A production process of ultra-soft, slippery, anti-pilling and skin-friendly cvc jersey

A production process and anti-fluffing technology, which is applied in the field of fabric production, can solve the problems that the anti-fluffing performance and comfort cannot meet high standards, it is difficult to meet the needs of the market and consumers, and the fabric is not smooth and hydrophilic, etc. , to achieve the effect of improving anti-pilling performance, good ventilation and perspiration effect, and tight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A production process of super-soft slippery anti-pilling skin-friendly CVC jersey, comprising the following steps:

[0033] (1) Spinning: use the siro spinning process to blend 80% cotton and 20% polyester into yarn by weight percentage;

[0034] (2) Weaving: the yarn in step (1) is spun into 26S / 1 plain jersey;

[0035] Middle-row knitting in the weaving process: first-level needles and second-level needles, the two kinds of needles are arranged in turn, and the yarn is doffed and fed into each mold.

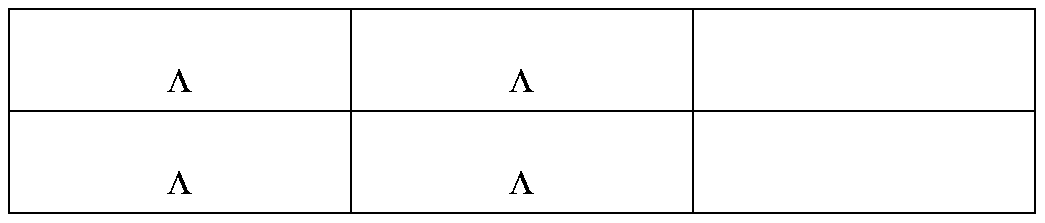

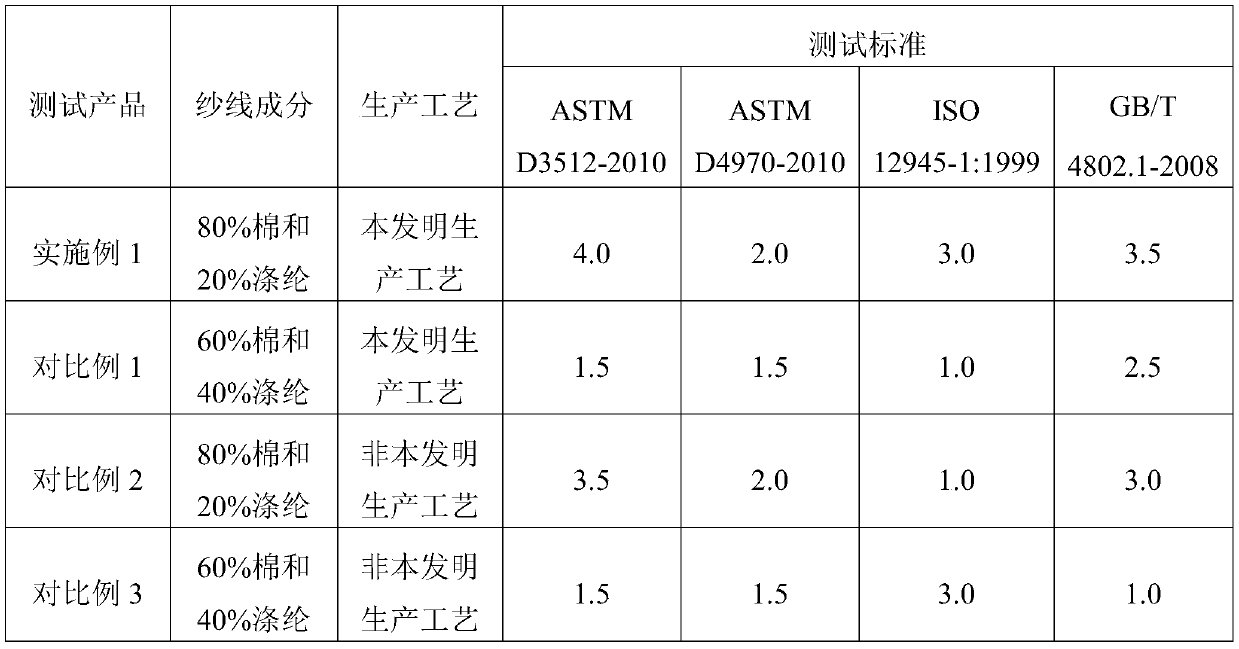

[0036] Row of knitting needle runway or row of water chestnut: as shown in Table 1.

[0037] Table 1: Λ means circle, n means tuck, - means floating line.

[0038]

[0039]

[0040] (3) Pretreatment: Treat the jersey in step (2) at 98°C for 30 minutes with a pretreatment solution containing 1 g / L of penetrant, 2 g / L of caustic soda and 2 g / L of hydrogen peroxide, and then take out the cloth;

[0041] (4) peracid deoxygenation: add acetic acid 0.5g / L and 0.05wt% ...

Embodiment 2

[0051] A production process of super-soft slippery anti-pilling skin-friendly CVC jersey, comprising the following steps:

[0052] Step (1) and step (2) of this embodiment 2 are identical with step (1) and step (2) of embodiment 1;

[0053] (3) Pretreatment: Treat the jersey cloth in step (2) at 95°C for 20 minutes with a pretreatment liquid containing 0.5g / L of penetrant, 1g / L of caustic soda and 1g / L of hydrogen peroxide, and then take out the cloth;

[0054] (4) peracid deoxygenation: add acetic acid 0.2g / L and 0.01wt% deoxygenase to the cloth of step (3) to carry out peracid deoxygenation treatment;

[0055] (5) Dyeing polyester: add acetic acid 0.2g / L, sodium acetate 0.2g / L and JH-T / C disperse dye leveling agent 0.2g / L and disperse dye to the cloth of step (4), and heat at 125 ℃ Under treatment for 40min;

[0056] (6) Reduction: Add caustic soda 2g / L and sodium hydrosulfite 2g / L to the cloth in step (5), and treat at 70°C for 10 minutes;

[0057] (7) Cleaning: Add 0.5 ...

Embodiment 3

[0064] A production process of super-soft slippery anti-pilling skin-friendly CVC jersey, comprising the following steps:

[0065] Step (1) and step (2) of present embodiment 3 are identical with step (1) and step (2) of embodiment 1;

[0066] (3) Pretreatment: Treat the jersey in step (2) at 100°C for 40 minutes with a pretreatment solution containing 1.5g / L of penetrant, 3g / L of caustic soda and 3g / L of hydrogen peroxide, and then take out the cloth;

[0067] (4) peracid deoxygenation: add acetic acid 0.8g / L and 0.08wt% deoxygenase to the cloth of step (3) to carry out peracid deoxygenation treatment;

[0068] (5) Dyeing polyester: add acetic acid 0.8g / L, sodium acetate 0.8g / L and JH-T / C disperse dye leveling agent 0.8g / L and disperse dye to the cloth of step (4), and heat at 135 ℃ Under treatment for 50min;

[0069] (6) Reduction: Add caustic soda 5g / L and sodium hydrosulfite 5g / L to the fabric in step (5), and treat at 90°C for 30 minutes;

[0070] (7) Cleaning: Add 0.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com