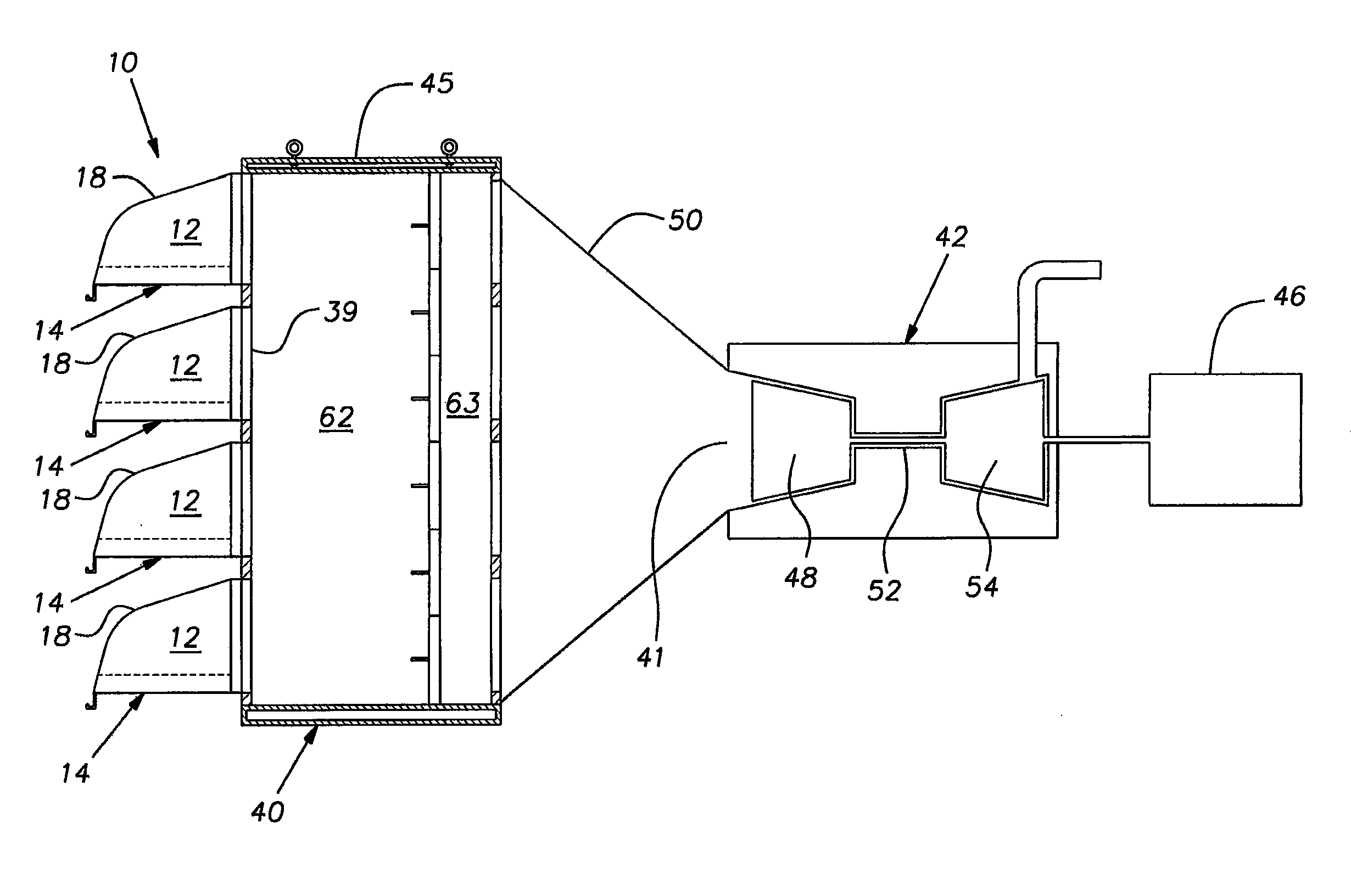

Gas-liquid distributor of trickle bed reactor

ActiveCN101279228BImprove reaction efficiencyImprove gas-liquid distributionChemical/physical processesHydrocarbon oils treatmentThermodynamicsPtru catalyst

The invention relates to a liquid-gas distributor of a trickle-bed reactor, which aims at solving the problems that the uneven liquid-gas distribution of the trickle-bed reactor in the prior art results in the uneven fluid distribution inside the layer of a catalyst bed; the trickling effect is not good; and the efficiency of the catalytic reaction is not well. The liquid-gas distributor adopts the following technical scheme: the liquid-gas distributor is provided with a gas passage pipe and a liquid passage pipe on a distributing plate; the gas passage pipe is composed of a cone roof and a straight nozzle stub; the liquid passage pipe is a vertical nozzle stub with the upper end extending 10 to 100mm out of the upper part of the distributing plate and the lower end extending 200 to 1000mm out of the lower part of the distributing plate; a plurality of pinholes are evenly opened on the cross section at different positions along the axial direction to form the liquid-gas distributor. The technical scheme better solves the problems, greatly improves the reaction efficiency of the trickle-bed reactor and can be applied to various trickle-bed reactors.

Owner:CHINA PETROLEUM & CHEM CORP +1

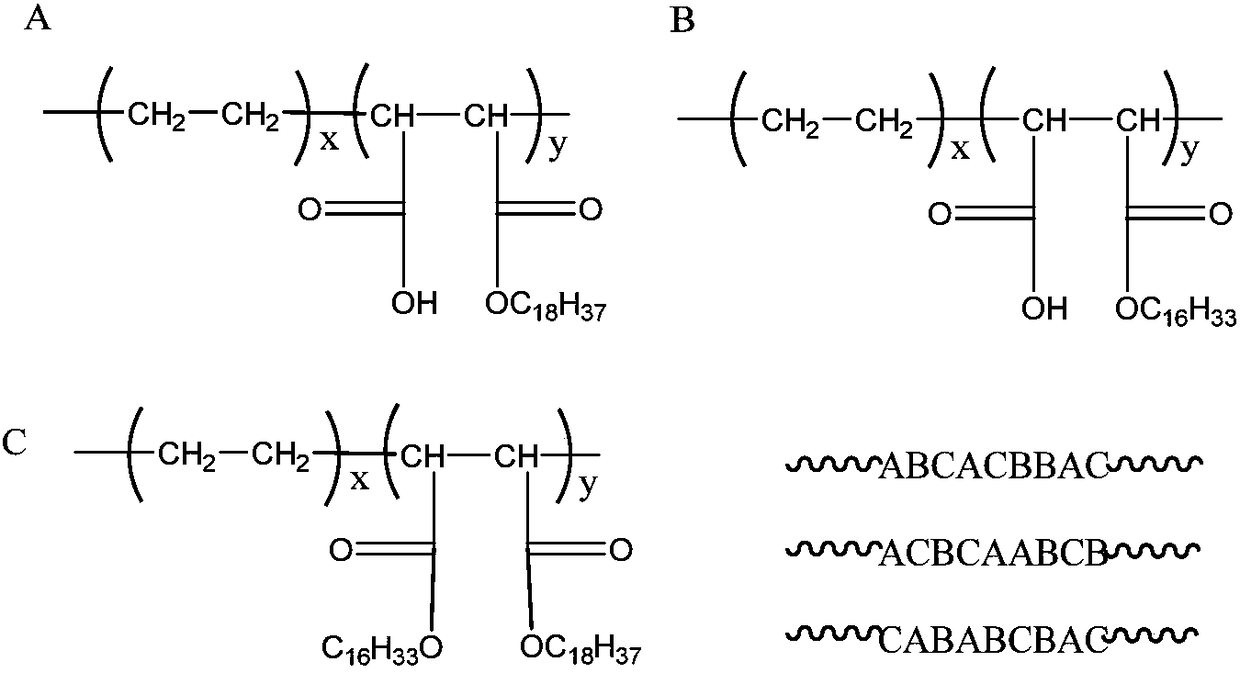

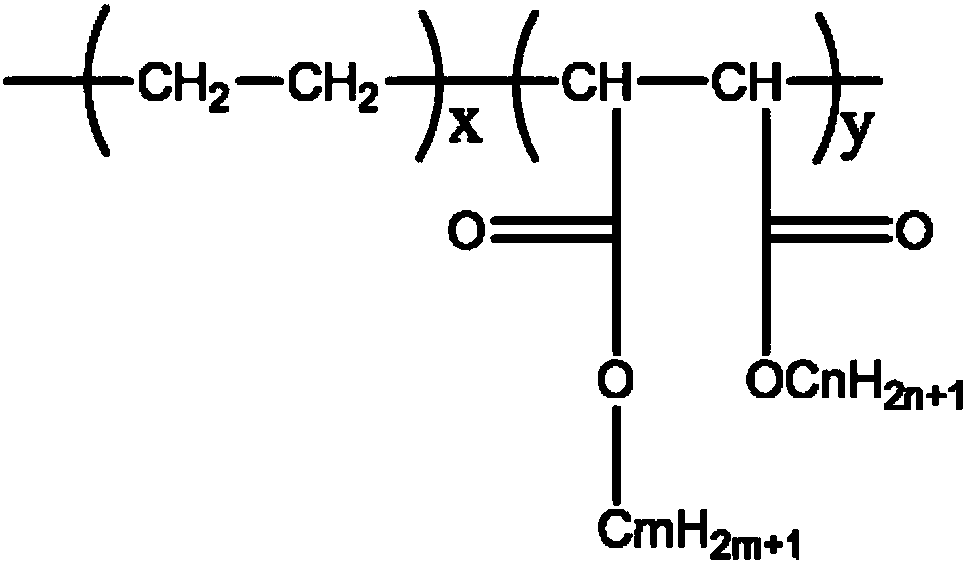

Heat-storage temperature-adjustment fiber and preparation method thereof

ActiveCN108265348AImprove structural stabilityExcellent phase change heat storage capacityFilament/thread formingConjugated synthetic polymer artificial filamentsFiberMelt extrusion

The invention discloses heat-storage temperature-adjustment fiber and a preparation method thereof. According to the invention, fiber is taken as a sheath core structure, a sheath layer is a fiber-forming polymer, and a core layer is a comb high-molecular phase-transition material; the comb high-molecular phase-transition material is poly(ethylene-g-maleic anhydride)-g-alphanol; and according to the mass percentage, the mass of the comb high-molecular phase-transition material accounts for 30-70% of that of the heat-storage temperature-adjustment fiber. The preparation method comprises the following steps: 1) performing respective fusion extrusion on dried raw materials, passing the materials through a filter screen and a shaped spinneret plate to obtain spinning trickle flow; 2) performing air bath cooling and drying on the spinning trickle flow at the temperature of 0-40 DEG C, and reeling the material at the speed of 500-3500 m / min for forming fiber, or directly collecting the material without reeling to obtain nascent fiber; and 3) after post-treatment, obtaining the heat-storage temperature-adjustment fibers with different forms. The phase-transition heat-storage value of theheat-storage temperature-adjustment fiber is 43-102 J / g, no supercooling crystallization and liquid external migration phenomena is generated, after extracting tests, the mass loss late of the phase transition material does not exceed 5%.

Owner:TIANJIN POLYTECHNIC UNIV

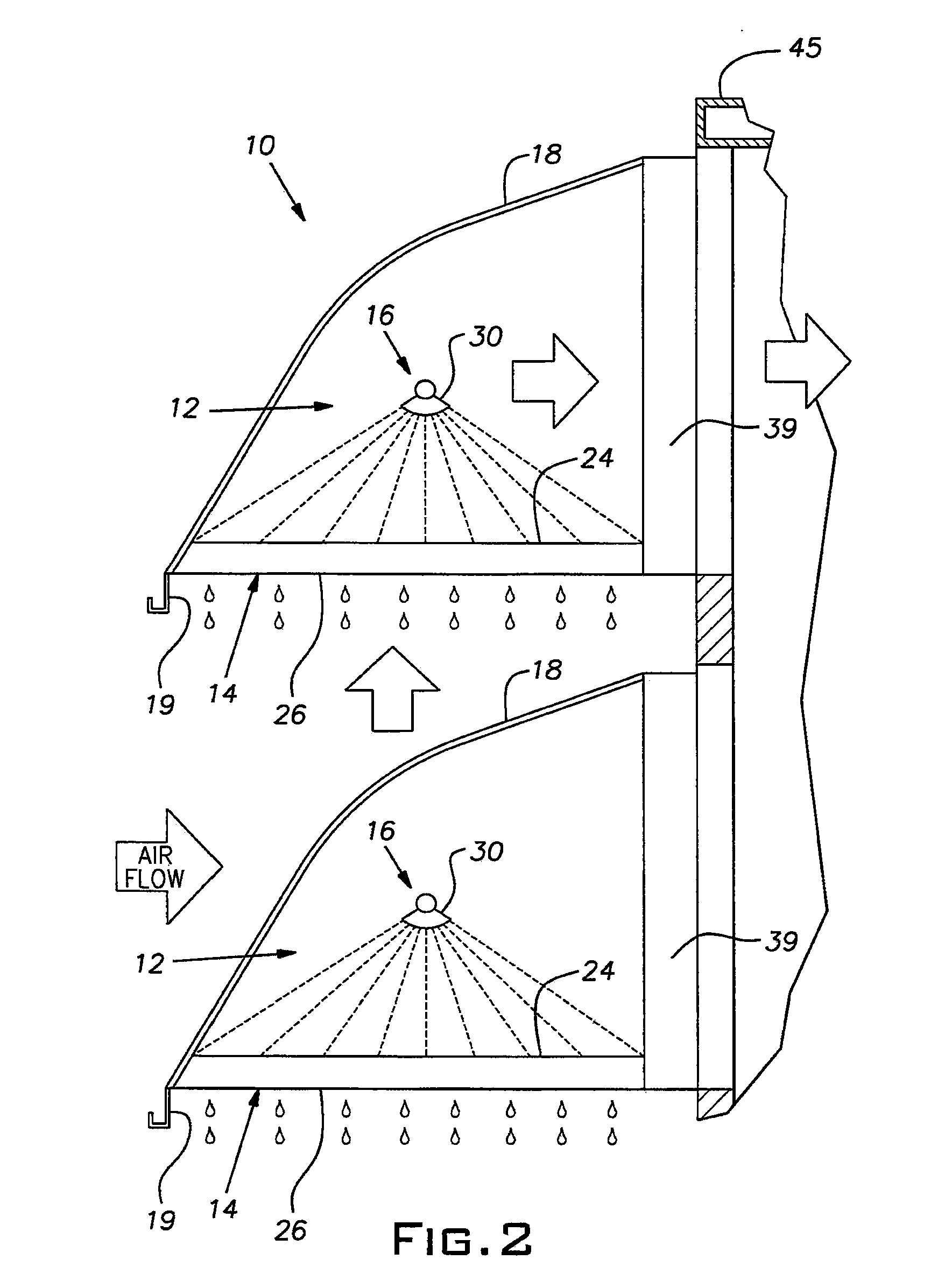

Mist/moisture removal using fixed bed trickle columns

A moisture removal system for removing water moisture from an air stream and an associated method are provided. The moisture removal system includes one or more packed beds that include a water-entry surface at which liquid water is received and an air-entry surface that is located substantially opposite the water-entry surface and at which the air stream is received. The air stream passes through the one or more packed beds in a direction substantially counter-current to the passage of the liquid water and the liquid water and the air stream contact one another in the one or more packed beds resulting in the removal of at least a portion of the water moisture from the air stream. The moisture removal system can be located upstream of and be operably connected to the inlet of a gas turbine system to which the air stream is delivered from the moisture removal system.

Owner:BHA ALTAIR

A kind of open flow flow table refreshing method and routing equipment

ActiveCN104038423BImprove update efficiencyGuaranteed processing accuracyData switching networksTrickle flowComputer science

The invention discloses a method for refreshing an Open flow flow table. Each table item in the table item search chip is divided into multiple position intervals according to the priority, so that multiple consecutive table items in the same position interval have the same priority. When it is judged that the new entry needs to be inserted, determine the entry in the Open flow flow table with a lower priority than the new entry, and sequentially place the first entry in each position interval corresponding to the entry in this position After the end entry of the interval, so that the new entry can be inserted into the vacant position after the entry with the same priority as the new entry. On the premise of ensuring the correct rate of processing, the update efficiency of the Open flow flow table in the table item lookup chip is effectively improved.

Owner:NEW H3C TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com