Preparation method of polyacrylonitrile fibres by using protein as modifier

A technology of polyacrylonitrile fiber and polyacrylonitrile, which is applied in the field of preparation of polyacrylonitrile fiber, can solve problems such as cumbersome process parameters, endangering the health of operators, a large amount of waste gas and waste water, etc., to increase economic benefits and improve production Efficiency, ease of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Raw material: silk protein, protein content 90%;

[0040] Polyacrylonitrile, with a viscosity-average molecular weight of 2.0×104, is a copolymer comprising a first monomer, a second monomer and a third monomer, wherein the first monomer is 81.8% by mass of acrylonitrile, and the first The mass percent of the second monomer methyl acrylate is 18%, and the content of the third monomer itaconic acid is 0.2%;

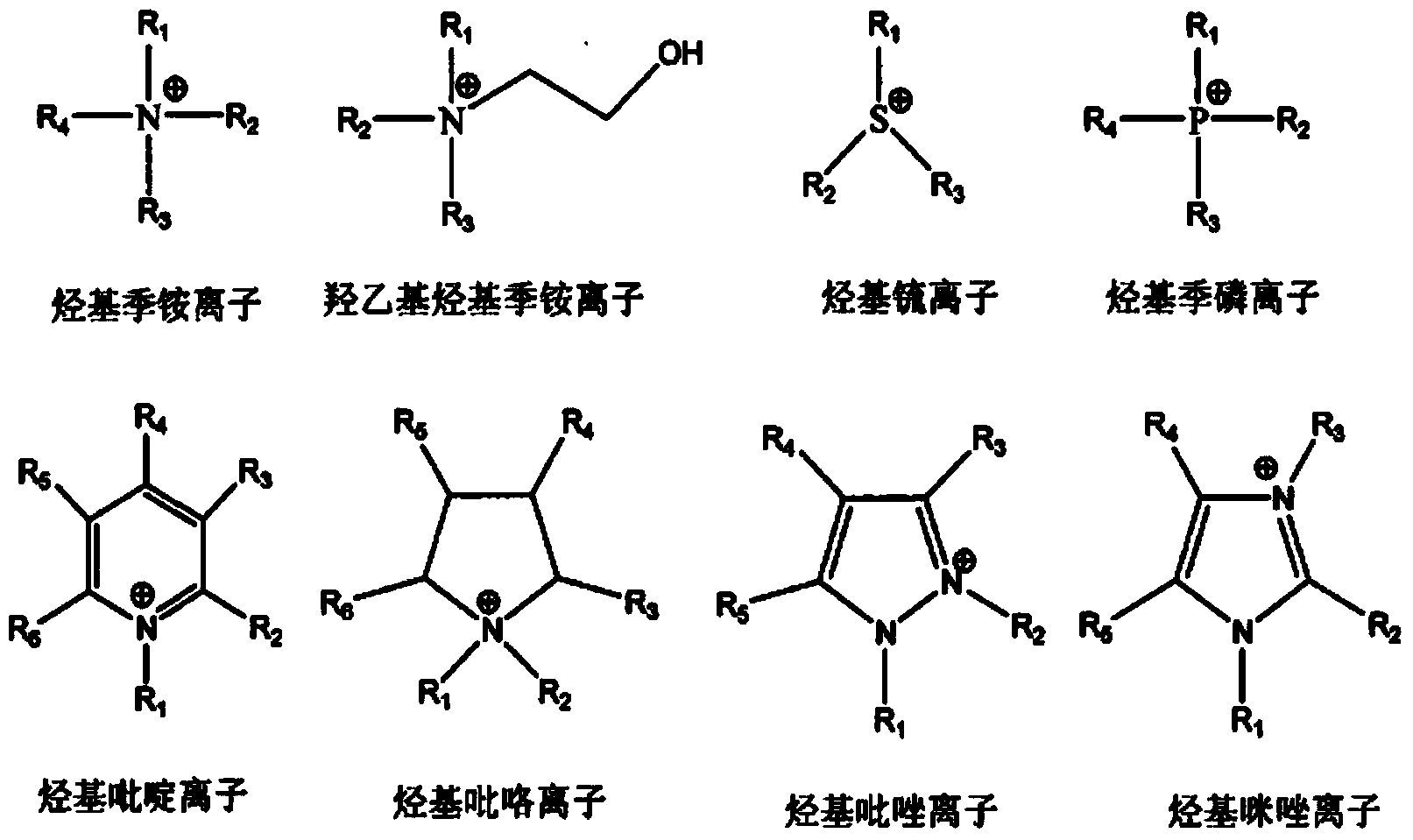

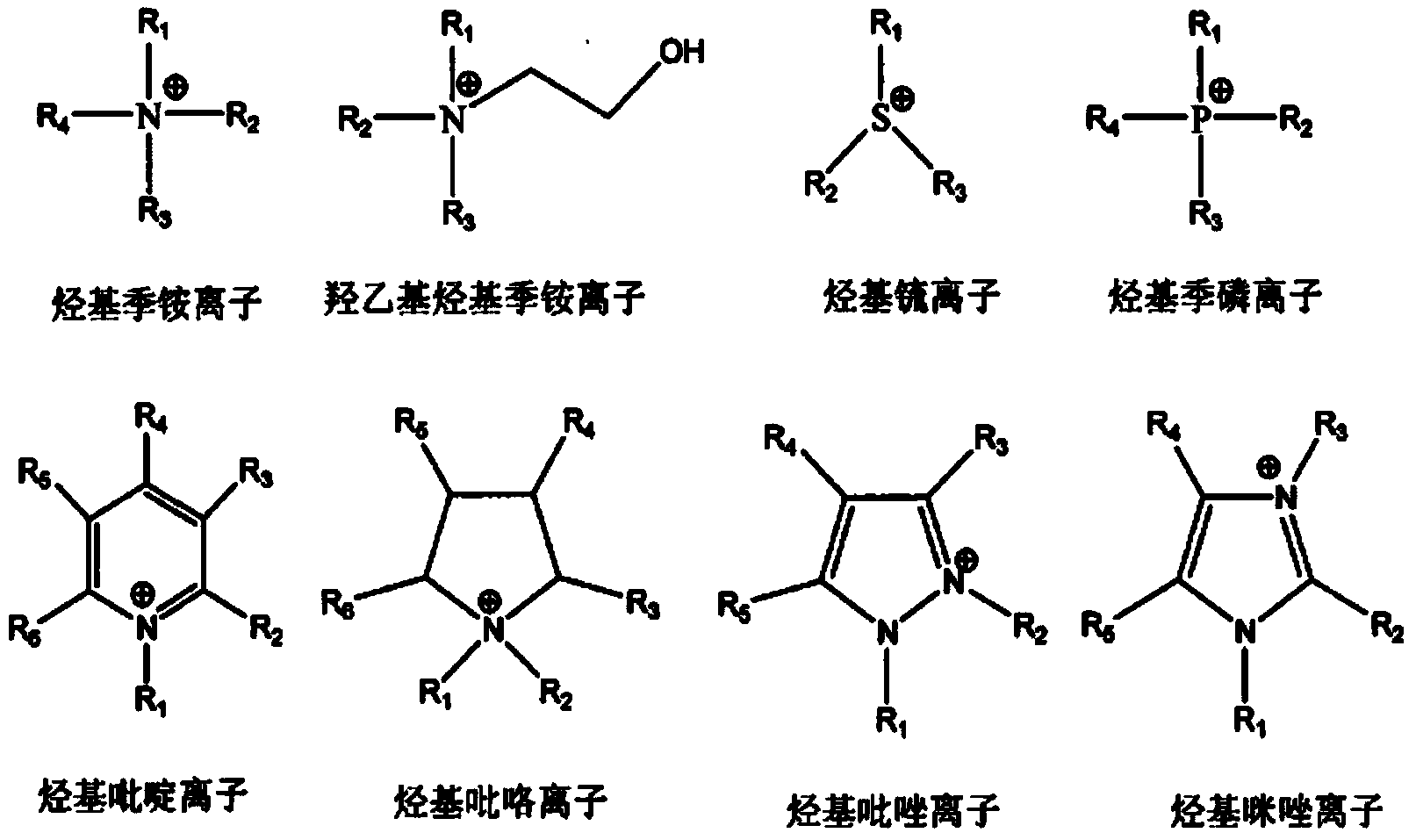

[0041] Ionic liquid, 1-allyl-3-methylimidazolium chloride.

[0042] Mix dry silk protein with a mass percentage of 1% and dry polyacrylonitrile with a mass percentage of 99%, add it to 1-allyl-3-methylimidazolium chloride, and dissolve it at 50°C for 2 hours to obtain a stable Uniform spinning solution, the mass percentage of 1-allyl-3-methylimidazolium chloride in the solution is 95%, the spinning solution is filtered and defoamed at 50°C, extruded through a metering pump and a spinneret, and passed through 1cm layer of humid air, temperature is 5°C, humidity is ...

Embodiment 2

[0044] Raw material: wool protein, protein content 92%;

[0045] Polyacrylonitrile, with a viscosity-average molecular weight of 2.0×105, is a copolymer comprising a first monomer and a second monomer, wherein the content of the first monomer is 90% of acrylonitrile, and the second monomer is methyl methacrylate The content of ester is 10%;

[0046] Ionic liquid, 1-butyl-3-methylimidazolium chloride.

[0047] Mix 20% wool protein with 80% polyacrylonitrile, add 1-butyl-3-methylimidazolium chloride, swell at 30°C for 2 hours, dehydrate, dissolve at 120°C for 1.5 hours, Obtain a stable and uniform spinning solution, the mass percentage of 1-butyl-3-methylimidazolium chloride in the solution is 92%, filter and defoam at 120°C, extrude through a metering pump and a spinneret, and pass through a 2cm wet In the air layer, the temperature is 15°C, the humidity is 80%, enter the coagulation bath at 0°C, the mass percentage of 1-butyl-3-methylimidazolium chloride in the coagulation b...

Embodiment 3

[0049] Raw materials: soybean protein, protein content 94%;

[0050] Polyacrylonitrile, with a viscosity average molecular weight of 5.0×104, is an acrylonitrile homopolymer;

[0051] Ionic liquid: 1-butyl-2-methylpyrazole bromide.

[0052] Mix 1% of dry soybean protein with 99% of 1-butyl-2-methylpyrazole bromide in mass percentage, dissolve at 70°C for 2 hours to obtain solution ①; mix 15% of Mix dry polyacrylonitrile with 85% by mass of 1-butyl-2-methylpyrazole bromide, dissolve at 80°C for 1 hour to obtain solution ②, then mix equal amounts of solution ①②, and stir at 80°C After 0.5 hours to obtain a stable and uniform spinning solution, filter and defoam at 80°C, extrude through a metering pump and a spinneret, pass through a 3cm layer of humid air at a temperature of 15°C and a humidity of 75%, and enter a coagulation bath at 20°C. The mass percent of 1-butyl-2-methylpyrazole bromide in the coagulation bath is 8%, and enters the hot water bath of 50 ℃ through the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com