Reinforcement cage feeding method of long auger drilling press-grouting pile

A technology of long helical drilling and reinforcement cage, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of inability to reach the preset position and easy to be stuck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further illustrated below by specific examples.

[0018] A pile foundation project adopts long auger bored grouting piles, the natural floor elevation is -0.5m, and the pile top elevation is -1.9m; the following methods are used for construction:

[0019] 1. Preliminary drilling operation: drill to the design depth first, then lift the drill 200mm, pump in the concrete, and then lift the drill while pumping in the concrete. Among them, the concrete slump must be greater than 200mm to facilitate insertion of the reinforcement cage;

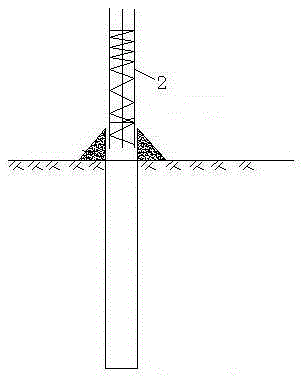

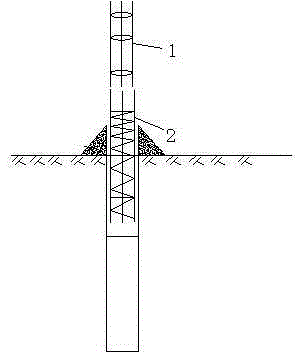

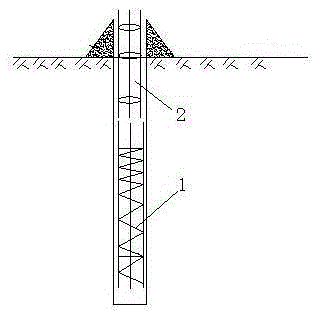

[0020] 2. If Figure 1~Figure 4 As shown, adopting the cage column 1 to carry out the reinforcement cage feeding operation includes the following steps:

[0021] Step 1. The pushing device includes vertical rods and hoops. There are multiple vertical rods arranged vertically, and the hoops surround the vertical rods to form a cage-shaped column 1;

[0022] Step 2. Inject concrete into the pile hole to the elevati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com