Mist/moisture removal using fixed bed trickle columns

a technology of water moisture and trickle column, which is applied in the direction of machine/engine, combustion-air/fuel-air treatment, and separation processes, etc., can solve the problems of increasing pressure loss at the filter, affecting the airflow, and affecting the flow rate of air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]Examples of embodiments that incorporate one or more aspects of the present invention are described below with references, in certain respects, to the accompanying drawings. These examples are not intended to be limitations on the present invention. Thus, for example, in some instances, one or more examples of the present invention described with reference to one aspect or embodiment can be utilized in other aspects and embodiments. In addition, certain terminology is used herein for convenience only and is not to be taken as limiting the present invention.

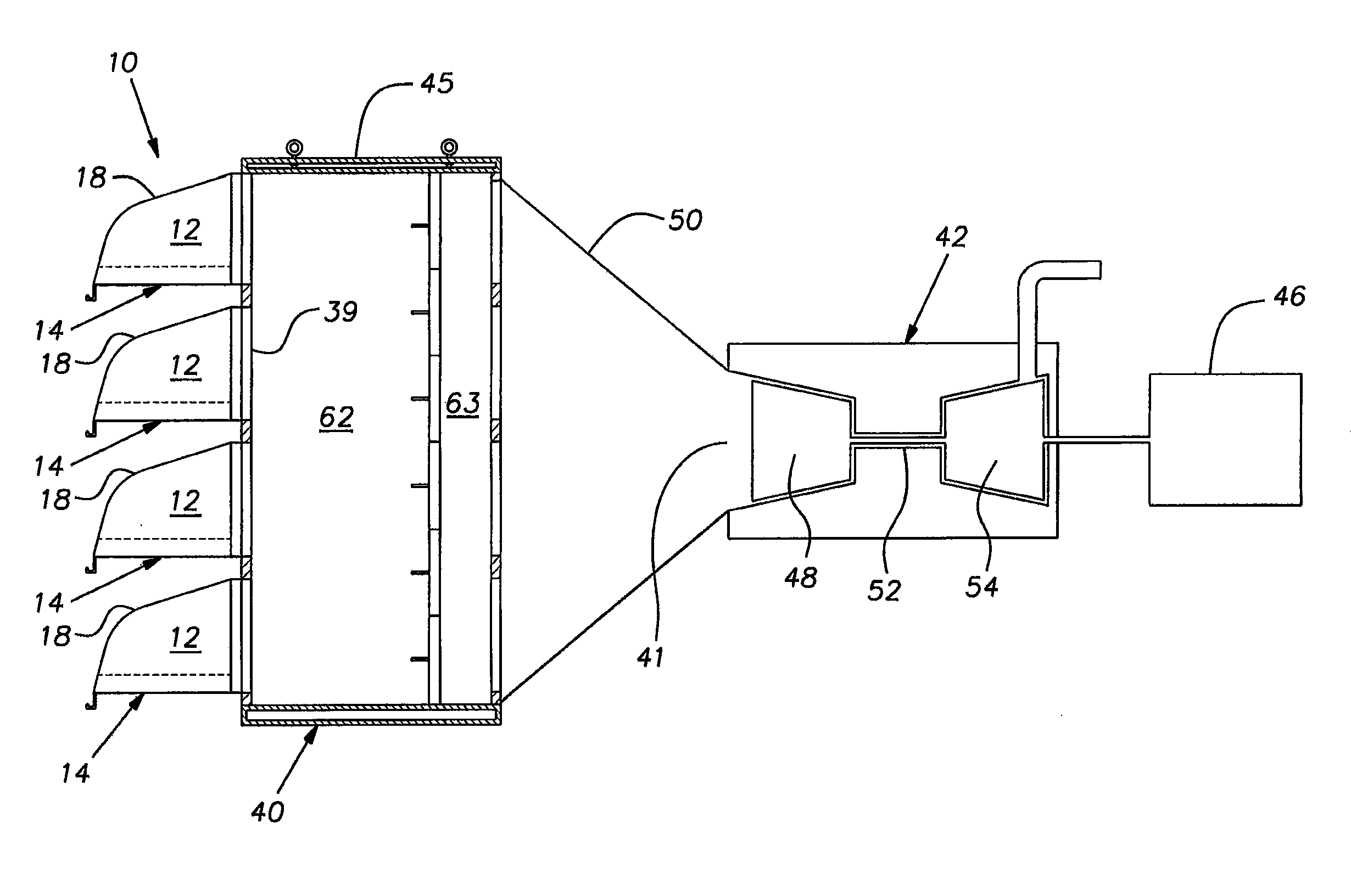

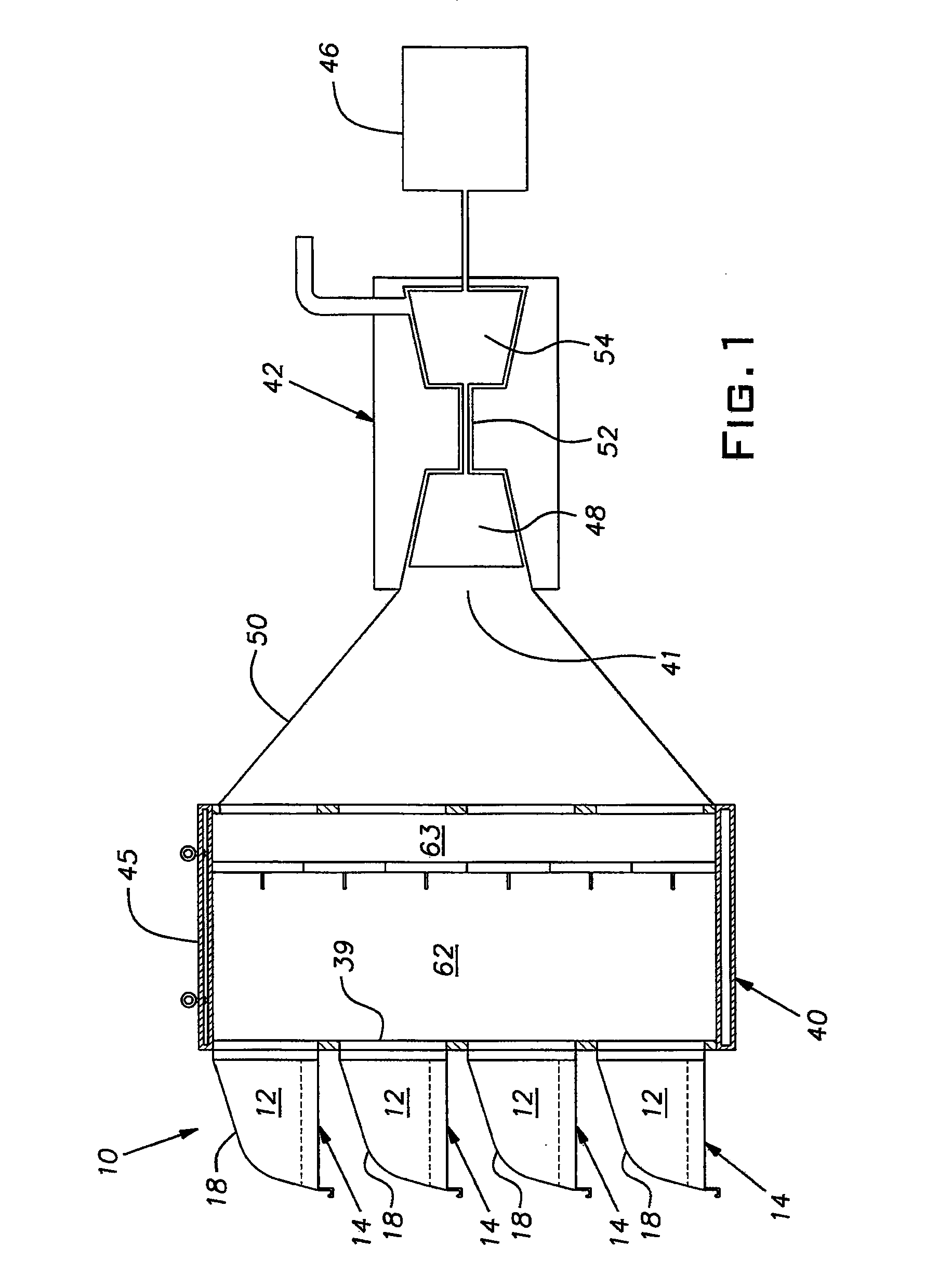

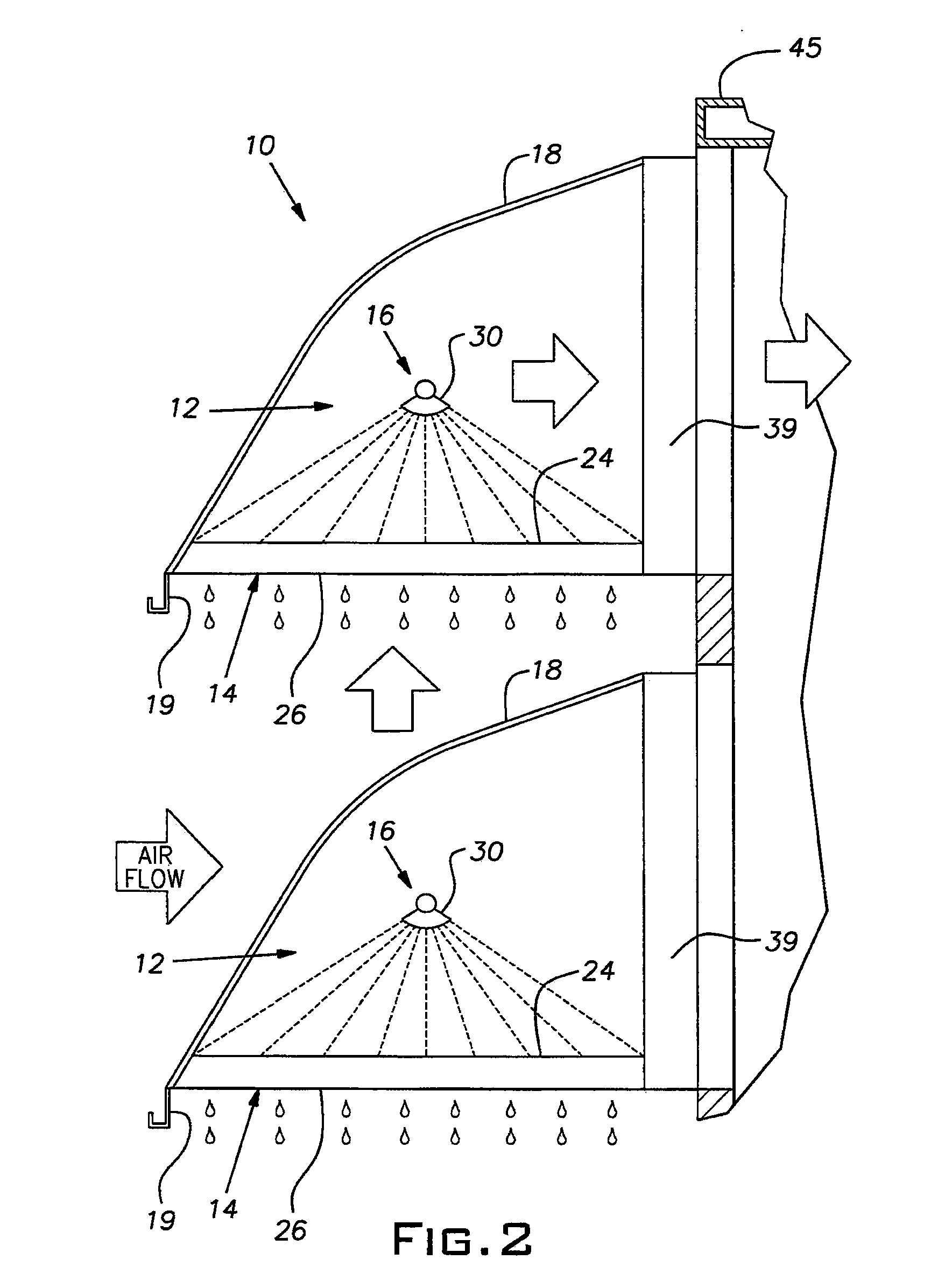

[0013]FIG. 1 schematically illustrates an aspect of the present invention wherein a moisture removal system, indicated generally at 10, for removing water moisture from an air stream is associated with an air-conditioning system, indicated generally at 40. The moisture removal system 10 is located at an air inlet 39 of the air-conditioning system 40 that further conditions the air stream after the air stream has passed throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| mass flow rate | aaaaa | aaaaa |

| pressure ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com