A kind of rubber band shrinkage processing method

A processing method and rubber band technology, applied in the field of garment processing, can solve the problems of low efficiency and shrinkage in the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

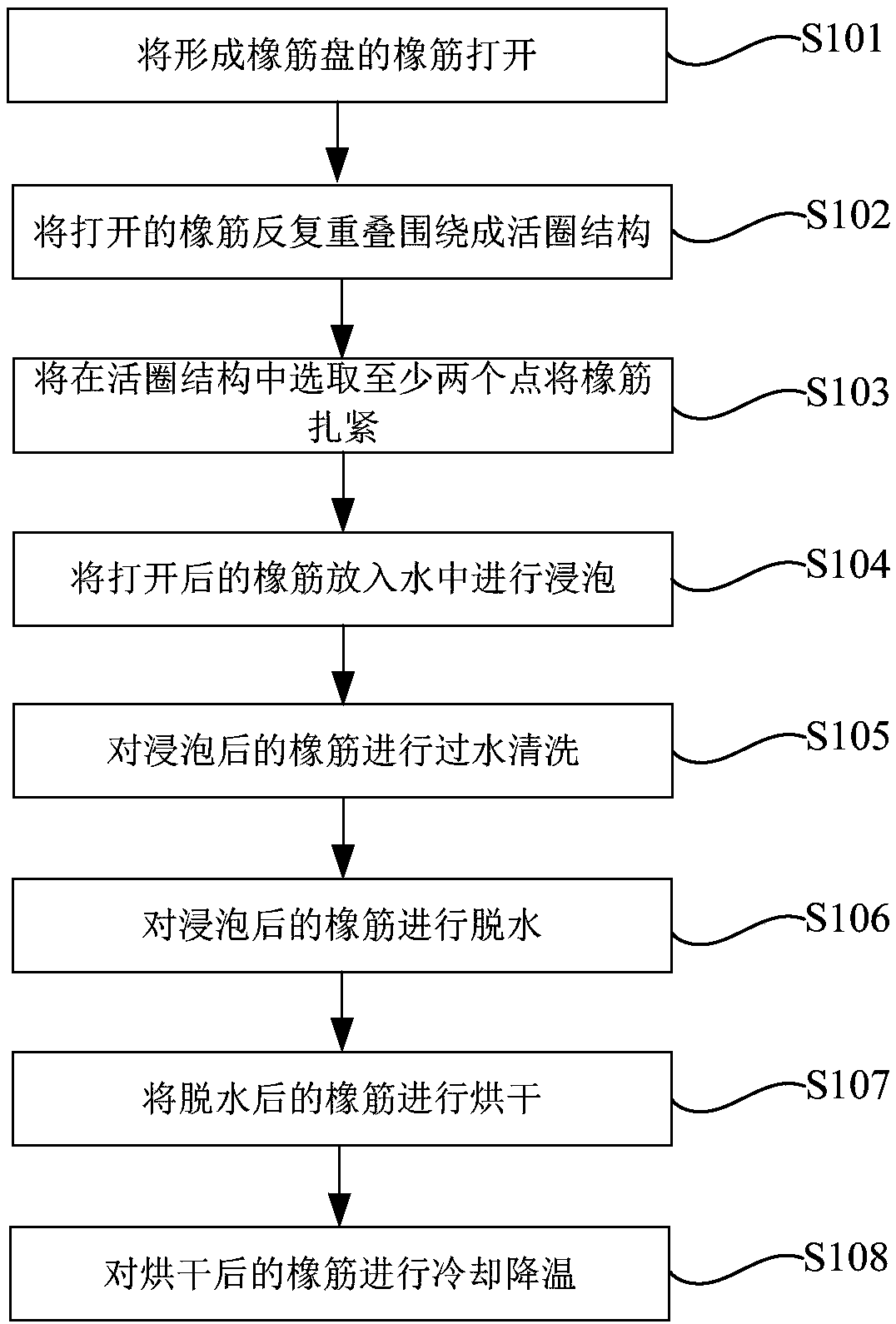

[0068] Such as figure 1 Shown, according to a kind of elastic shrinkage treatment method provided by the present invention, comprising:

[0069] Step S101, opening the elastic bands forming the elastic disc;

[0070] Step S102, overlapping and surrounding the opened elastic repeatedly to form a living ring structure;

[0071] Step S103, select at least two points in the loop structure to tighten the elastic;

[0072] Step S104, soaking the opened elastic in water;

[0073] Step S105, washing the soaked elastic with water;

[0074] Step S106, dehydrating the soaked elastic;

[0075] Step S107, drying the dehydrated elastic;

[0076] Step S108, cooling down the dried rubber band.

[0077] The specific operation process is as follows:

[0078] In step S101, when the elastic band forming the elastic disc is opened, the straight rod is inserted into the center of the elastic disc, and the head of the outer ring of the elastic disc is pulled to rotate the elastic coil around ...

Embodiment 2

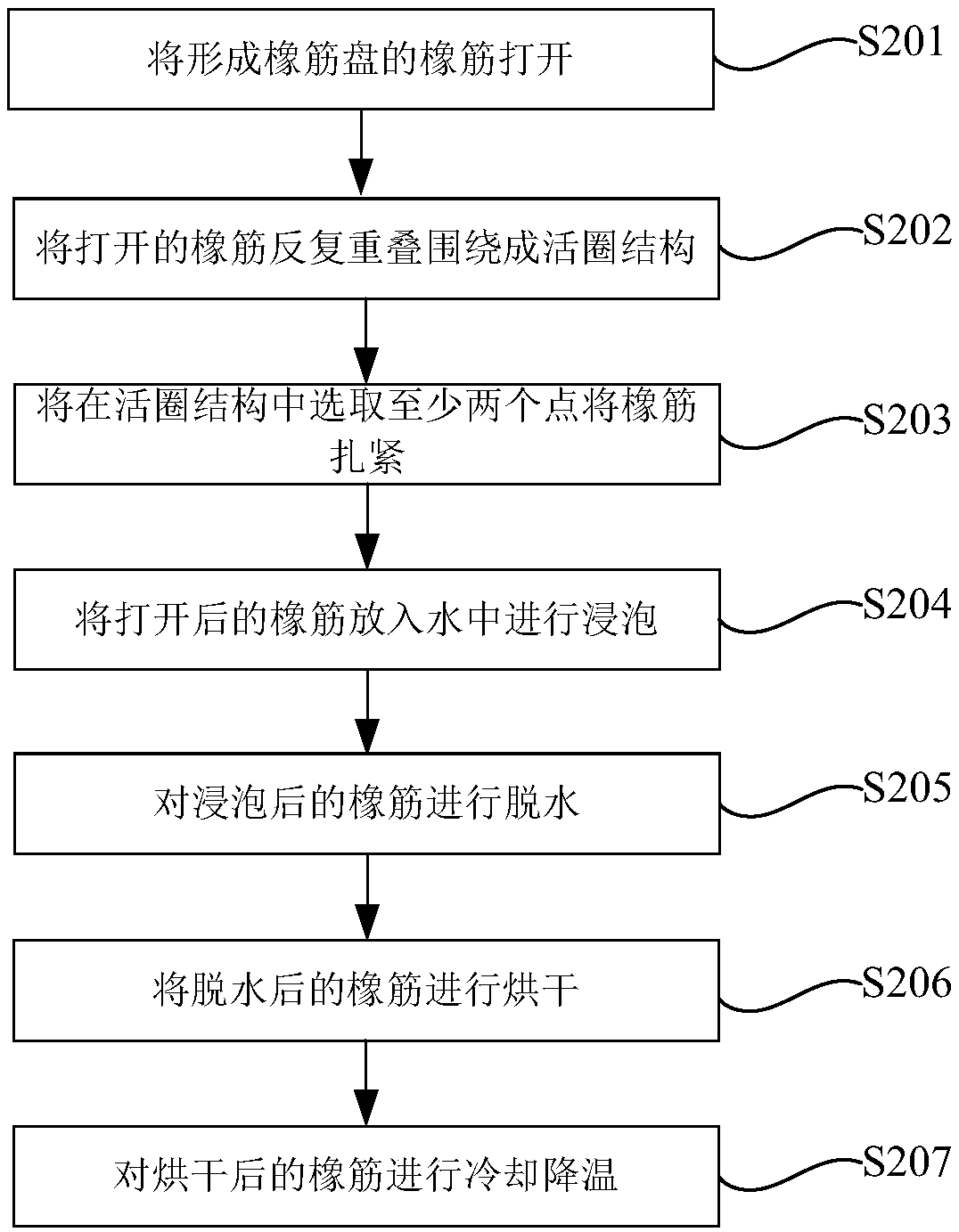

[0080] Such as figure 2 Shown, according to a kind of elastic shrinkage treatment method provided by the present invention, comprising:

[0081] Step S201, opening the elastic bands forming the elastic disc;

[0082] Step S202, repeatedly overlapping the opened elastic bands to form a living ring structure;

[0083] Step S203, select at least two points in the loop structure to tighten the elastic;

[0084] Step S204, soaking the opened elastic in water;

[0085] Step S205, dehydrating the soaked elastic;

[0086] Step S206, drying the dehydrated elastic;

[0087] Step S207, cooling down the dried rubber band.

[0088] The specific operation process is as follows:

[0089] In step S201, when the elastic band forming the elastic disc is opened, the straight rod is inserted into the center of the elastic disc, and the head of the outer circle of the elastic disc is pulled to rotate the elastic coil around the axis line of the straight rod. In step S202, the The opened el...

Embodiment 3

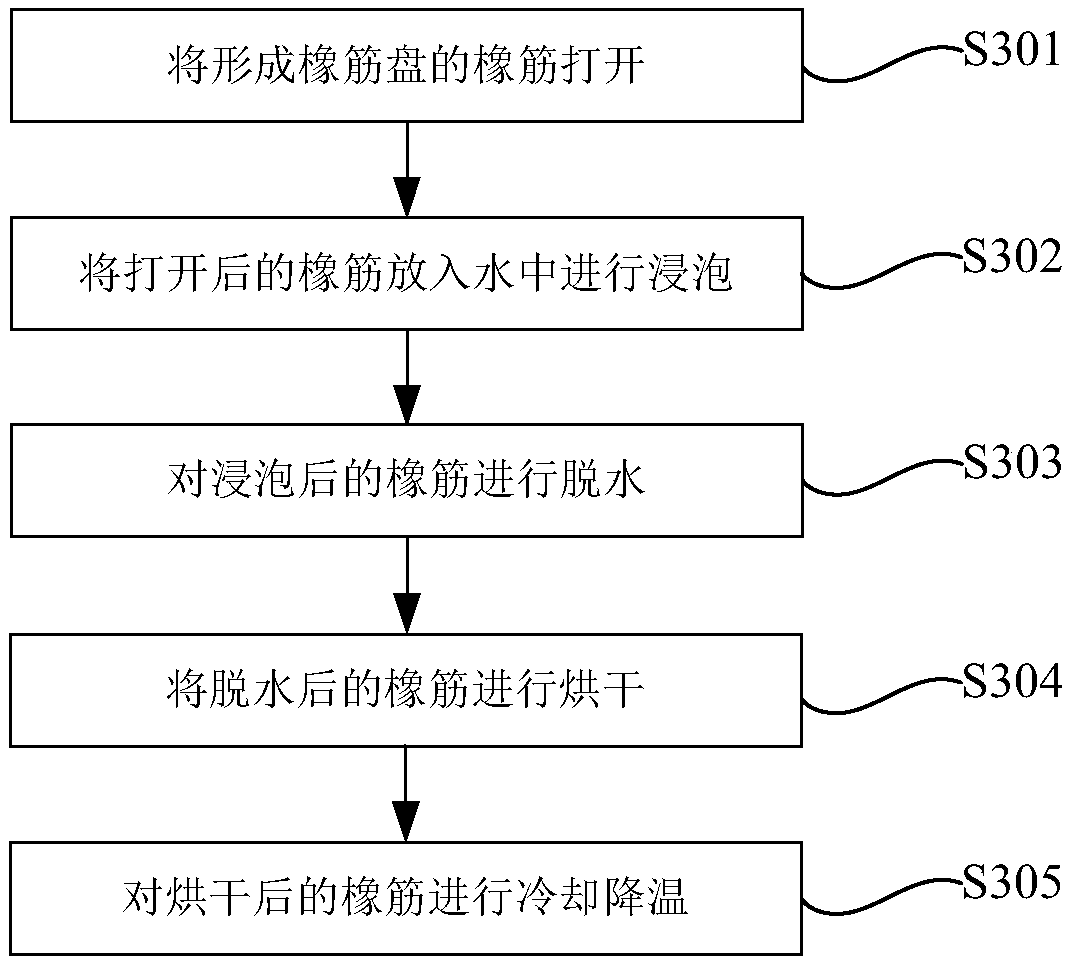

[0091] Such as image 3 Shown, according to a kind of elastic shrinkage treatment method provided by the present invention, comprising:

[0092] Step S301, opening the elastic bands forming the elastic disc;

[0093] Step S302, soaking the opened elastic in water;

[0094] Step S303, dehydrating the soaked elastic;

[0095] Step S304, drying the dehydrated elastic;

[0096] Step S305, cooling down the dried rubber band.

[0097] The specific operation process is as follows:

[0098] In step S301, when the elastic band forming the elastic disc is opened, the straight rod is inserted into the center of the elastic disc, and the head of the outer ring of the elastic disc is pulled to rotate the elastic coil around the axis line of the straight rod, and then the steps are carried out S302 put the opened elastic into water for soaking, and the amount of soaking water is 5 times that of the elastic and the water cannot be heated. The soaking time is 30 minutes. In step S303, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com