Process for preparing Ag-carried antibacterial composite non-woven fabric

A silver-loaded antibacterial and manufacturing method technology, applied in rayon manufacturing, textiles and papermaking, non-woven fabrics, etc., can solve the problems of long process route, poor texture, and difficulty in maintaining constant impregnation amount of antibacterial non-woven fabrics, and achieves enhanced Insufficient water strength, good water absorption and comfort, and the effect of improving wearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

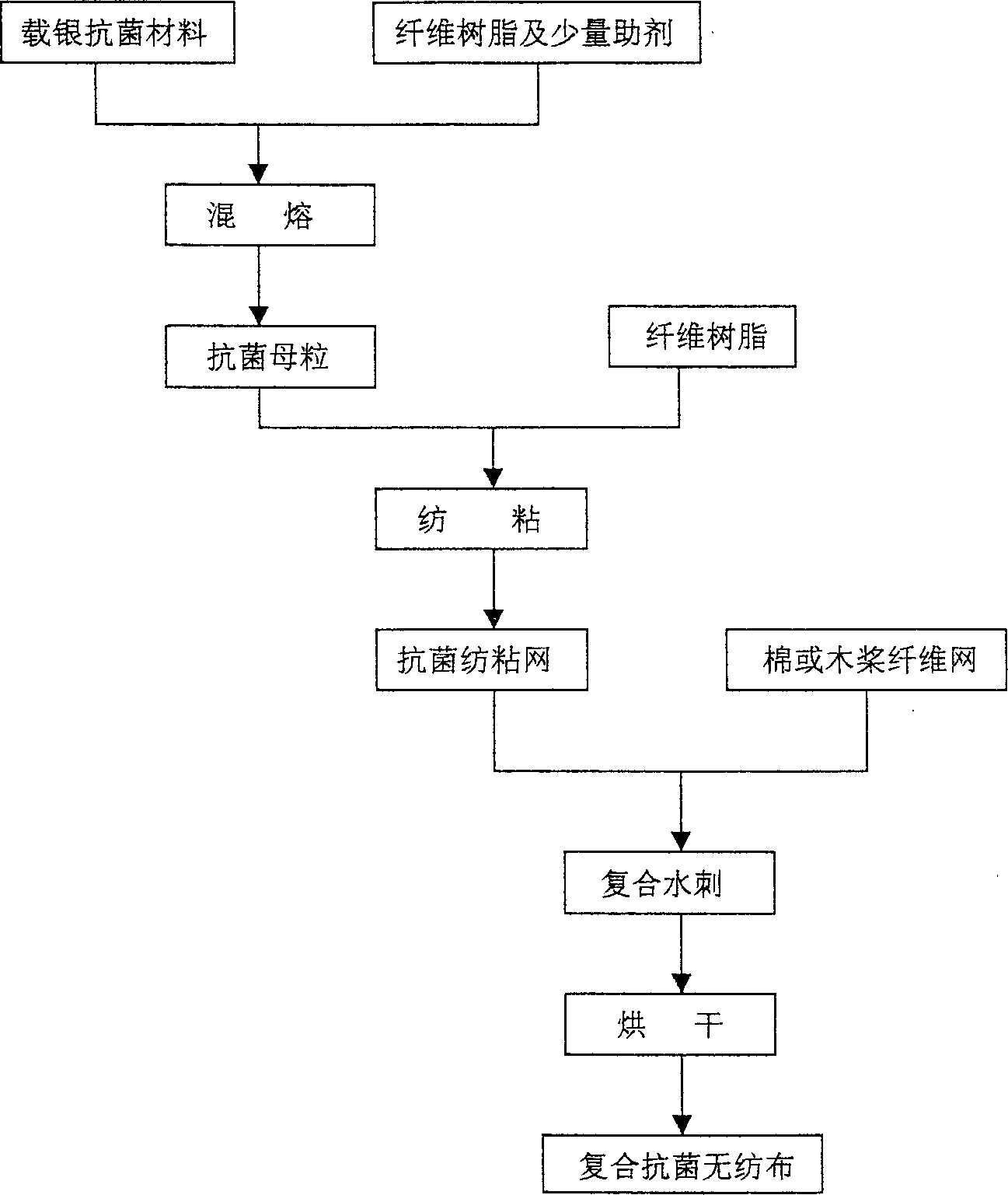

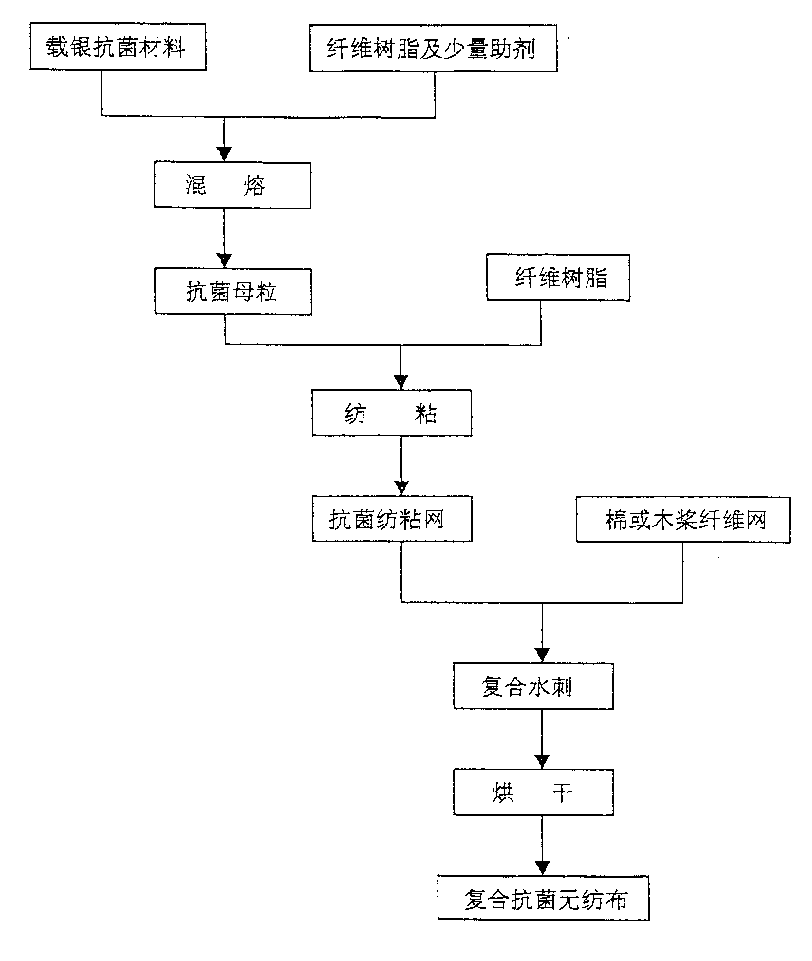

[0027] Embodiment 1: carry out according to the process flow diagram shown in Figure 1:

[0028] 1. Production of antibacterial masterbatch: Take 40kg of silicate silver-loaded antibacterial material with an average particle size of 1.5um, 50kg of fiber-grade polypropylene resin, and 10kg of dispersant polyethylene wax, stir and mix evenly, and then pass through a twin-screw extrusion granulator Melt and granulate at 140°C to make antibacterial masterbatch, the specification of antibacterial masterbatch is φ3mm×5mm, and the melt index is 110g / 10min;

[0029] 2. Production of antibacterial spunbond mesh: Mix 10kg of antibacterial masterbatch and 1000kg of fiber-grade polypropylene resin evenly, and use conventional spunbond equipment to spin and lay the mesh at a melting temperature of 285°C to make 50g / M 2 antibacterial spunbond mesh;

[0030] 3. Production of composite antibacterial non-woven fabric: combine antibacterial spunbond net with 25g / M 2 The cotton fiber web is su...

Embodiment 2

[0031] Embodiment 2: The process of this embodiment is basically the same as that of Embodiment 1, except that the cotton fiber web is replaced with 20g / M 2 The composite antibacterial non-woven fabric made of wood pulp fiber net has similar properties to the previous example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com