Preparation method and application of waterproof and oilproof fluorosilicone acrylate finishing agent

A silicone-acrylic, water- and oil-repellent technology, which is used in fiber processing, textiles and papermaking. Performance, soft and slippery hand, the effect of improving fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation steps of the present invention are:

[0034] (1), get the following combinations by weight and mix uniformly:

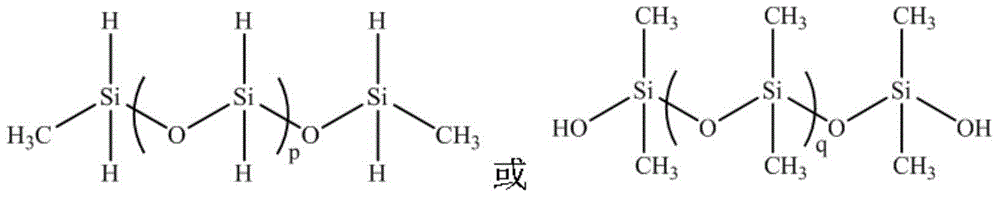

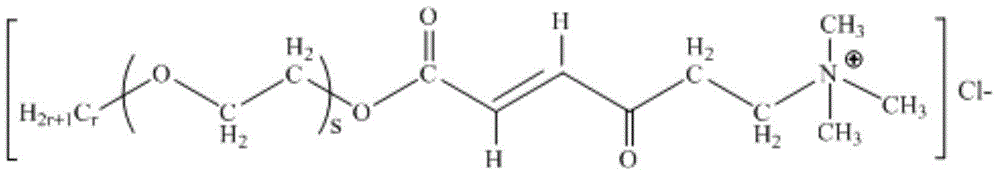

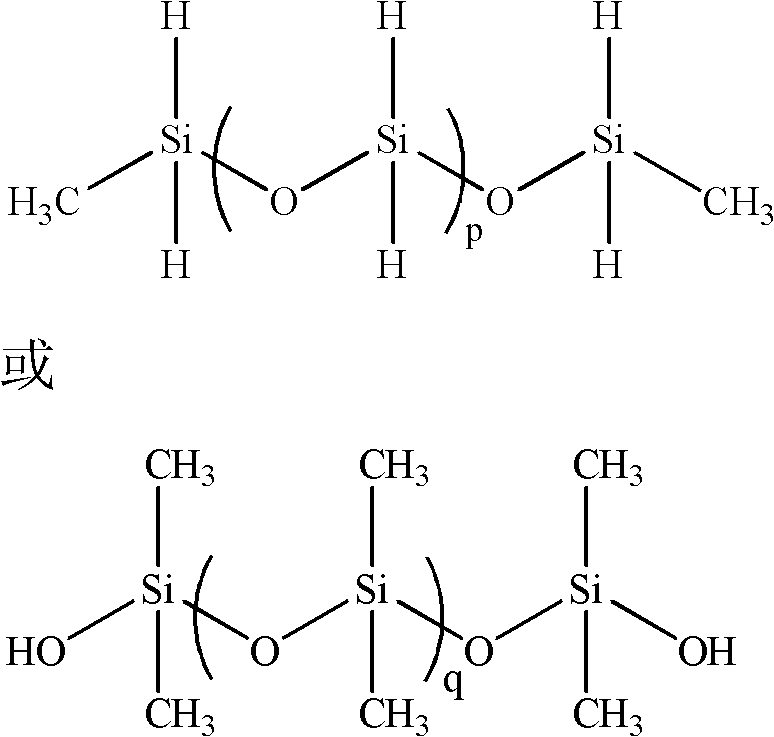

[0035] 400 parts of deionized water, 3-6 parts of cationic surfactant, 1-4 parts of non-ionic surfactant, 50-70 parts of perfluoroalkyl ethyl methacrylate, 5 parts of polyethylene glycol (mono) acrylate ~10 parts, 20-30 parts of alkyl acrylate, 5-10 parts of modified dimethyl silicone oil, 20 parts of alcohol or ether co-solvent;

[0036] (2), homogeneously emulsify the mixture of step (1) at 30-40°C for 15 minutes;

[0037] (3), transfer the reactant of step (2) into a reaction flask equipped with a condenser, nitrogen tube, stirrer, and thermometer, turn on the nitrogen protection and heat to 60°C, and then add 1 to 2 parts by weight of a free radical initiator , stirred and reacted for 8 hours;

[0038] (4) Cool to room temperature and filter to obtain the fluorine-containing silicone acrylic finishing agent.

Embodiment 1

[0041] Weigh 400 grams of deionized water, 3 grams of polymerizable cationic surfactant, 2 grams of TO-5 fatty alcohol polyoxyethylene ether (EO number is 5), perfluoroalkyl (C6-10) ethyl methacrylate 70 grams, 5 grams of methoxypolyethylene glycol (polyethylene glycol molecular weight is 300) methacrylate, 20 grams of octadecyl acrylate, 5 grams of dimethyl hydrogen silicone oil, 20 grams of ethylene glycol, After mixing evenly, place it at 30-40°C for homogeneous emulsification for 15 minutes, transfer it to a 1L four-necked bottle equipped with a condenser, nitrogen tube, stirrer, and thermometer, turn on the nitrogen gas and heat it to 60°C in a water bath. Add 1.8 g of initiator azobisisobutylimidazole hydrochloride (V-50), react for 8 hours, cool to room temperature and filter to obtain polymer emulsion.

Embodiment 2

[0043] Weigh 400 grams of deionized water, 5 grams of polymerizable cationic surfactant, 2 grams of TO-5 fatty alcohol polyoxyethylene ether (EO number is 5), perfluoroalkyl (C6-10) ethyl methacrylate 70 grams, 5 grams of methoxypolyethylene glycol (polyethylene glycol molecular weight is 350) methacrylate, 20 grams of octadecyl acrylate, 5 grams of dimethyl hydrogen-containing silicone oil, 20 grams of propylene glycol, mix well After that, place it at 30-40°C for homogeneous emulsification for 15 minutes, transfer it to a 1L four-necked bottle equipped with a condenser, nitrogen tube, stirrer, and thermometer, turn on the nitrogen gas and heat it to 60°C in a water bath, add trigger Agent azobisisobutylimidazole hydrochloride (V-50) 2 grams, reacted for 8 hours, cooled to room temperature and filtered to obtain a polymer emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com