An electric spindle supported by a five-degree-of-freedom alternating current six-pole active magnetic bearing

A technology of active magnetic bearing and degrees of freedom, which is applied to holding devices, electrical components, and electromechanical devices using magnetic attraction or thrust. Control, good for speed, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below with reference to the accompanying drawings, but the protection scope of the present invention is not limited thereto.

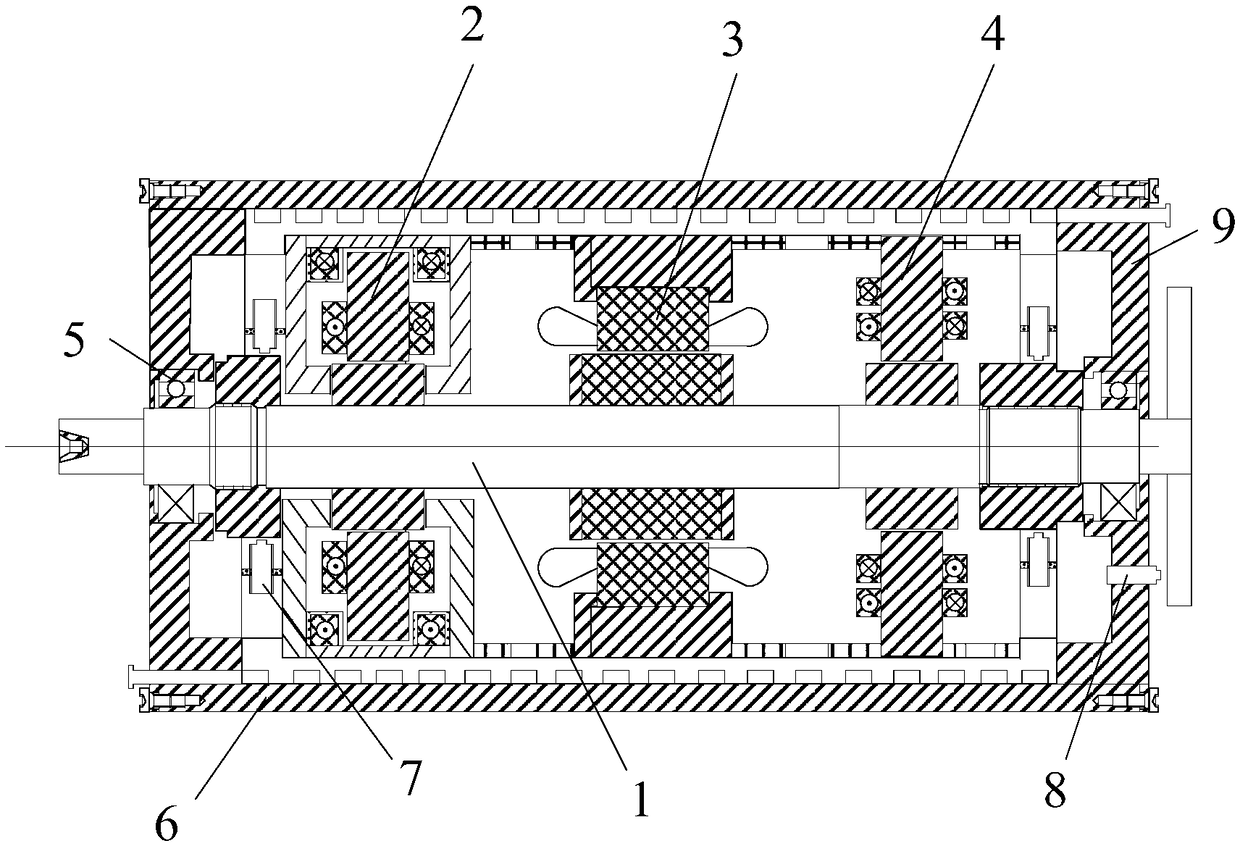

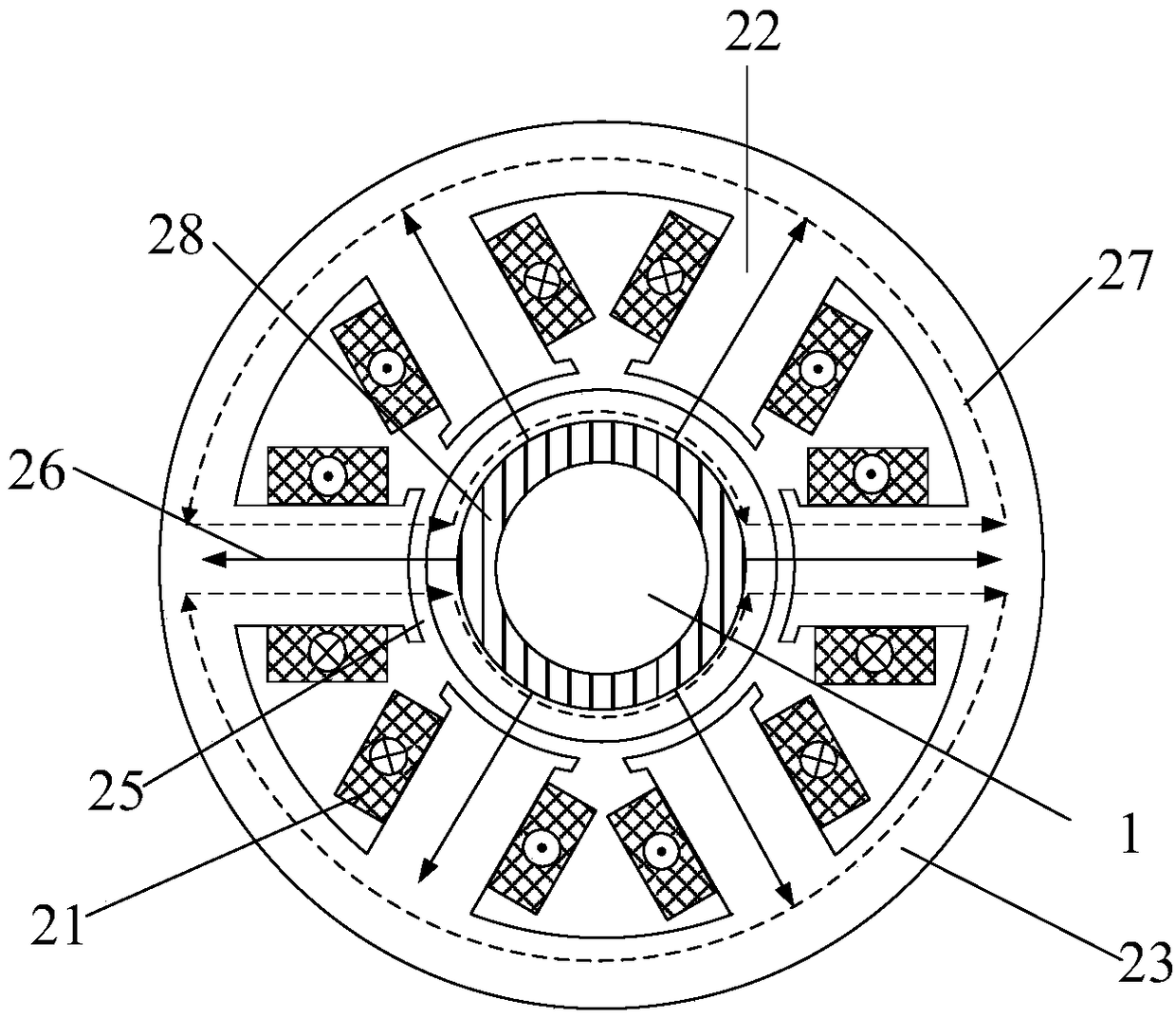

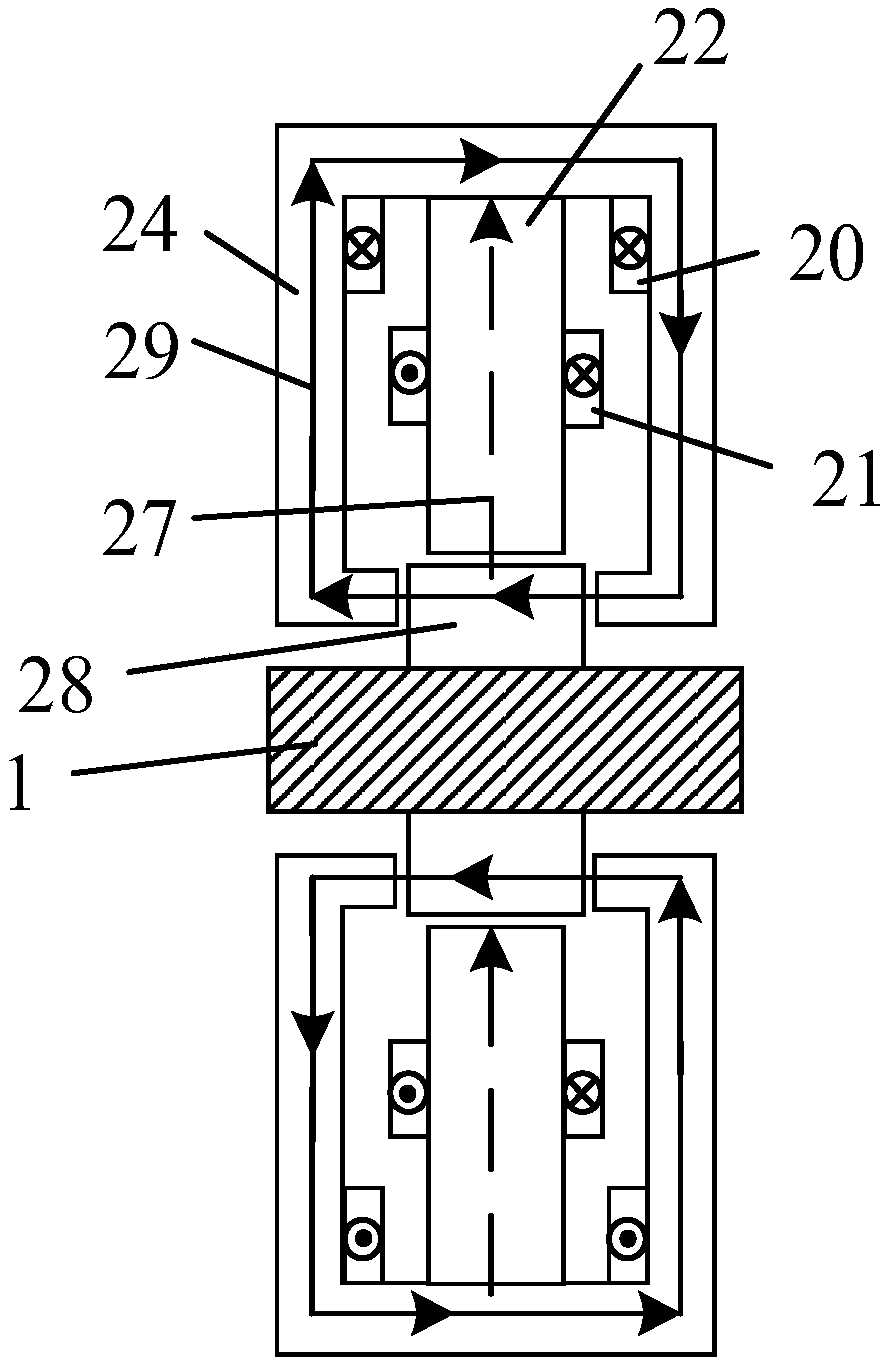

[0021] like figure 1 As shown, an electric spindle supported by a five-degree-of-freedom AC six-pole active magnetic bearing includes a rotating shaft 1, a six-pole three-degree-of-freedom active magnetic bearing 2, a high-speed spindle motor 3, a six-pole two-degree-of-freedom active magnetic bearing 4, and an auxiliary bearing 5 , steel cylinder 6, radial sensor 7 and axial sensor 8. The outside is wrapped by a steel cylinder 6. The steel cylinder 6 is composed of a steel cylinder outer sleeve and a steel cylinder inner sleeve. Between the steel cylinder outer sleeve and the steel cylinder inner sleeve, there is a spiral channel for water cooling and heat dissipation of the system; An end cover 9 is connected, and a rotating shaft 1 is coaxially installed at the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com