High-pressure vapour sterilization method of mushroom stick

A technology of high-pressure steam sterilization and shiitake mushroom sticks, which is applied in botany equipment and methods, mushroom cultivation, gardening, etc., to achieve the effects of avoiding plastic bag deterioration, ensuring killing, and avoiding excessive heat reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method of the invention is adopted to sterilize the mushroom sticks.

[0024] First of all, put the mushroom cultivation bags with perforated holes pasted with air-permeable film on the sterilization rack in a straight line, so as to avoid excessive air expansion of the mushroom sticks during the sterilization process and ensure that the mushroom sticks do not expand the bag. Seal the autoclave cabinet.

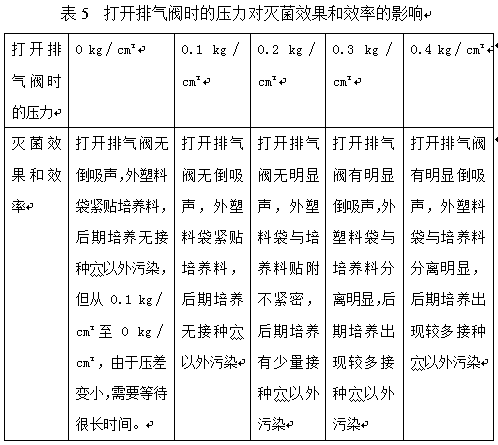

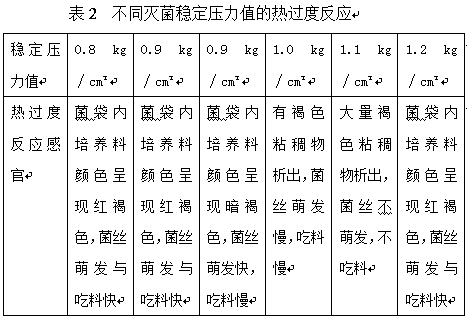

[0025] Secondly, let in the steam, adjust the steam volume to the maximum, so that the steam pressure in the sterilizer can rise as fast as possible, when the pressure rises to 0.9 kg / cm², turn down the intake valve, and gradually open the exhaust valve, Allow the cold air to discharge slowly, and when the pressure drops to zero (no harsh sound), fully open the intake valve, and adjust the steam volume to the maximum, and keep it for 3 to 5 minutes until dense steam is discharged from the exhaust port, then close it After that, adjust the steam volume to the maxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com