Eccentric mechanism used on working table of vertical grinder

A technology of vertical grinding machine and eccentric mechanism, which is applied to grinding machines, mechanical equipment, manufacturing tools, etc., can solve the problems of high cost and high dynamic response performance requirements of machine tools, and achieves convenient adjustment of eccentricity, easy accurate control, and large transmission ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

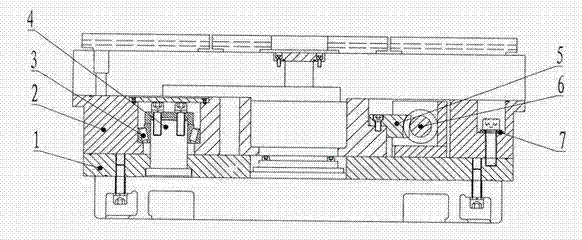

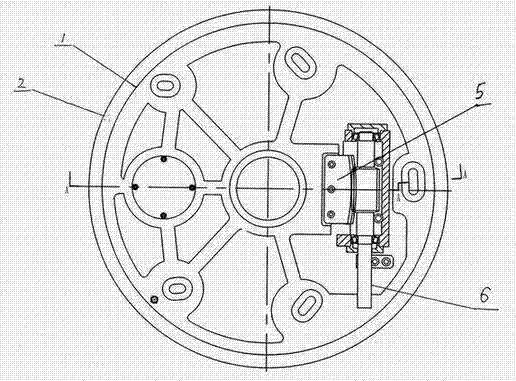

[0007] Embodiments are described in detail in conjunction with the above accompanying drawings, see figure 1 with figure 2 , the rotating shaft 4 is installed on the worktable 1, the bearing 3 is assembled on the rotating shaft, the eccentric turntable 2 is installed on the worktable to cooperate with the outer ring of the bearing, there is a certain distance between the rotation axis of the worktable and the center of the eccentric turntable, and the worm wheel 5 is fixed on the eccentric turntable 2 Inside, the worm 6 is installed on the workbench 1 to mesh with the worm wheel, and the disc spring 7 is installed in the arc groove of the eccentric turntable. The disc spring and the eccentric turntable are fixed on the workbench by screws, and the eccentric turntable is driven by the rotation of the worm. The center makes a swinging motion.

[0008] The worm wheel 5 is driven to rotate by turning the worm 6 , and driven by the worm wheel 5 , the eccentric turntable 2 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com