Numerical control machining method of brake head

A processing method and brake shoe technology, which are applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large workpiece processing deformation, long processing cycle, low processing efficiency, etc., and achieve high processing accuracy, Controllable processing parameters and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail through specific embodiments below.

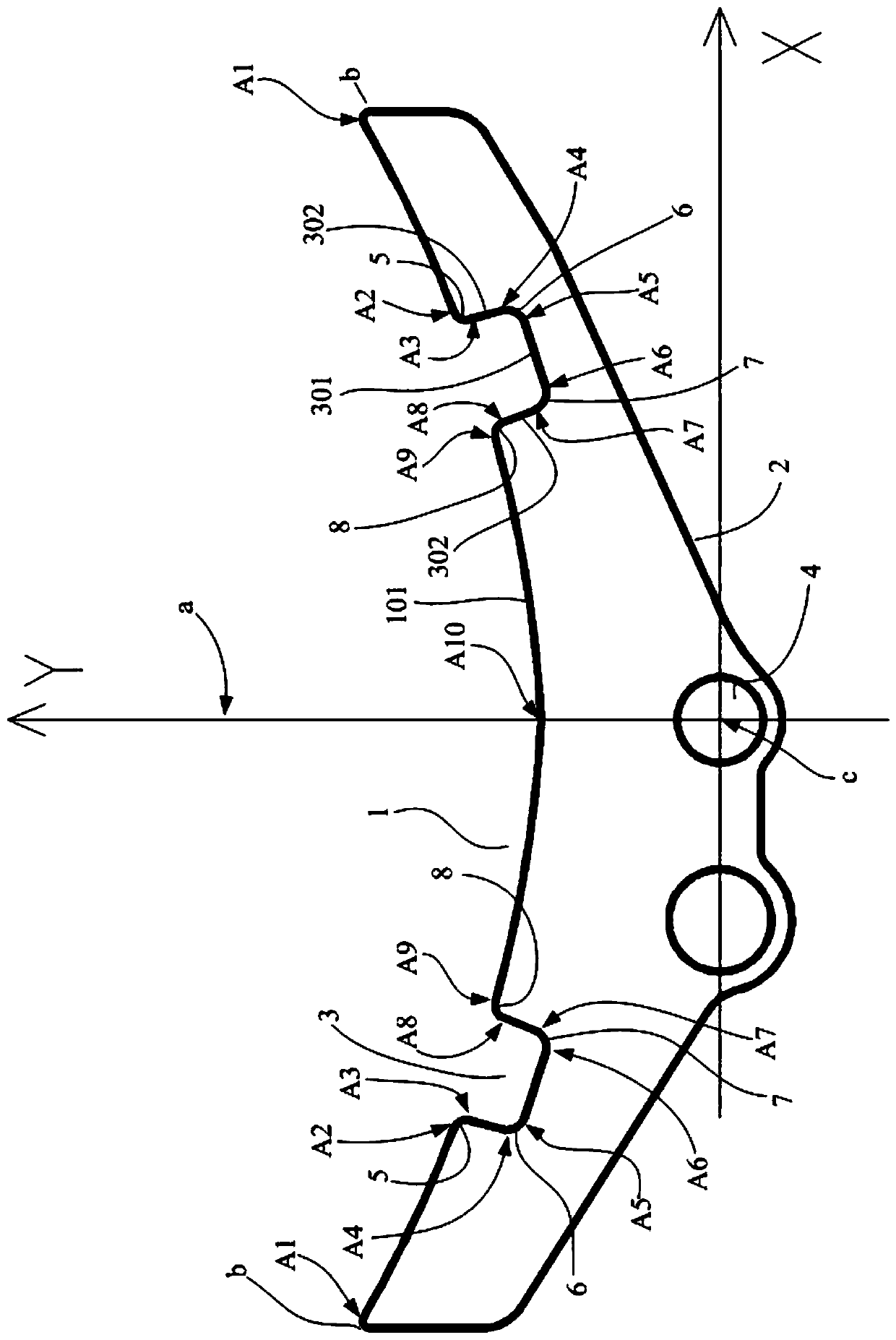

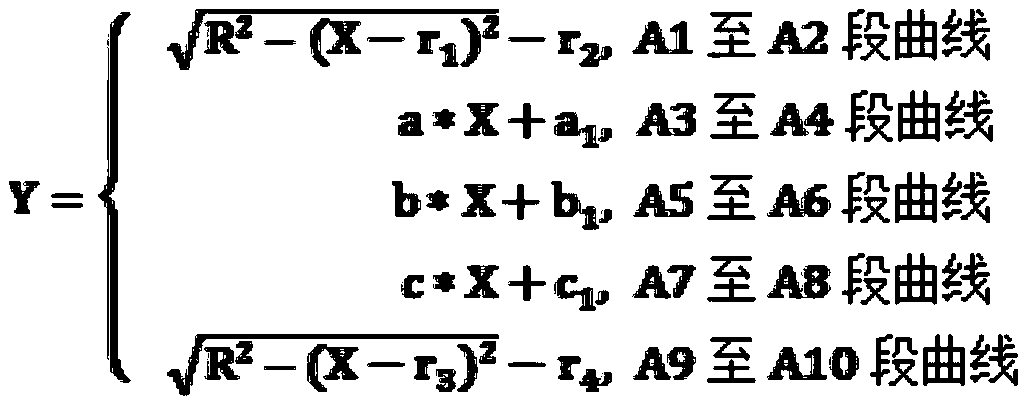

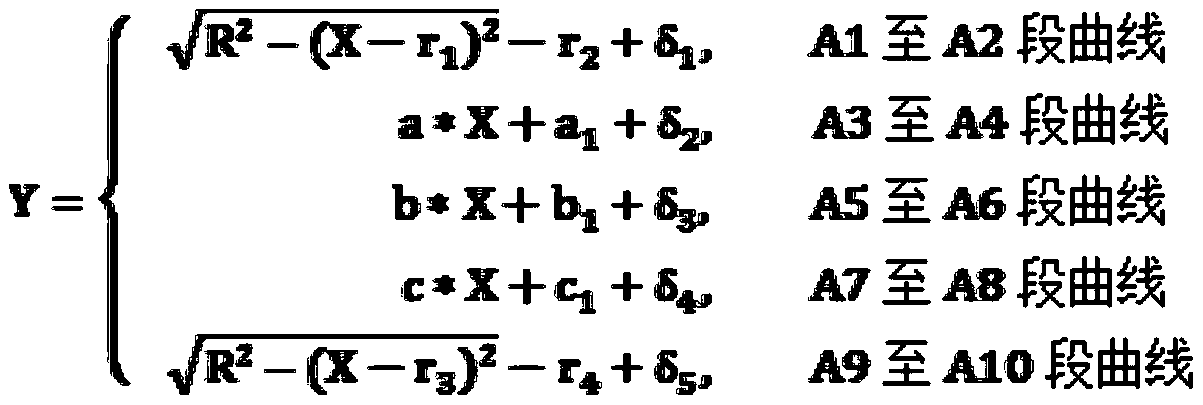

[0018] The numerical control machining method of the brake shoe holder in the embodiment of the present invention is suitable for processing parts with long span structures, especially double brake shoe holders. The method includes the following steps:

[0019] Step a), in the automatic programming software, the model of the brake shoe holder is compiled to generate a numerical control machining program, and the automatic programming software is to generate a language that can be recognized by the numerical control processing equipment for the three-dimensional solid model to drive the machine tool to process the workpiece computer software, the model of the brake shoe support is a three-dimensional model established in the three-dimensional software with the shape and size in the design drawing, and then the numerical control machining program of the brake shoe support is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com