Elastic fabric with compound layer for bubble shirt

An elastic fabric and composite layer technology, applied in the field of fabrics and textile fabrics, can solve the problems of not easy elasticity of fabrics, no three-dimensional feeling, and not long-lasting, and achieve the effects of easy elasticity, enhanced three-dimensional feeling, and soft fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

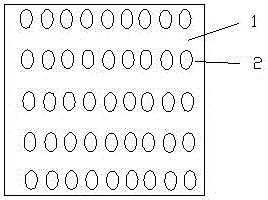

[0010] See figure 1 The present invention relates to a bubble shirt elastic fabric with a composite layer, which comprises a shirt fabric body 1, and a plurality of rows of bubbles 2 are provided on the outer surface of the shirt fabric body 1. The bubble 2 is formed into an oval shape by hot pressing and protrudes from the main body 1 of the fabric.

[0011] The fabric body 1 is made of fabric, the fabric is a warp knitted fabric, the lay-in rule is 1-0 / 2-3, the veil is 75D / 36 T400 polyester fiber full-stretched filament, and the bottom yarn is FDY 84D / 36F polyester filament, the T400 polyester fiber fully drawn filament filament is hollow and has a cross-shaped cross section. A composite layer is arranged under the fabric, and the composite layer is composed of a front anti-wrinkle layer, a middle antibacterial layer and a back layer wear-resistant layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com