Anchoring ball type casing truing unit and truing method thereof

A ball shaping and shaping device technology, which is applied in the direction of earthwork drilling, wellbore/well parts, etc., can solve the problems of unstable state of the pipe string, long repair operation time, increased operation cost, etc., achieve shortened construction period, simple structure, The effect of reducing construction work costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

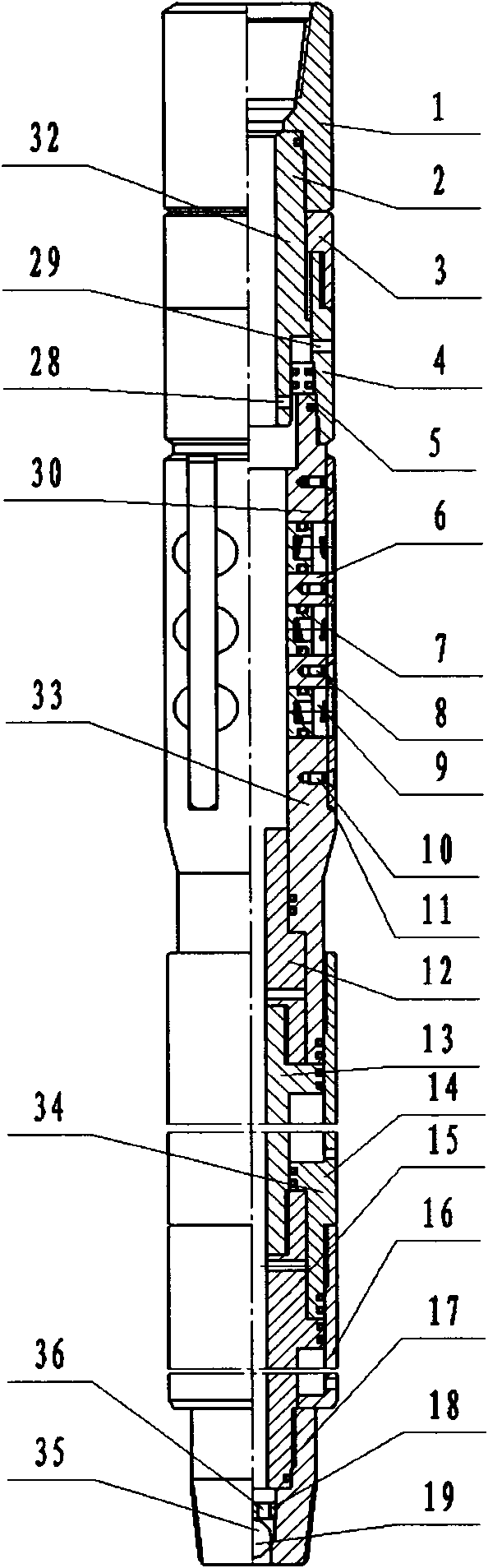

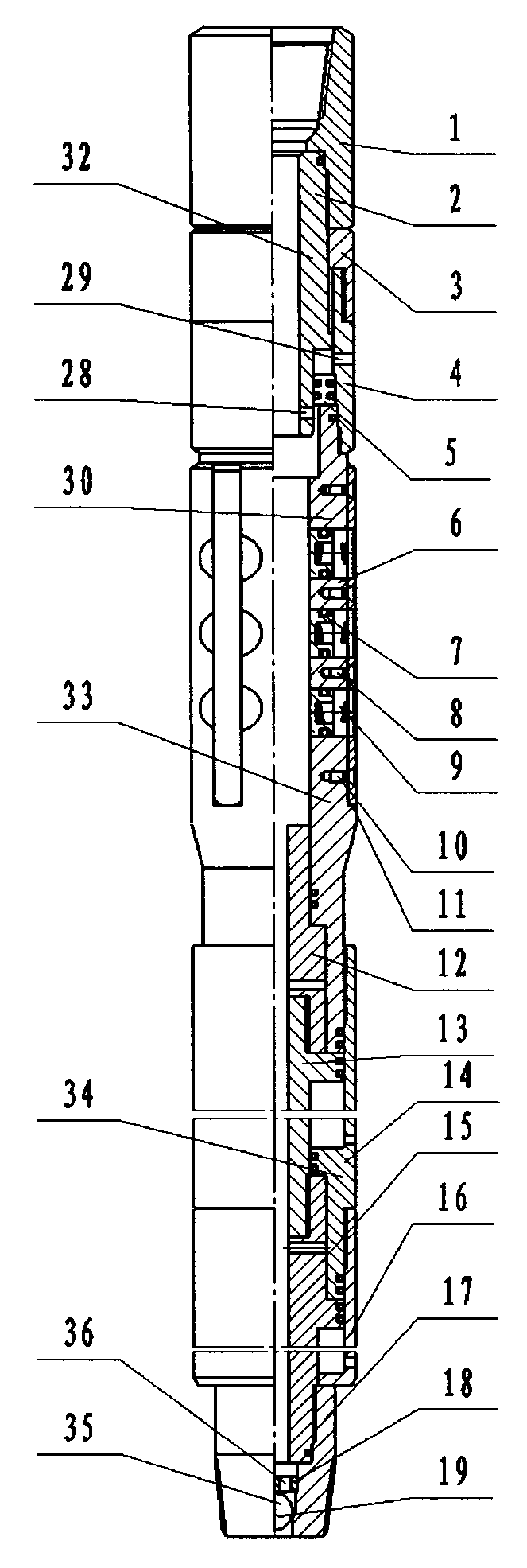

[0020] Anchored ball casing shaping device comprises anchor 30 (see attached figure 1 ) and ball shaper 31 (see attached figure 2 ), the lower end of the anchor 30 is fixedly connected with the upper end of the ball shaper 31; or the anchor 30, the drill collar, and the ball shaper 31 are fixedly connected in turn from top to bottom, and the length of the inserted drill collar is according to the It depends on the needs of the shaping operation well.

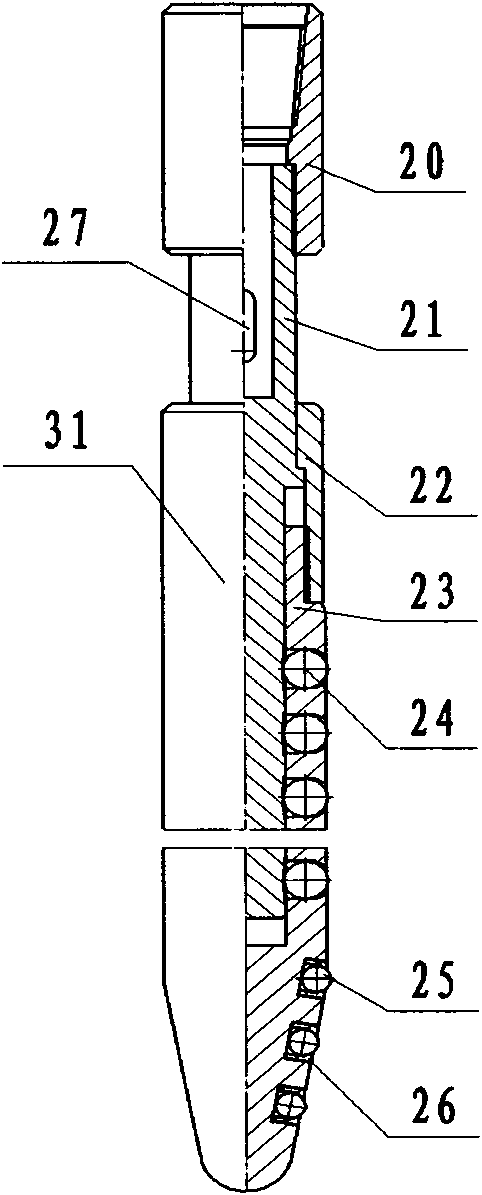

[0021] The ball shaper 31 includes an upper joint 20 , a mandrel 21 , a tapered sleeve 23 and a connecting sleeve 22 . The upper end of the mandrel 21 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com