Gas-liquid distributor of trickle bed reactor

A gas-liquid distributor and reactor technology, used in chemical instruments and methods, petroleum industry, processing hydrocarbon oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

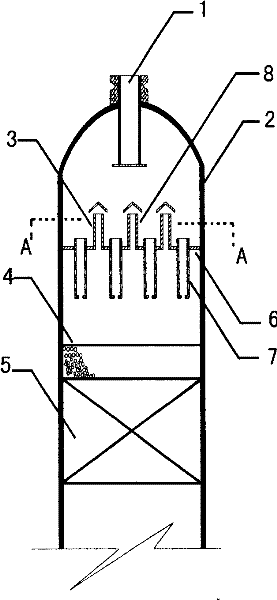

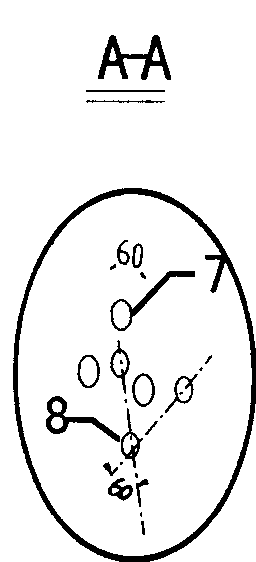

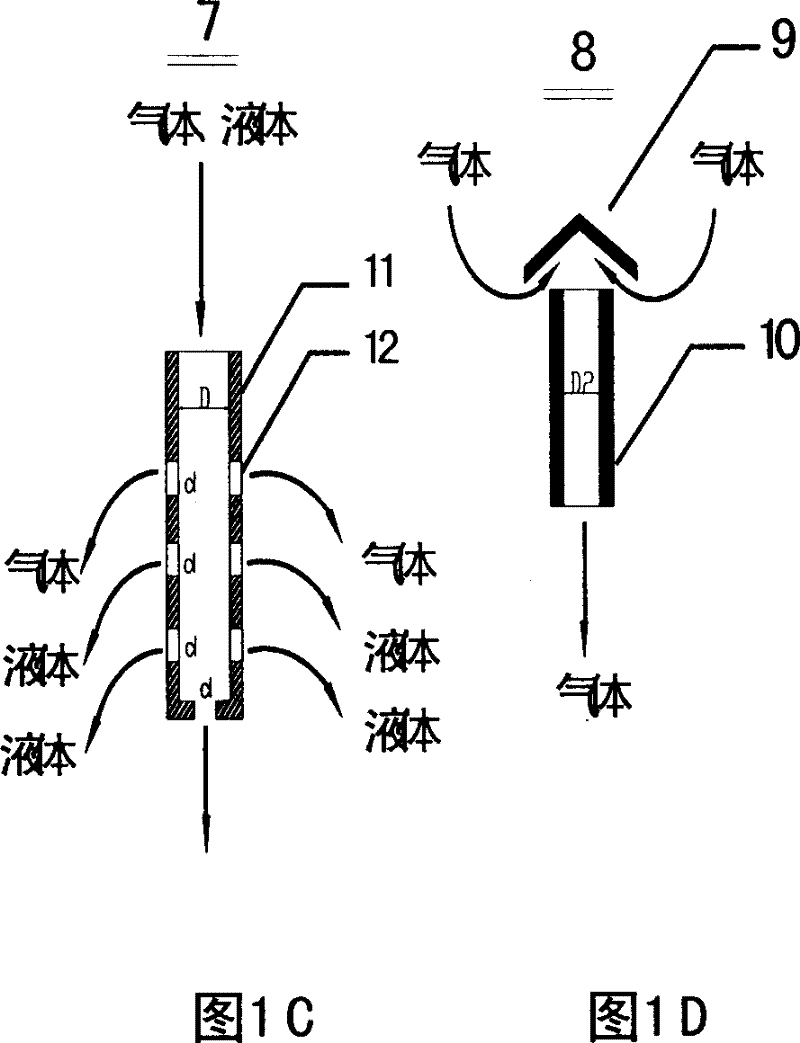

[0024] As shown in Figure 1, the initial pyrolysis gasoline C 5 ~C 9 Fractions (oils) with a diene value greater than 25 g I 2 / 100 grams of Oil, hydrogen enters the trickle bed reactor with a hydrogen-oil ratio equal to 100, the catalyst adopts a general-purpose palladium series hydrogenation catalyst, adopts the gas-liquid distributor of the present invention, and the upper end of the short pipe 11 stretches out from the top of the distribution plate 6 for 50 mm, the lower end protrudes 500 mm below the distribution plate 6, the ratio of the diameter d of the small hole 12 to the inner diameter D of the liquid channel pipe 7 is 0.015: 1.0, and the area S of all the small holes 12 1 and the area S of the inner cross-section of the liquid channel tube 7 2 The ratio of the ratio is 1.01:1.0; the opening ratio of the gas passage pipe 8 on the distribution plate 6 is 15%, and the opening ratio of the liquid passage pipe 7 on the distribution plate 6 is 20%. Experiments have pr...

Embodiment 2

[0026] As shown in Figure 1, the initial pyrolysis gasoline C 5 ~C 9 Fractions (oils) with a diene value greater than 30 g I 2 / 100 grams of Oil, hydrogen enters the trickle bed reactor with a hydrogen-oil ratio equal to 100, the catalyst adopts a general-purpose palladium series hydrogenation catalyst, adopts the gas-liquid distributor of the present invention, and the upper end of the short pipe 11 stretches out from the top of the distribution plate 6 25 mm, the lower end stretches out 800 mm below the distribution plate 6, the ratio of the diameter d of the small hole 12 to the inner diameter D of the liquid channel pipe 7 is 0.011: 1.0, the area S of all the small holes 12 1 and the area S of the inner cross-section of the liquid channel tube 7 2 The ratio of the ratio is 0.95:1.0; the opening ratio of the gas passage pipe 8 on the distribution plate 6 is 10%, and the opening ratio of the liquid passage pipe 7 on the distribution plate 6 is 15%. Experiments have proved...

Embodiment 3

[0028] As shown in Figure 1, the initial pyrolysis gasoline C 5 ~C 9 Fractions (oils) with a diene value greater than 20 g I 2 / 100 gram of Oil, hydrogen enters the trickle bed reactor with a hydrogen-oil ratio of 100, the catalyst adopts a general-purpose palladium series hydrogenation catalyst, adopts the gas-liquid distributor of the present invention, and the upper end of the short pipe 11 stretches out 80 above the distribution plate 6 mm, the lower end extends 650 mm below the distribution plate 6, the ratio of the diameter d of the small hole 12 to the inner diameter D of the liquid channel pipe 7 is 0.15:1.0, and the area S of all the small holes 12 1 and the area S of the inner cross-section of the liquid channel tube 7 2 The ratio of the ratio is 1.1:1.0; the opening ratio of the gas passage pipe 8 on the distribution plate 6 is 20%, and the opening ratio of the liquid passage pipe 7 on the distribution plate 6 is 30%. Experiments have proved that the diene value o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com