Antibacterial non-woven fabric and preparation method thereof

A non-woven fabric and antibacterial spinning technology, which is applied in the direction of non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of limited use and development, unsatisfactory antibacterial effect, etc., achieve soft surface, improved antibacterial effect, The effect of improving the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

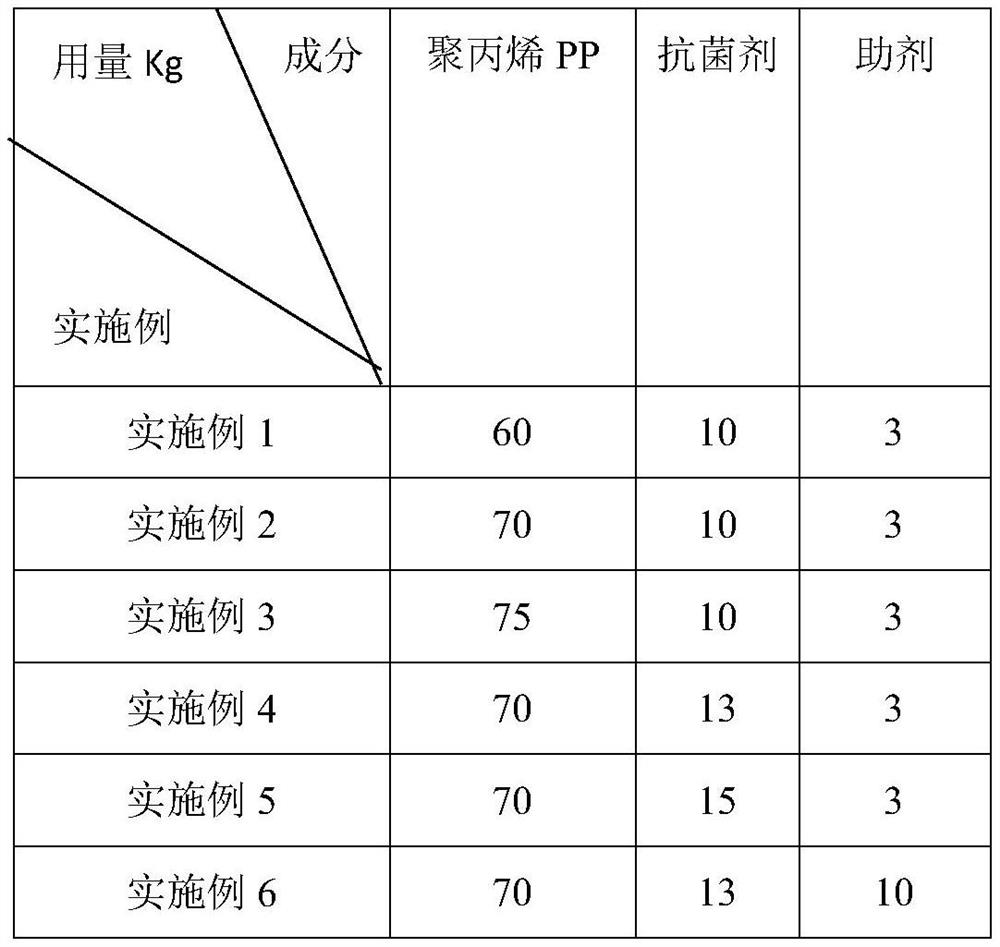

[0040] As described in Table 1, the main difference between Examples 1-6 is that the raw material ratios of the antibacterial particles are different.

[0041] Example 1 is taken as an example for description below. The embodiment of the present application discloses an antibacterial non-woven fabric, which is composed of an antibacterial spunbond mesh and a cotton fiber mesh. PP 60Kg and antibacterial agent 10kg are prepared as raw materials.

[0042]The present embodiment also discloses a preparation method of an antibacterial non-woven fabric, and the specific method is as follows:

[0043] S10, Preparation of Inorganic / Organic Hybrid Composite Nanoparticles:

[0044] S101, dissolve 1kg of chitosan in 5L of distilled water to form a suspension, and place it in a ball mill, select agate balls with a diameter of 0.5cm to pulverize the chitosan in the suspension, at a rotational speed of 500r / min , the time is 2h; the obtained product is added to the ultrasonic crusher, and...

Embodiment 7

[0054] The difference between this example and Example 1 is that dodecylamine in step S102 is replaced with tetradecylamine.

Embodiment 8

[0056] The difference between this example and Example 1 is that dodecylamine in step S102 is replaced with hexadecylamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com