Cooling shaping device of full-automatic packing belt producing machine

A technology of cooling and shaping and packing belts, which is applied to belts, other household appliances, household appliances, etc., can solve the problems of insufficient cooling and thermal shaping, poor product quality, and affecting the output of packing belts, etc., to improve quality and aesthetics , Eliminate deformation, prolong the effect of cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

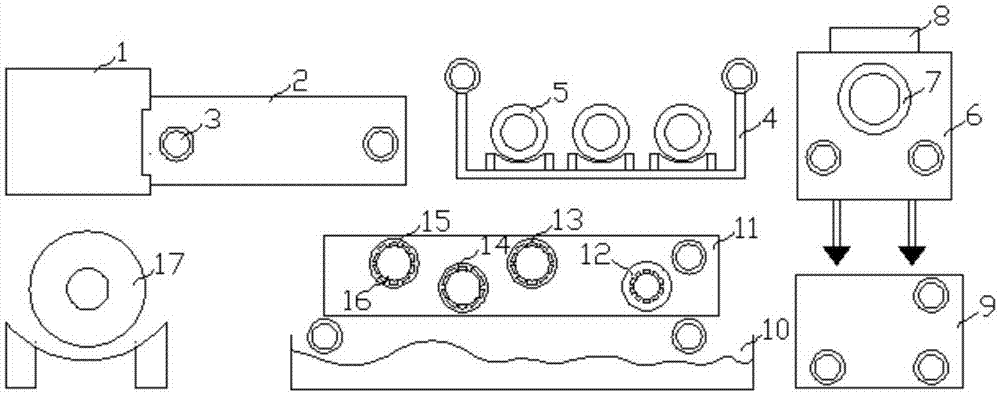

[0015] Example: such as figure 1 As shown, the present invention provides a cooling and shaping device for a fully automatic production machine for strapping, comprising an extruder 1 and a cooling water tank 2 connected to one side of the extruder 1, and the other end of the cooling water tank 2 passes through a transmission roller 3 and a packaging The belt is connected to the printing machine 4, the interior of the printing machine 4 is provided with a printing frame 5, the other end of the printing machine 4 is connected to the oven 6, the oven 6 is provided with a stretching roller 7, the top of the oven 6 is provided with a heater 8, and the oven 6 passes through The transmission roller 3 and the packing belt are connected to the thermal shaping machine 9, and one end of the thermal shaping machine 9 is connected to the motor box 11 through the transmission roller 3, and the surface of the motor box 11 is provided with a first steel wheel 12, a second steel wheel 13, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com