Bent anchor cable yielding top beam and construction method

A technology for pressing roof beams and anchor cables, which is applied in the field of anchor cables, can solve problems such as low active yielding capacity, insufficient elongation of anchor cables, failure of support systems, etc., achieve low labor intensity, improve load-bearing positioning operation capacity, and load-carrying capacity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

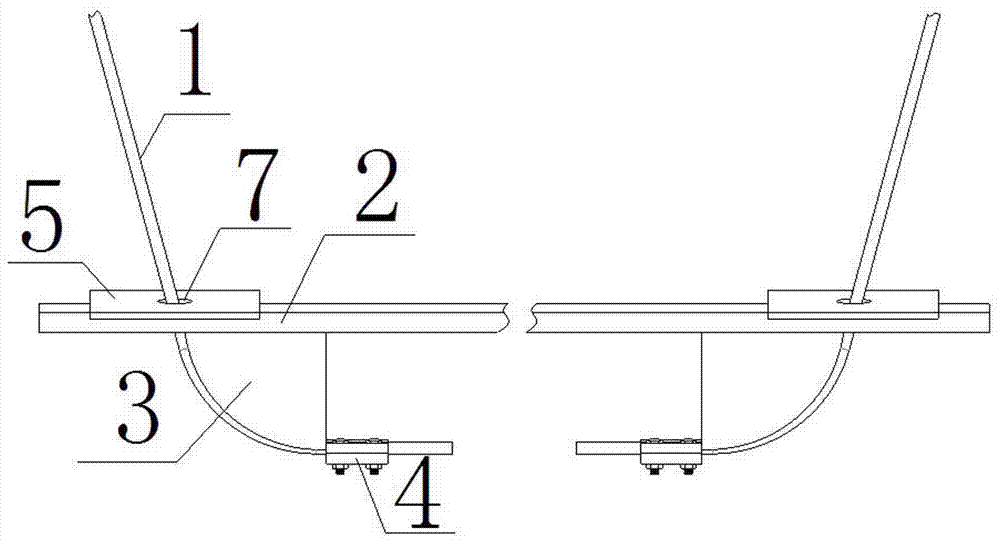

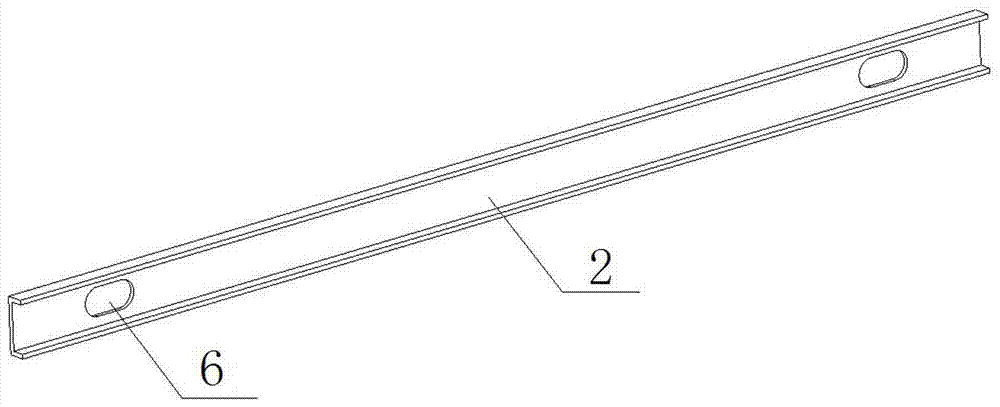

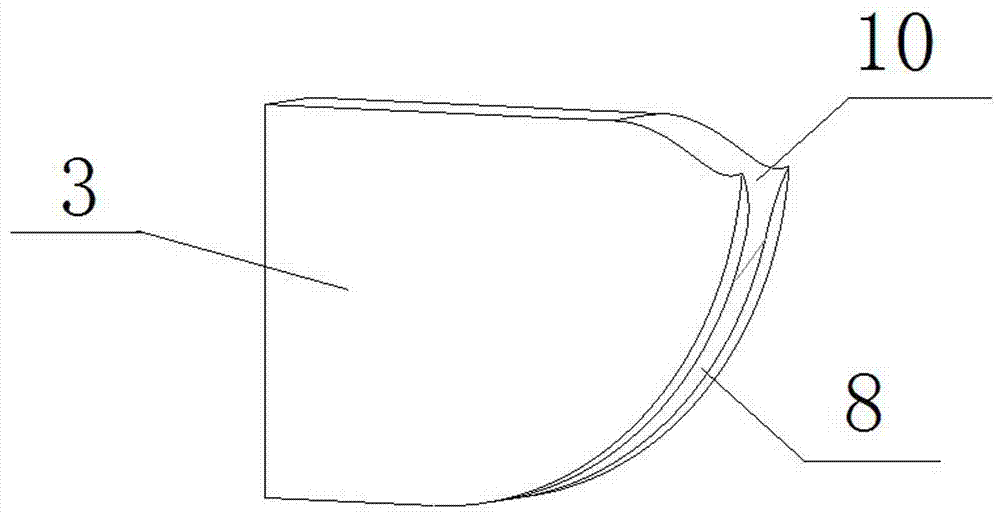

[0028] Such as figure 1 - As shown in -8, a kind of curved anchor cable yielding top beam includes cable body 1, cross beam 2, anchor cable guide plate 3, friction fastening device 4 and tray 5, and cross beam 2 is a groove with a "冂" font in cross section Two positioning holes 6 are evenly distributed on the upper end surface of the beam 2, and the positioning holes 6 are symmetrically distributed at both ends of the beam 2 with the center line of the beam 2, and the axis of the positioning hole 6 is perpendicular to and intersects with the axis of the beam 2, and the cable body 1 has two The ends of which are respectively connected to the beam 2 through the positioning holes 6. The cable body 1 is located at the position of the lower end surface of the beam 2 by 1 / 10-1 / 3 of the length of the cable body 1, and is connected to the beam through the anchor cable guide plate 3 and the friction fastening device 4. 2. The lower end faces are connected to each other. The upper end f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com