Slurry shield split launching construction method for water-rich sandy gravel stratum

A mud-water shield, split-start technology, applied in the direction of earth drilling, underground chambers, shaft equipment, etc., can solve the problems of inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Step A, the door is sealed and the warehouse is built.

[0114] A1. Apply grease to the portal brush, that is, before the shield tunnel is jacked up, apply the portal brush Ⅰ7 and portal brush Ⅱ8 with shield tail grease. Preferably, use hand-applied shield tail grease, and let the grease cover every steel wire as much as possible to ensure the sealing of the hole brush.

[0115] A2. The hole is broken, and the shield cutter head is driven to the face of the tunnel, that is:

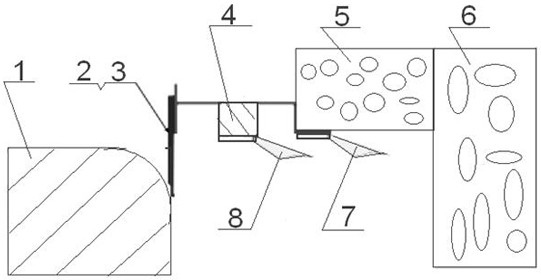

[0116] According to the length of the short sleeve 4 (70cm) and the length of the shield cutter head 1 (92cm), the thickness of the ground connection wall 6 at the entrance is determined to be 70cm;

[0117] After the hole is broken, the shield is jacked into the short sleeve 4;

[0118] After the jacking of the shield machine is completed, the distance between the shield cutterhead 1 and the ground wall 6 is 5 cm, and the root of the cutterhead leaves the shield tail brush inside the short sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com