Heat-storage temperature-adjustment fiber and preparation method thereof

A technology for heat storage and temperature regulation, and fiber, which is applied in fiber processing, conjugated synthetic polymer rayon, and filament/thread forming. It can solve problems such as reducing application value and achieve good interface compatibility and operation methods. Simple, guaranteed continuity of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Poly(ethylene-g-maleic anhydride)-g-n-octadecyl alcohol with a grafting degree of 50% was used as a comb-shaped polymer phase change material, and PET (intrinsic viscosity number 0.56) with a melting temperature of 250°C was used as a synthetic material. Fiber polymer, after the two components are dried until the moisture content is lower than 50ppm, the contents of the comb-shaped polymer phase change material and the fiber-forming polymer are controlled to be 40wt.% and 60wt.%, respectively, and melt-extruded at 280°C After passing through a filter screen and an annular spinneret, fine spinning streams are obtained, cooled and dried in an air bath at 25°C, and then wound at a winding speed of 800m / min to obtain primary fibers. Then after double drafting, setting and drying, it is processed into long fibers, and short fibers are obtained after cutting.

[0036]The fineness of the short fiber is 2.1dtex, the tensile breaking strength is 3.2cN / dtex, and the elongation at...

Embodiment 2

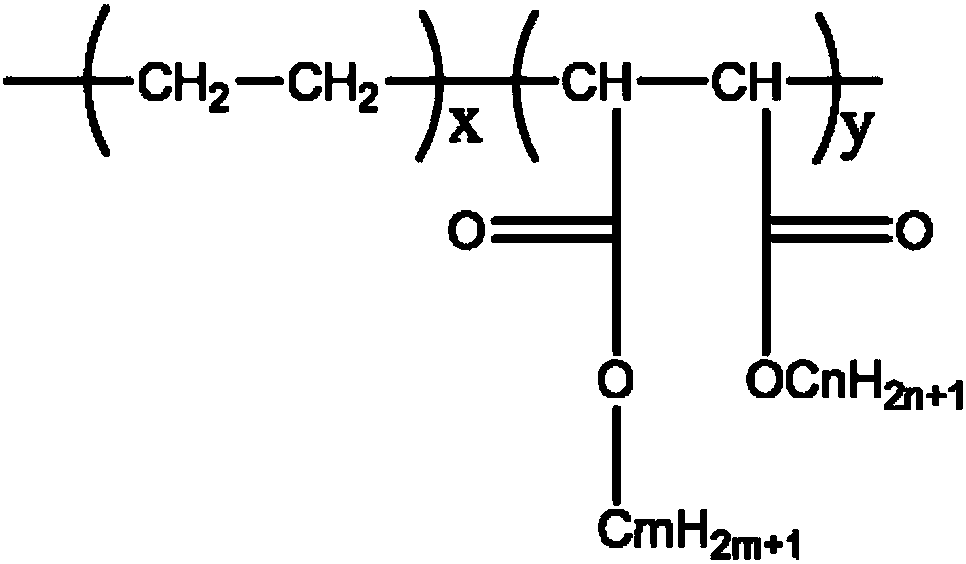

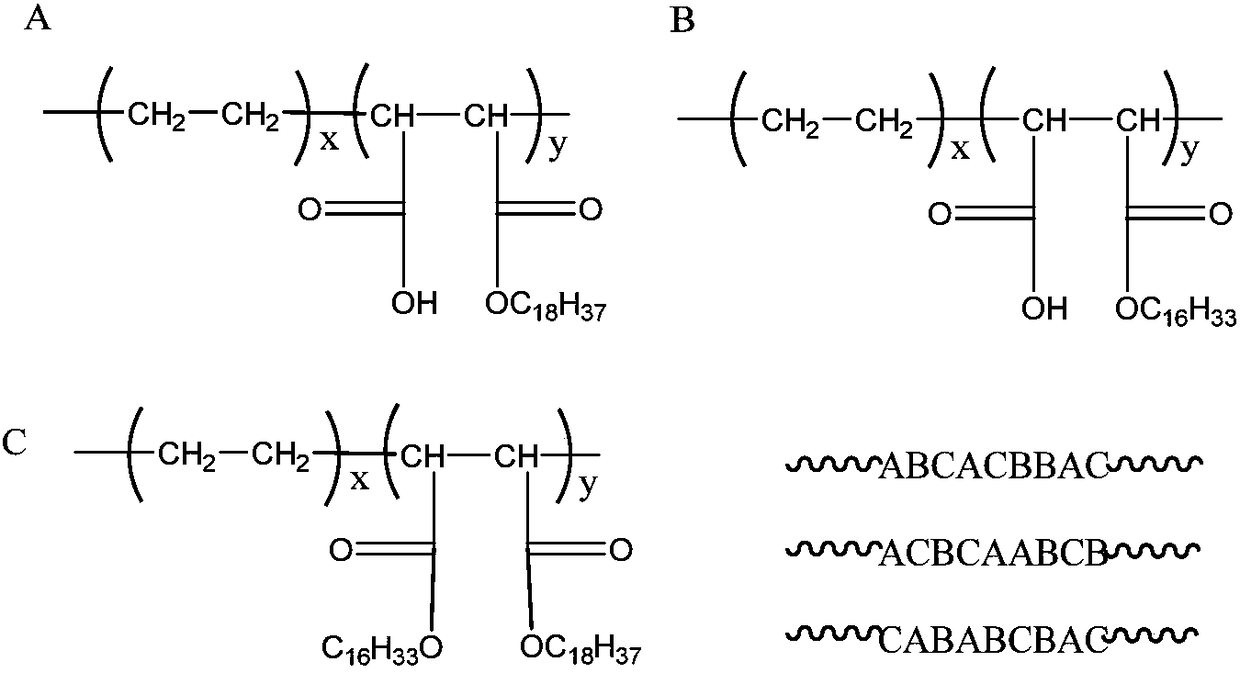

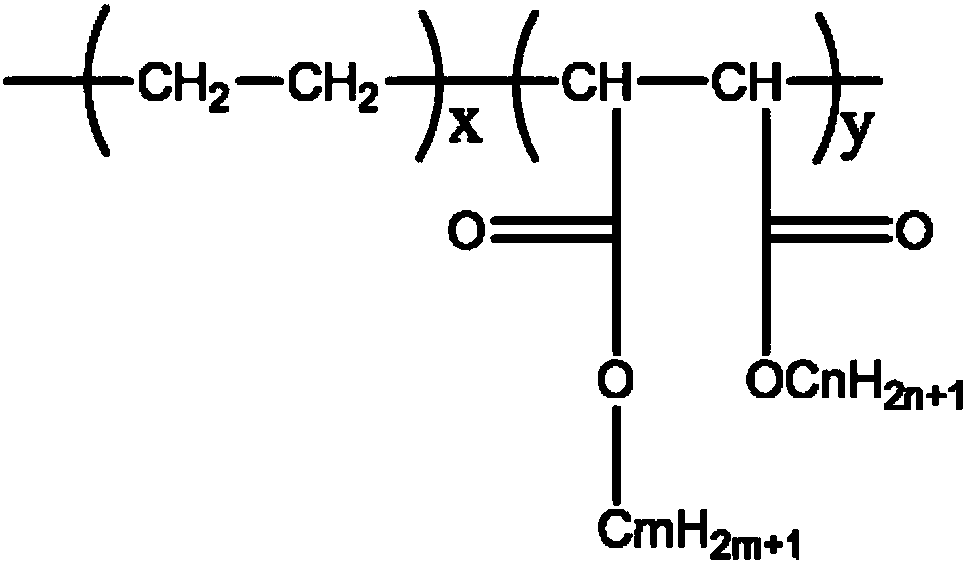

[0038] Graft copolymer of poly(ethylene-g-maleic anhydride)-g-octadecyl alcohol and poly(ethylene-g-maleic anhydride)-g-hexadecanol at a molar ratio of 50:50 (the degree of grafting is 45%) as the comb polymer phase change material, its structural formula is as follows:

[0039]

[0040] Using polylactic acid (intrinsic viscosity 0.62) as the fiber-forming polymer, after the two components are dried until the moisture content is lower than 90ppm, the contents of the comb-like polymer phase change material and the fiber-forming polymer are controlled to be 50wt.% and 50wt.%, were melted and extruded at 190°C respectively, passed through a filter screen and a C-shaped spinneret to obtain fine spinning streams, cooled and dried in an air bath at 25°C, and wound at a winding speed of 800m / min. The raw fibers are obtained, and then processed into long fibers after double drafting, heat setting and drying.

[0041] After inspection, the fineness of the long fiber is 90dtex / 48f, ...

Embodiment 3

[0043] Poly(ethylene-g-maleic anhydride)-g-n-hexacosanol with a grafting degree of 48% is used as a comb-shaped polymer phase change material, and polycaprolactam (intrinsic viscosity number 0.65) is used as a fiber-forming polymer. After the two components are dried until the moisture content is lower than 50ppm, the contents of the comb-like polymer phase change material and the fiber-forming polymer are controlled to be 50wt.% and 50wt.%, respectively, melted and extruded at 240°C, and filtered net, annular spinneret, to obtain fine spinning streams, after cooling and drying in an air bath at 25°C, and winding at a winding speed of 800m / min to obtain primary fibers. Then after double drafting, setting and drying, it is processed into long fibers, and short fibers are obtained after cutting.

[0044] The denier of the short fiber is 3.0dtex, the tensile breaking strength is 3.5cN / dtex, and the elongation at break is 28%. / g; 5% thermal weight loss temperature is 255°C; afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| endothermic temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com