Colored knitted fleeced cloth, dyeing process thereof in O-type vat and clothes

A flannel, colored technology, applied in the direction of dyeing, textile and papermaking, etc., can solve the problems of general bulkiness and elasticity of knitted fleece, and achieve the effect of obvious coloring effect, strong color three-dimensional effect and high comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

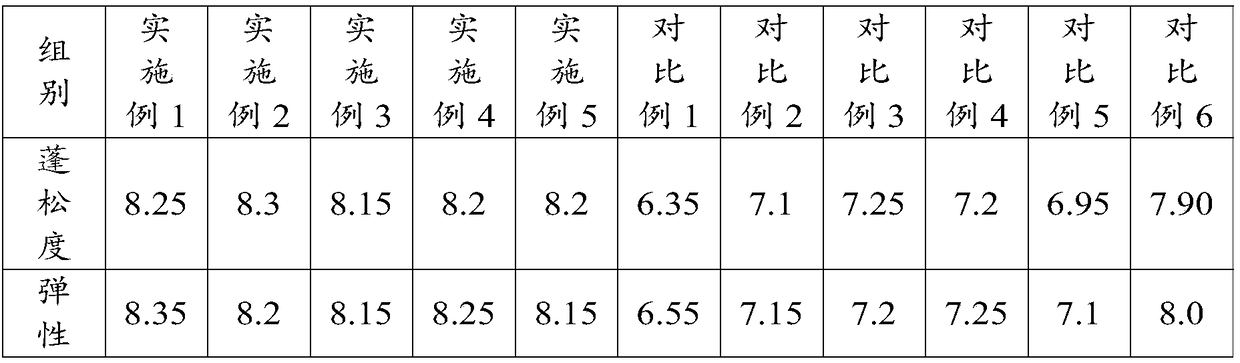

Examples

Embodiment 1

[0037] The embodiment of the invention provides colored knitted fleece and O-shaped cylinder dyeing process.

[0038] A kind of O-type cylinder dyeing process of colored knitted fleece, the specific operation steps are as follows:

[0039] The knitted flannelette which is processed by the reduction process and processed by blending polyester yarn with a share ratio of 1:1 and modified polyester yarn is transported to the O-shaped cylinder, and the mass ratio is 1:1. It is a dyeing agent mixed with a neutral dyeing agent and a cationic dyeing agent, and the dosage of the dyeing agent is 0.5g / L. After the dyeing agent is added, it is evenly mixed with the liquid in the O-type cylinder, and then the temperature of the O-type cylinder is increased to raise the temperature of the dye solution to 125 degrees Celsius, and the temperature is kept for 25 minutes, so that part of the dye solution in the O-type cylinder is converted into a gaseous state. The medium dyeing liquid is spra...

Embodiment 2

[0044] The embodiment of the invention provides colored knitted fleece and O-shaped cylinder dyeing process.

[0045] A kind of O-type cylinder dyeing process of colored knitted fleece, the specific operation steps are as follows:

[0046]The knitted flannelette to be raised after the reduction process and processed by the blending of polyester yarn with a share ratio of 1:2 and modified polyester yarn is transported to the O-type cylinder, and the mass ratio of 1:2 is added. The dyeing agent is a mixture of neutral dyeing agent and cationic dyeing agent, and the dosage of dyeing agent is 1g / L. After the dyeing agent is added, it is evenly mixed with the liquid in the O-type cylinder, and then the temperature of the O-type cylinder is increased to raise the temperature of the dye solution to 150 degrees Celsius, and the temperature is kept for 35 minutes, so that part of the dye solution in the O-type cylinder is converted into a gaseous state. The medium dyeing liquid is spr...

Embodiment 3

[0051] The embodiment of the invention provides colored knitted fleece and O-shaped cylinder dyeing process.

[0052] A kind of O-type cylinder dyeing process of colored knitted fleece, the specific operation steps are as follows:

[0053] The knitted flannelette which has been processed by the reduction process and processed by blending polyester yarn with a share number ratio of 1:1.5 and modified polyester yarn is transported to the O-shaped cylinder, and the mass ratio is 1:1.5. It is a dyeing agent mixed with a neutral dyeing agent and a cationic dyeing agent, and the dosage of the dyeing agent is 0.6g / L. After the dyeing agent is added, it is evenly mixed with the liquid in the O-type tank, and then the temperature of the O-type tank is increased to raise the temperature of the dye solution to 130 degrees Celsius, and the temperature is kept for 30 minutes, so that part of the dye solution in the O-type tank is converted into a gaseous state. The medium dyeing liquid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com