Method for processing super fluff memory stretch fabric

A processing method and fabric technology, applied in the field of fabric processing, can solve the problems of hard hand feeling, poor wearing comfort, and strong chemical fiber texture of memory fabrics, and achieve the effect of improving hard hand feeling, soft hand feeling and good resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] As a preferred embodiment of the present invention, the pre-shrinking process is specifically:

[0036] Place the fabric after weaving in a mixed pre-finishing agent including 30% concentration of liquid alkali, diffusing agent, penetrating agent and softener, and pre-shrink at 110°C for 60 minutes, wherein, liquid alkali, diffusing agent, penetrating agent and The mass proportions of softeners added are 0.15%, 0.8%, 1% and 1% respectively.

[0037] More preferably, the penetration agent is penetration agent JFC, the diffusion agent is diffusion agent NNO, and the softener is softener N-100.

[0038] As a preferred embodiment of the present invention, the pre-setting process conditions are as follows: process the pre-shrunk fabric on a setting machine at a speed of 45m / min at 190-193°C, and then cool to complete the pre-setting.

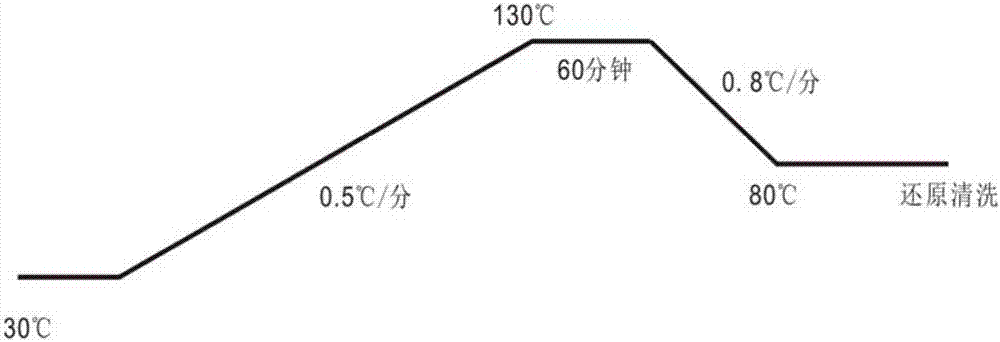

[0039] As a preferred embodiment of the present invention, the fiber opening process includes weight reduction primary fiber opening and com...

Embodiment 1

[0050] A processing method of a super cashmere memory elastic fabric, which is obtained by weaving memory fibers as warp yarns and T400 fibers as weft yarns, followed by preshrinking, presetting, fiber opening, airflow dyeing, setting and cashmere calendering.

[0051] In this embodiment, the memory fiber adopts 75D PPT shape memory fiber, and the T400 fiber adopts 150D T400 fiber;

[0052] The memory fiber is twisted to 76 twists / m, and the T400 fiber is twisted to 40 twists / m. The pre-shrinking process of the present embodiment is specifically:

[0053] Place the fabric after weaving in the mixed pre-finishing agent including 30% concentration of liquid alkali, diffusing agent NNO, penetrating agent JFC and softener N-100, and pre-shrink at 110°C for 60 minutes. Among them, liquid alkali, diffusing agent The mass proportions of additives, penetrating agents and softeners are 0.15%, 0.8%, 1% and 1% respectively.

[0054] The technical conditions of the pre-setting in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com