Air-cooled liquid-cooled combined thermally superconducting plate radiator

A technology of thermal superconductivity and heat sink, applied in the field of heat transfer, can solve the problems that aluminum heat sinks cannot meet the heat dissipation requirements of high heat flux density and high power modules, and achieve long-term stable operation, improved heat dissipation capacity, and high heat conduction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

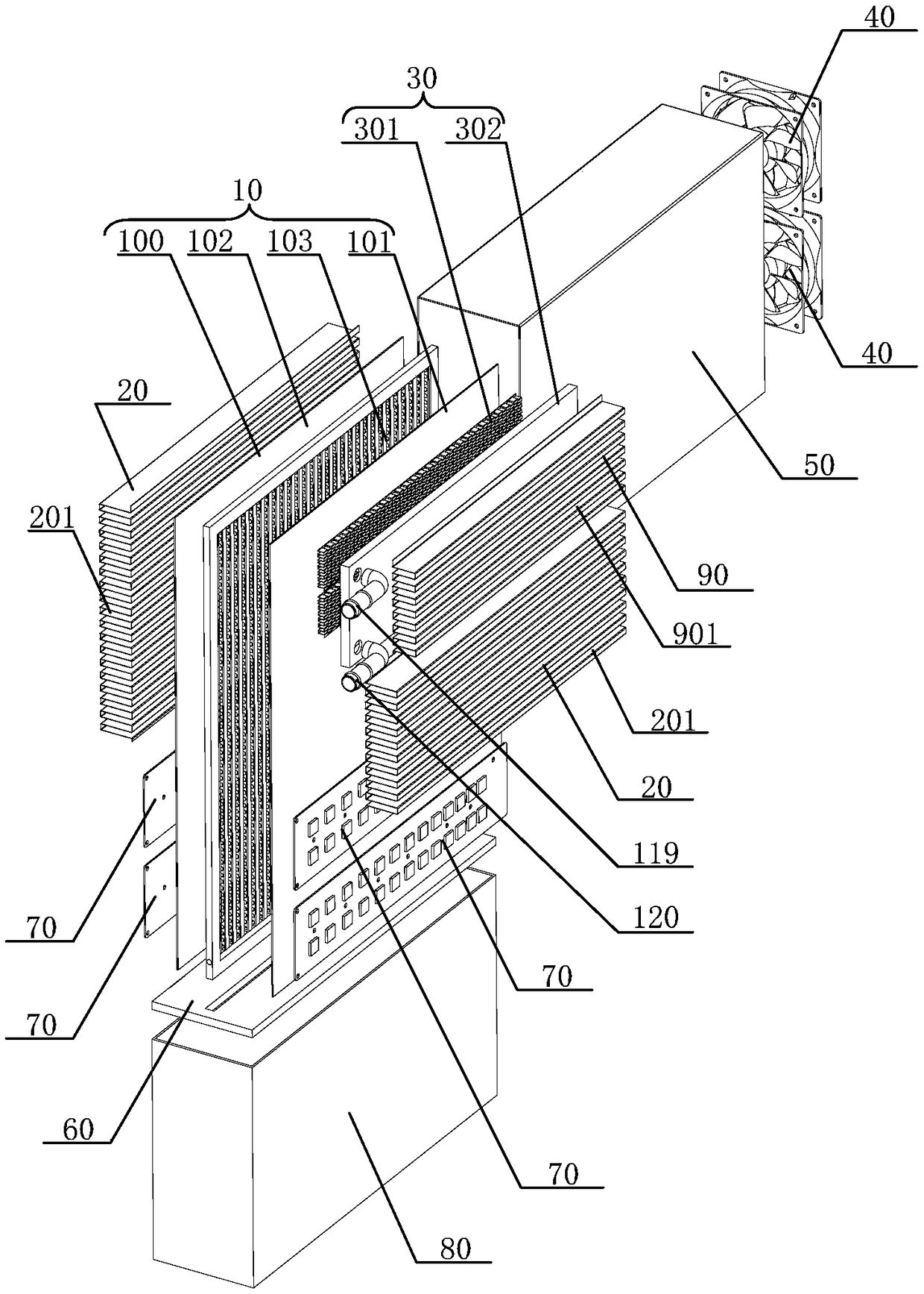

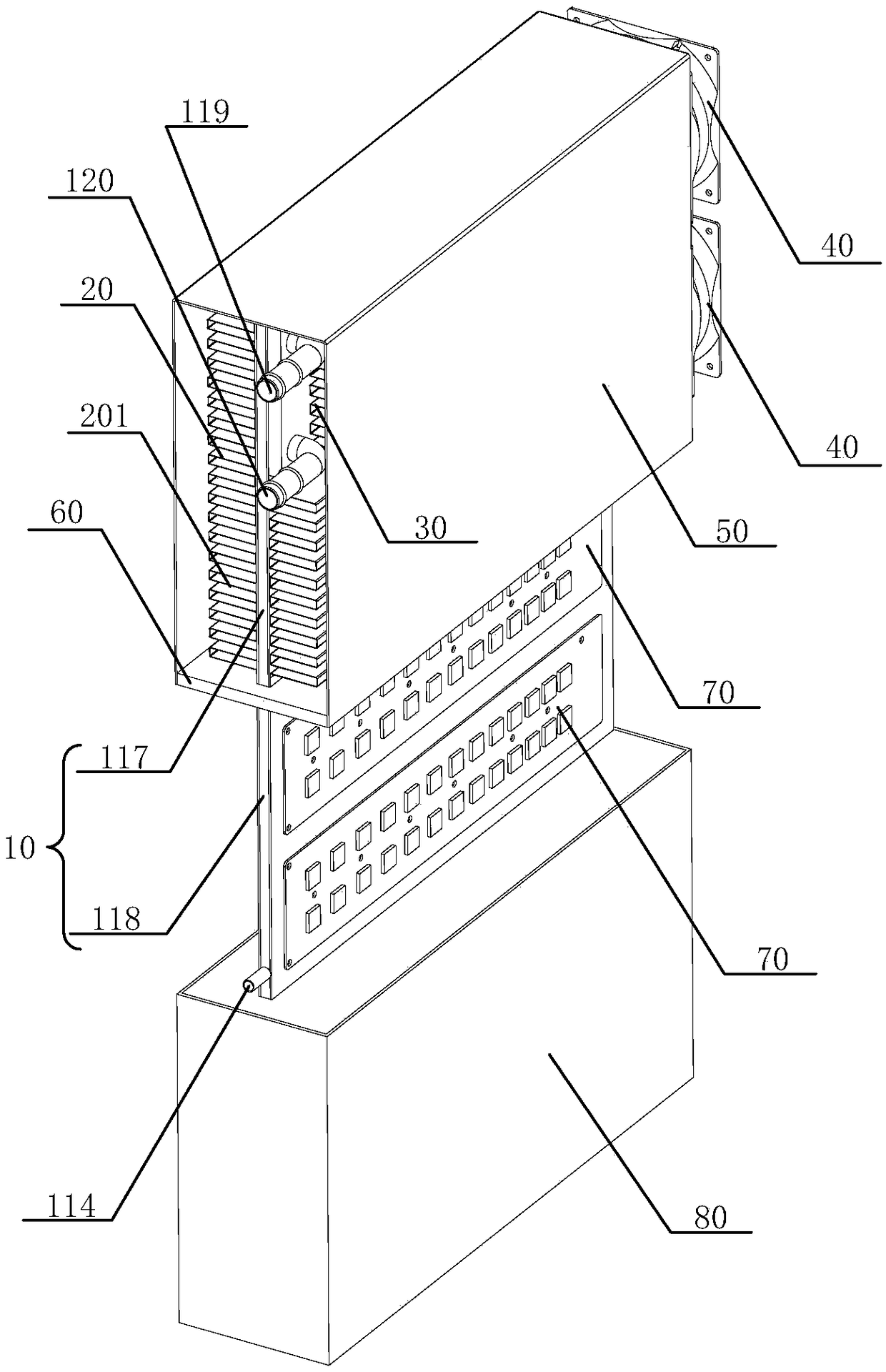

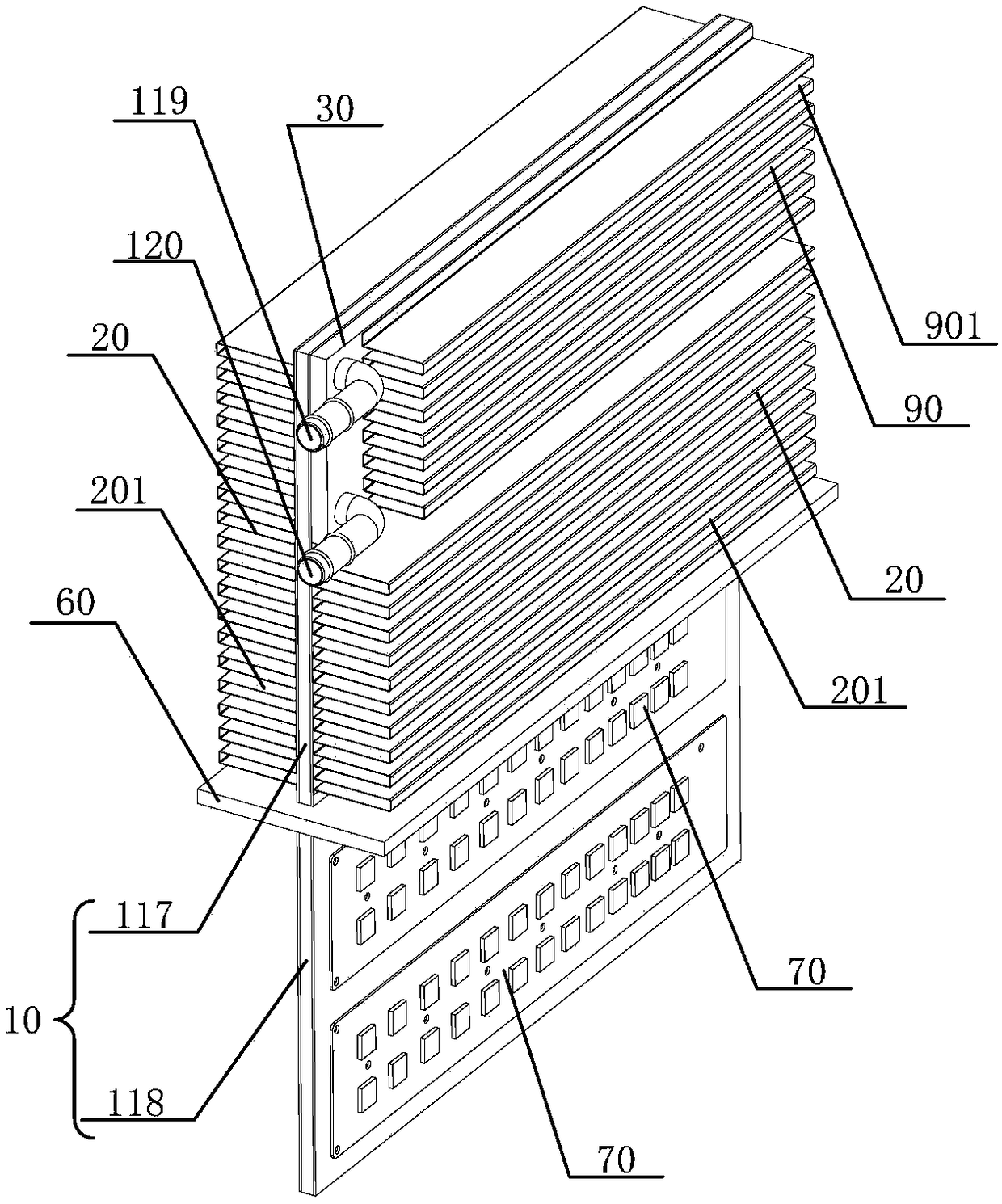

[0124] see Figure 1 to Figure 12 , the present invention provides an air-cooled and liquid-cooled combined thermal superconducting plate radiator, the air-cooled and liquid-cooled combined thermal superconducting plate radiator includes: a thermal superconducting plate 10, the thermal superconducting plate 10 is formed There are interconnected sealed passages 106, and the sealed passages 106 are filled with heat transfer working medium 1061; a liquid cooling radiator 30, the liquid cooling radiator 30 is located on the surface of the thermal superconducting plate 10, and the liquid cooling A liquid channel is formed in the radiator 30, and the liquid cooling radiator 30 is provided with a liquid inlet 3023 and a liquid outlet 3024 communicating with the liquid channel; the first cooling fin 20, the first cooling fin The sheet 20 is located on at least one surface of the thermal superconducting plate 10, and a plurality of first heat dissipation channels 201 arranged in parall...

Embodiment 2

[0152] Please combine Figure 1 to Figure 20 refer to Figure 21 to Figure 23 , this embodiment also provides an air-cooled and liquid-cooled combined thermal superconducting plate radiator, the structure of the air-cooled and liquid-cooled combined thermal superconducting plate radiator described in this embodiment is the same as that described in Embodiment 1 The structure of the air-cooled and liquid-cooled combined thermal superconducting plate radiator is roughly the same, the difference between the two is that the specific structure of the thermal superconducting plate 10 is different: the thermal superconducting plate 10 described in this embodiment is compared to the embodiment The thermal superconducting plate 10 described in Example 1 is provided with at least one reserved gap 1035 in the second deflector 103, and at the same time, the thermal superconducting plate 10 also includes at least one spacer 109 or the first At least one punching boss 113 is disposed on th...

Embodiment 3

[0157] Please combine Figure 1 to Figure 20 refer to Figure 24 to Figure 25, this embodiment also provides an air-cooled and liquid-cooled combined thermal superconducting plate radiator, the structure of the air-cooled and liquid-cooled combined thermal superconducting plate radiator described in this embodiment is the same as that described in Embodiment 1 The structure of the air-cooled and liquid-cooled combined thermal superconducting plate radiator is roughly the same, the difference between the two is that the structure of the thermal superconducting plate 10 is different: the thermal superconducting plate 10 described in the first embodiment The number of the two deflectors 103 is one, and the number of the second deflectors 103 described in this embodiment is at least two, and there is a gap between the adjacent second deflectors 103, so as to The first balance passage 107 of the heat transfer working medium 1061 is formed between the adjacent second guide plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com