Maca extract and preparation method thereof

A maca extract and extract technology are applied in the field of maca extract preparation, which can solve the problems that the natural active components of maca are not separated by extraction, the effect is not obvious, the extraction rate is low, etc., so as to improve the product purity and avoid the The effect of pollution and extraction rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

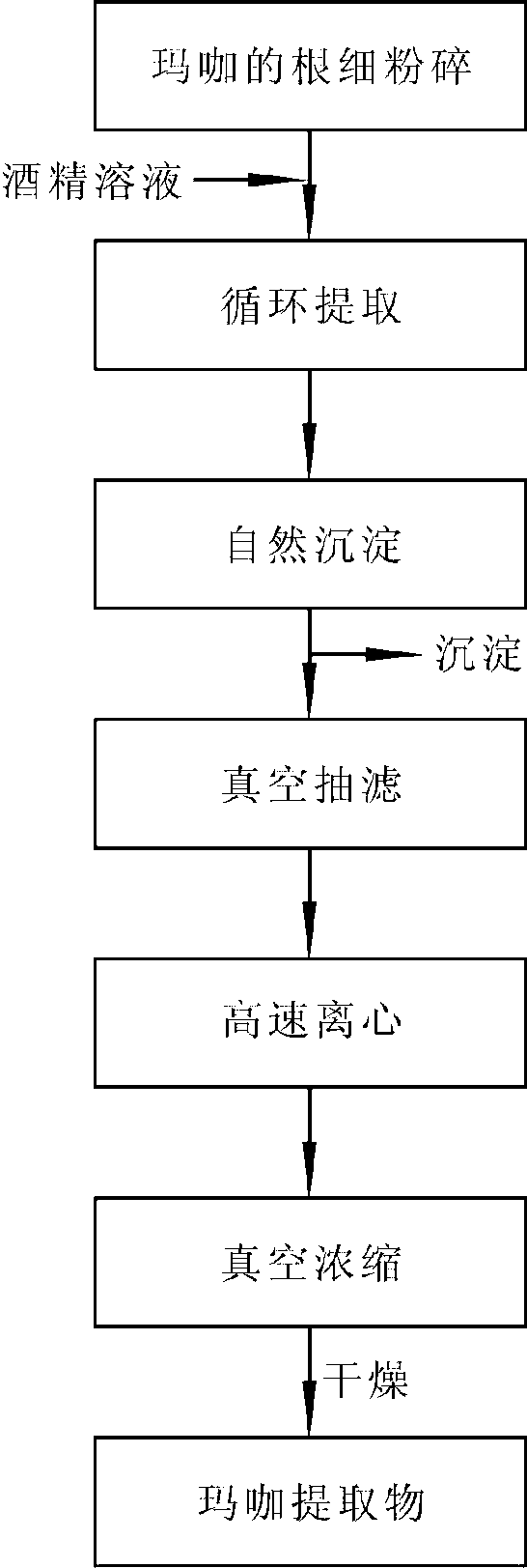

Method used

Image

Examples

Embodiment 1

[0025] Select no rot, no mildew, no maca dry root 50kg visible to the naked eye, and finely pulverize to pass through a 60 mesh sieve; the pulverized raw material is dropped into the extraction tank, and the 50% alcohol solution of 7 times the amount by weight is added Circulate extraction at 45°C for 2 hours to obtain the extract; put the extract into a sedimentation tank for natural precipitation for 6 hours, take the supernatant for vacuum filtration, and centrifuge the filtrate with a high-speed centrifuge at a speed of 10000r / min; take the centrifuge at 0.02~0.08 Mpa, concentrated in vacuum at 40°C to a relative density of 1.0, dried at 40°C to obtain 14kg of maca extract.

[0026] After testing, the total weight ratio of fatty acids is 30.3%, the content of benzyl isothiocyanate is 18.7%, and the total amount of macamide and macaene is 13.5%.

Embodiment 2

[0028] Select 50kg of dried Maca roots without rot, mildew, and no visible foreign impurities, and finely pulverize them until they can pass through a 100-mesh sieve; put the pulverized raw materials into the extraction tank, and add 60% alcohol solution with a weight ratio of 9 times Circulate extraction at 55°C for 5 hours to obtain the extract; put the extract into a sedimentation tank for natural precipitation for 10 hours, take the supernatant for vacuum filtration, and centrifuge the filtrate with a high-speed centrifuge at a speed of 40,000r / min; take the centrifuge at 0.02~0.08 Mpa, concentrated in vacuum at 55°C to a relative density of 1.3, dried at 55°C to obtain 12.8 kg of maca extract.

[0029] After testing, the total weight ratio of fatty acids is 39.7%, the content of benzyl isothiocyanate is 26.3%, and the total amount of macamide and macaene is 20.2%.

Embodiment 3

[0031] Select 50kg of dried Maca roots without rot, mildew, and no visible foreign impurities, and finely pulverize them until they can pass through a 70-mesh sieve; put the pulverized raw materials into the extraction tank, and add 70% alcohol solution with a weight ratio of 7.5 times Circulate extraction at 50°C for 4 hours to obtain the extract; put the extract into a sedimentation tank for natural precipitation for 9 hours, take the supernatant for vacuum filtration, and centrifuge the filtrate with a high-speed centrifuge at a speed of 35000r / min; take the centrifuge at 0.02~0.08 Mpa, concentrated in vacuum at 50°C to a relative density of 1.2, dried at 45°C to obtain 12.9kg of maca extract.

[0032] After testing, the total weight ratio of fatty acids is 35.6%, the content of benzyl isothiocyanate is 24.3%, and the total amount of macamide and macaene is 18.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com