Patents

Literature

54results about How to "Fluffy surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

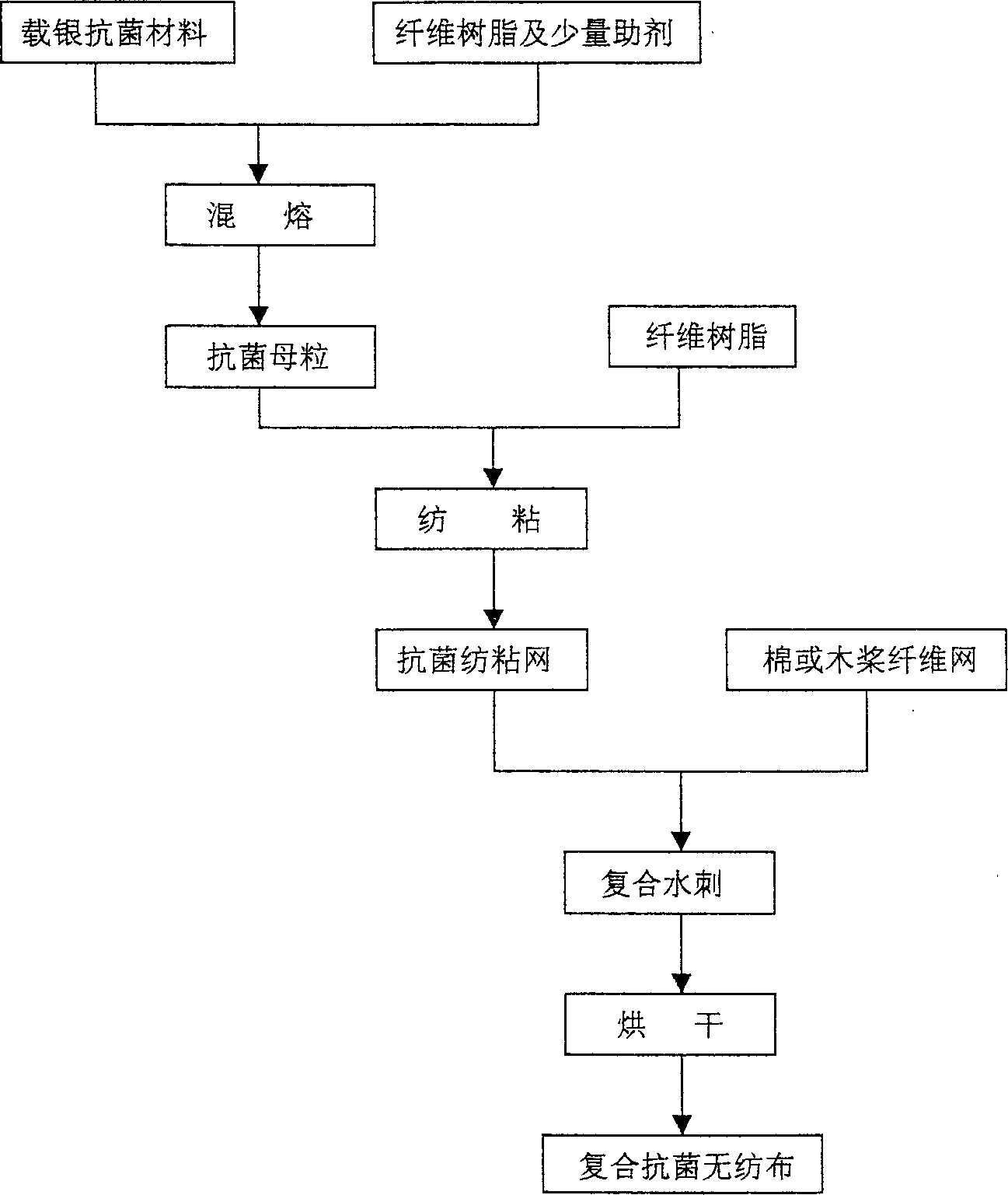

Process for preparing Ag-carried antibacterial composite non-woven fabric

InactiveCN1346905ANot easy to fall offImprove antibacterial propertiesNon-woven fabricsArtifical filament manufacturePolymer scienceCotton fibre

A process for preparing Ag-carried antibacterial composite non-woven fabric includes preparing antibacterial mother particles from Ag-carried antibacterial material, fibre resin and plastic assistant by screw extruding, preparing antibacterial spun-bonded mesh from said antibacterial mother particles and fibre resin, combining said antibacterial spun-bonded mesh with cotton fibre mesh or wood pulp fibre mesh, hydro-entangling, and drying. Its advantages are high antibacterial power and durability, and broad spectrum.

Owner:韦卫军

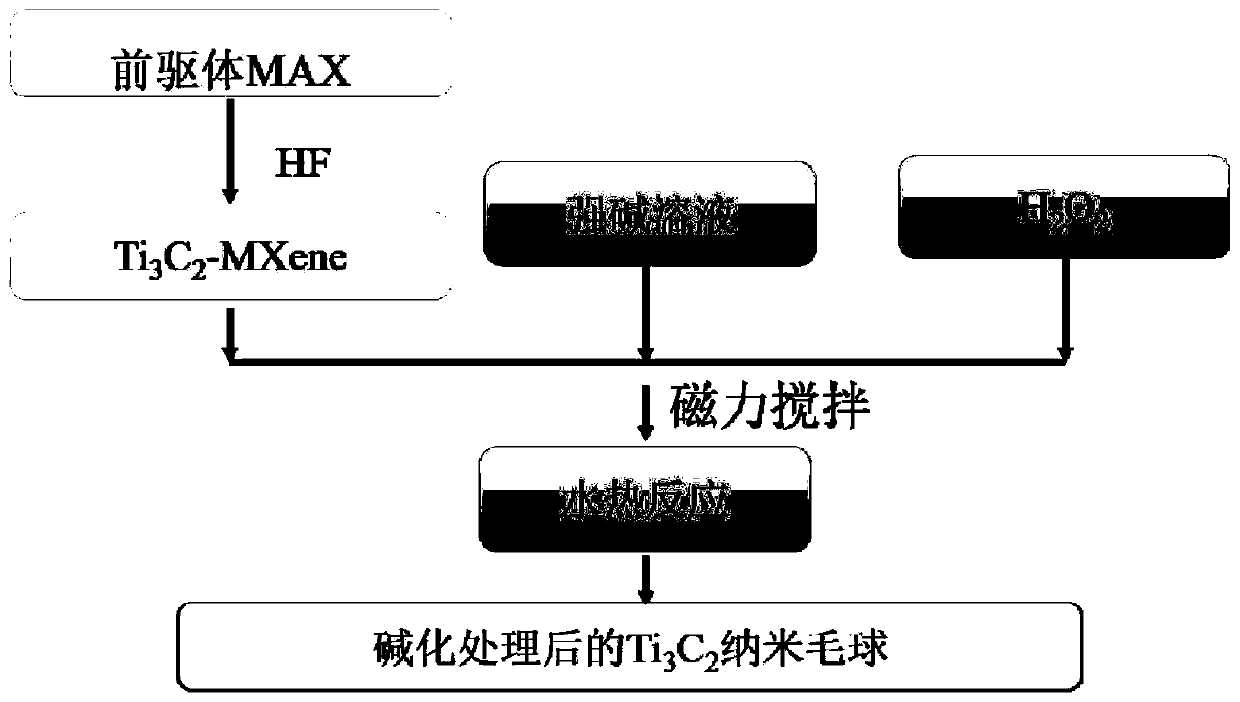

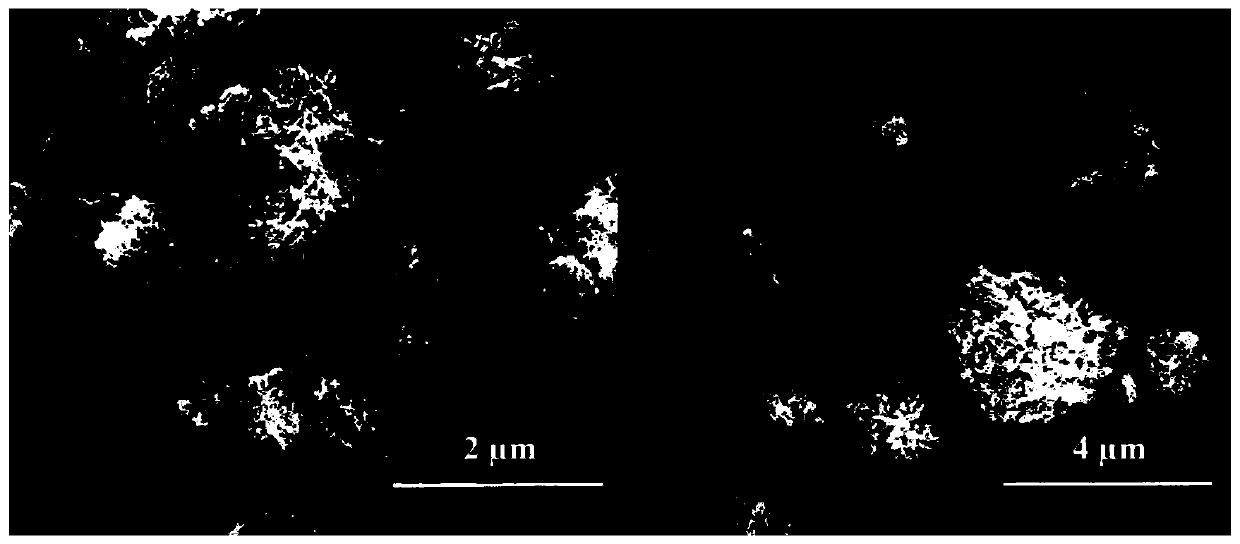

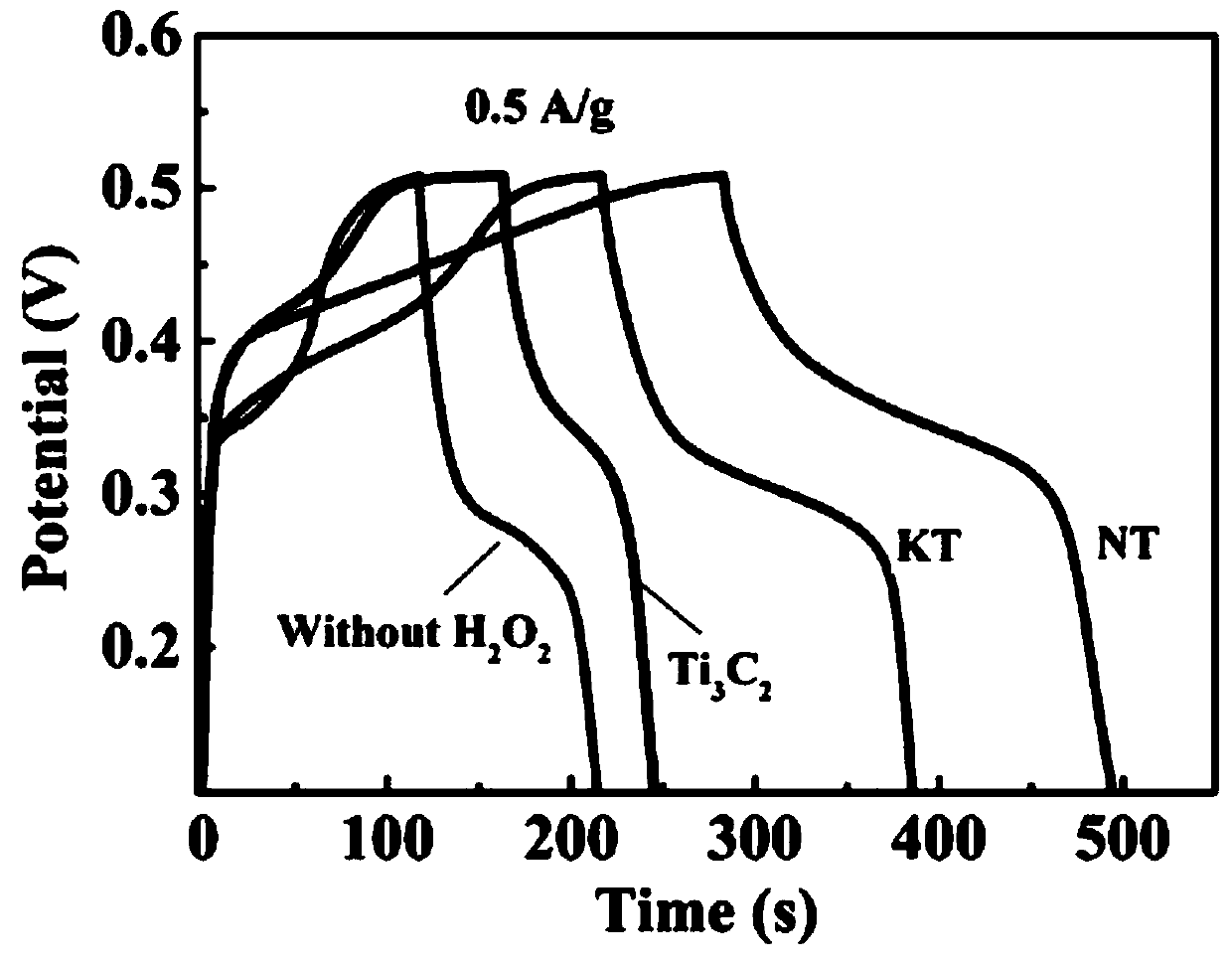

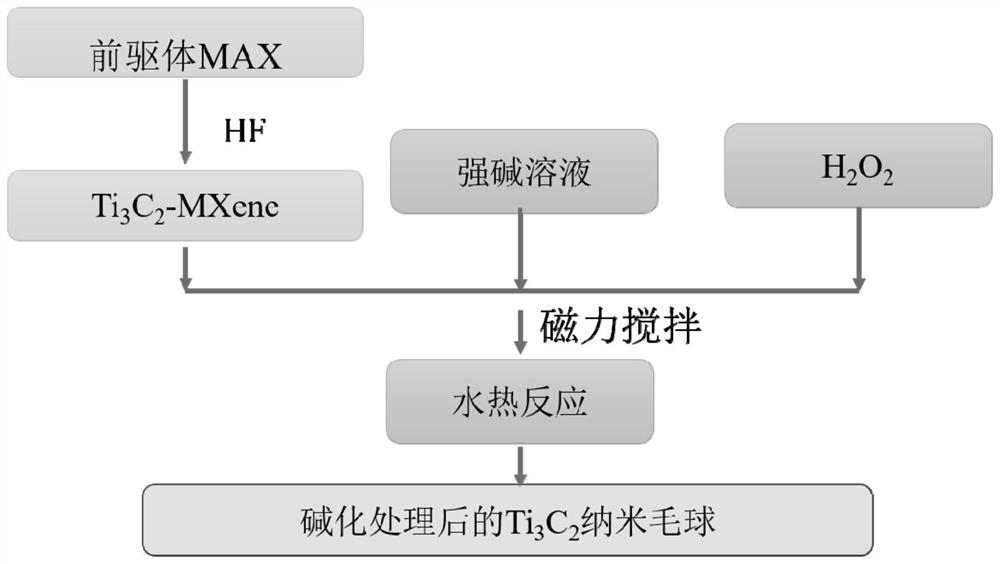

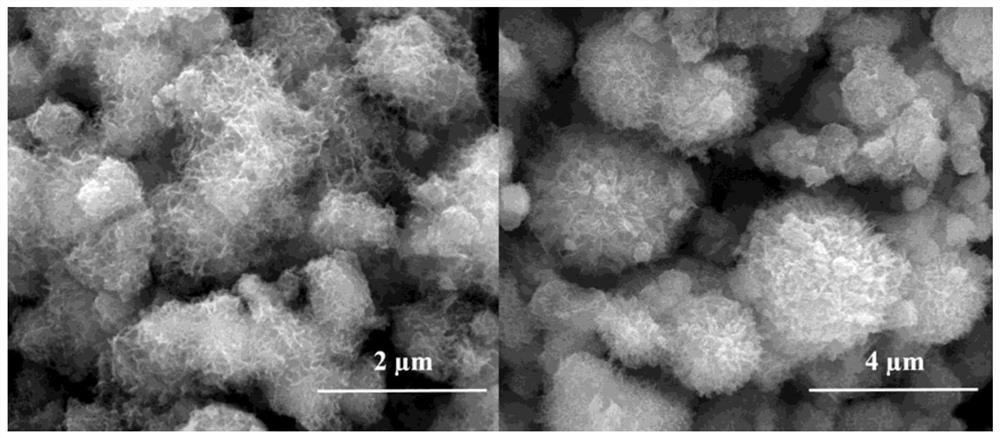

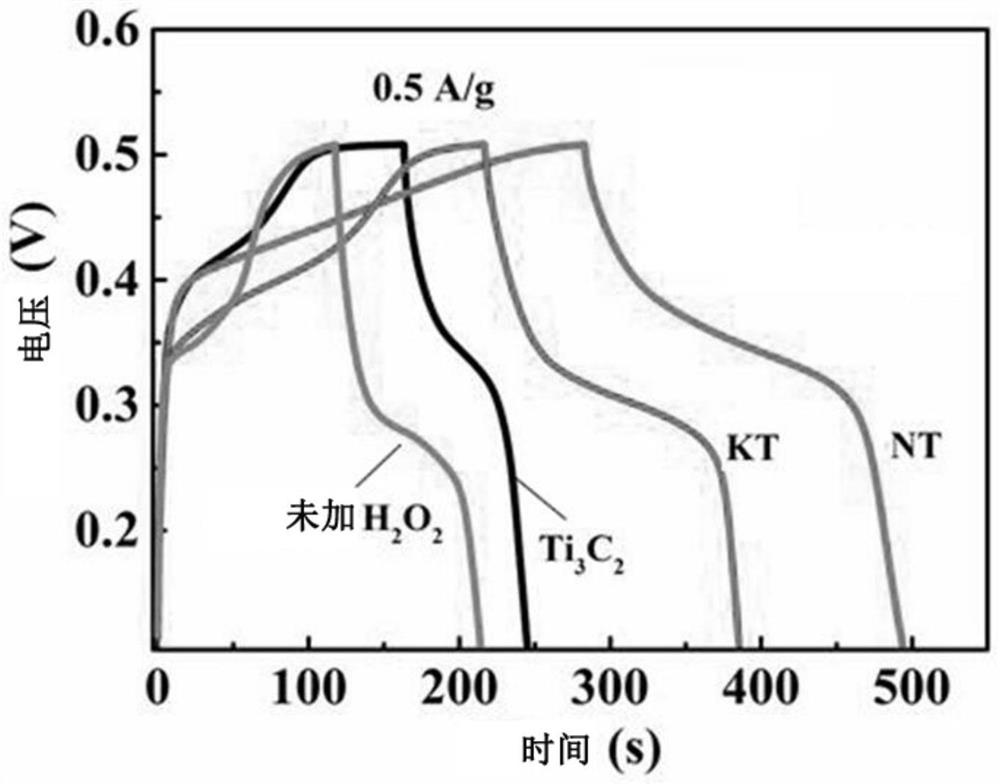

Preparation method and applications of hairy ball type Ti3C2(MXene)nanometer material

ActiveCN110723737AFluffy surfaceIncrease surface areaMaterial nanotechnologyCell electrodesElectrochemical energy storageLithium electrode

The invention discloses a preparation method and applications of a hairy ball type Ti3C2(MXene)nanometer material. The preparation method comprises: adding a precursor Ti3AlC2(MAX) into HF, magnetically stirring for 72 h at a room temperature, centrifugally washing to achieve a neutral state, collecting precipitate, and drying at 60 DEG C to obtain black powder, ie., a two-dimensional Ti3C2(MXen)material; and adding the two-dimensional Ti3C2(MXene) material into a mixed solution containing a strong alkali and H2O2, uniformly stirring, carrying out hydrothermal treatment, centrifugally collecting precipitate, and drying at 60 DEG C to obtain a white powdery sample, ie., the hairy ball type Ti3C2(MXene) nanometer material. According to the invention, the prepared hairy ball type Ti3C2(MXene) nanometer material has excellent electrochemical energy storage performance, and the simple and easy-to-operate preparation path is provided for application of the hairy ball type Ti3C2(MXene)nano material in the field of electrode materials such as supercapacitors, lithium ion batteries and the like.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

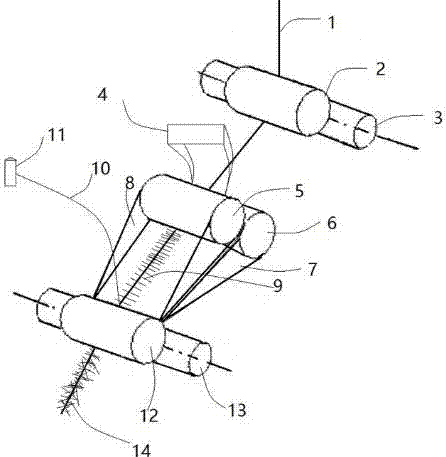

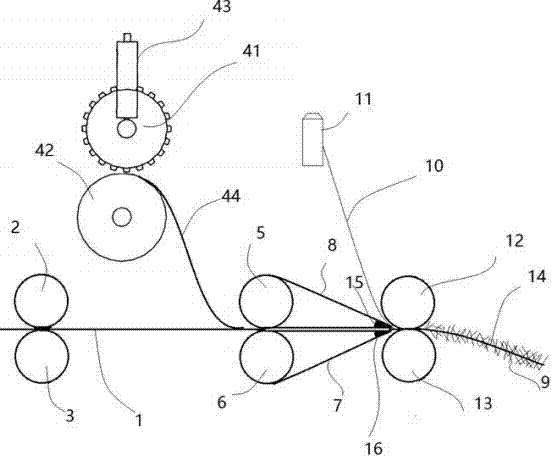

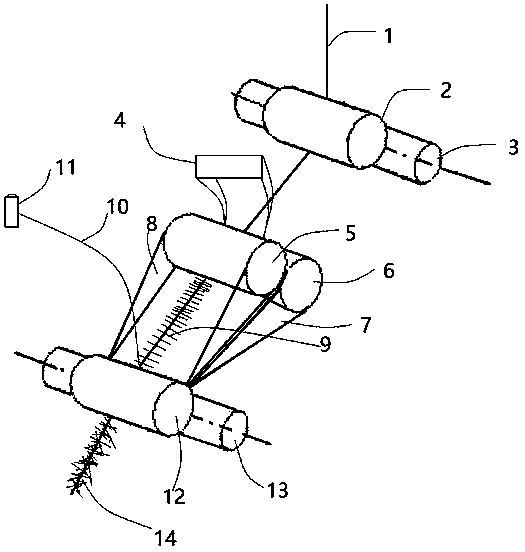

Production method for thermal-insulating fabric

The invention relates to the technical field of fabrics, in particular to a method for producing warm fabrics. The down yarn is used in the fabric, and the down yarn is produced by a down yarn production device. During production, two yarns are used to clamp loose fibers during plying and twisting to form a down yarn. The down yarn production device includes a loose fiber feeding device, Multiple feeding roller pairs, upper apron, lower apron, twisting device and winding device, etc. The production device of the invention has a simple structure and is easy to assemble, and the produced down yarn has good bulkiness, good heat retention, low cost and high production efficiency. The thermal fabric produced by the thermal yarn is light in texture, high in quality and low in price, can store more still air, and has good warmth retention property.

Owner:桐乡佳车科技股份有限公司

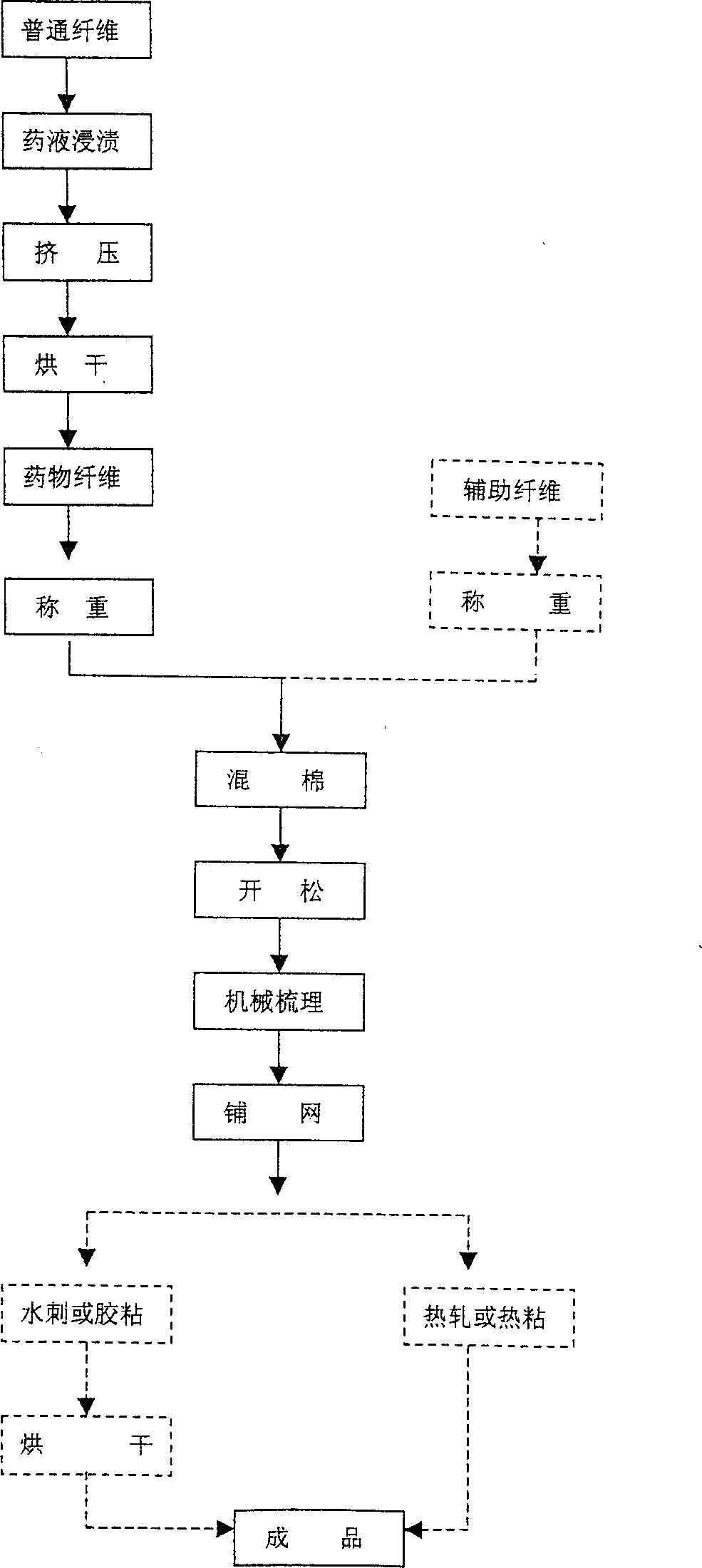

Antibacterial non-woven fabric production process

InactiveCN112481814AImprove antibacterial propertiesGood for healthConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolymer science(Hydroxyethyl)methacrylate

The invention discloses an antibacterial non-woven fabric production process, and belongs to the technical field of non-woven fabric production. The preparation process comprises the following processing steps of S1, preparing the following raw materials in parts by weight of 12-28 parts of deacetylated chitin, 25-36 parts of benzoin, 18-38 parts of sodium cocoate, 22-42 parts of trichlorocarbanilide, 21-35 parts of ethylene glycol salicylate, 22-35 parts of hydroxyethyl methacrylate, 18-25 parts of a polymer nano-carrier, 12-17 parts of chlorothalonil, 8-25 parts of bamboo acetic acid, 22-46parts of water, 12-33 parts of coconut oil fatty acyl diethanol amine, 6-17 parts of polypropylene resin, and 14-26 parts of a peroxide. The antibacterial performance of the non-woven fabric is greatly improved; when a human body wears the non-woven fabric, protection is formed, the health performance is improved, the non-woven fabric has a very good mildew-proof effect, the surface of the non-woven fabric is soft, fluffy and excellent in texture, and the toughness and the wear resistance are greatly improved.

Owner:MEDWELL MEDICAL PROD

Jacquard non-woven fabric and preparation method thereof

The invention provides a jacquard non-woven fabric and a preparation method of the jacquard non-woven fabric, and relates to the technical field of production of non-woven fabrics. The jacquard non-woven fabric is mainly prepared from a three-dimensional crimp hollow fiber, a polypropylene fiber and a common polyester staple fiber, the three-dimensional crimp hollow fiber has a crimping arc, the radius of curvature is relatively large, the jacquard non-woven fabric has the characteristic that the jacquard non-woven fabric does not cause fatigue yield easily after deforming because of compression for multiple times; the common polyester staple fiber increases the entanglement degree of the non-woven fabric; the polypropylene fiber improves the strength of the non-woven fabric, and the jacquard non-woven fabric does not deform easily. Therefore, the jacquard non-woven fabric has the advantages that the pattern is clear, the hand feeling is soft, the stereoscopic impression is strong, thestatic electricity is high, the elasticity of compression is good, the surface is fluffy, and the dust collection effect is good.

Owner:高长水

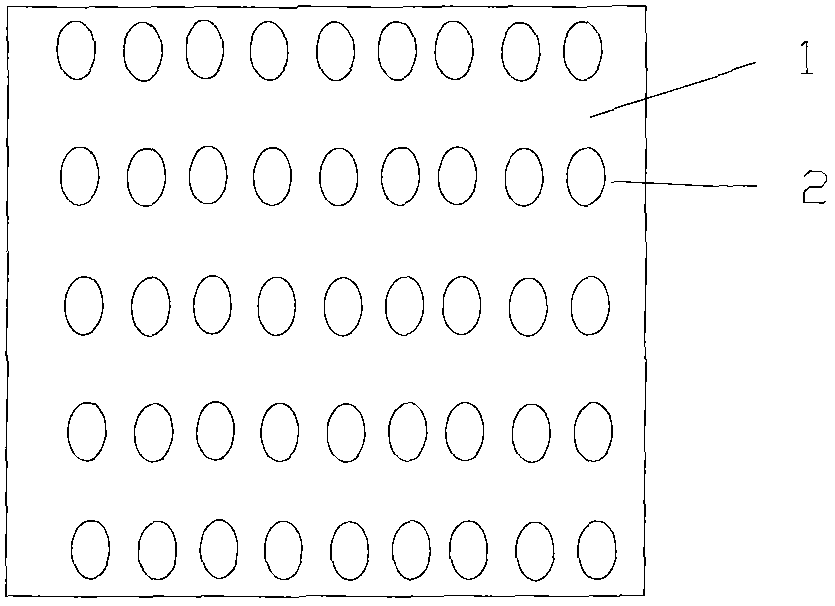

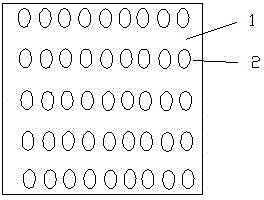

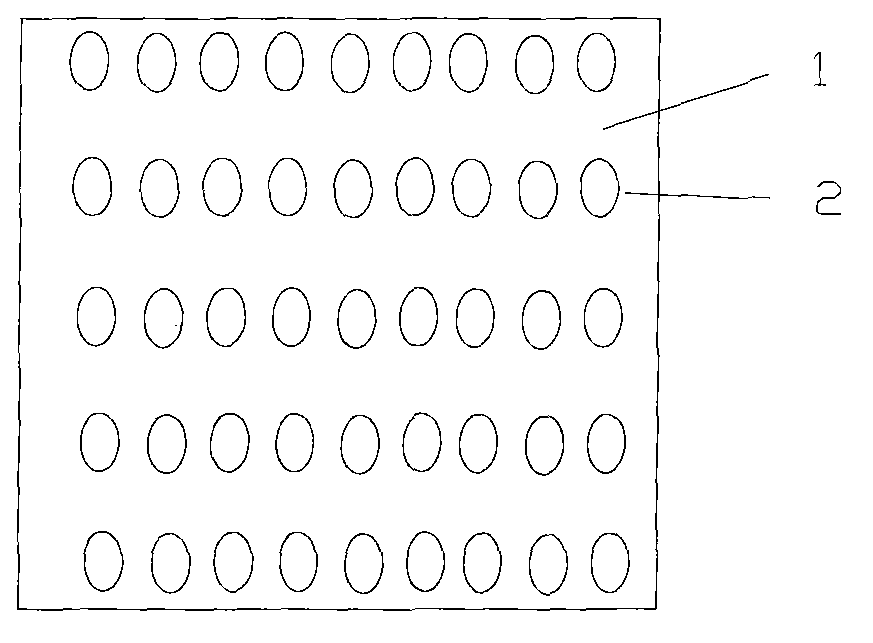

Elastic fabric for bubble shirts

InactiveCN103815558AFluffy surfaceAdd dimensionLayered productsWarp knittingEngineeringFilament yarn

The invention relates to fabric. The fabric comprises a shirt fabric body (1). A plurality of rows of oval bubbles (2) are arranged on the outer surface of the shirt fabric body (1) and protrude out of the same. The fabric body (1) is made of fabric which is warp-knitting fabric, the rule of yarn laying is 1-0 / 2-3, surface yarns are 75D / 36T400 fully-drawn polyester fiber filament yarns, bottom yarns are FDY (fully-drawn yarns) 84D / 36F polyester filament yarns, and the section of the T400 polyester fiber filament yarns is crisscrossed. The elastic fabric does not cling to the skin when being sweated, and permeability and cooling are improved. The fabric is elastic, loose, comfortable, long in service life, soft, stiff and smooth and good in draping.

Owner:徐浩

Electro-conductive and anti-bacterial bubble shirt fabric with ultraviolet resistant layer

InactiveCN104957783AFluffy surfaceAdd dimensionFibre treatmentSynthetic resin layered productsFiberUltraviolet

The invention relates to a fabric, in particular to an electro-conductive and anti-bacterial bubble shirt fabric with an ultraviolet resistant layer. The fabric comprises a shirt fabric body (1) on the outside surface of which several lines of bubbles (2) are arranged. The bubbles (2) are oval in shape and protrude from the shirt fabric body (1) made of cloth, the cloth comprises warp threads and weft threads which are mutually interlaced, and the fibers of the warp threads and weft threads are wrapped in a silver plating layer. The fabric enables sweat not to stick to the skin, and therefore air permeability and cool sense are improved.

Owner:JIANGYIN NEW QUANSHENG TEXTILE PRINTING & DYEING

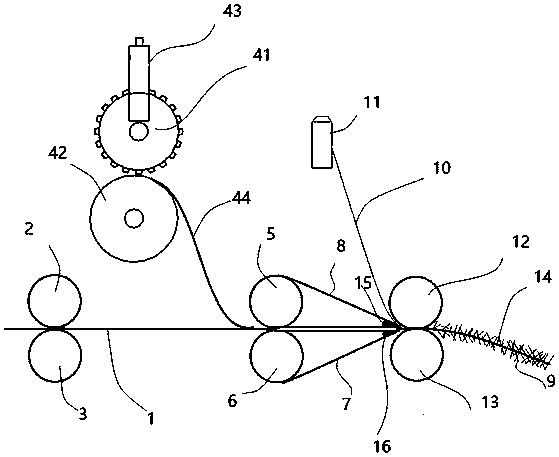

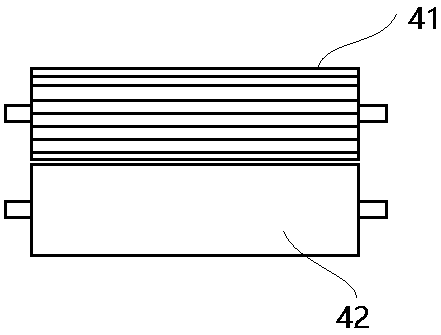

Down yarn production device

The present invention relates to the field of yarn technology, in particular to a production device for down yarn. The production device uses two yarns to clamp loose fibers during plying and twisting to form down yarn. The production device includes a bulk fiber feeding device, a plurality of feeding roller pairs, an upper apron, a lower apron, and a twisting device. and winding devices, etc. The production device of the invention has a simple structure and is easy to assemble, and the produced down yarn has good bulkiness, good heat retention, low cost and high production efficiency. The thermal fabric produced by using the down yarn is light in texture, high in quality and low in price, can store more still air, and has good warmth retention property.

Owner:NINGBO FENGHUA FEITIANREN PRECISION MOLD DESIGN CO LTD

Blistered shirt luminous fabric

InactiveCN106313708AFluffy surfaceEnhance the three-dimensional senseLayered productsTextile decorationEngineeringTextile

The invention relates to a fabric, in particular to a blistered shirt luminous fabric which comprises a shirt fabric body (1), wherein a plurality rows of blisters (2) are formed in the outer surface of the shirt fabric body (1); the blisters (2) are elliptic and protrude outside the fabric body (1); the fabric body (1) is made of a textile; the textile comprises a textile body and a luminous wire material; the luminous wire material is fixedly arranged on the textile body in a knitted or embroidery manner, and form objects on the textile body. By adopting the blistered shirt luminous fabric, sweat can be isolated from skin, and the breathability and the cool feeling can be achieved.

Owner:王凤华

Bubble shirt elastic shell fabric provided with anti-bacterial shell fabric layer

InactiveCN104939333AFluffy surfaceAdd dimensionSynthetic resin layered productsUndergarmentsEngineeringAnti bacterial

The invention relates to shell fabric. The shell fabric comprises a shirt shell fabric body (1), multiple rows of bubbles (2) are arranged on the outer surface of the shirt shell fabric body (1), each bubble (2) is in an oval shape and protrudes out of the shell fabric body (1), the shell fabric body (1) is made of fabric, the fabric is warp knitting fabric, the yarn laying rule is 1-0 / 2-3, the surface yarn is 75D / 36 T400 polyester fiber fully drawn yarn filaments, the bottom yarn is FDY 84D / 36F polyester filament yarn, the T400 polyester fiber fully drawn yarn filaments are hollow, and the cross section of each T400 polyester fiber fully drawn yarn filament is in a cross shape. By means of the shell fabric, sweat is prevented from being attached to the skin closely, and air permeability and cool sensation are further achieved. The textile fabric made of the bubble shirt elastic shell fabric is loose in elasticity, comfortable and durable. The textile fabric is soft, stiff and good in draping property.

Owner:JIANGYIN KEHAO GARMENT & YARN DYE WEAVING

Bubble shirt good-dimensional-stability fabric with temperature-sensitive fabric layer

InactiveCN104939334AEnhance the three-dimensional senseBig spaceLayered productsWoven fabricsYarnEngineering

The invention relates to fabric, in particular to bubble shirt good-dimensional-stability fabric with a temperature-sensitive fabric layer. The bubble shirt good-dimensional-stability fabric comprises a shirt fabric body (1), a plurality of rows of bubbles (2) are arranged on the outer surface of the shirt fabric body (1), the bubbles (2) are elliptic and protrude out of the fabric body (1), the fabric body (1) is made of textile, the textile is formed by interweaving warp and weft, every two pieces of warp are arranged above every two pieces of weft, the warp is 50D / 72F dacron low stretch yarn, the weft is 5D / 36F dacron low stretch yarn, and the warp and the weft are of a twill weave structure. By means of the fabric, sweat is not attached to the skin, and breathability and the cool sense are increased. The dimensional stability of the fabric is good.

Owner:JIANGSU HEJIA TEXTILE

Environment-friendly bubble shirt fabric

InactiveCN105011428AFluffy surfaceAdd dimensionProtective garmentSpecial outerwear garmentsYarnWear resistant

The invention relates to an environment-friendly bubble shirt fabric and a fabric. The fabric comprises a shirt fabric body (1), wherein the outer surface of the shirt fabric (1) is provided with a plurality of rows of bubbles (2); the bubbles (2) are elliptical and are projected out of the fabric body (1); the fabric body (1) is prepared from fabric; the fabric comprises a pure wool tissue layer and a wool and tencel blended yarn tissue layer; the wool and tencel blended yarn texture layer and the pure wool texture layer respectively form an inner layer and an outer layer of the fabric; the wool and tencel blended yarn texture layer and the pure wool texture layer are locally connected; and the lower surface of the shirt fabric body (1) is orderly provided with an antibacterial layer and a soft wear-resistant layer. The fabric can enable sweat not to cling to the skin, so that the fabric has higher air permeability and better cool feeling. The shell fabric is environment-friendly, and can also cause no damage to wool.

Owner:吴孟涛

Bubble elastic shirt fabric

InactiveCN105648806AFluffy surfaceAdd dimensionHollow filament manufactureWarp knittingFilament yarnCivil engineering

The invention relates to fabric. The fabric comprises a shirt fabric body, wherein multiple rows of bubbles are arranged on the outer surface of the shirt fabric body, the bubbles are oval and bulge out of the fabric body, the fabric body is made of warp knitted fabric, the yarn laying rule is 1-0 / 2-3, surface yarn adopts 75D / 36 T400 polyester fiber FDY (fully drawn yarn) filaments, base yarn adopts FDY 84D / 36F polyester filaments, and the T400 polyester fiber FDY filaments are hollow and have cross sections. The fabric prevents sweat from closely attaching to the skin and is more breathable and cooler. The produced fabric is elastic, comfortable, lasting, soft, stiff and good in drapability.

Owner:JIANGYIN CHUNLAN TEXTILE

Bubble shirt black-out cloth fabric

The invention relates to a bubble shirt black-out cloth fabric and relates to a fabric comprising a fabric body (1). A plurality rows of bubbles (2) are formed on the external surface of the shirt fabric body (1); the bubbles (2) are elliptic and project from the fabric body (1); the fabric body (1) is formed by base cloth formed by warp yarns and weft yarns interweaved with the warp yarns; the warp and weft yarns are both formed by blending between stainless steel fibers and terylene fibers; the stainless steel fibers takes up 20 to 30% of the total weight of the fabric; the terylene fibers takes up 70 to 80% of the total weight of the fabric; one side of the base cloth is coated with nanometer coating liquid; and the other side of the base cloth is covered with a far infrared coating layer. Sweat cannot be attached to skin, so ventilating and cooling properties are enhanced.

Owner:陆秋亚

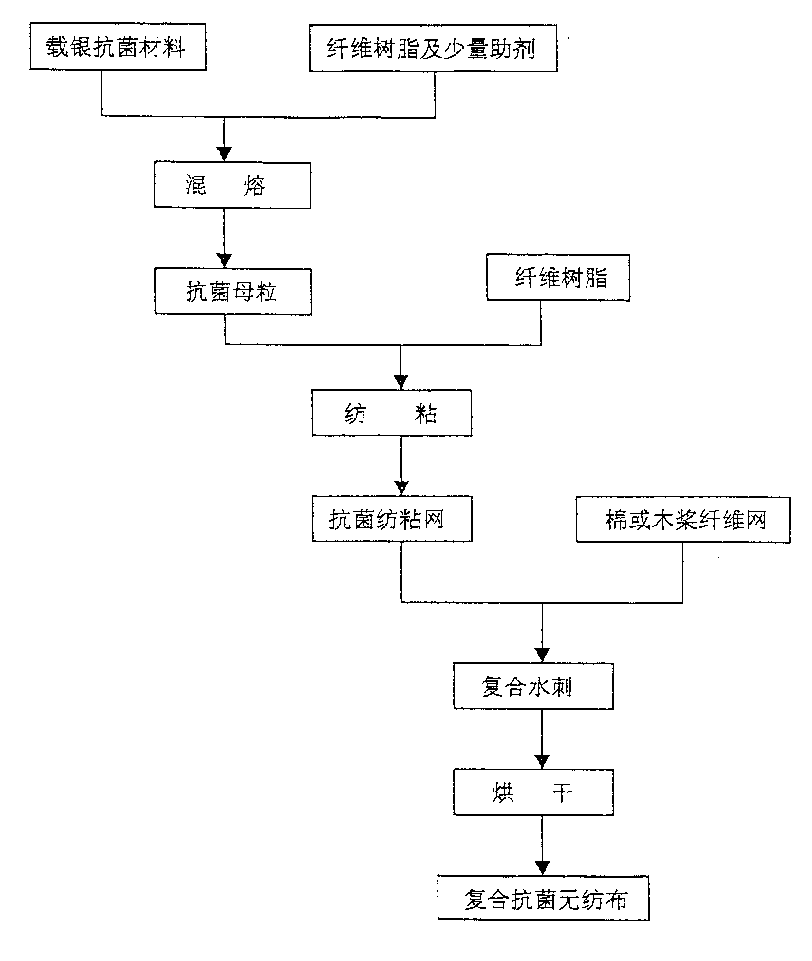

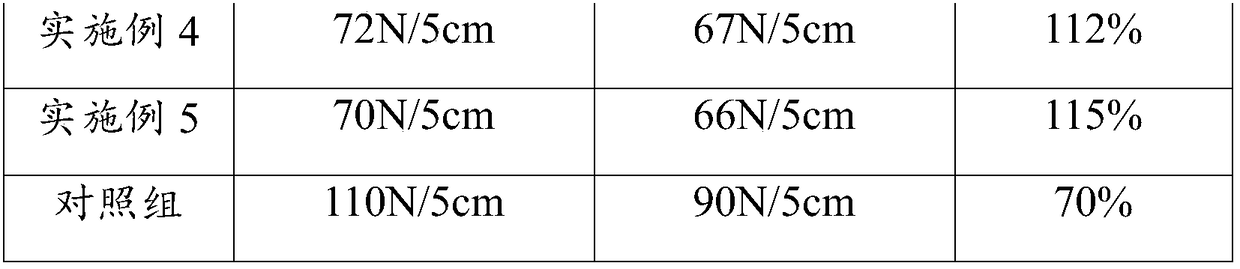

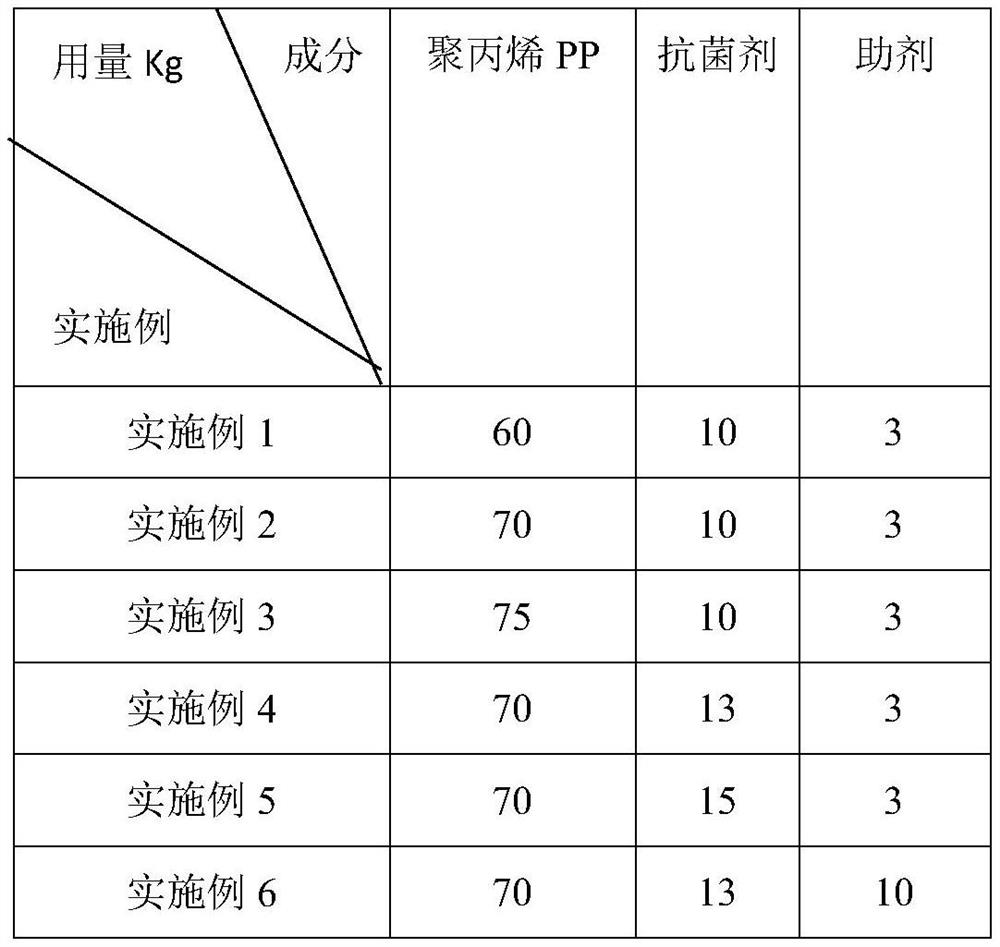

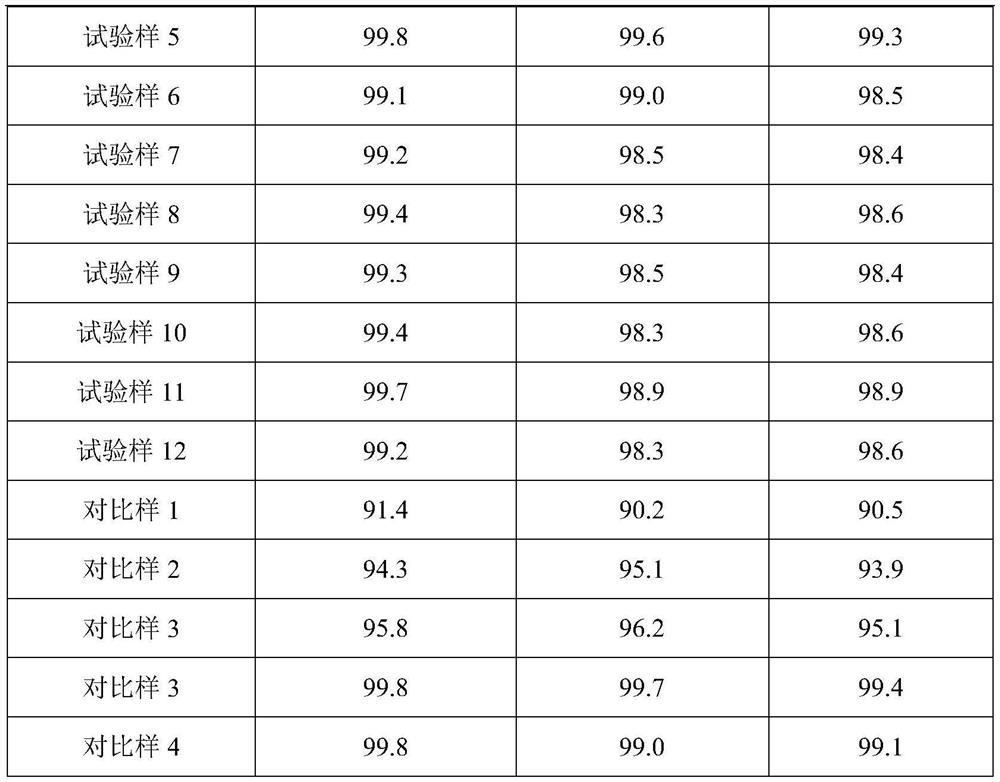

Antibacterial non-woven fabric and preparation method thereof

InactiveCN114575042AGood antibacterial effectHigh antibacterial activityNon-woven fabricsMonocomponent polyolefin artificial filamentMicro nanoPolyol

The invention relates to the technical field of non-woven fabrics, and particularly discloses an antibacterial non-woven fabric and a preparation method thereof. The antibacterial non-woven fabric is formed by compounding an antibacterial spunbond net and a cotton fiber net, and the antibacterial fiber net is prepared from antibacterial particles and fiber resin by adopting a spunbond process; the antibacterial particles comprise fiber resin, an antibacterial agent and a plastic additive; the antibacterial agent is prepared from inorganic / organic hybrid composite nanoparticles, polyquaternium, ethylenediamine tetraacetic acid and polyhydric alcohol; the inorganic / organic hybrid composite nanoparticles are compounds formed by micro-nano chitosan, nano-silver and nano-crystal stone powder. The preparation method of the antibacterial non-woven fabric comprises the following steps: mixing the fiber resin, the antibacterial agent and the plastic additive, extruding, cooling and pelletizing to obtain antibacterial particles; mixing the antibacterial particles and fiber resin, and preparing an antibacterial spunbond net by adopting a spunbond process; the antibacterial spunbond net and the cotton fiber net are subjected to composite spunlace treatment and dried, and then the antibacterial non-woven fabric is obtained. The antibacterial non-woven fabric provided by the invention has excellent antibacterial property.

Owner:浙江盛纺纳米材料科技有限公司

Bubble shirt looped fabric with antibiosis fabric layer

InactiveCN104921384AFluffy surfaceAdd dimensionSynthetic resin layered productsProtective garmentAntibiosisEngineering

The invention relates to a fabric which comprises a shirt fabric body (1). Multiple lines of bubbles (2) are arranged on the outer surface of the shirt fabric body (1), are elliptic and protrude out of the fabric body (1). The fabric body (1) is made of fabric which is formed by interweaving warp yarn and weft yarn, wherein the warp yarn includes looped yarn and base yarn, the looped yarn forms a fixed weave after striding certain pieces of weft yarn, three pieces of weft yarn are located between the start point and the end point of each loop formed by the looped yarn, and three pieces of weft yarn are located between every two adjacent interweaving points of the fixed weave formed by the bottom yarn. Sweat is not closely attached to skin, and the breathability and cooling feeling are improved. The product can be plump, loose, soft and firm in hand feeling.

Owner:JIANGYIN NEW QUANSHENG TEXTILE PRINTING & DYEING

Bubble antibacterial and crease-resistant shirt fabric

InactiveCN103879055AFluffy surfaceAdd dimensionSynthetic resin layered productsEngineeringBamboo charcoal

The invention relates to a fabric, particularly a bubble antibacterial and crease-resistant shirt fabric, which includes a shirt fabric body (1). The external surface of the shirt fabric body (1) is provided with several rows of bubbles, which are elliptical and protrude from the fabric body (1). The fabric body (1) is made from a textile fabric composed of a front crease-resistant layer, an intermediate adhesive layer and a back antibacterial layer. The crease-resistant layer is a polyurethane material with a memory function, the adhesive layer is a thermosetting adhesive layer, and the antibacterial layer is a fabric layer containing nano-bamboo charcoal fiber. The bubble antibacterial and crease-resistant shirt fabric provided by the invention enables sweat not to cling to the skin, increases breathability and cool feeling. The fabric provided by the invention is antibacterial and crease-resistant.

Owner:沈卫军

A hairball type ti 3 c 2 Preparation methods and applications of (mxene) nanomaterials

ActiveCN110723737BFluffy surfaceIncrease surface areaMaterial nanotechnologyCell electrodesCentrifugationWhite powder

The invention discloses a hairball type Ti 3 C 2 The preparation method and application of (MXene) nanomaterials, the steps are as follows: the precursor Ti 3 AlC 2 Add (MAX) to HF, stir magnetically at room temperature for 72 hours, centrifuge and wash until neutral, collect the precipitate, and dry at 60°C to obtain a black powder, which is two-dimensional Ti 3 C 2 (MXene) material; the two-dimensional Ti 3 C 2 (MXene) material is added to the 2 o 2 In the mixed solution, stir evenly, then conduct hydrothermal treatment, collect the precipitate by centrifugation, and dry at 60°C to obtain a white powder sample, which is the hairball-type Ti 3 C 2 (MXene) nanomaterials. Hairy Ti 3 C 2 (MXene) nanomaterials have excellent electrochemical energy storage performance, which provides a simple and easy-to-operate preparation path for their application in electrode materials such as supercapacitors and lithium-ion batteries.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

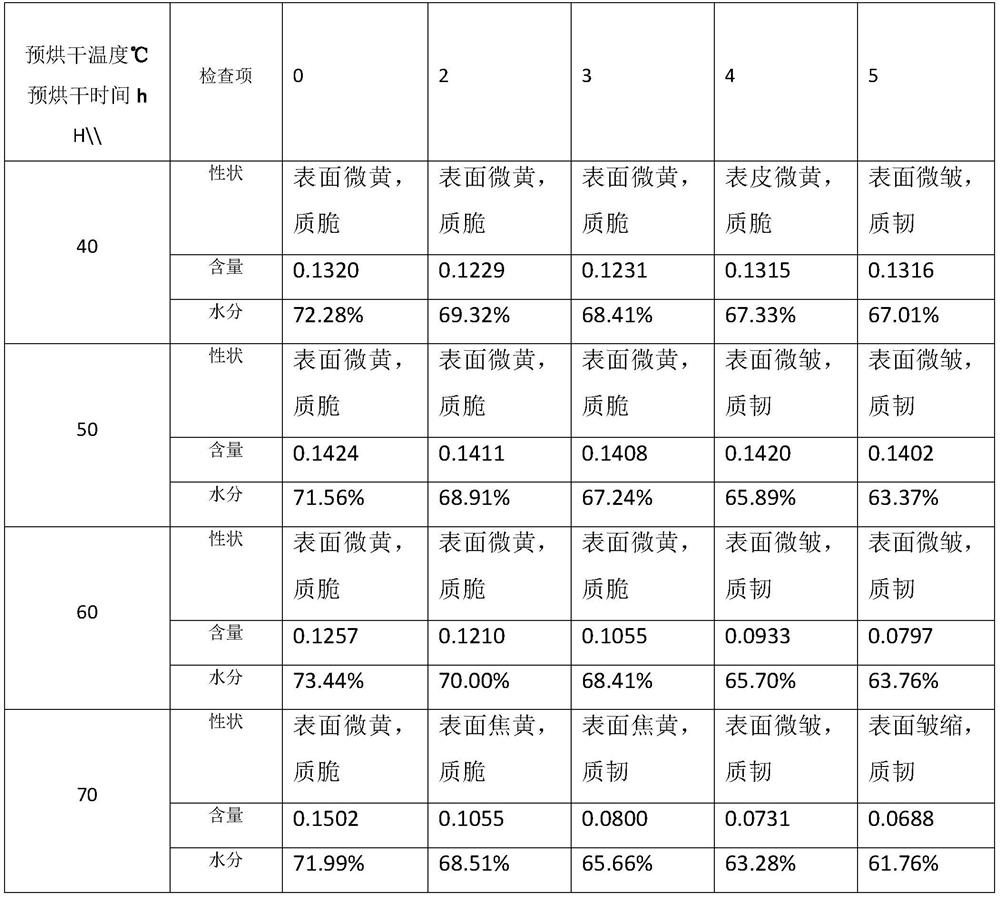

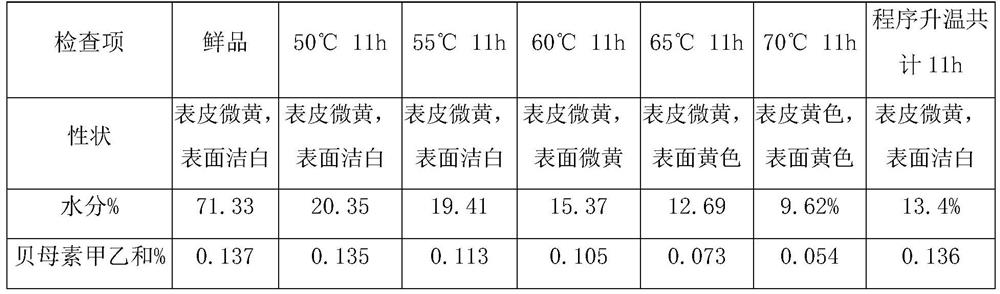

A kind of processing technology of high-quality Zhejiang fritillary pieces

ActiveCN111643595BAvoid severe lossesLight textureAntibacterial agentsRespiratory disorderMedicinal herbsFritillaria thunbergii

The invention relates to a processing technology for high-quality Fritillaria tablets, which is characterized by comprising the following steps: step (1), excavation and grading of the Fritillaria; step (2), cleaning: placing the Fritillaries in air bubbles Wash in the cleaning pool to remove the surface sediment; step (3), pre-drying: place the fritillary in a drying room for at least 4 hours of pre-drying to remove part of the water; step (4), slicing: cut the fritillary Slice with a thickness of 3-5mm; step (5), drying: put the fritillary pieces obtained in step (4) on a plate, place them in a tunnel drying room for gradient drying, and set the temperature for the linkage drying room respectively, until Zhebei slices are completely dried to obtain Zhebei slices medicinal materials. On the basis of the traditional processing technology, the invention adopts the gradient drying technology, which can not only ensure its appearance and properties, but also can efficiently produce high-quality Fritillaria fritillary with little or no loss of index components.

Owner:浙江磐康药业有限公司

Looped fabric for bubble shirt

The invention relates to a fabric which comprises a shirt fabric body (1), wherein a plurality rows of bubbles (2) are arranged on the outer surface of the shirt fabric body (1); the bubbles are ellipse-shaped and convex outside the fabric body (1); the fabric body (1) is made of a textile; the textile consists of warps and wefts which are interwoven with one another; the warps comprise loop yarns and bottom yarns; the loop yarns are formed into fixed texture after crossing a certain number of wefts; three wefts are arranged between the starting point and the final point of a loop formed by the loop yarns; the bottom yarns are formed into fixed texture; three wefts are arranged between adjacent interweaving points. Through the adoption of the fabric, the shirt is not clung to skin due to sweat, and furthermore the breathability and the cool feeling are improved. According to the invention, the fabric product can be full, fluffy, soft and thick and solid in hand feeling.

Owner:夏宏希

Bubbled shirt moisture-transmitting breathable fabric with antibacterial fabric layer

InactiveCN105172235AFluffy surfaceAdd dimensionSynthetic resin layered productsCellulosic plastic layered productsYarnFiber

The invention relates to a fabric. The fabric comprises a skirt fabric body (1), the external surface of the skirt fabric body (1) is provided with a plurality of rows of bubbles (2); each bubble (2) is in an oval shape and protrudes out of the fabric body (1), the fabric body (1) is made of fabrics, which comprise warps and wefts, the warps are made of spun rayon yarns, the wefts are made of mixed yarns of linen and richcel fiber, and the warps and wefts are perpendicular to each other. The provided fabric will not tightly adhere on the skin after sweating, thus the breathability and cooling function of the fabric are both enhanced, and the fabric has a moisture-transmitting functional and is breathable.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Bubble type shirt elastic fabric

InactiveCN106307742AFluffy surfaceAdd dimensionTextile decorationProtective garmentEngineeringFilament yarn

The invention relates to a bubble type shirt elastic fabric. The bubble type shirt elastic fabric comprises a shirt fabric body (1); multiple rows of bubbles (2) are arranged on the outer surface of the shirt fabric body (1); the bubbles (2) are elliptic and protrude out of the fabric body (1); the fabric body (1) is made of a fabric; the fabric is a warp knitted fabric; a yarn laying law is 1-0 / 2-3; a surface yarn adopts a 75D / 36 T400 polyester fiber fully drawn filament yarn; a base yarn adopts an FDY 84D / 36F polyester filament yarn; and the T400 polyester fiber fully drawn filament yarn is hollow and has a cross-shaped section. According to the bubble type shirt elastic fabric, sweat does not cling to the skin, and the breathability and the coolness are enhanced. The produced fabric is easy, comfortable and lasting in elastic force. The fabric is soft, is stiff and smooth, and is good in drapability.

Owner:冯爱华

Elastic fabric with compound layer for bubble shirt

The invention relates to a fabric which comprises a shirt fabric body (1), wherein a plurality of rows of bubbles (2) are arranged on the outer surface of the shirt fabric body (1); the bubbles (2) are elliptical and protruded from the fabric body (1); the fabric body (1) is made of a textile fabric; the textile fabric is a warp knitted textile fabric; the yarn laying rule is 1-0 / 2-3; surface yarns adopt polyester fiber fully-drawn filament yarns 75D / 36 T400, and bottom yarns adopt polyester filament yarns FDY 84D / 36F; the polyester fiber fully-drawn filament yarns T400 are hollow, and the sections are cross-shaped. The fabric enables sweats to be not close to the skin, so that the breathability and the cooling feel are improved. A textile made of the fabric is high in elasticity, comfortable and durable, is soft, stiff and smooth and is high in drapability.

Owner:杨洪兴

Bubble shirt woven and knitted composite fabrics

The invention relates to fabrics. The fabrics comprises a shirt fabric body (1). A plurality lines of bubbles (2) are arranged on the outer surface of the shirt fabric body (1). The bubbles (2) are oval and are protruding from the fabric body (1). The fabric body is prepared with a textile product. One side of the textile product is a woven product, and the other side of the textile product is a knitted product. With the fabrics, sweat is prevented from sticking on skins, and breathability and cool senses are enhanced. The fabrics shows two different styles, and is novel and unique.

Owner:吴刚

Bubble- shirt- easy-washing- quick-dry fabric with compound silk fabric

The invention relates to a fabric. The fabric comprises a noumenon of shirt fabric (1), the outer surface of the noumenon of shirt fabric (1) is provided with a plurality of rows of bubbles (2), the bubbles are ovals and bulge out of the noumenon of shirt fabric (1), the noumenon of shirt fabric (1) is made of fabrics, the fabrics are made of longitudinal yarns and weft yarns, which are interweaved with each other. Both of the longitudinal yarns and the weft yarns are covering yarns of cotton-covered polyester filaments, the lateral surfaces of the polyester filaments are pentacles. The fabric has the advantages of being capable of making sweat not close skin, being breathable and cool.

Owner:吴银芝

Easy-washing and quick-drying bubble shirt fabric

InactiveCN105774071AFluffy surfaceAdd dimensionSynthetic resin layered productsClothingsEngineeringWeft yarn

The invention discloses easy-washing and quick-drying bubble shirt fabric, and relates to fabric. The shirt fabric comprises a shirt fabric body, wherein multiple rows of bubbles are arranged on the outer surface of the shirt fabric body and elliptical-shaped, and protrude from the fabric body; the fabric body is made of a textile; the textile is formed by interweaving warp yarn and weft yarn; the warp yarn and the weft yarn are all core-spun yarn with polyester filament yarn covered with cotton, and the cross section of the polyester filament yarn is in a pentagram shape. By means of the fabric, sweat is not tightly attached to the skin, and the breathability and the coolness are improved.

Owner:江苏红柳床单有限公司

Anti-radiation and anti-bacteria deodorizing bubble shirt fabric

The invention provides anti-radiation and anti-bacteria deodorizing bubble shirt fabric and relates to fabric. The anti-radiation and anti-bacteria deodorizing bubble shirt fabric comprises a shirt fabric body (1); the outer surface of the shirt fabric body (1) is provided with a plurality of rows of bubbles (2); the bubbles are oval in shape and protrude out of the fabric body (1); the fabric body (1) is made of a textile formed by closely combining a silver fiber fabric layer and a bamboo carbon fiber fabric layer. The fabric prevents sweat from being attached to skin, so that the breathability and the cool feel are improved. The fabric has the advantages of radiation resistance, bacterium resistance and deodorization.

Owner:吴银芝

Luminous fabric with composite fabric layer and for bubble shirt

The invention relates to a fabric. The fabric comprises a shirt fabric body (1); the outer surface of the shirt fabric body (1) is provided with a plurality of rows of bubbles (2); the bubbles (2) are elliptical and protrude out from the shirt fabric body (1); and the shirt fabric body (1) is prepared from a fabric which comprises a fabric body and a luminous thread material, and luminous threads are fixed on the fabric body in a knitting or embroidering way and form a shape on the fabric body. The fabric provided by the invention enables sweat not to stick to the skin and has improved air permeability and cooling performance.

Owner:夏宏希

Bubble shirt looped cloth with composite fabric layer

The invention relates to a bubble shirt looped cloth with a composite fabric layer. The bubble shirt looped cloth with the composite fabric layer comprises a shirt fabric body (1). Multiple rows of bubbles (2) are arranged on the outer surface of the shirt fabric body (1). The bubbles are in an elliptical shape and are protruded out of the shirt fabric body (1). The shirt fabric body is made of cloth. The cloth is made by interweaving warp yarns and weft yarns, wherein the warp yarns comprise looped yarns and bottom yarns, and the looped yarns form a fixed tissue by crossing a certain number of weft yarns. Three weft yarns are arranged between a starting point and an ending point of a looped pile formed by the looped yarns. Three weft yarns are arranged between adjacent interweaving points of the fixed tissue formed by the bottom yarns. The bubble shirt looped cloth with the composite fabric layer has the advantages that the sweat cannot cling to the skin tightly, the gas permeability and cool feeling are increased further, and the product is full, fluffy, soft and firm in hand feeling.

Owner:江苏红柳床单有限公司

Bubble shirt easy-washing quick-drying fabric with insulating fabric layer

InactiveCN105029726AFluffy surfaceAdd dimensionSynthetic resin layered productsWoven fabricsBiomedical engineeringWeft yarn

The invention relates to a bubble shirt easy-washing quick-drying fabric with an insulating fabric layer, which comprises a shirt fabric body (1), wherein a plurality of rows of bubbles (2) are set on an outer surface of the shirt fabric body (1); each of the bubbles (2) is shaped as an oval and is projected out of the fabric body (1); the fabric body (1) is made of fabric; warp yarn and weft yarn are interwoven to form the fabric; the warp yarn and the weft yarn are respectively core spun yarns of cotton bale polyester filament; and the transverse cross section of the polyester filament is shaped as a five-pointed star. With the fabric, sweat won't cling to the skin, thus the fabric is more breathable and cooler.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com