Patents

Literature

38results about How to "Fully contracted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

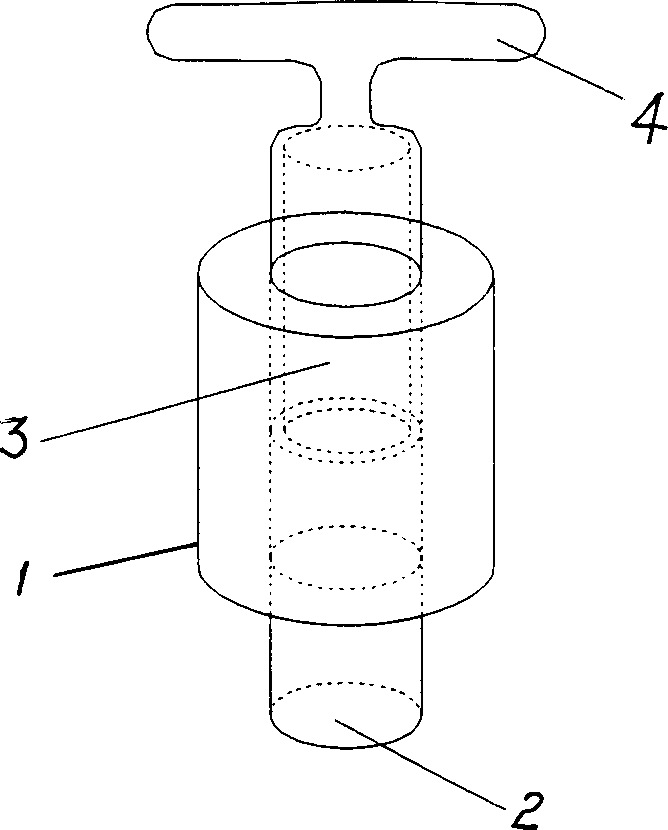

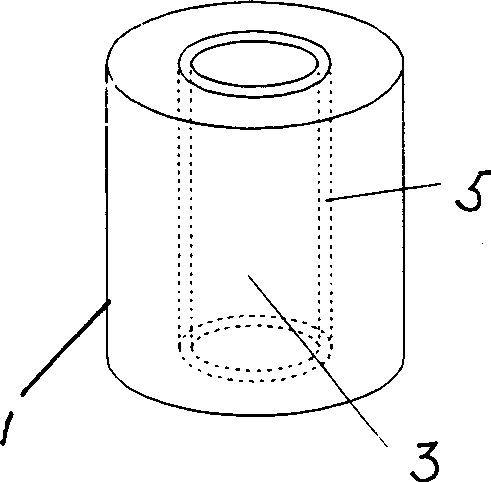

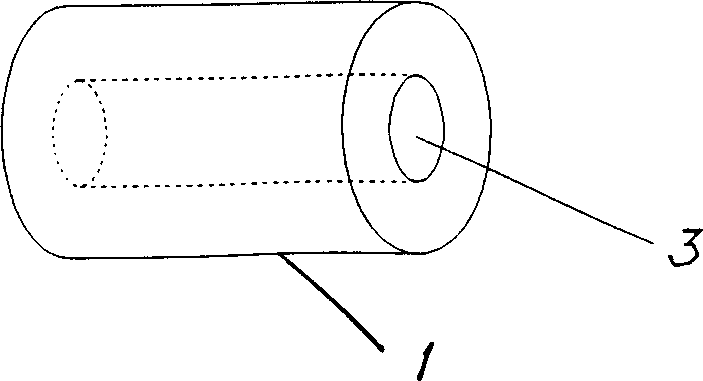

Elastic filament and processing method for drum dyeing of elastic yarn

ActiveCN1807741AFully contractedFlat surfaceLiquid/gas/vapor yarns/filaments treatmentBobbinPulp and paper industry

The invention relates to a flexible filament and its flexible yarn barrel dye process method, which has the following steps: convoluting the flexible filament or flexible yarn loosely around the slippery paper tube, wrapping them with the netted fabric; pressing the netted plastic tube that the dye barrel yarn used into the paper core, dropping out the wrapped paper tube; rewrapping the exchanged barrel yarn with the plastic tube again and putting them in cross and parallel direction into the flexible yarn swelling, contracting and shaping device, and they receive the first contracting through temperature rising, then the second contracting through the second temperature rising; after the yarn is tightened in the netted plastic tube, caging and dyeing; rising when dyeing to make the yarn contract again; after dyeing, soap washing - water washing - dehydrating - drying-semi - finished product checking - waxing - bobbin-winding - product checking - product casing or weaving.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

Method for preparing down-proof fabric

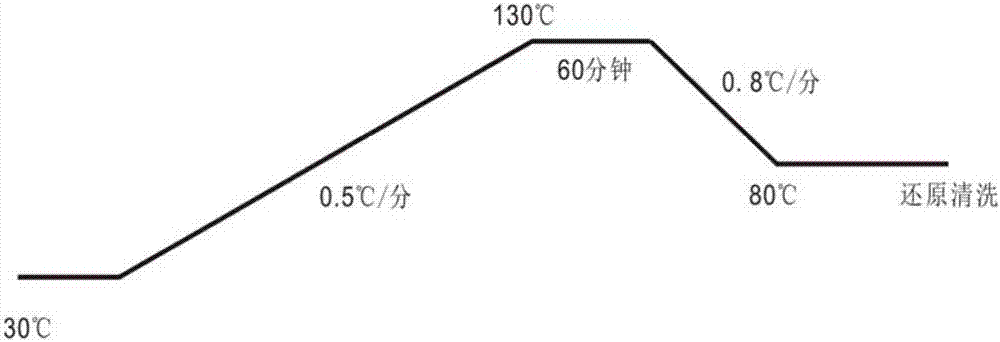

InactiveCN102493075AFiber shrinkageFully contractedFibre typesHeating/cooling textile fabricsVolumetric Mass DensityEngineering

The invention discloses a method for preparing down-proof fabric, which comprises the steps of: a, unwinding gray fabric and then adsorbing furs of the gray fabric, wherein the gray fabric is fine denier filament; b, adding the treated gray fabric into an overflow dyeing machine, carrying out high-temperature reduction operation through programmed heating; c, dyeing the gray fabric in dyeing solution; d, putting the fabric in a setting machine for setting, and then drying the fabric, and adding wind-proof agent for setting; and e, calendaring, checking the fabric, and packaging. The method disclosed by the invention has the advantages that: 1, as polyster fibers contract sufficiently under the condition of high temperature, grains on the surface of the fabric are dense and smooth; 2, the fine denier filament are applied to reacting with the polyster fibers in a certain amount of alkali solution at a high temperature, thereby slightly corroding fiber layers on the surfaces of the fibers, increasing air permeability and reducing static generation probability of the fibers, improving bulkiness of the fibers, and enhancing the sense of puffing of the fibers; 3, by adjusting tissues of the fabric, density is increased and printing and dyeing processes are adjusted, in this way, eiderdowns and wools can be prevented from penetrating down from the fabric; and 4, the fabric is excellent in performance and low in price.

Owner:GUANGDONG SI HAI WEI YE TEXTILE TECH

Method for producing polyester cotton blended spinning latitudinal elastic fabric

InactiveCN101392425AHigh weft stretchEasy to retractFibre treatmentSingeingPolyurethane elastomerPolyester

This invention provides a production method of stretch-yarnless cotton-polyester blended latitudinal stretch fabric. The production method successively comprises the working procedures as follows: manufacture of grey cloth, sewing of the lining side of the grey cloth, singeing of the grey cloth, desizing, sizing, coloration, preshrinking and trimming inspection. After the desizing procedure and before the sizing procedure, a slack mercerizing procedure is conducted; after the coloration procedure and before the preshrinking procedure, a slack cloth-ironing procedure is conducted. By using the trimming method, before the singeing and desizing procedures, the pick count of the cotton-polyester blended fabric is small, thereby being prone to be back-shrunk. Trough the sizing procedure, the width can be shrunk and the capillary effect is increased, then through the slack mercerizing procedure, by slackly piling in a J-shaped box and mercerizing in the condition free from latitudinal tension, the width can be sufficiently shrunk and get an excellent stretch effect. In the procedure of slack cloth-ironing, polyurethane elastomer is added to the cotton-polyester blended fabric under the condition free from latitudinal tension, and through sanforizing cotton-polyester blended fabric gets higher longitudinal elasticity.

Owner:HUAFANG

Preparation method for water-based wet-process microfiber leather

InactiveCN108823679AFully contractedEliminate needle stick stressGrip property fibresConjugated synthetic polymer artificial filamentsWater basedPolyester

The invention provides a preparation method for a water-leatherd wet-process microfiber leather. The preparation method comprises the following steps of preparing non-woven leather cloth; carrying outwater-soluble polyester pre-shrinking treatment on the non-woven leather cloth; carrying out waterborne polyurethane wet-process impregnation treatment; carrying out extruding; carrying out wet-process solidification; carrying out splitting and reduction; and carrying out post-processing. The preparation method has the advantages that the key of the method lies in how to avoid using an organic solvent in the whole producing and manufacturing processes, a water-leatherd wet process is adopted, so that all process materials are environmentally-friendly, and the prepared leather can achieve thestructural characteristics of leatherette; and a figured sea-island short fiber leather material is used, ultrafine fibers with the fineness of 0.05 D can be obtained after sea components are dissolved away, and prepared leather is soft in hand feeling, good in drapability, attractive and good in air permeability, is similar to real leather in strength, folding resistance and other performances, is superior to natural leather in water resistance and anti-mildew and antibacterial performance and is a novel material with vitality in the industry of artificial leather and synthetic leather.

Owner:LANZHOU SCISKY AQUEOUS POLYMER MATERIAL CO LTD

Full hemp liner for men's suits and manufacturing method thereof

InactiveCN101637319AStructural fitStrong three-dimensional senseGarmentsClothes making applicancesEngineeringFormaldehyde

The invention discloses a full hemp liner for men's suits, which comprises a bodice liner, a front chest liner, an armhole liner, an internal shoulder liner, an external shoulder liner and a bias chest liner. The invention also discloses a manufacturing method of the full hemp liner for men's suits, which comprises the following steps: putting the full hemp liner in a container, leading steam intothe container, and steaming the full hemp liner at the high temperature of 110-120 DEG C for 12-16 hours; then, taking out the full hemp liner, and cooling and airing the full hemp liner; and shrinking, expanding, shaping, pressing and ironing the full hemp liner to obtain a finished product. The full hemp liner for men's suits has the advantages of natural and neat wear and good air permeability, better joints the structure of a human body, does not contain formaldehyde and does not need a bonding liner. In addition, because the high-temperature steaming technology is adopted in the manufacturing process, the raw liner is made into a steamed liner, thus the liner is softer and can not be deformed by ironing.

Owner:NINGBO SHANSHAN +1

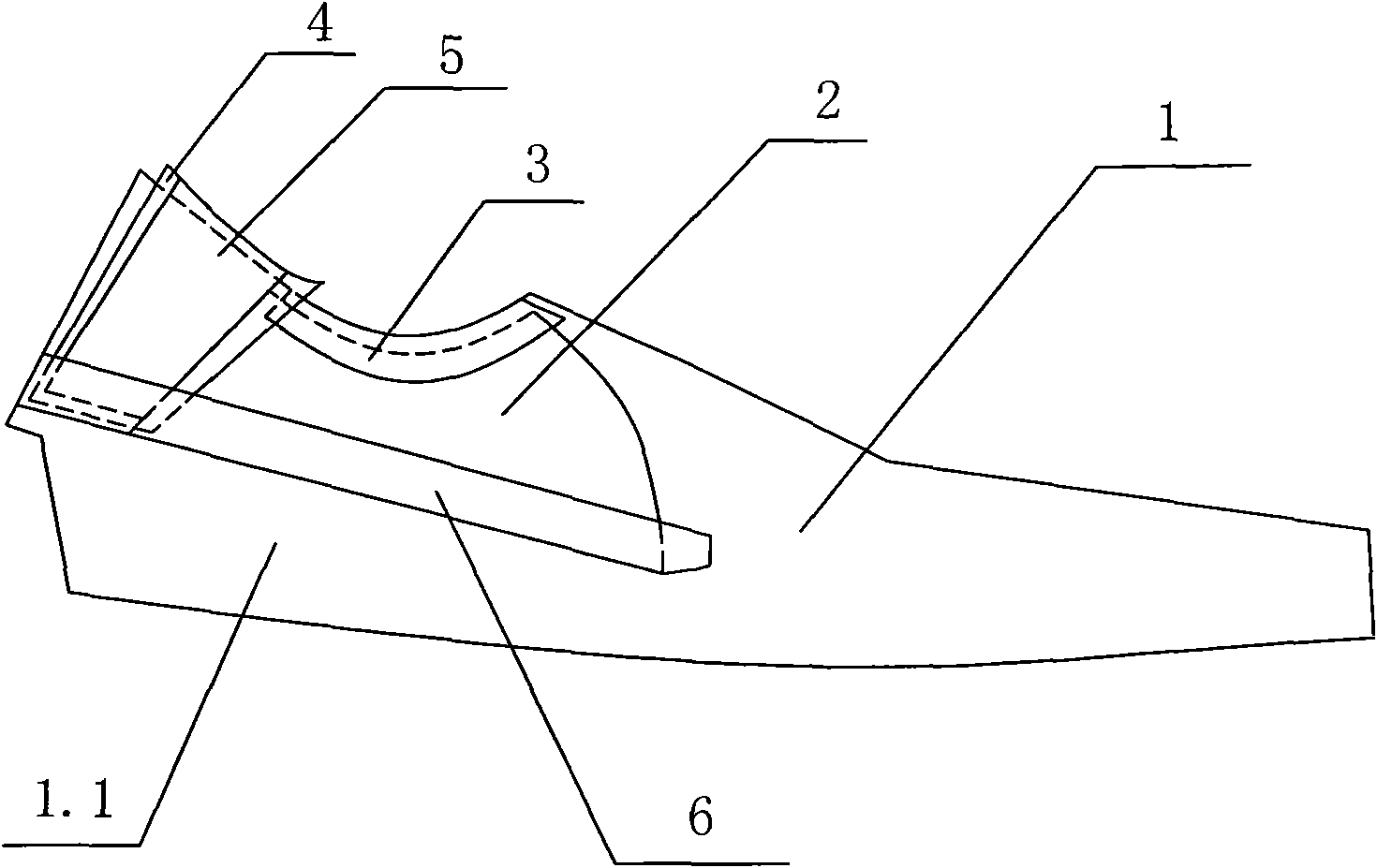

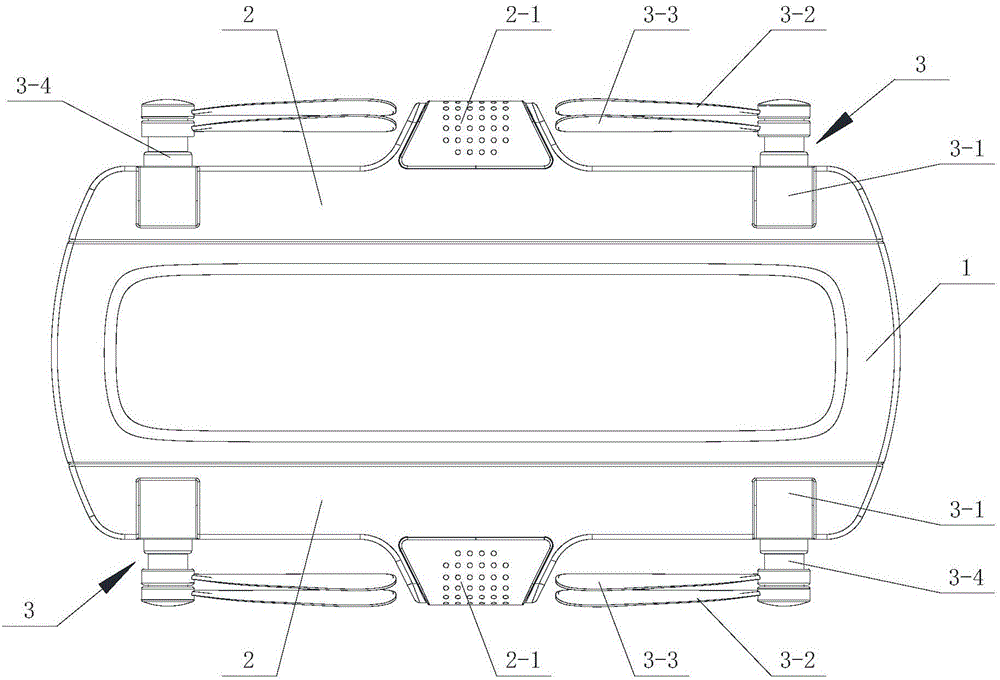

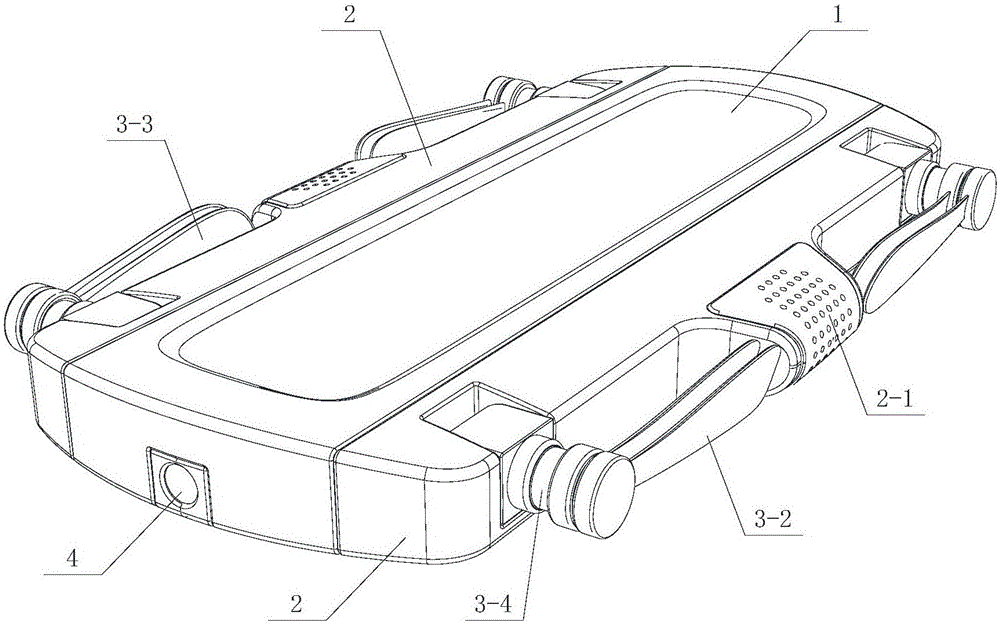

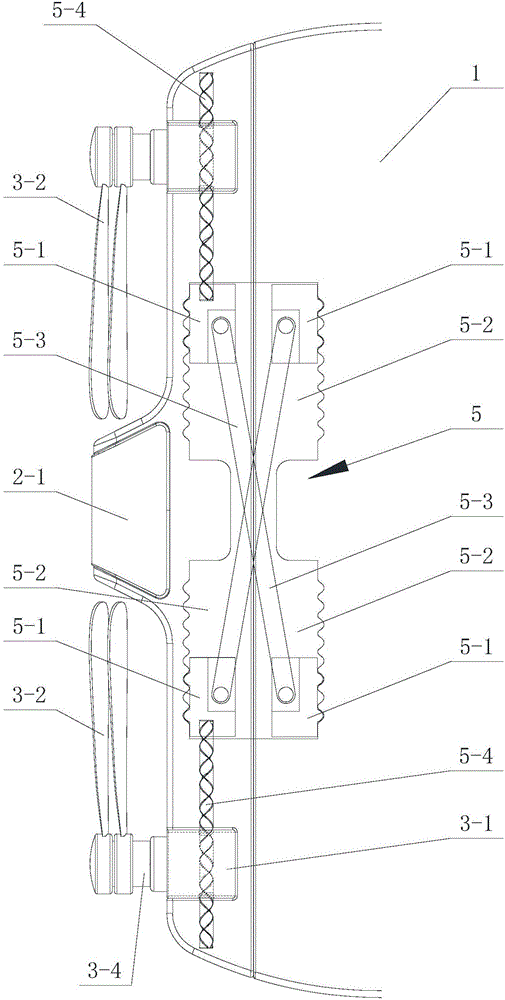

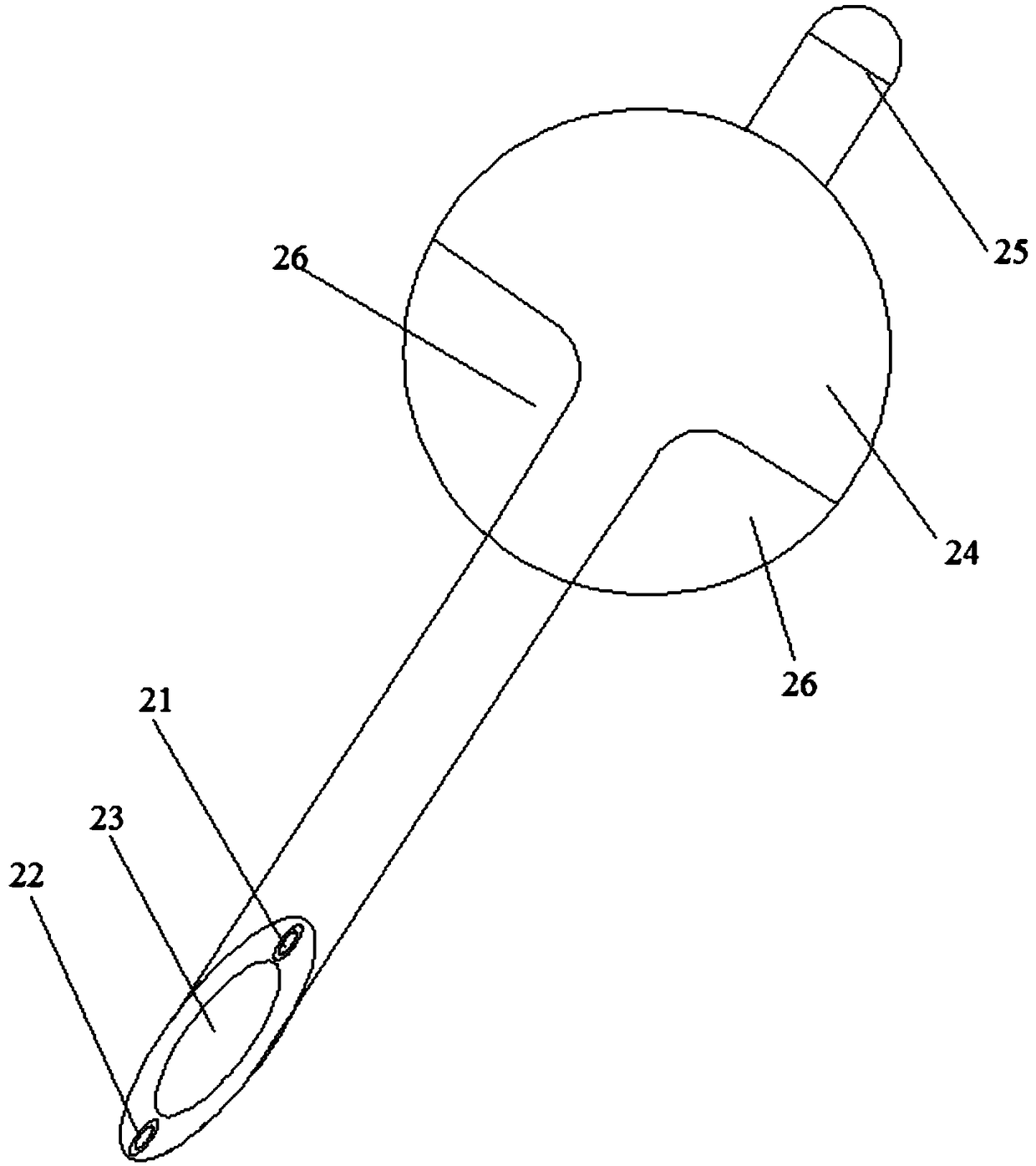

Portable telescopic unmanned aerial vehicle

ActiveCN106585971AReduce the number of movesSimplified expansionFuselagesAir-flow influencersPropellerFuselage

Owner:GEER TECH CO LTD

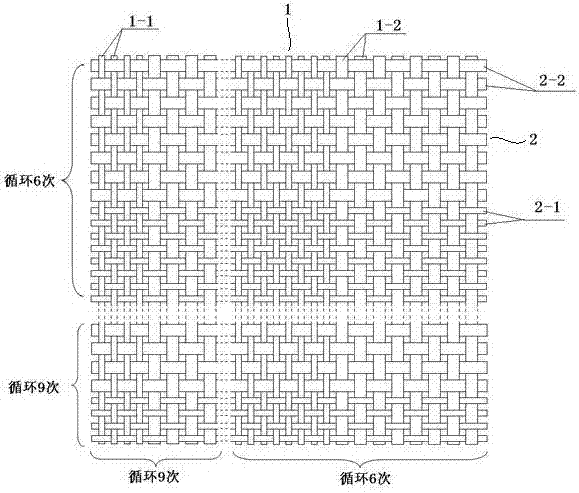

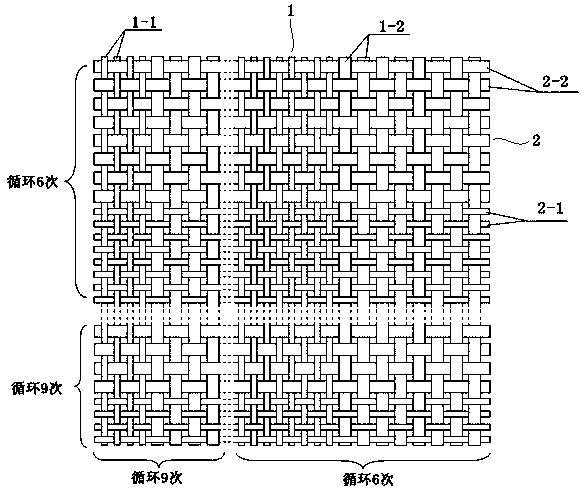

Plisse crepe lattice fabric production technology

ActiveCN107488927ASolve the impossible to weave puzzleReduce weaving costHeating/cooling textile fabricsDry-cleaning apparatus for textilesEngineeringDyeing

The invention discloses a plisse crepe lattice fabric production technology which is characterized by comprising the following steps: evenly winding first warps and second warps on a warp beam through a warping technology, wherein warps include the first warps and the second warps, and the first warps and the second warps have different warp tensions; utilizing a single warp beam weaving technology to weave gray fabric of the plisse crepe lattice fabric; finishing through a later dyeing and finishing technology to enable the shell fabric to not only form grid shape distribution Plisse crepe lattice fabric with a unique style, but also have good all-side stretch touch of shell fabric. According to the seersucker grid shell fabric production technology disclosed by the invention, the technologies of warping, re-beaming, weaving, desizing, scouring, bleaching and the like are innovated, so that the problem that single warp beam weaving cannot weave plisse crepe is solved.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

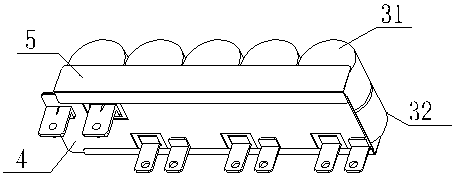

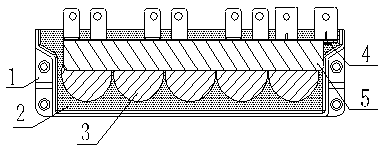

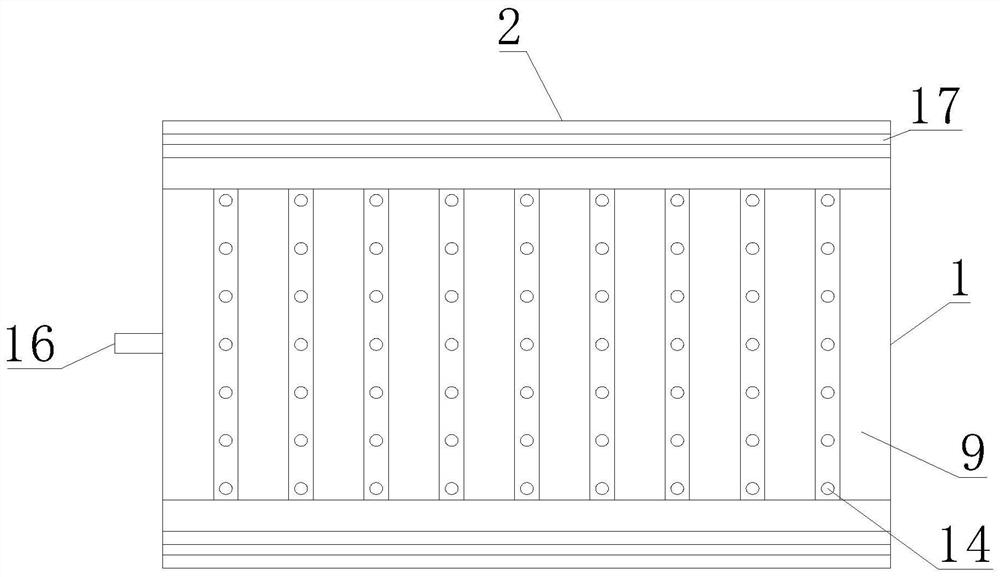

Thin-film capacitor for high-temperature-resistant and high-humidity-resistant application and processing method thereof

ActiveCN106409507AFit tightlyFully contractedThin/thick film capacitorFixed capacitor housing/encapsulationFilm capacitorPolypropylene

The invention relates to the technology of the thin-film capacitor, particularly to a thin-film capacitor for high-temperature-resistant and high-humidity-resistant application and a processing method thereof. Therefore, the thin-film capacitor can still be used in a high-temperature and high-humidity environment and requirements of long service life and high reliability are met. And the prepared thin-film capacitor has high security and stability. Besides, the processing method includes an evaporation process, a heat setting process and an embedment process. The thin-film capacitor consists of a capacitor core, a potting material and a shell and is characterized in that the capacitor core is formed by winding of a metalized polypropylene film, wherein the front side and the back side of the metalized polypropylene film are processed by a plasma treatment technology.

Owner:WUXI CHENRUI NEW ENERGY TECH

Method for producing polyester cotton blended spinning latitudinal elastic fabric

InactiveCN101392425BHigh weft stretchEasy to retractFibre treatmentSingeingPolyurethane elastomerPolyester

This invention provides a production method of stretch-yarnless cotton-polyester blended latitudinal stretch fabric. The production method successively comprises the working procedures as follows: manufacture of grey cloth, sewing of the lining side of the grey cloth, singeing of the grey cloth, desizing, sizing, coloration, preshrinking and trimming inspection. After the desizing procedure and before the sizing procedure, a slack mercerizing procedure is conducted; after the coloration procedure and before the preshrinking procedure, a slack cloth-ironing procedure is conducted. By using thetrimming method, before the singeing and desizing procedures, the pick count of the cotton-polyester blended fabric is small, thereby being prone to be back-shrunk. Trough the sizing procedure, the width can be shrunk and the capillary effect is increased, then through the slack mercerizing procedure, by slackly piling in a J-shaped box and mercerizing in the condition free from latitudinal tension, the width can be sufficiently shrunk and get an excellent stretch effect. In the procedure of slack cloth-ironing, polyurethane elastomer is added to the cotton-polyester blended fabric under the condition free from latitudinal tension, and through sanforizing cotton-polyester blended fabric gets higher longitudinal elasticity.

Owner:HUAFANG

Method for processing super fluff memory stretch fabric

ActiveCN107881623AImprove the shortcomings of hard hand feeling and strong chemical fiber feelingSoft and slipperyShrinkingTwo or more solvent application treatmentFiberPulp and paper industry

The invention relates to a method for a processing super fluff memory stretch fabric. The fabric is acquired after the weaving of a memory fiber used as a warp and T400 fiber used as a weft is completed, and sequentially conducting pre-shrinking, preforming, splitting, air-flow dyeing, stereotyping and calendering for velvet feeling. Compared with the prior art, the method adopts the memory fiberand T400 fiber with higher F number, in the subsequent dyeing and finishing process, processes such as pre-shrinking, splitting and preforming are added to make the fibers fully shrink and fluffy andstabilize the fabric style, so that the velvet feeling and the surface feeling are enhanced, and the elasticity of finished products is improved.

Owner:劲霸男装(上海)有限公司

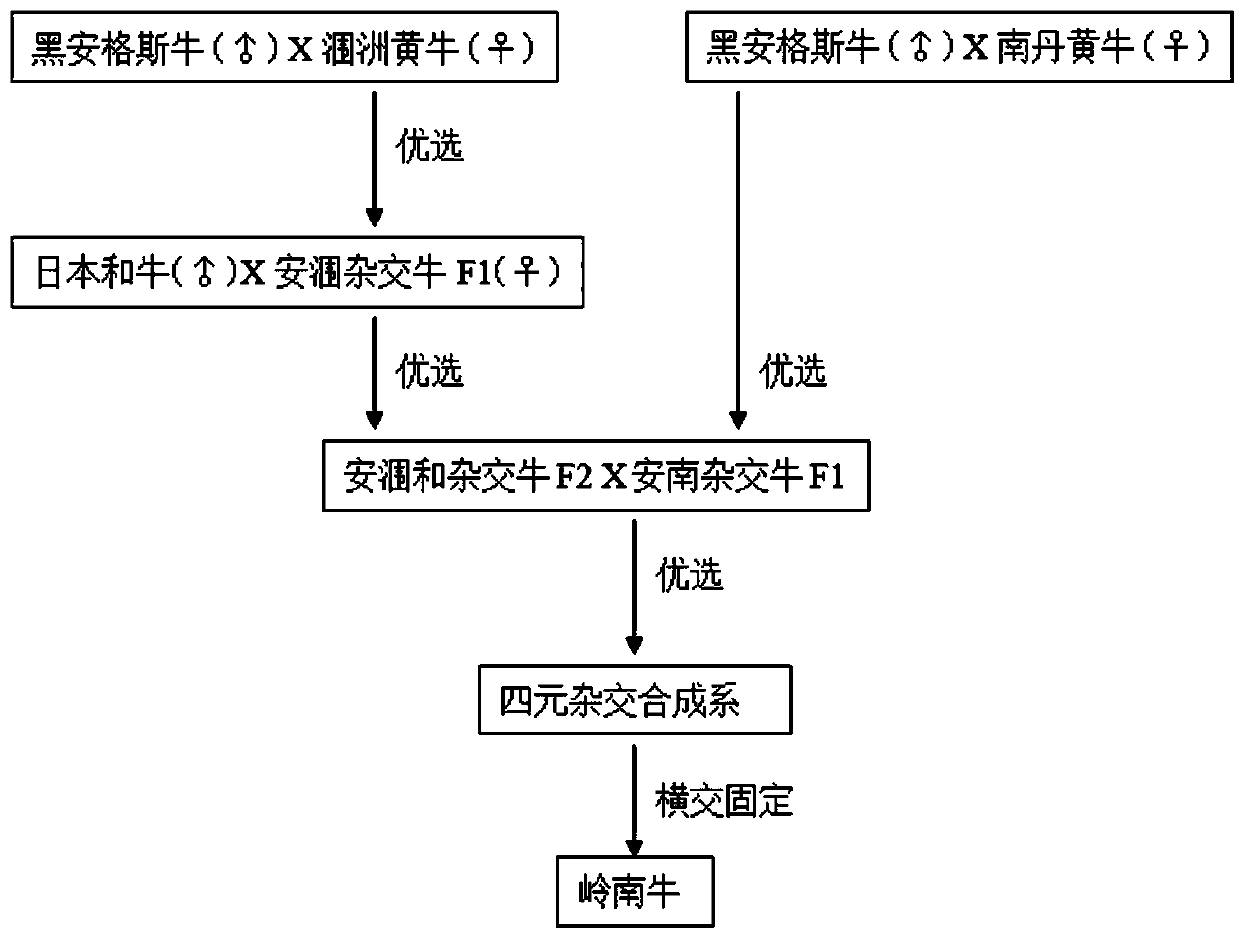

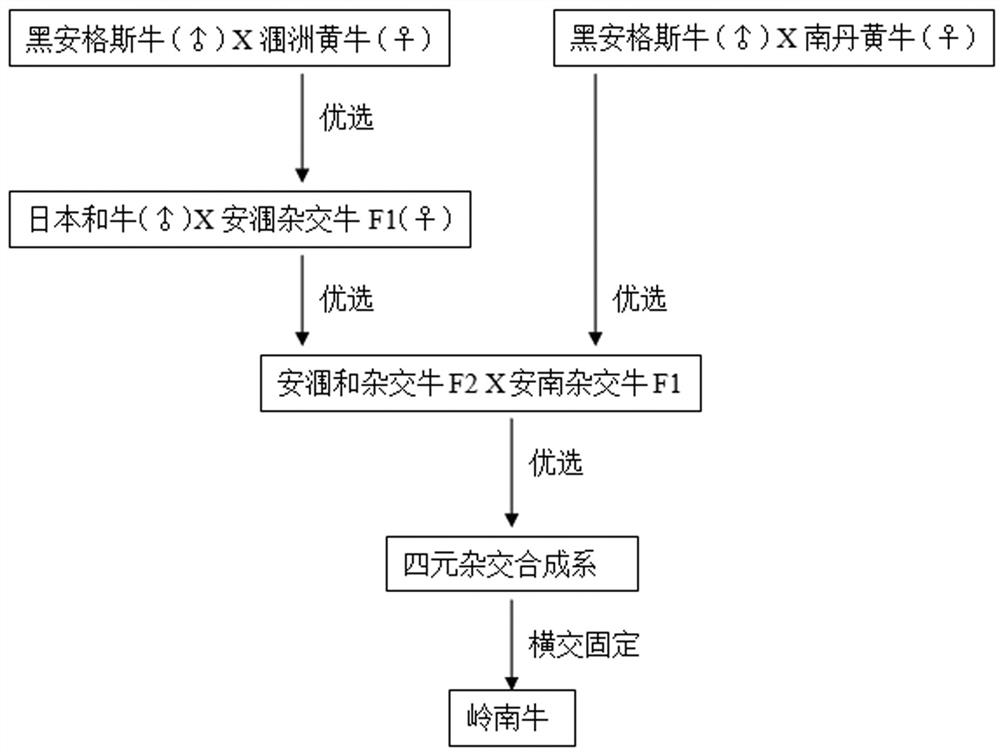

Lingnan cattle and breeding method thereof

Owner:广西四野牧业有限公司

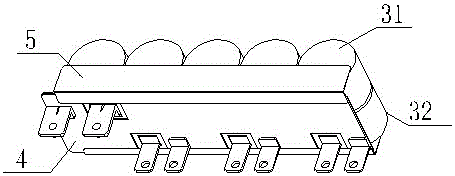

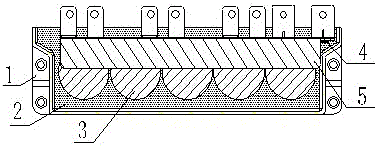

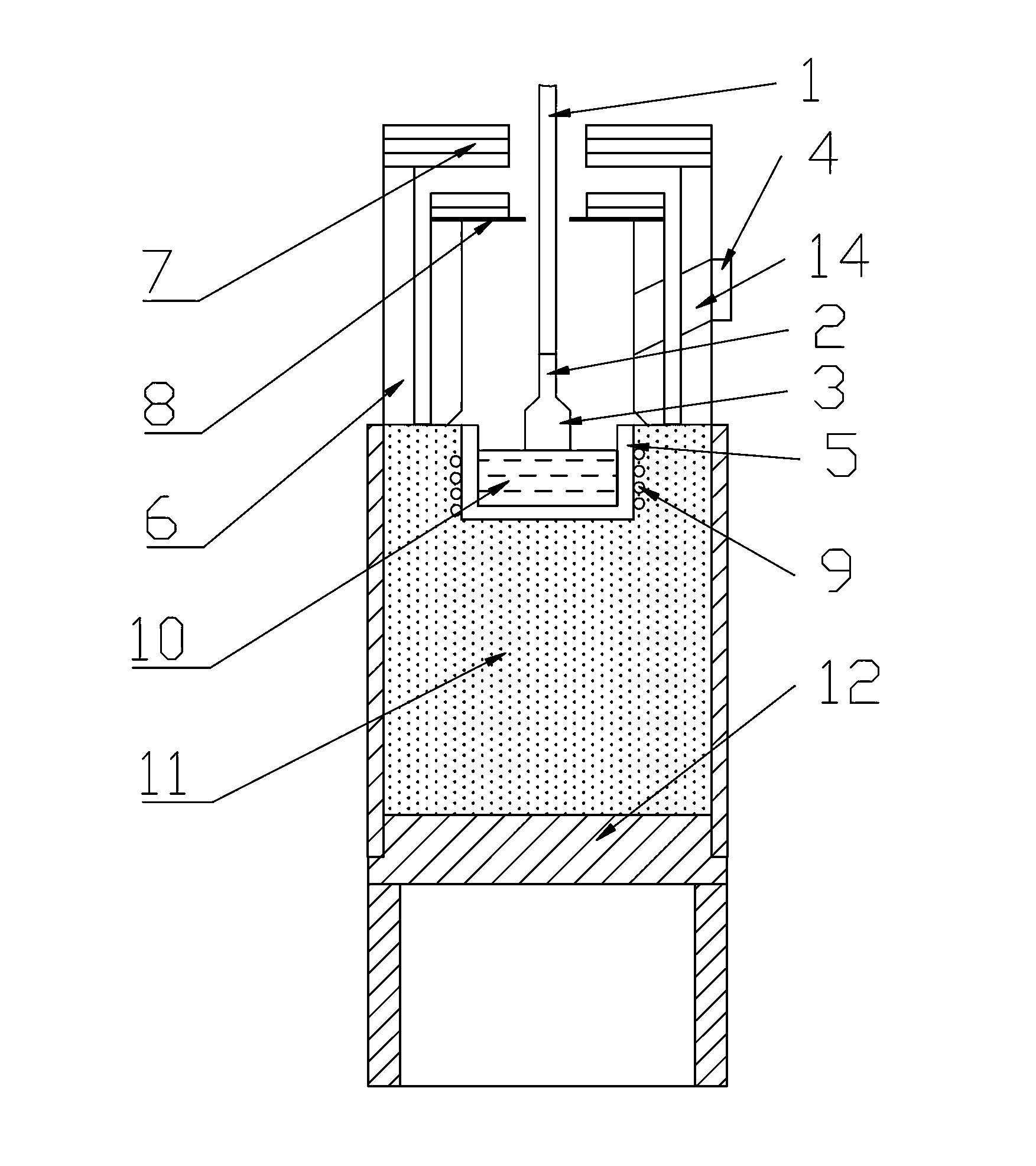

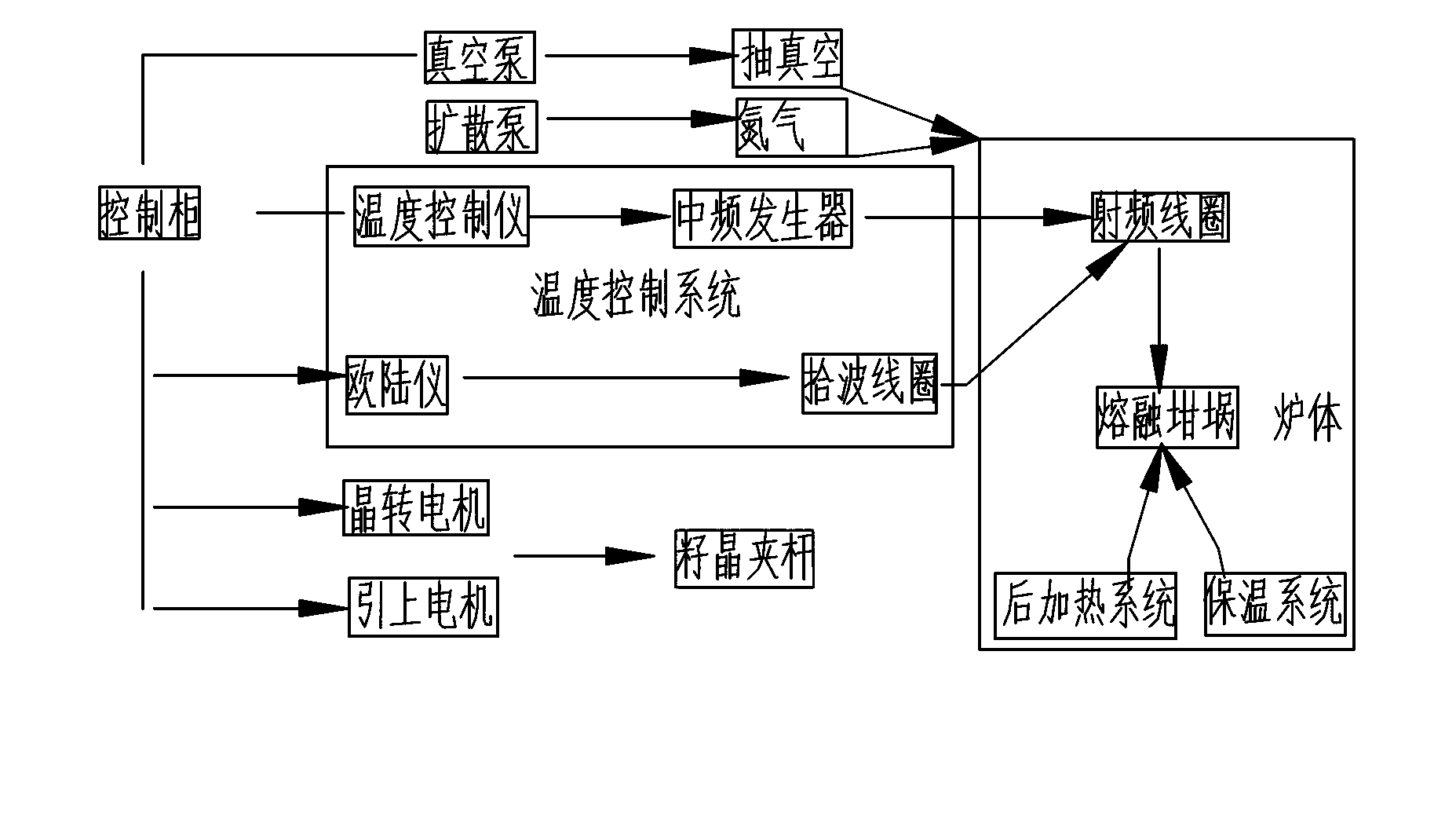

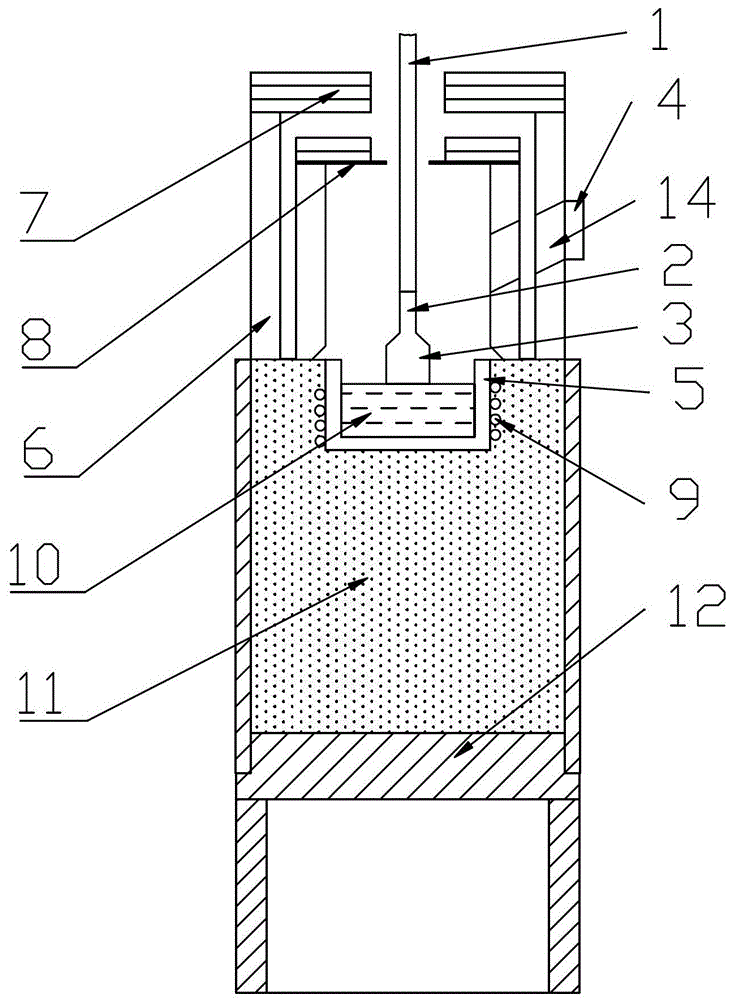

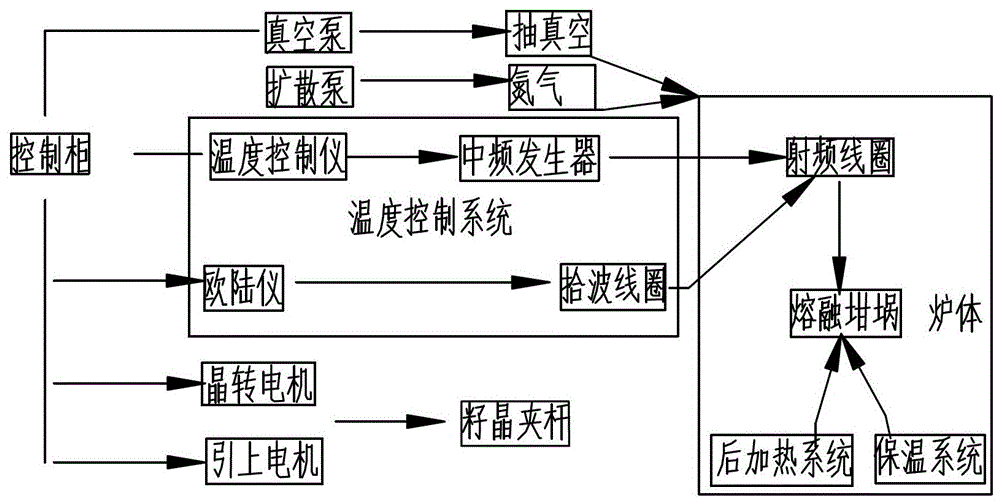

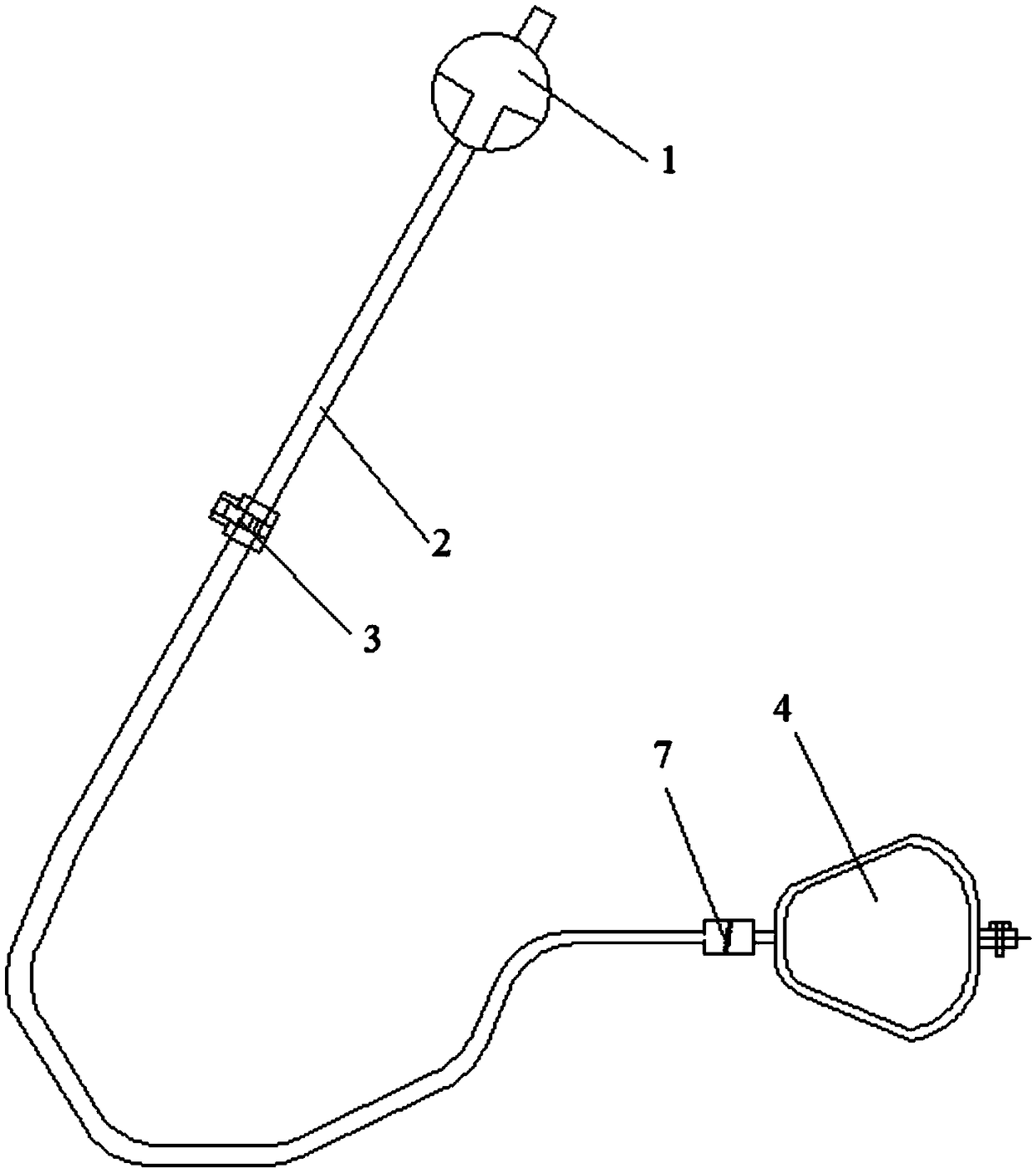

Growing equipment for growing YVO4 (Yttrium Vanadate) crystal with drawing method and growing method based on same

ActiveCN103266346AIncrease radial temperature gradientGood thermal conductivityPolycrystalline material growthBy pulling from meltYttriumHeating system

The invention provides growing equipment for growing YVO4 (Yttrium Vanadate) crystal with a drawing method and a growing method based on the same. The growing equipment is provided with a temperature control system and a post-heating system, and the temperature control system stably controls a heating system through heating power. In the post-heating system, the upper end of a melting crucible is provided with post-heating metal sheets. In a heat-insulation system, the upper end of the melting crucible is provided with multiple corundum heat-insulation covers. A seed crystal lifting clamping bar penetrates through the post-heating metal sheets and the multiple heat-insulation covers. For the growing method, in the process of temperature rising, at low temperature, the heating power is maintained for a long time; the rate of temperature fall is adjusted under different states in the growing process by combining the lifting speed of the seed crystal clamping bar and the design of a temperature field; and the best temperature rising, constant temperature and temperature fall method of the heat treatment temperature is determined at a later stage. According to the growing equipment and the growing method based on the growing equipment, the YVO4 crystal with high quality and a large size can be provided.

Owner:TONGLING RIKE ELECTRONICS

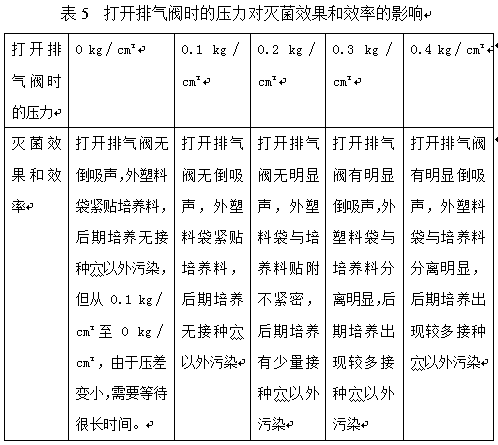

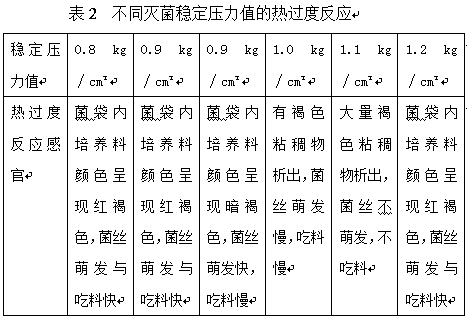

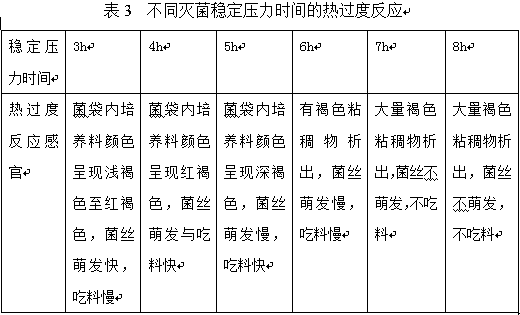

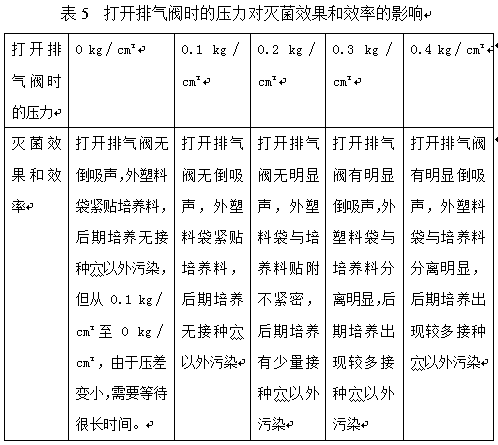

High-pressure vapour sterilization method of mushroom stick

ActiveCN108739066AAvoid thermal expansionNo bag swellingCultivating equipmentsMushroom cultivationExhaust valveInlet valve

The invention discloses a high-pressure vapour sterilization method of a mushroom stick. The method comprises the steps that (1),the mushroom stick is punctured, a breathable film is bonded to the mushroom stick, and the breathable film is sealed after the mushroom stick is placed in a high-temperature sterilization device; (2), vapour is added, an air inlet valve is adjusted to a lower magnitudewhen the pressure is increased to 0.9 kg / cm <2>, an air discharging valve is switched on gradually, the air inlet valve is completely switched on when the pressure drops to zero, the state of the airinlet valve is maintained for 3-5 min until dense vapour is discharged out from an air discharging port, the air discharging valve is switched off, and the air discharging operation is repeated; (3),when the vapour pressure is increased to 0.8 kg / cm <2> and the temperature is increased to 108 DEG C + / - 1 DEG C, the air inlet valve is adjusted to stabilize the pressure and the temperature, and the pressure and the temperature are maintained for 4 hours; (4), the vapour pressure is adjusted from 0.8 kg / cm <2> to 0.4 kg / cm <2> within 0.8-1 hour, the temperature is 105 DEG C + / - 1 DEG C, andthe pressure and the temperature are stabilized for 5 hours; (5), the air inlet valve is switched off, the air discharging valve is switched on when the vapour pressure is naturally reduced to 0.1 kg / cm <2>, the air discharging valve is switched off when no vapour is discharged from the air discharged valve, and the sterilization is completed.

Owner:SHANXI AGRI UNIV

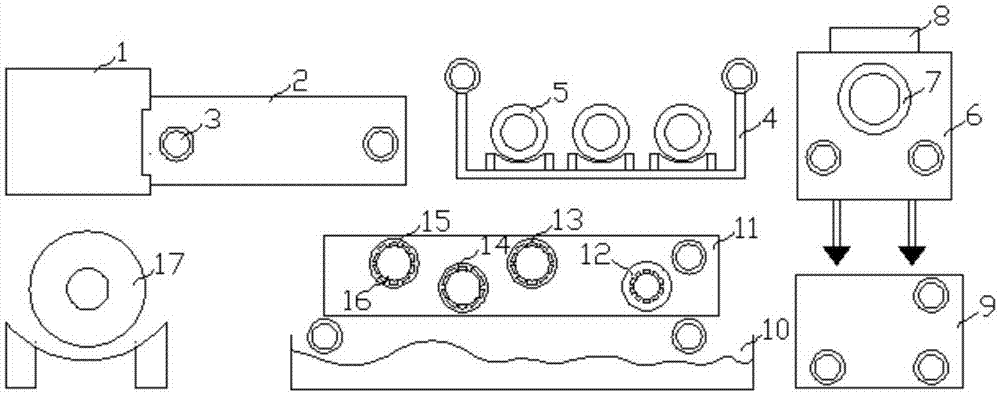

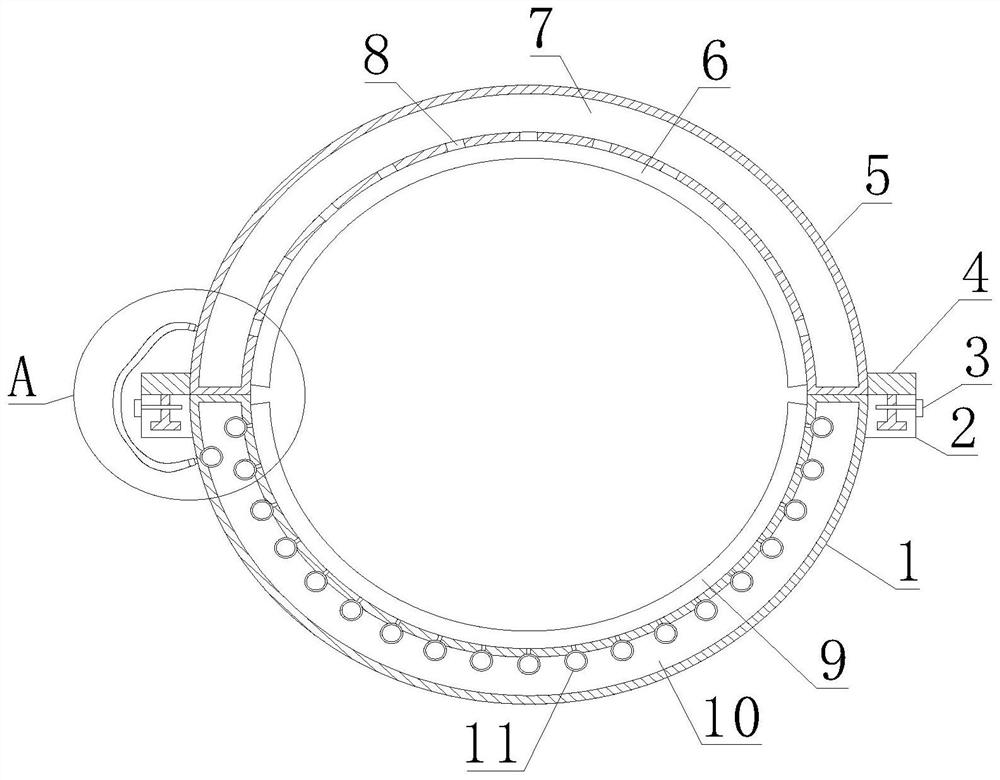

Cooling shaping device of full-automatic packing belt producing machine

The invention provides a cooling and setting device for a fully automatic production machine for packing belts, which includes an extruder and a cooling water tank connected to one side of the extruder, and the other end of the cooling water tank is connected to a printing machine through a transmission roller and a packing belt. There is a printing rack inside, the other end of the printing machine is connected to the oven, the oven is equipped with stretching rollers, the top of the oven is equipped with a heater, the oven is connected to the thermal shaping machine through the transmission roller and the packing belt, and one end of the thermal shaping machine The roller is connected to the motor box, the surface of the motor box is provided with the first steel wheel, the second steel wheel, the third steel wheel and the fourth steel wheel, the bottom of the motor box is provided with an ice water tank, and one end of the ice water tank is connected to the winder; The invention first bakes and stretches in an oven to eliminate internal stress and deformation caused by printing, and then uses four steel wheels with different rotation speeds to prolong the cooling time of the packing belt in the ice water tank, thereby improving the quality of the product. quality and aesthetics.

Owner:CHONGQING SHANGSHANG SCI & TECH CO LTD

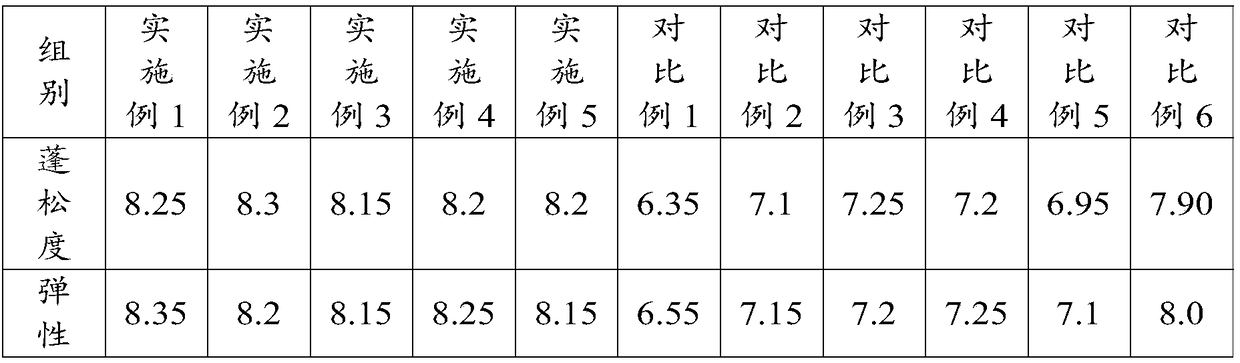

Colored knitted fleeced cloth, dyeing process thereof in O-type vat and clothes

The invention relates to the technical field of textile and provides a dyeing process for colored knitted fleeced cloth in an O-type vat. The dyeing process comprises the following steps of: placing knitted cloth to be fleeced into the O-type vat for dyeing, wherein the concentration of a dyeing agent in the O-type vat is 0.5-1g / L; rising the temperature of dyeing liquor in the O-type vat to 125-150 DEG C to lead partial dyeing liquor in the O-shaped vat to be transformed into a gas state, and spraying the dyeing liquor in the O-type vat to the knitted cloth to be fleeced in the form of gas-liquid mixing so as to start dyeing; after dyeing, carrying out cleaning and dewatering. The dyeing process is good in dyeing effect, and the colored knitted fleeced cloth prepared by the dyeing processis high in bulkiness and good in elasticity. The invention also provides the colored knitted fleeced cloth which are obtained by adopting the dyeing process for colored knitted fleeced cloth in the O-type vat to dye and then fleecing. The colored knitted fleeced cloth is high in bulkiness, good in elasticity and good in color. The invention also provides clothes with the manufacturing fabric including the colored knitted fleeced cloth. The clothes are beautiful in appearance and high in comfort level.

Owner:JIANGSU DINGXIN PRINTING & DYEING

Production method for building block taking steel slag as raw material

A related production method for a building block taking steel slag as a raw material is characterized by comprising the following steps: 1) performing hot disintegration on steel slag; 2) crushing steel slag, performing magnetic selection, ball milling and water selection, so as to select iron and obtain the residual tailing slurry; 3) piling the tailing slurry obtained in the step 2) for storage, disposing and coagulating so as to form a coagulum; 4) crushing the coagulum in the step 3), screening to obtain an aggregate with the particle size of 0.5-6 mm; 5) mixing the aggregate in the step 4) with cement, an additive and other lightweight raw material according to the following weight fractions: 65%-75% of the aggregate, 12%-18% of cement, 1%-6% of the additive, and 5%-13% of the lightweight raw material; 6) adding water into the mixed materials of the step 5) and stirring, so as to obtain a mixed slurry; 7) adding the mixed slurry of the step 6) into a die and performing vibrating compaction molding; 8) performing steam curing by high-pressure steam; and 9) stacking for storage. Compared with the prior art, the method possesses the characteristics of strong compressive resistance and high stability.

Owner:SHANDONG XINNUO NEW ENERGY SAVING MATERIALS CO LTD

A kind of high pressure steam sterilization method of mushroom stick

ActiveCN108739066BAvoid thermal expansionNo bag swellingCultivating equipmentsMushroom cultivationThermodynamicsInlet valve

The invention discloses a high-pressure vapour sterilization method of a mushroom stick. The method comprises the steps that (1),the mushroom stick is punctured, a breathable film is bonded to the mushroom stick, and the breathable film is sealed after the mushroom stick is placed in a high-temperature sterilization device; (2), vapour is added, an air inlet valve is adjusted to a lower magnitudewhen the pressure is increased to 0.9 kg / cm <2>, an air discharging valve is switched on gradually, the air inlet valve is completely switched on when the pressure drops to zero, the state of the airinlet valve is maintained for 3-5 min until dense vapour is discharged out from an air discharging port, the air discharging valve is switched off, and the air discharging operation is repeated; (3),when the vapour pressure is increased to 0.8 kg / cm <2> and the temperature is increased to 108 DEG C + / - 1 DEG C, the air inlet valve is adjusted to stabilize the pressure and the temperature, and the pressure and the temperature are maintained for 4 hours; (4), the vapour pressure is adjusted from 0.8 kg / cm <2> to 0.4 kg / cm <2> within 0.8-1 hour, the temperature is 105 DEG C + / - 1 DEG C, andthe pressure and the temperature are stabilized for 5 hours; (5), the air inlet valve is switched off, the air discharging valve is switched on when the vapour pressure is naturally reduced to 0.1 kg / cm <2>, the air discharging valve is switched off when no vapour is discharged from the air discharged valve, and the sterilization is completed.

Owner:SHANXI AGRI UNIV

High temperature and high humidity resistant film capacitor and processing method thereof

ActiveCN106409507BFit tightlyFully contractedThin/thick film capacitorStacked capacitorsHigh humidityEvaporation

The invention relates to the technology of the thin-film capacitor, particularly to a thin-film capacitor for high-temperature-resistant and high-humidity-resistant application and a processing method thereof. Therefore, the thin-film capacitor can still be used in a high-temperature and high-humidity environment and requirements of long service life and high reliability are met. And the prepared thin-film capacitor has high security and stability. Besides, the processing method includes an evaporation process, a heat setting process and an embedment process. The thin-film capacitor consists of a capacitor core, a potting material and a shell and is characterized in that the capacitor core is formed by winding of a metalized polypropylene film, wherein the front side and the back side of the metalized polypropylene film are processed by a plasma treatment technology.

Owner:WUXI CHENRUI NEW ENERGY TECH

A kind of growth equipment for growing yvo4 crystals by the upward method and the growth method based on the growth equipment

ActiveCN103266346BIncrease radial temperature gradientOptimum temperature field conditionsPolycrystalline material growthBy pulling from meltEngineeringInsulation system

The invention provides growing equipment for growing YVO4 (Yttrium Vanadate) crystal with a drawing method and a growing method based on the same. The growing equipment is provided with a temperature control system and a post-heating system, and the temperature control system stably controls a heating system through heating power. In the post-heating system, the upper end of a melting crucible is provided with post-heating metal sheets. In a heat-insulation system, the upper end of the melting crucible is provided with multiple corundum heat-insulation covers. A seed crystal lifting clamping bar penetrates through the post-heating metal sheets and the multiple heat-insulation covers. For the growing method, in the process of temperature rising, at low temperature, the heating power is maintained for a long time; the rate of temperature fall is adjusted under different states in the growing process by combining the lifting speed of the seed crystal clamping bar and the design of a temperature field; and the best temperature rising, constant temperature and temperature fall method of the heat treatment temperature is determined at a later stage. According to the growing equipment and the growing method based on the growing equipment, the YVO4 crystal with high quality and a large size can be provided.

Owner:TONGLING RIKE ELECTRONICS

Breeding method of Lingnan cattle

Owner:广西四野牧业有限公司

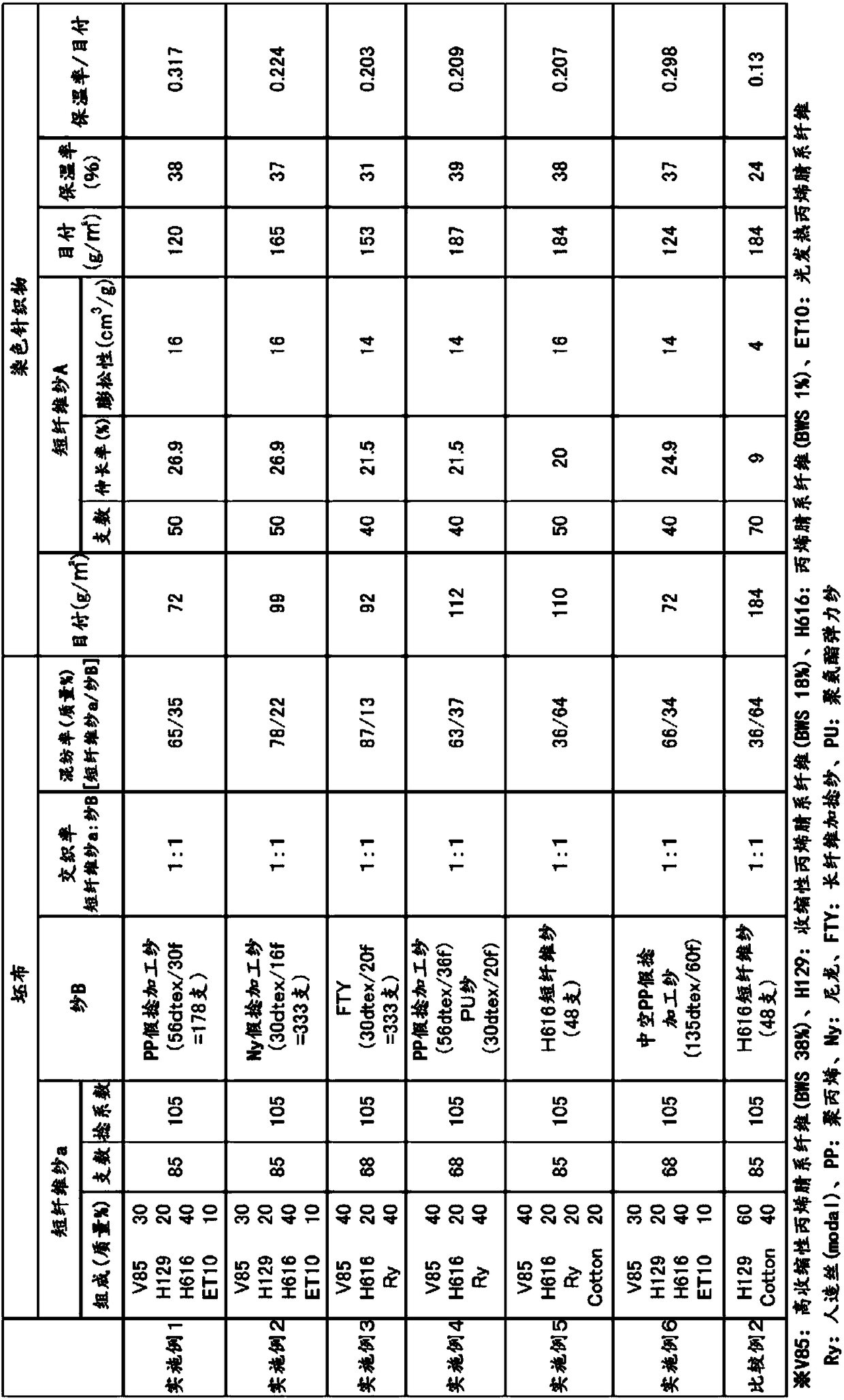

Knitted fabric having excellent heat-retaining properties and production method therefor

A knitted fabric having an interknitting rate of 2:1-1:3 between a spun yarn A and a thread B, said spun yarn A containing an acrylic fiber and having 15%-30% elongation and said thread B having a metric count of 40-350. The knitted fabric is obtained by: knitting a knitting fabric including 35%-95% by mass fine spun yarn a including a high-shrinkage fiber having a boiling-water shrinkage of 30%-45%; heating the knitting fabric at a moist heat of at least 70 DEG C; shrinking the high-shrinkage fiber in the spun yarn a constituting the fabric; and making same a thick spun yarn having said metric count. The knitted fabric obtained in this manner has a small basis weight, is lightweight, and has excellent heat-retaining properties and a knitted fabric having said light-weight, heat-retainingproperties can be commercially obtained.

Owner:MITSUBISHI CHEM CORP

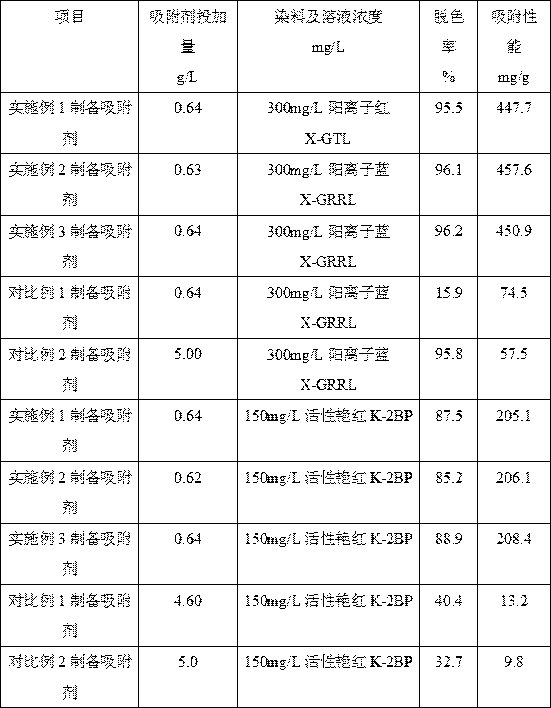

Preparation method for improving adsorption performance of adsorbent prepared from printing waste liquid

InactiveCN109126706AImprove adsorption capacityIncrease profitOther chemical processesWater contaminantsLiquid wasteWater based

The invention discloses a preparation method for improving an adsorption performance of adsorbent prepared from printing waste liquid. The method includes steps: adding chemical agents capable of generating hydrogen ions into high-concentration water-based ink printing waste liquid to enable extractable substances to be just coagulated into insoluble fine solid particles without flocculation; stirring, and adding chemical agents capable of generating tiny bubbles through reaction with the waste liquid into the waste liquid to form a gas-liquid-solid three-phase contact interface among the finesolid particles; heating to form large-particle solid extract; after the temperature is 5-25 DEG C higher than a softening point of a connection material, keeping the temperature to form block extract; after the block extract is completely contracted in volume, discharging water, and hardening the extract; taking out the block extract, cooling, and subjecting to low-temperature drying or naturaldrying; crushing the dried extract, adding an activating agent, well mixing, performing one-step carbonizing and activating at 500-800DEG C for 1-4h under nitrogen protection, and crushing to obtain the adsorbent with the excellent adsorption performance.

Owner:QINGDAO UNIV

A kind of lactase microcapsule and preparation method thereof

ActiveCN107252108BGood acid stabilityAchieve gastric protectionFood ingredient as solidifying agentFood shapingFirming agentBiotechnology

The invention discloses a lactase microcapsule and a preparation method thereof, belonging to the field of food processing. The present invention uses lactase as the core material, κ-carrageenan and sodium alginate as the wall material, CaCl 2 and ε‑polylysine as the curing agent of the colloidal particles, κ‑carrageenan as the film coating agent, ε‑polylysine as the surface hardener, prepared by lactase glue, ultrasonic defoaming, and spray granulation , curing, secondary coating and hardening, and drying to prepare the lactase microcapsules. The technology of the invention is reasonable, and the obtained product has the properties of being stable in the stomach, dissolving and releasing lactase in the small intestine, and has fine particles, good fluidity and dispersibility, and good quality, and can be widely applied to people with lactose intolerance. Good economic and social benefits.

Owner:FUJIAN AGRI & FORESTRY UNIV

3D printing fracture rehabilitation support replacing gypsum

InactiveCN111870419AImprove treatment efficiencyPromote circulationFractureTherapeutic coolingMining engineeringStructural engineering

The invention relates to a 3D printing fracture rehabilitation support replacing gypsum. The 3D printing fracture rehabilitation support replacing gypsum comprises a first clamping plate, fastening pieces, a second clamping plate and a connecting pipe, wherein the first clamping plate is in sliding connection with the second clamping plate and fixedly connected with the second clamping plate through a plurality of groups of fastening pieces; a first air bag is arranged on the inner end surface of the first clamping plate, and a first hollow bin is arranged in the first clamping plate; a plurality of groups of exhaust pipes, a first air conveying pipe and a third air conveying pipe are arranged in the first hollow bin; a plurality of groups of first vent holes are formed in the inner end surface of the first clamping plate by the exhaust pipes; the exhaust pipes and the first air conveying pipe are connected with the third air conveying pipe; the air inlet end of the third air conveyingpipe is connected with a second air conveying pipe for circularly conveying cold and hot air; a plurality of groups of second air bags are arranged on the inner end surface of the second clamping plate, and a second hollow bin is arranged in the second clamping plate; the second hollow bin is provided with a plurality of second vent holes in the inner end surface of the second clamping plate; andthe second hollow bin is connected with the first air conveying pipe through the connecting pipe. The 3D printing fracture rehabilitation support replacing gypsum is convenient to use and can well fix fractured limbs of a patient.

Owner:南宁壶兰科技有限公司

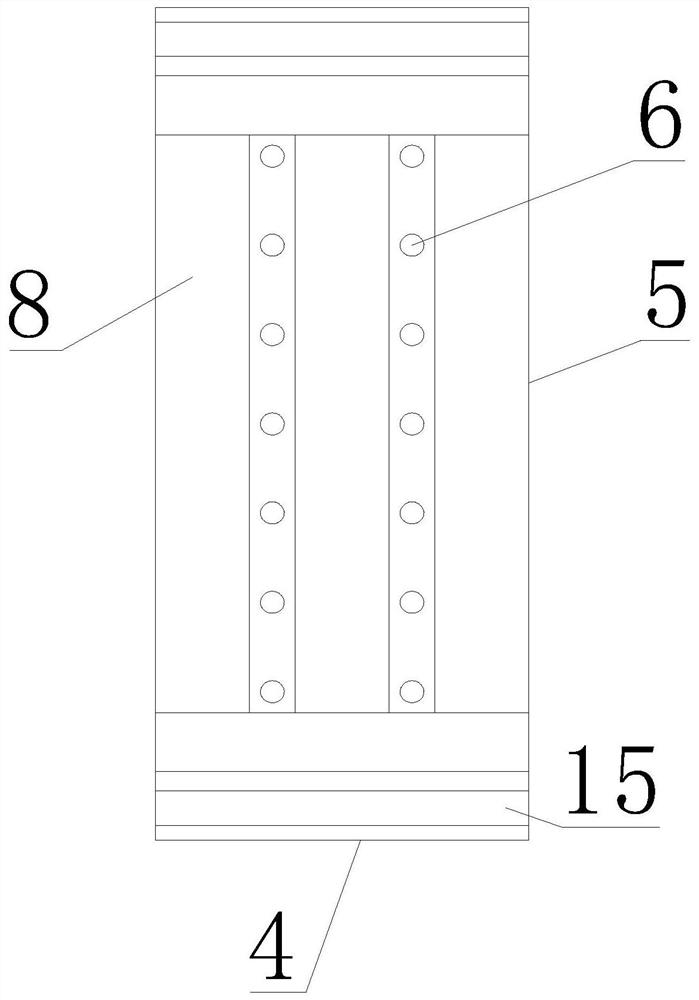

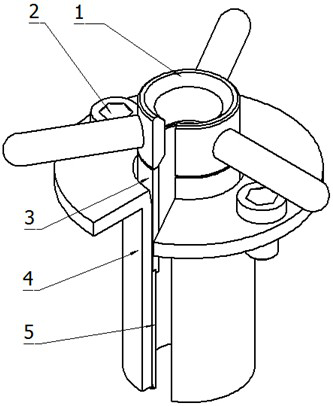

Bladder function rehabilitation training system and method

InactiveCN109364437AFull fillingFully contractedGymnastic exercisingChiropractic devicesDrainage tubesControl unit

The embodiment of the invention discloses a bladder function rehabilitation training system and method. The bladder function rehabilitation training system comprises a sacculus, a drainage tube, a control valve, a control unit and a drainage bag; the sacculus is communicated with one end of the drainage tube, the drainage bag is communicated with the other end of the drainage tube, the two ends ofthe control valve are communicated with the drainage tube, and opening and closing of the drainage tube are controlled through a control unit; the control unit comprises a controller, a power supplyunit, a time relay, a pressure sensor and a flow instrument, a pressure cavity is formed between a sliding block and a front end tube, a liquid flow cavity is formed between the sliding block and a tail end tube, the controller is in communication connection with the pressure sensor in the pressure cavity and the flow instrument and the power supply unit which are arranged in the liquid flow cavity, the power supply unit is electrically connected to an electric push rod, and the electric push rod is controlled to stretch out and draw back. According to the bladder function rehabilitation training system, flow of urine of a patient can be sufficient, the bladder contraction and filling can be sufficient, and the bladder exercise can be achieved.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

Diaphragm for lithium-ion power battery and manufacturing method thereof

ActiveCN104037375BImprove structural strengthImprove heat resistanceCell seperators/membranes/diaphragms/spacersLaminationPower batterySlurry

The invention discloses a diaphragm for lithium-ion power batteries, which solves the problems of poor heat resistance, puncture resistance and corrosion resistance of the diaphragm in the prior art. It includes a base material layer and coating on both sides of the base material layer The slurry layer, the substrate layer is a non-woven fabric processed from nano-cellulose and polymer with a mass ratio of 1:20-25, and the raw materials of the slurry layer include binders and ceramic particles. The invention has excellent heat resistance, puncture resistance and corrosion resistance. The invention also discloses a manufacturing method of a separator for a lithium-ion power battery, which mainly includes the following steps: first cleaning the non-woven fabric with sodium chloride solution; then washing the non-woven fabric with deionized water and drying; After the binder is mixed with the ceramic particles, a solvent is added and ball milled with 5-20% alcohol of the mass of the ceramic particles to obtain a slurry; finally, the slurry is coated on both sides of the non-woven fabric and dried in stages to obtain a separator. The process step of the invention is simple, easy to operate, and the slurry is thoroughly dried.

Owner:WANXIANG 123 CO LTD

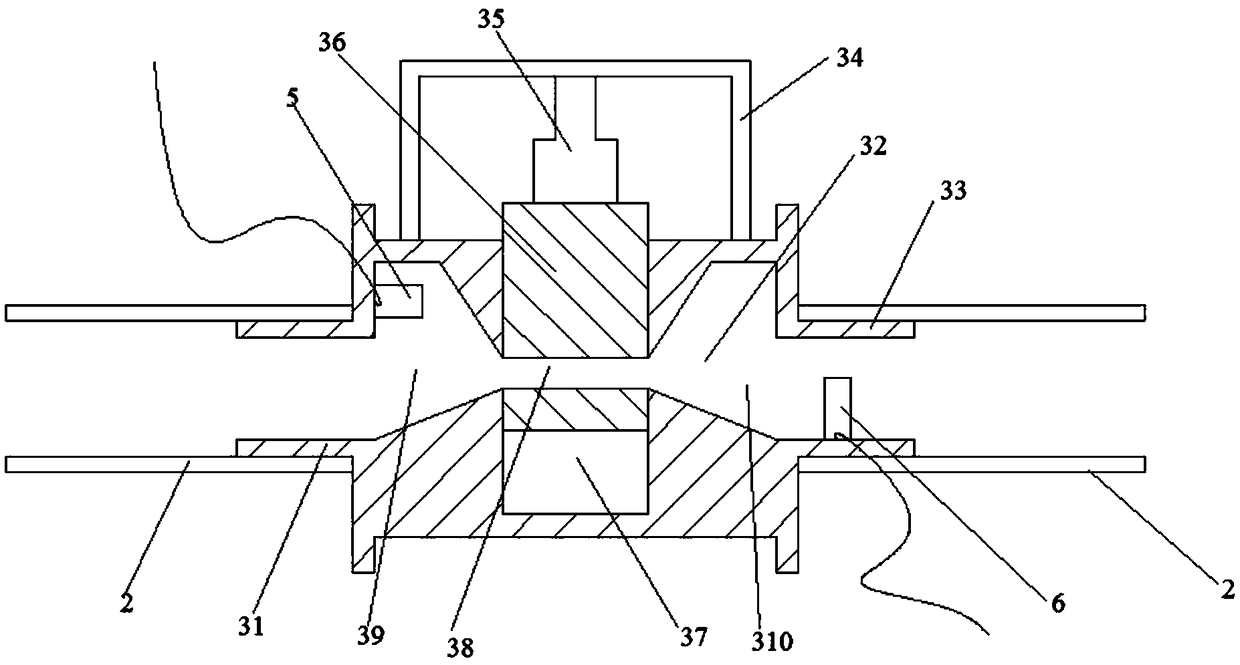

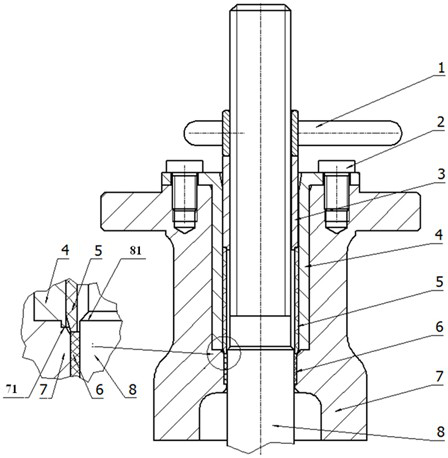

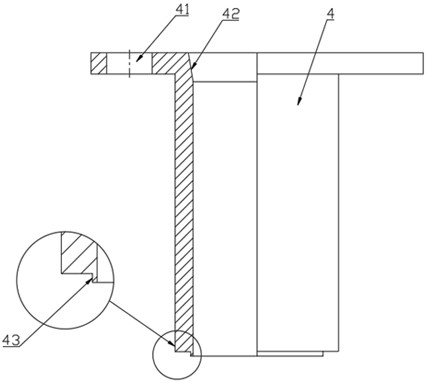

A sliding bearing assembly tool and its assembly method

ActiveCN114055400BAssembly precisionImprove assembly efficiencyValve housingsMetal-working hand toolsSlider bearingEngineering

The invention relates to the technical field of valves, and discloses a sliding bearing assembly tool and an assembly method thereof, including a compression nut, a friction gasket, a shaft sleeve and a compression ring, the shaft sleeve is fixed in a stuffing box of a valve cover, the compression ring, The friction pad is coaxial with the shaft sleeve and arranged in the shaft sleeve. The friction pad abuts against the top of the pressure ring, and the top of the friction pad abuts against a compression nut, and the compression nut is threadedly connected with the valve stem. In the sliding bearing assembly tooling of the present invention, the overall tooling adopts a split assembly structure, and the accurate assembly of the parts can be quickly realized by rotating the compression nut, and the disassembly is convenient, which improves the assembly efficiency of the valve; during the assembly process of the parts, the sliding bearing can be prevented. , The damage of the contact parts of the valve stem and the valve cover ensures the overall quality of the product.

Owner:CHENGDU CHENGGAO VALVE +1

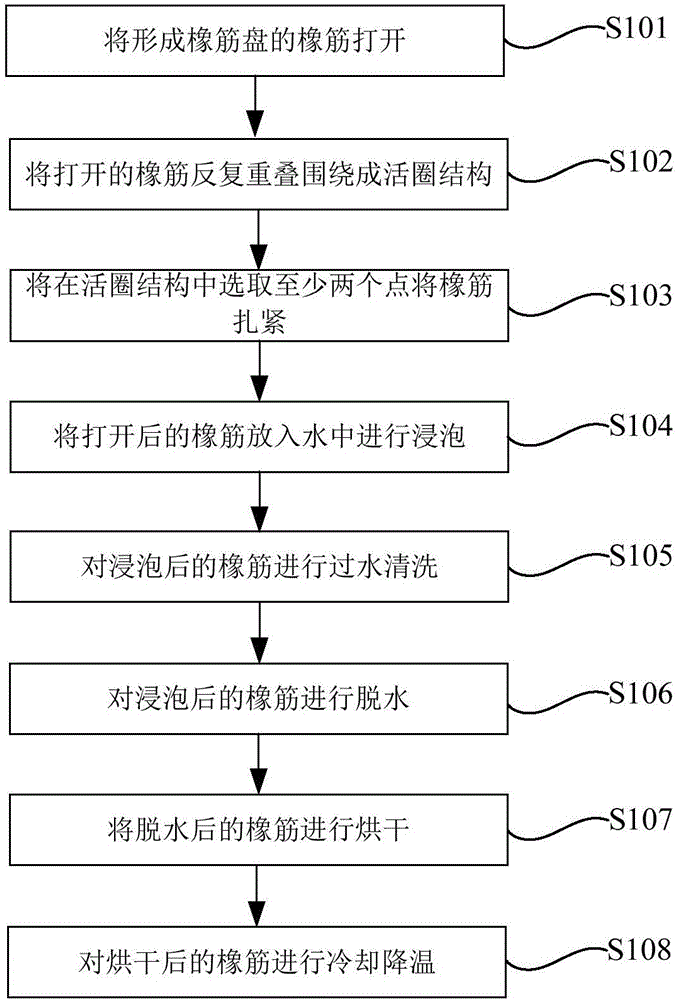

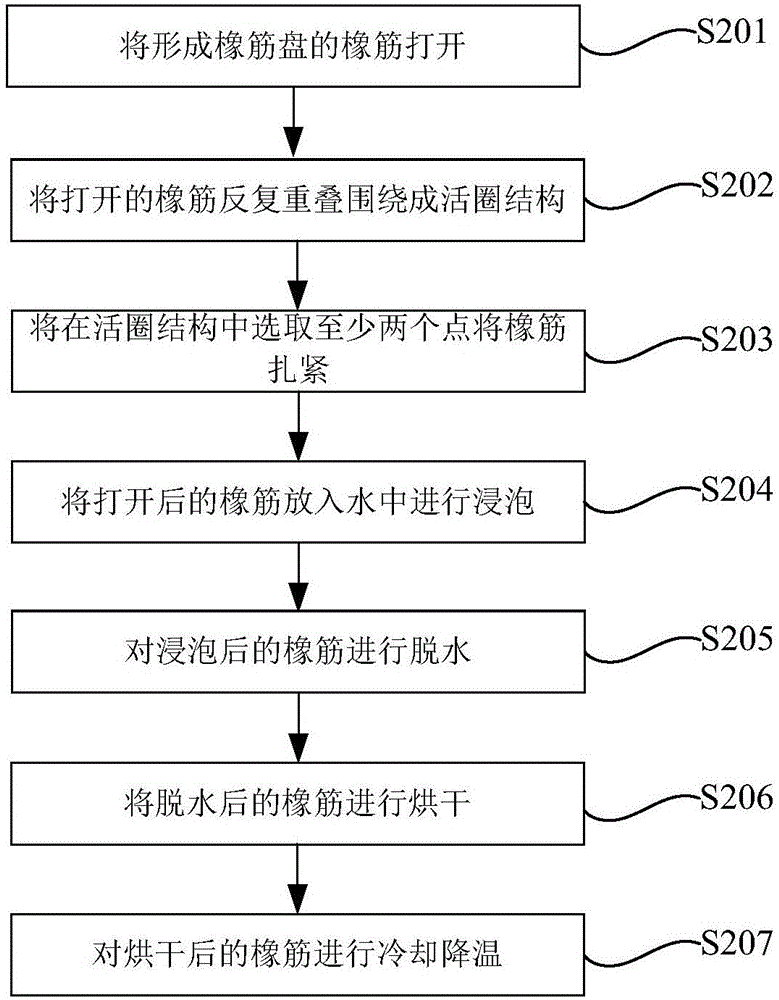

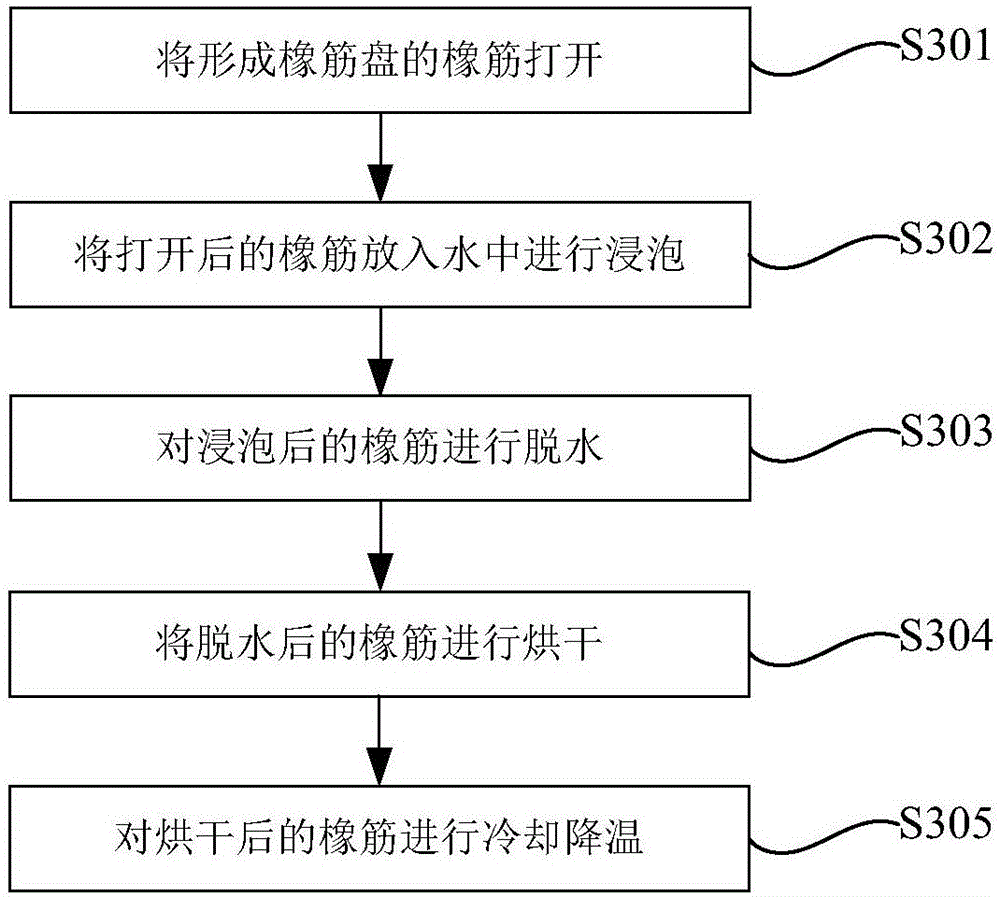

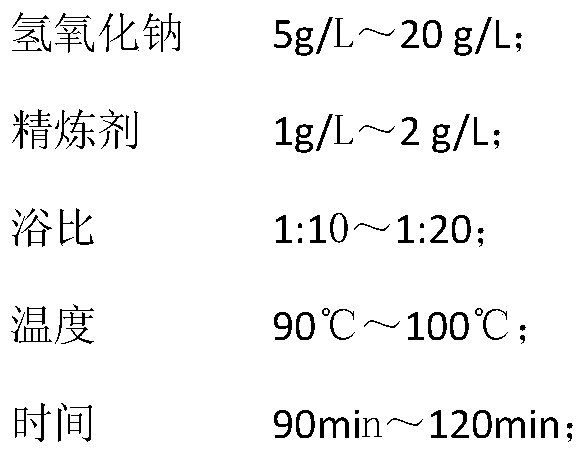

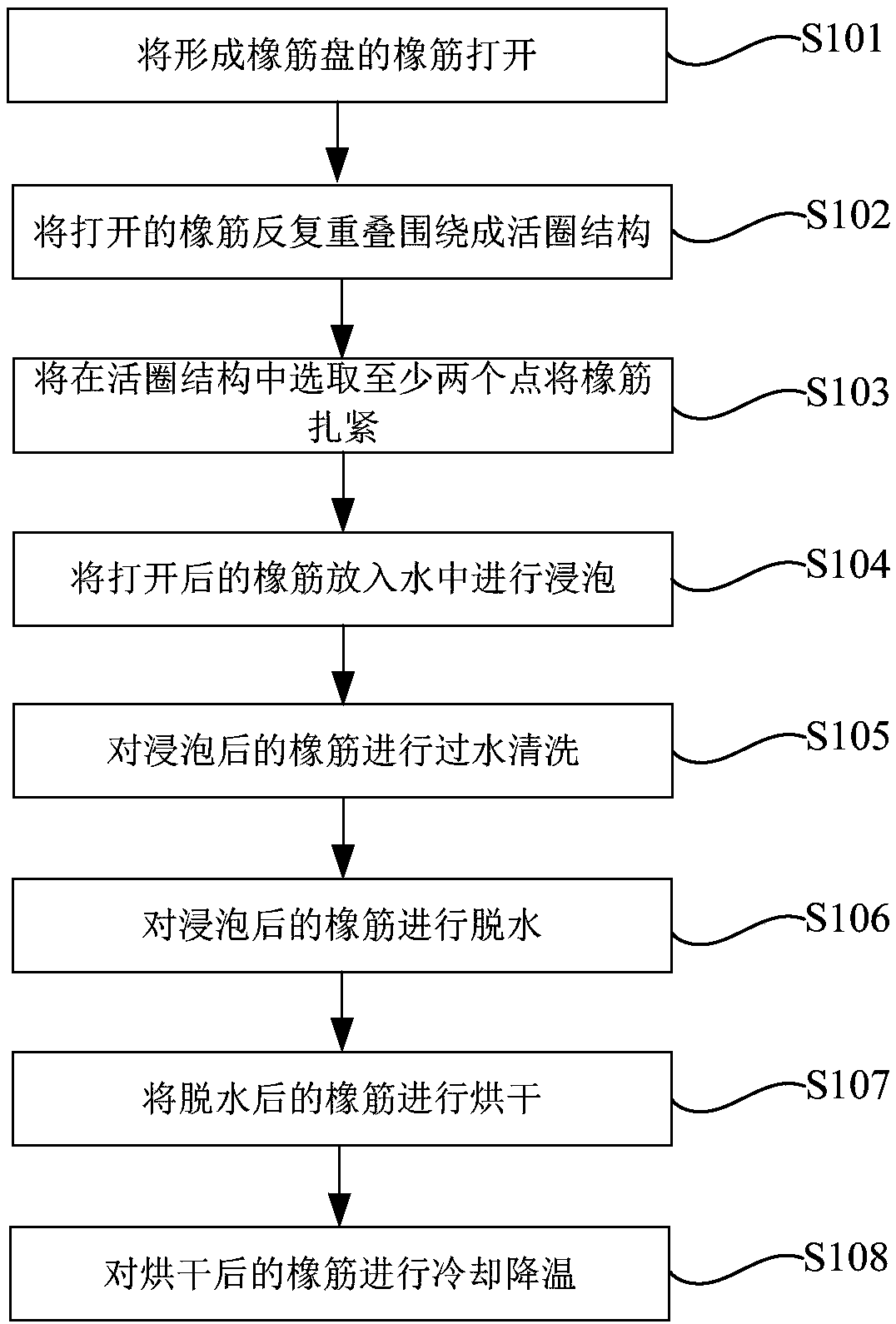

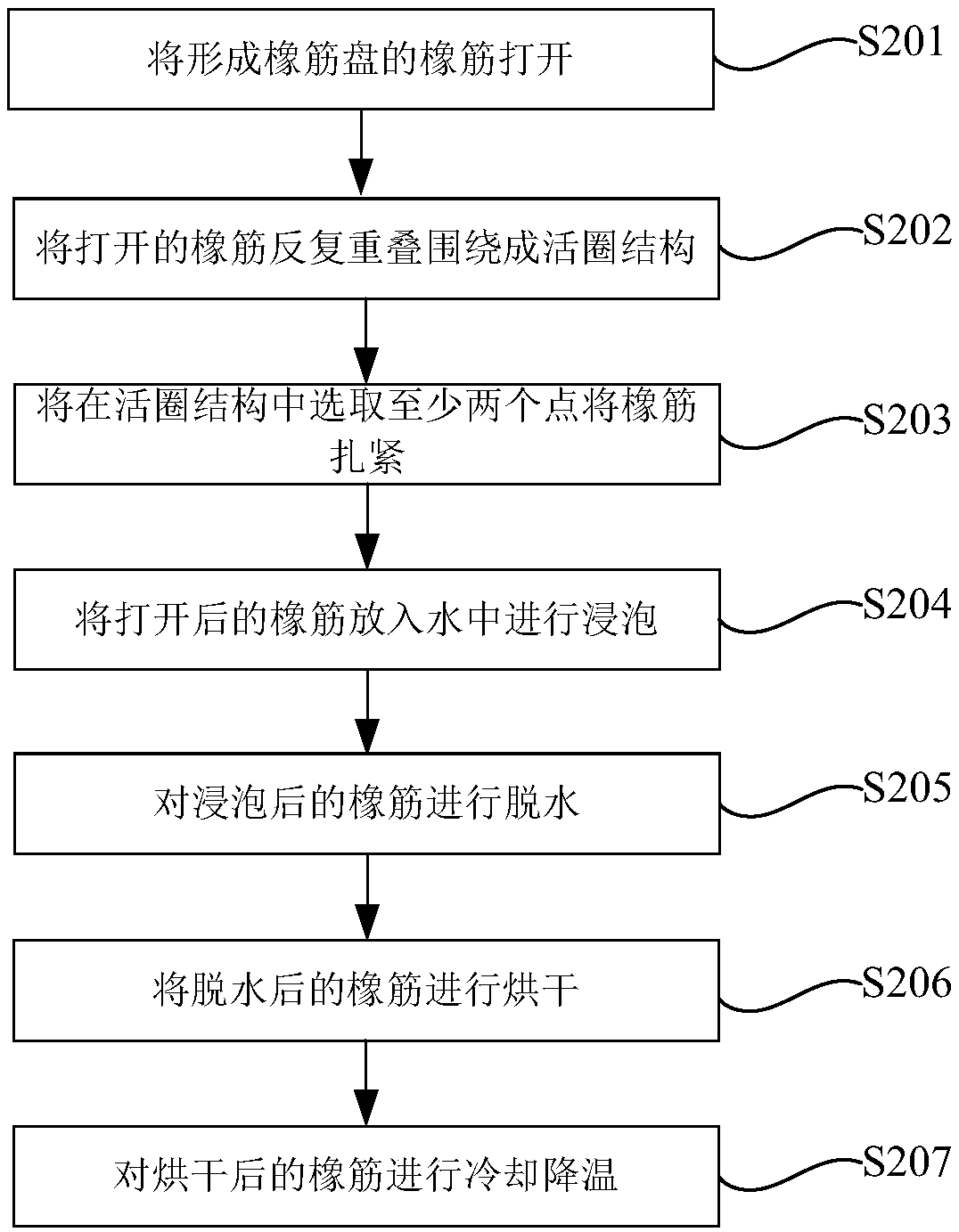

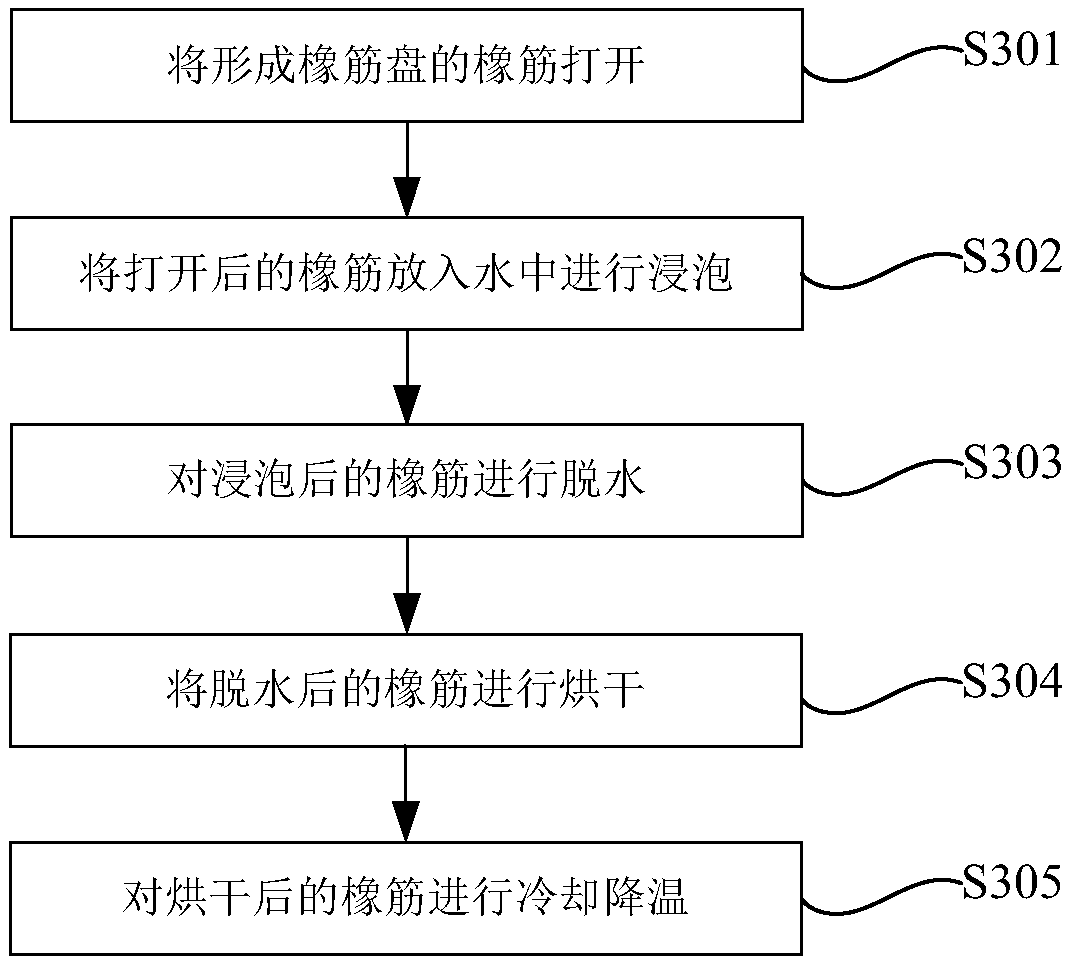

Method for treating water shrinkage of rubber bands

The invention relates to the technical field of garment processing, and discloses a method for treating water shrinkage of rubber bands. The method comprises the following steps of opening a rubber band forming a rubber band disc; putting the opened rubber band into water, and soaking; dewatering the soaked rubber band; drying the dewatered rubber band; cooling the dried rubber band, and lowering the temperature; after the opening of the rubber band forming the rubber band disc, and before the soaking of the opened rubber band into the water, repeatedly surrounding the opened rubber band into a loop structure; selecting at least two points in the loop structure, and binding the rubber band. The method for treating the water shrinkage of the rubber bands has the advantages that the operation is simple, the water shrinkage is completed at one time, the extension and shrinkage rate of the treated rubber band is better, and the problems of serious water shrinkage after water shrinkage of rubber bands and containing of a large amount of harmful matters in the rubber bands in prior art are solved.

Owner:HUNAN DONGFANG FASHION

A kind of production process of bubble wrinkled lattice fabric

ActiveCN107488927BGet a wrinkled effectTargeted optimizationHeating/cooling textile fabricsDry-cleaning apparatus for textilesWrinkle skinEngineering

The invention discloses a production process of bubble wrinkle lattice fabric, which is characterized in that it comprises the following steps: the warp yarns include first warp yarns and second warp yarns, and the first warp yarns and the second warp yarns with different warp yarn tensions are made uniform through a warping process Wound on the warp beam; using the single warp beam weaving process, it is woven into a bubble wrinkled lattice fabric gray cloth; through the post-dyeing and finishing process, the fabric not only forms a unique grid-like distributed bubble fabric, but also has a good texture The four-way elastic hand feeling, the invention solves the problem that single warp beam weaving bubble wrinkle cannot be weaved by innovating in the technology of warping, doubling, weaving, descouring and bleaching.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

A kind of rubber band shrinkage processing method

The invention relates to the technical field of garment processing, and discloses a method for treating water shrinkage of rubber bands. The method comprises the following steps of opening a rubber band forming a rubber band disc; putting the opened rubber band into water, and soaking; dewatering the soaked rubber band; drying the dewatered rubber band; cooling the dried rubber band, and lowering the temperature; after the opening of the rubber band forming the rubber band disc, and before the soaking of the opened rubber band into the water, repeatedly surrounding the opened rubber band into a loop structure; selecting at least two points in the loop structure, and binding the rubber band. The method for treating the water shrinkage of the rubber bands has the advantages that the operation is simple, the water shrinkage is completed at one time, the extension and shrinkage rate of the treated rubber band is better, and the problems of serious water shrinkage after water shrinkage of rubber bands and containing of a large amount of harmful matters in the rubber bands in prior art are solved.

Owner:HUNAN DONGFANG FASHION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com