Bubble elastic shirt fabric

A technology of elastic fabrics and fabrics, applied in the field of fabrics and textile fabrics, can solve the problems of fabrics that are not easy to stretch, have no three-dimensional effect, and not last long, and achieve the effects of easy elasticity, enhanced three-dimensional effect, and soft fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

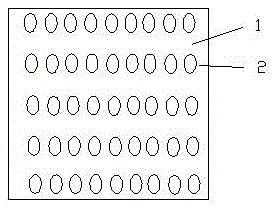

[0010] see figure 1 , The present invention relates to a bubble shirt elastic fabric, comprising a shirt fabric body 1, and a plurality of rows of bubbles 2 are arranged on the outer surface of the shirt fabric body 1. The bubbles 2 are heat-pressed to have an oval shape and protrude from the fabric body 1 .

[0011] The fabric body 1 is made of fabric, and the fabric is a warp knitted fabric. 36F polyester filament, the T400 polyester fiber fully drawn filament is hollow, and the cross section is cross-shaped. A sweat-absorbing fabric is arranged under the fabric, and the sweat-absorbing fabric includes a moisture-conducting layer, a water-absorbing layer and an antibacterial agent layer between the moisture-conducting layer and the water-absorbing layer, and the moisture-conducting layer is a mixture of natural fibers, chemical fibers, or natural fibers and chemical fibers, The water-absorbing layer is superabsorbent fiber, and the antibacterial agent layer is silver-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com