A layered ignition gas injection string

A gas injection pipe and gas injection technology, which is applied in wellbore/well components, production fluid, sealing/packing, etc., can solve the problem that fire-flooding wells cannot achieve multi-layer ignition and gas injection separately, and improve the fire-flooding effect. , Improve work efficiency and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

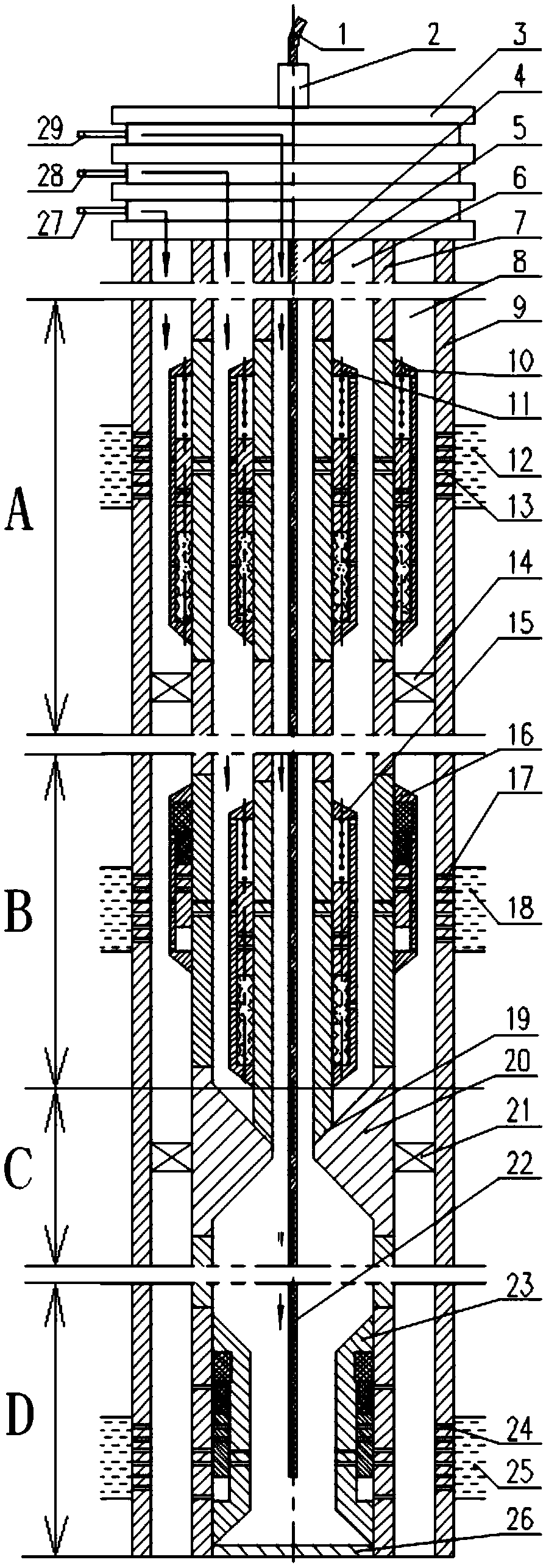

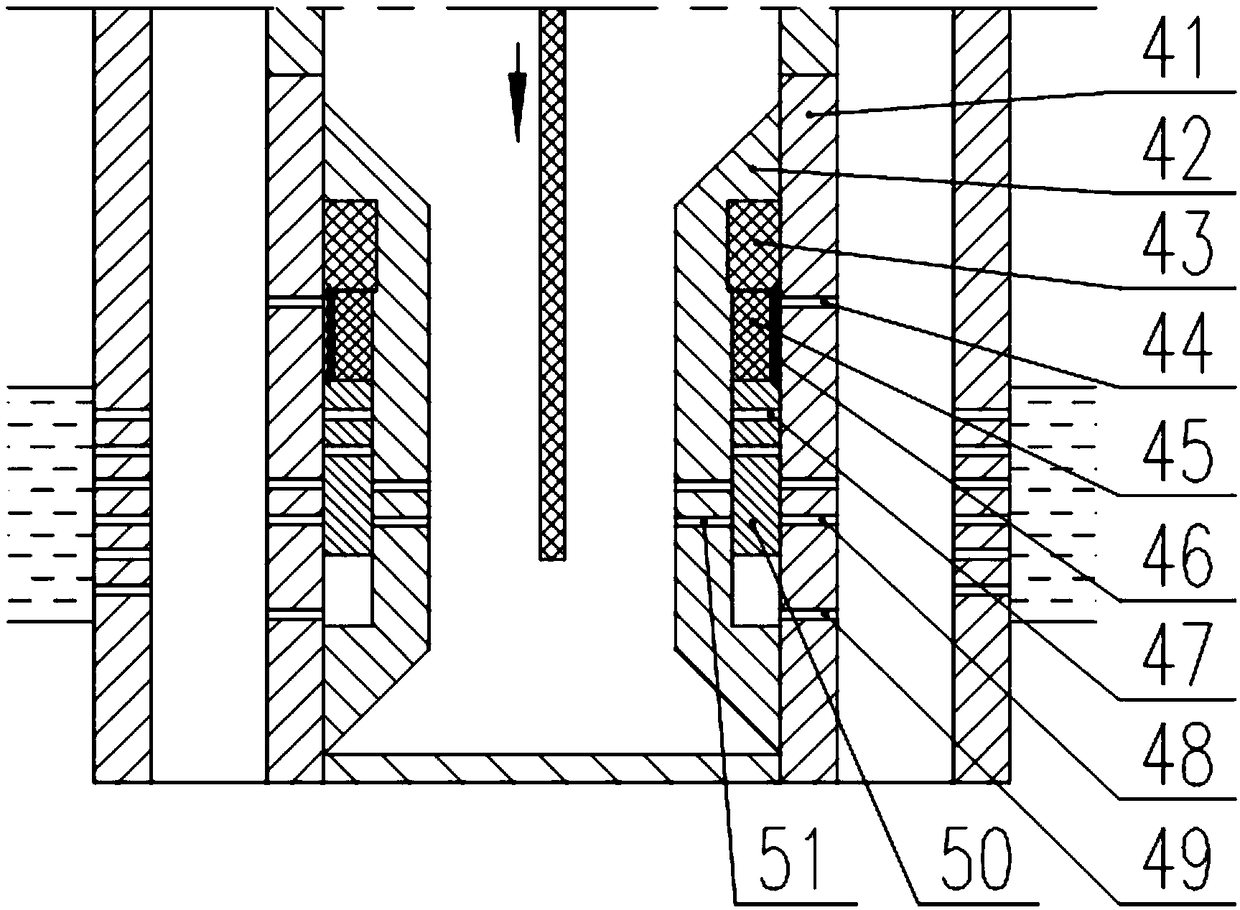

Embodiment 1

[0019] A layered ignition gas injection pipe string, including an inner pipe string 5 and an outer pipe string 7, both of which are in an upright state, the outer pipe string 7 is sleeved outside the inner pipe string 5, and the outer pipe string An annular space is formed between 7 and the inner pipe string 5, and the outer pipe string 7 contains the first gas injection valve 10, the fourth gas injection valve 16 and the fifth gas injection valve 23 arranged sequentially from top to bottom, and the inner pipe string 5 It contains the second gas injection valve 11 and the third gas injection valve 15 arranged in sequence from top to bottom, the position of the first gas injection valve 10 corresponds to the position of the second gas injection valve 11, and the position of the third gas injection valve 15 The position corresponds to the position of the fourth gas injection valve 16; the first gas injection valve 10, the second gas injection valve 11 and the third gas injection ...

Embodiment 2

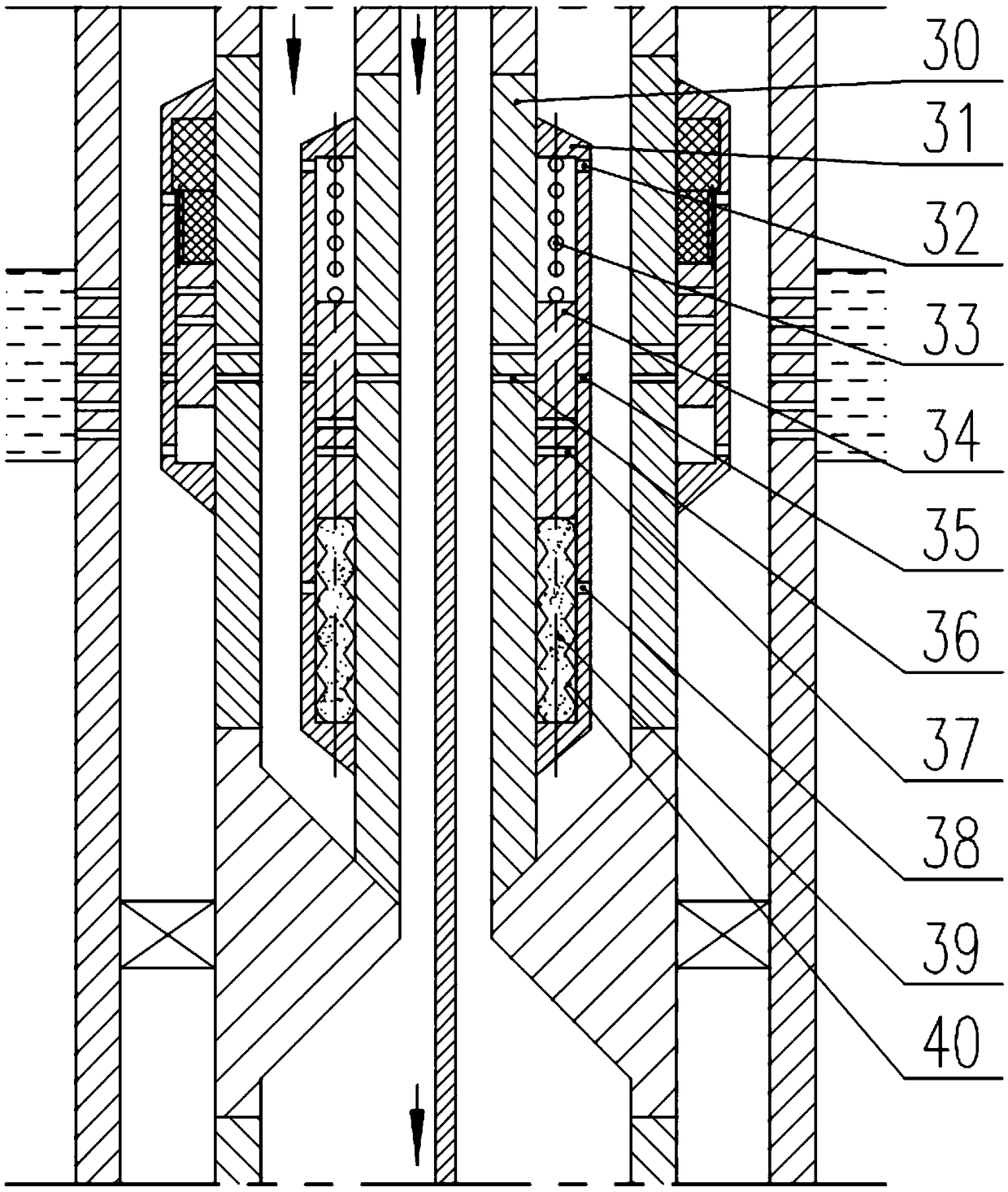

[0033] The layered ignition gas injection string introduced in Example 1 is mainly for ignition and gas injection of three oil layers. This embodiment introduces a layered ignition gas injection string suitable for ignition and gas injection of two oil layers.

[0034] A layered ignition gas injection pipe string, comprising an inner pipe string 5 and an outer pipe string 7, the outer pipe string 7 is sleeved outside the inner pipe string 5, an annular space is formed between the outer pipe string 7 and the inner pipe string 5, and the outer pipe string 7 The column 7 contains the first gas injection valve 10 and the fourth gas injection valve 16 arranged in sequence from top to bottom, and the inner pipe column 5 contains the second gas injection valve 11 and the third gas injection valve arranged in sequence from top to bottom 15. The position of the first gas injection valve 10 corresponds to the position of the second gas injection valve 11, and the position of the third ga...

Embodiment 3

[0038] The layered ignition gas injection string introduced in Example 1 is mainly for ignition and gas injection of three oil layers. This embodiment introduces a layered ignition gas injection string suitable for ignition and gas injection of two oil layers.

[0039] A layered ignition gas injection pipe string, comprising an inner pipe string 5 and an outer pipe string 7, the outer pipe string 7 is sleeved outside the inner pipe string 5, an annular space is formed between the outer pipe string 7 and the inner pipe string 5, and the outer pipe string 7 The column 7 contains the fourth gas injection valve 16 and the fifth gas injection valve 23 arranged sequentially from top to bottom, and the inner pipe column 5 contains the third gas injection valve 15, the position of the third gas injection valve 15 and the fourth gas injection valve. The position of the gas valve 16 is corresponding; the third gas injection valve 15 is a temperature-controlled gas injection valve that ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com