High temperature and high humidity resistant film capacitor and processing method thereof

A technology of film capacitors and processing methods, applied in the direction of film/thick film capacitors, wire wound capacitors, laminated capacitors, etc., can solve the problems of capacitance capacity and loss changes, life and reliability cannot be guaranteed, and achieve safety Stability improvement, satisfying long life and reliability, and effect of preventing moisture residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

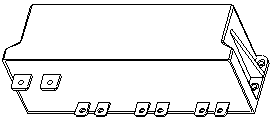

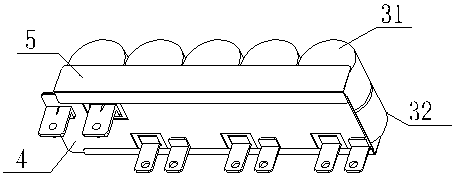

Image

Examples

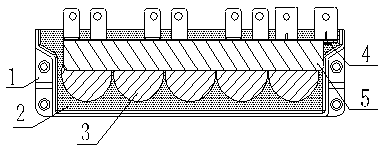

Embodiment Construction

[0021] A processing method for high-temperature and high-humidity film capacitor applications, which includes the following steps: evaporation process, heat setting process and potting process. After the core is shaped, the film layer is more closely bonded to prevent the residual water vapor from causing the film to oxidize, and its oxidation resistance is greatly improved; in the heat setting process, vacuum is drawn during the setting process, and the setting temperature is 100 ° C ~ 120 ° C The time is 4~8 hours, so that the film is fully shrunk, and when the temperature is raised and the vacuum is released, it is filled with an inert gas (such as nitrogen) to isolate the air; The potting is carried out in a vacuum environment, so that the core can effectively isolate the influence of water vapor in the air and improve its oxidation resistance under high temperature and high humidity conditions. In the sealing process, an acid anhydride epoxy high-temperature curing materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com