A kind of processing technology of high-quality Zhejiang fritillary pieces

A processing technology and technology of Fritillaria, applied in the processing field of Fritillaria tablets, can solve the problems of protruding shape of Fritillaria tablets, yellowing of Fritillaria tablets, influence on product quality, etc. The effect of the mother-of-pearl chip is flat and reduces the energy consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of processing technology of high-quality Zhe fritillary piece, is characterized in that, comprises the following steps:

[0024] Step (1), individual excavation and grading of Fritillaria zeifolia: Fritillaria zeifolia excavates from May to July every year, and after excavating Fritillaria zeifolia, the individual with diameter less than 3cm is screened out with a vibrating sieve;

[0025] Step (2), cleaning: the Fritillaria obtained in step (1) is placed in a bubble cleaning tank for cleaning, and the surface sediment is removed;

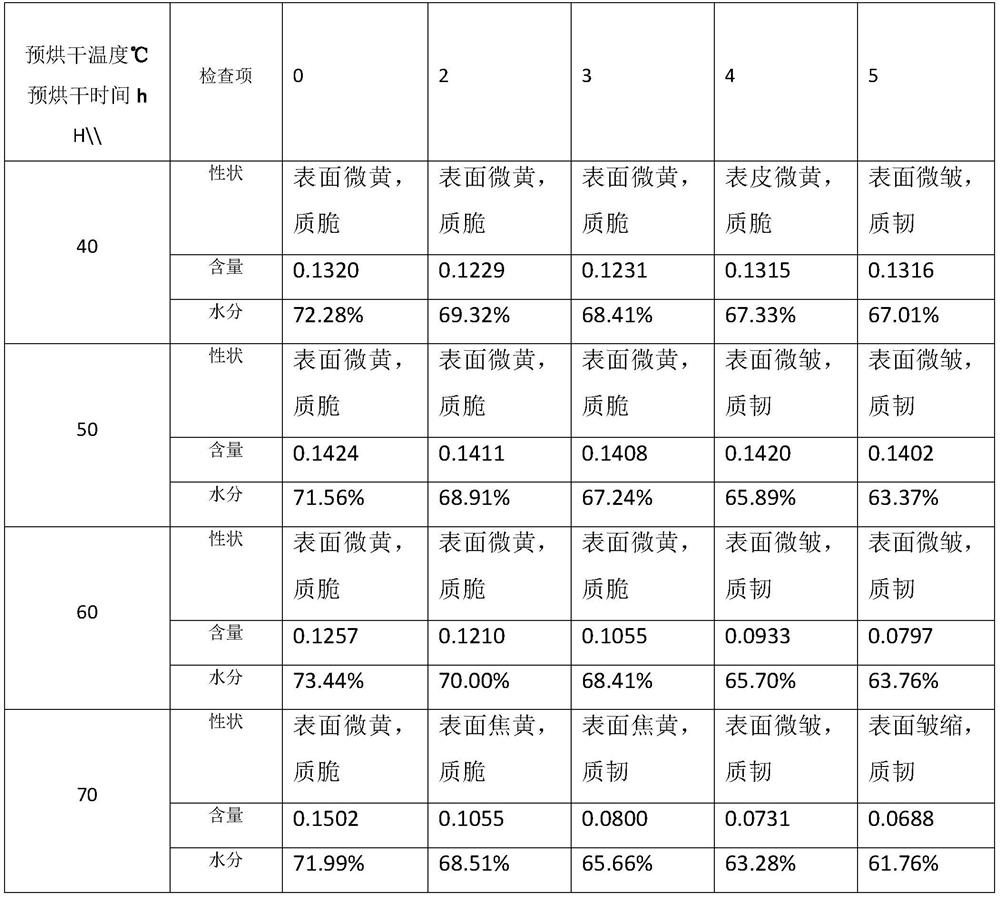

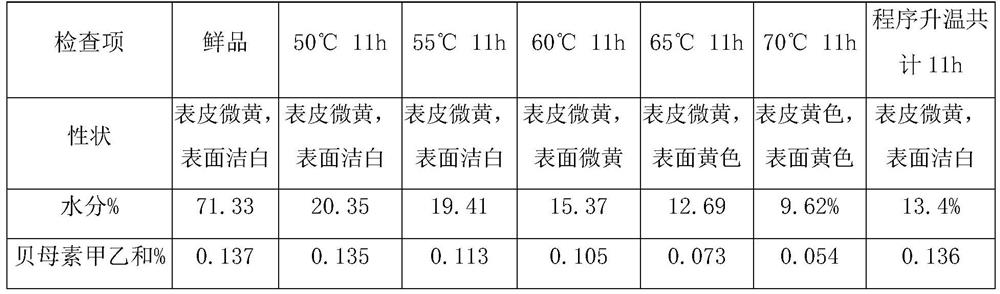

[0026] Step (3), pre-drying: place the Fritillaria fritillary with a diameter of not less than 3cm obtained in step (2) in the drying room for at least 4h pre-drying to remove part of the moisture; The evaporation of mother water reaches a certain proportion, which is more conducive to slicing; at the same time, the pre-drying temperature is 40-70 ℃, which makes the fresh Fritillaria have partial toughness and is not easy to be choppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com