Red fluorescent powder and preparation method thereof

A technology of red phosphor powder, me2xba1-xti1-yf6, applied in the field of red phosphor powder and its preparation, can solve the problems of performance attenuation, poor weather resistance of phosphor powder, etc., and achieve the effects of high water resistance, stable and lasting waterproof performance, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of red fluorescent powder and preparation method thereof, according to the following steps:

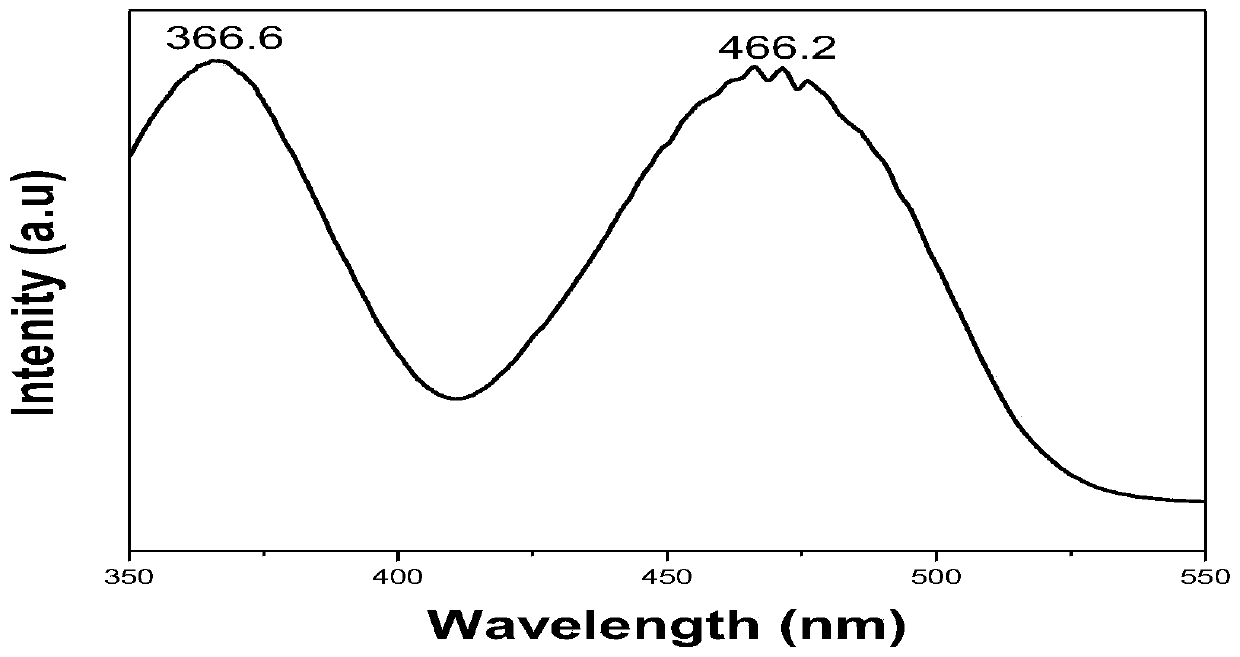

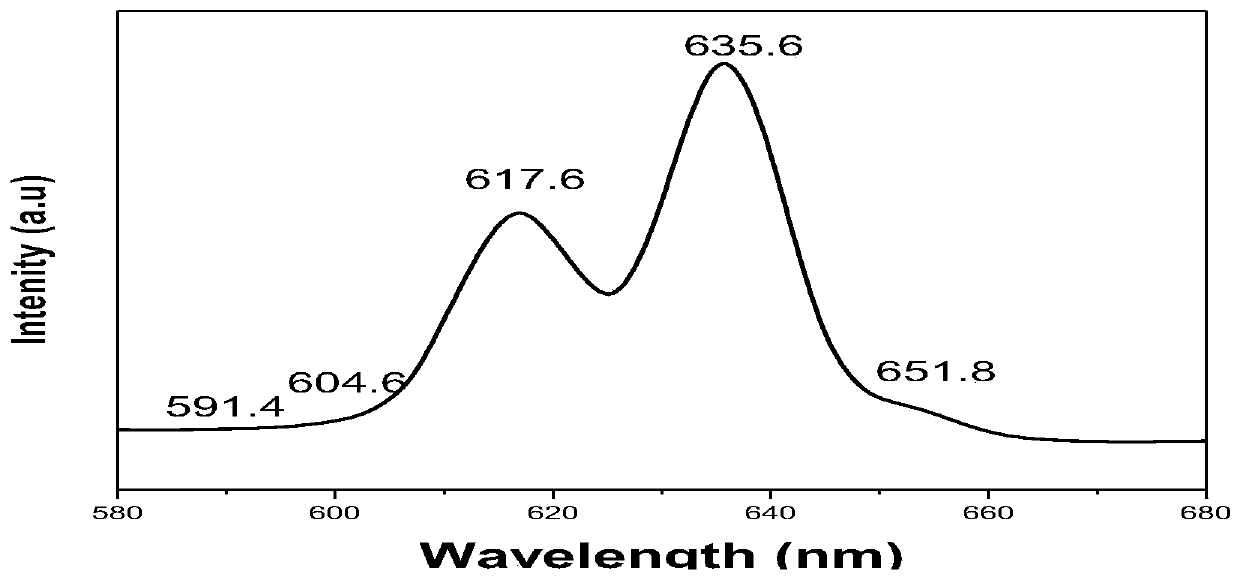

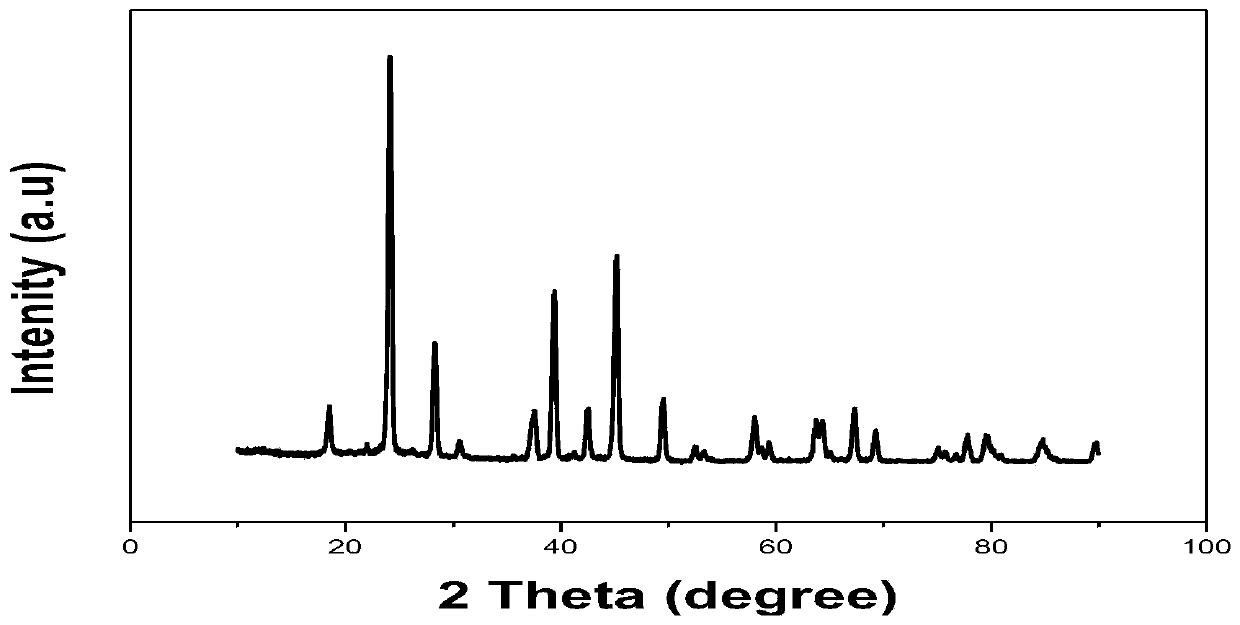

[0034] Under normal temperature and pressure conditions, Ba(NO 3 ) 2 Solution and mass percentage concentration are 35% Rb 2 CO 3 The solution was slowly dropped into 50% H by mass percentage successively. 2 TiF 6 In the solution, stir clockwise and circularly during the dropping process, the stirring speed is controlled at 80 rpm, continue stirring for 30 minutes after the dropping is completed, and the precipitate Rb is formed after 10 hours of reaction 0.254 Ba 0.873 TiF 6 ; Filtrate through a circulating water type multipurpose vacuum pump suction filter, use distilled water to wash to neutrality, and dry for 10 h in a vacuum oven at 90 ° C to obtain the intermediate product Rb 0.254 Ba 0.873 TiF 6 powder; then the intermediate product Rb 0.254 Ba 0.873 TiF 6 powder and KMnO 4 After mixing evenly, add HF aqueous solution with a mass percentage concentrat...

Embodiment 2

[0037] A kind of red fluorescent powder and preparation method thereof, according to the following steps:

[0038] Under normal temperature and pressure conditions, Ba(CO 3 ) 2 The solution and the 10% CsCl solution by mass percentage were slowly dropped into 50% H 2 TiF 6 In the solution, stir regularly along the counterclockwise direction during the dropwise addition, and the stirring speed is controlled at 60 rpm. After the dropwise addition is completed, continue to stir for 40 minutes. After 14 hours of reaction, a precipitate Cs is formed. 0.136 Ba 0.932 TiF 6 , the circulating water type multi-use vacuum pump filter, and the distilled water is washed to neutrality, and then dried in a vacuum oven at 90°C for 8 hours to obtain the intermediate product Cs 0.136 Ba 0.932 TiF 6 powder; then the intermediate product Cs 0.136 Ba 0.932 TiF 6 powder and KMnO 4 After mixing evenly, add it to 30% HF aqueous solution to react for 16 hours, filter it with a vacuum pump f...

Embodiment 3

[0041] A kind of red fluorescent powder and preparation method thereof, according to the following steps:

[0042] Under normal temperature and pressure conditions, Ba(Cl) with a concentration of 30% by mass 2 Solution and KNO with mass percent concentration of 30% 3 The solution was slowly dropped into 50% H by mass percentage successively. 2 TiF 6 In the solution, stir regularly along the counterclockwise direction during the dropwise addition, and the stirring speed is controlled at 70 rpm. After the dropwise addition is completed, continue to stir for 35min. After 20h of reaction, a precipitate K is formed. 0.842 Ba 0.579 TiF 6 , through the circulating water type multi-purpose vacuum pump suction filter, then wash with distilled water to neutrality, and dry in a vacuum oven at 90°C for 9 hours to obtain the intermediate product K 0.842 Ba 0.579 TiF 6 powder; then the intermediate product K 0.842 Ba 0.579 TiF 6 powder and KMnO 4 After mixing evenly, add HF aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com