Preparation method for improving adsorption performance of adsorbent prepared from printing waste liquid

A technology for adsorption properties and extracts, which is applied in the field of improving the adsorption properties of adsorbents prepared from printing waste liquid extracts, can solve the problems of large amount of adsorbents and low adsorption properties of adsorbents, and achieve improved utilization and adsorption properties , The effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

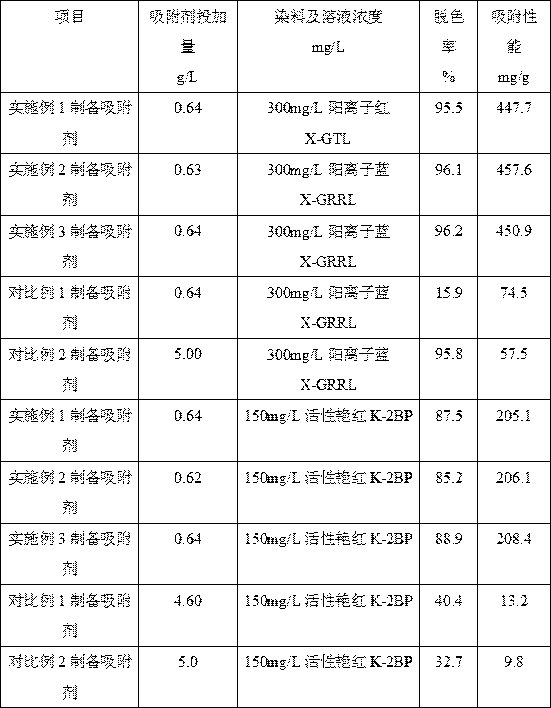

Examples

Embodiment 1

[0026] (1) Add 98% concentrated sulfuric acid to the high-concentration water-based ink printing waste liquid, and stir the reaction to inhibit the ionization degree of the ionizable group of the water-soluble polymer linking material in the waste liquid, reduce the solubility of the linking material, and destroy the connection The stability of the material, so that the extractable substances in the waste liquid just condense into insoluble fine solid particles and cannot be flocculated;

[0027] (2) Stir continuously to make the fine solid particles release bound water, reduce the viscosity of the waste liquid and prevent the further flocculation of the generated fine solid particles, and at the same time add the chemical agent sodium bicarbonate that reacts with the waste liquid to form tiny bubbles into the waste liquid 5g / L, make the air bubbles adhere to the fine solid particles in the waste liquid, form a three-phase contact interface of gas, liquid and solid between the ...

Embodiment 2

[0034] (1) Add 98% glacial acetic acid to the high-concentration water-based ink printing waste liquid, stir the reaction, inhibit the ionization degree of the ionizable group of the water-soluble polymer binder in the waste liquid, reduce the solubility of the binder, and destroy the connection The stability of the material, so that the extractable substances in the waste liquid just condense into insoluble fine solid particles and cannot be flocculated;

[0035] (2) Stir continuously to make the fine solid particles release bound water, reduce the viscosity of the waste liquid and prevent the further flocculation of the generated fine solid particles, and add 8g of sodium carbonate, a chemical agent that reacts with the waste liquid to form tiny bubbles, into the waste liquid / L, make the bubbles adhere to the fine solid particles in the waste liquid, form a gas, liquid and solid three-phase contact interface between the fine solid particles, prevent the fine solid particles ...

Embodiment 3

[0042] (1) Add 40% hydrochloric acid to the high-concentration water-based ink printing waste liquid, stir the reaction, inhibit the ionization degree of the ionizable group of the water-soluble polymer linking material in the waste liquid, reduce the solubility of the linking material, and destroy the linking material Stability, so that the extractable substances in the waste liquid just condense into insoluble fine solid particles and cannot be flocculated;

[0043] (2) Stir continuously to make the fine solid particles release bound water, reduce the viscosity of the waste liquid and prevent the further flocculation of the generated fine solid particles, and at the same time add 10g of potassium carbonate, a chemical agent that reacts with the waste liquid to form tiny bubbles, into the waste liquid / L, make the bubbles adhere to the fine solid particles in the waste liquid, form a gas, liquid and solid three-phase contact interface between the fine solid particles, prevent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com