Hole repairing construction machine for polyethylene anti corrosive coating of metallic tube and construction method thereof

A technology for metal pipelines and construction tools, which is applied in the direction of pipeline anticorrosion/rust protection, pipeline protection, pipe components, etc. It can solve the problems of environmental damage, high cost, limited pressure, etc., and achieve improved bonding strength, good construction quality, soft inner surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

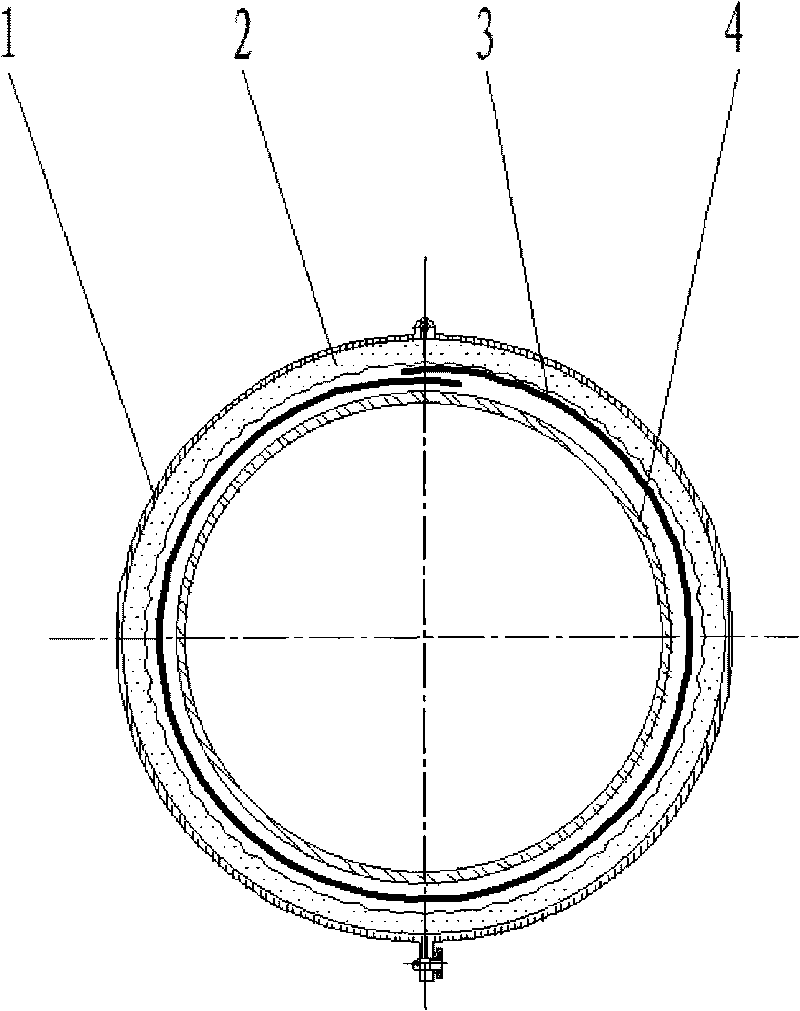

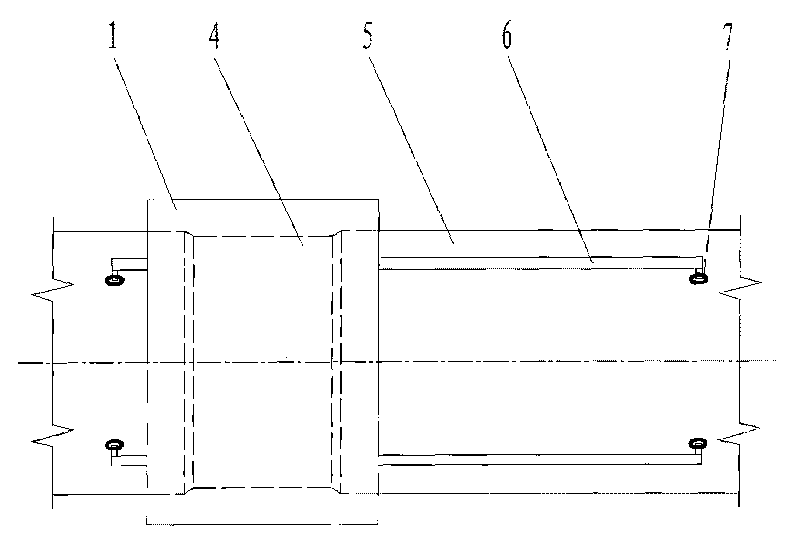

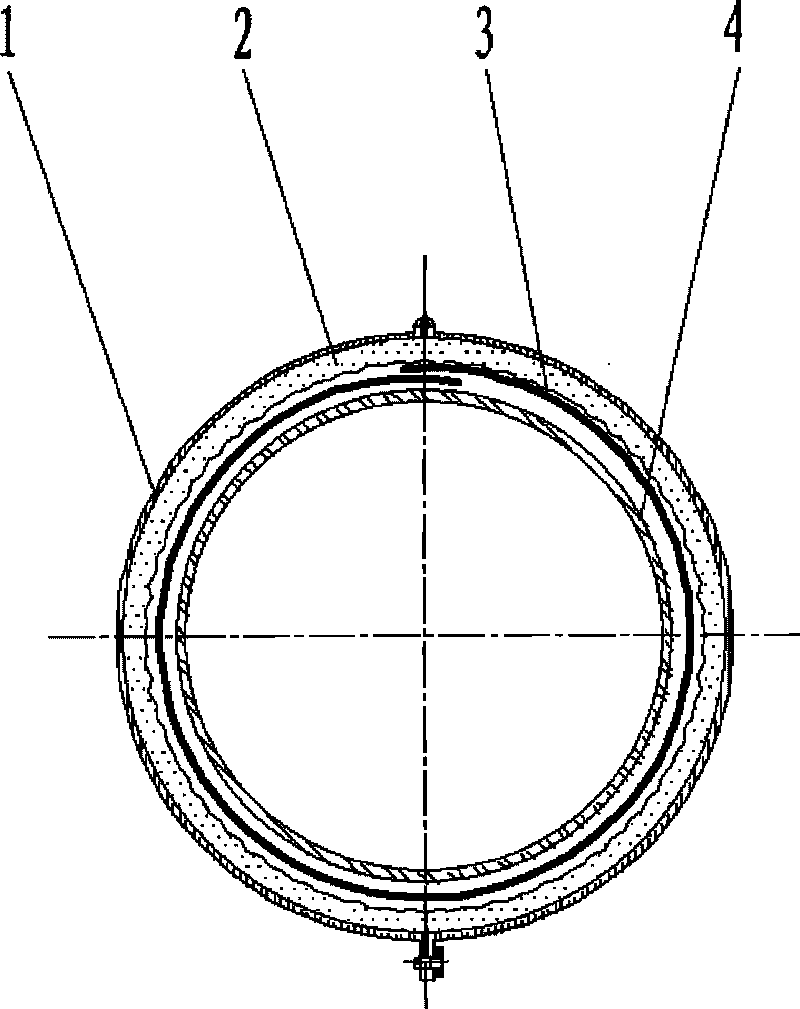

[0026] Embodiment 1: After the bare pipe 4 at the joint is derusted by sandblasting, preheated, sprayed or brushed with epoxy primer, the joint joint tool is slid to the position facing the joint. Select the polyethylene sealing tape 3 of electric melting shrinkage type. In order to make the effect of heating and melting better and ensure that the polyethylene sealing tape 3 is close to the bare pipe at the beginning of work, the rubber air bag 2 should be pressurized to 0.001 -0.1Mpa, so that the polyethylene joint tape 3 is tightened and then attached to the bare pipe 4 at the joint and the anti-corrosion layer at both ends; after the polyethylene joint tape 3 is energized and melted, the rubber airbag 2 is gradually pressurized to 0.01- 1Mpa; keep the pressure for 1-10 minutes. After the bonding is completed, the rubber airbag 2 is depressurized, and the patching machine is removed, and the patching place is immediately sprayed with cold water, and the temperature is lowere...

Embodiment 2

[0027] Embodiment 2: After the bare pipe 4 at the joint is derusted by sandblasting, preheated, sprayed or brushed with epoxy primer, the joint joint tool is slid to the position facing the joint. Choose the polyethylene sealing tape 3 of external heat shrinkable type, and use the heat conduction oil pump to fill the rubber airbag 2 with oil and pressurize it. The heat conduction oil should be heated to 150-250°C before use. In order to ensure that the polyethylene sealing tape 3 is close to the bare pipe at the beginning of the work, so that the effect of heating and melting is better, the rubber air bag 2 is pressurized to 0.001-0.1Mpa, so that the polyethylene sealing tape 3 is tightened and then pasted Fit on the bare pipe 4 at the joint and the anti-corrosion layer at both ends; after the polyethylene joint belt 3 is melted by heat conduction oil, the rubber airbag 2 is gradually pressurized to 0.01-1Mpa; after the bonding is completed, the rubber airbag 2 is released , R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com