A kind of acidification method of recoverable instant thickening acid

A technology of thickening acid and instant dissolving, which is applied in the direction of chemical instruments and methods, earth drilling and drilling compositions, etc. It can solve the problems of long thickening time of thickened acid and cannot be recycled and reused, so as to reduce construction work Low cost, reduced overall cost, and fast thickening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

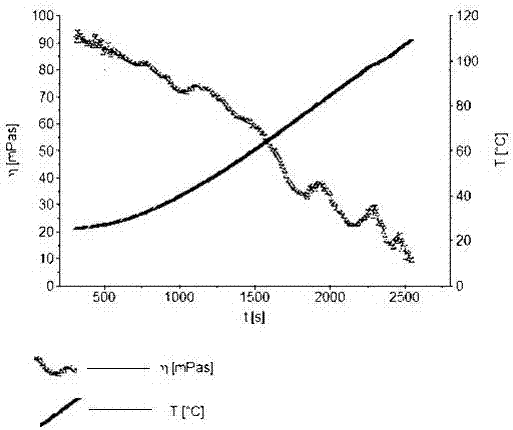

Image

Examples

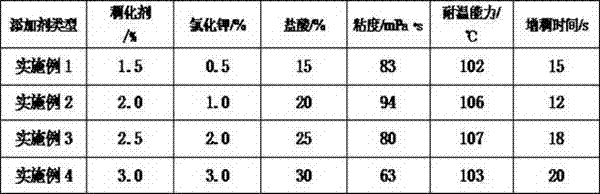

Embodiment 1

[0034] The present embodiment provides a kind of acidification method of recyclable instant thickened acid, comprising the steps of:

[0035] a. Pump the thickener, potassium chloride and hydrochloric acid solution together into the sand mixer and mix directly to form recyclable instant thickened acid;

[0036] The recyclable instant thickening acid is prepared from the following components according to the following mass component ratios:

[0037] Thickener: 1.5 parts;

[0038] Potassium chloride: 0.5 parts;

[0039] Hydrochloric acid solution: 100 parts.

[0040] The above thickener is a mixture of 55% N-lauroyl-N'-hydroxyethyl-N'-carboxypropyl ethylenediamine propionate or its derivatives, 8% ethanol and 37% water by mass ratio .

[0041] The mass concentration of the above-mentioned hydrochloric acid solution is 15%.

[0042] b. At a temperature of 90°C, acidify the recyclable instant-dissolved thickened acid-fractured intake well formation mixed in step a;

[0043] ...

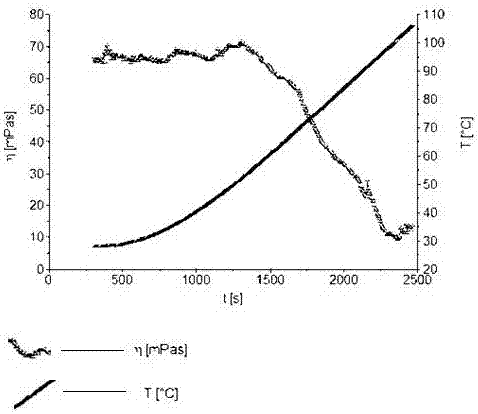

Embodiment 2

[0052] The present embodiment provides a kind of acidification method of recyclable instant thickened acid, comprising the steps of:

[0053] a. Pump the thickener, potassium chloride and hydrochloric acid solution together into the sand mixer and mix directly to form recyclable instant thickened acid;

[0054] The recyclable instant thickening acid is prepared from the following components according to the following mass component ratios:

[0055] Thickener: 2 parts;

[0056] Potassium chloride: 1 part;

[0057] Hydrochloric acid solution: 100 parts.

[0058] The thickener is a mixture of 48% N-lauroyl-N'-hydroxyethyl-N'-carboxypropyl ethylenediamine propionate or its derivatives, 10% ethanol and 42% water by mass ratio.

[0059] The mass concentration of hydrochloric acid solution is 20%.

[0060] b. At a temperature of 90°C, acidify the recyclable instant-dissolved thickened acid-fractured intake well formation mixed in step a;

[0061] c. Shut down the well for 30 min...

Embodiment 3

[0071] The present embodiment provides a kind of acidification method of recyclable instant thickened acid, comprising the steps of:

[0072] a. Pump the thickener, potassium chloride and hydrochloric acid solution together into the sand mixer and mix directly to form recyclable instant thickened acid;

[0073] The recyclable instant thickening acid is prepared from the following components according to the following mass component ratios:

[0074] Thickener: 2.5 parts;

[0075] Potassium chloride: 2 parts;

[0076] Hydrochloric acid solution: 100 parts.

[0077] The thickener is a mixture of 63% N-lauroyl-N'-hydroxyethyl-N'-carboxypropyl ethylenediamine propionate or its derivatives, 6% ethanol and 31% water by mass ratio.

[0078] The mass concentration of hydrochloric acid solution is 25%.

[0079] b. At a temperature of 100°C, perform acidizing construction on the recyclable instant thickened acid fracturing inlet well formation mixed in step a;

[0080] c. Shut down ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com