Method for producing novel environment-friendly wood-plastic floor

A wood-plastic floor and production method technology, applied in the directions of deodorization, disinfection, etc., can solve the problems of board formula and production method limitation, affecting popularization and use, etc., and achieve the effect of short growth cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

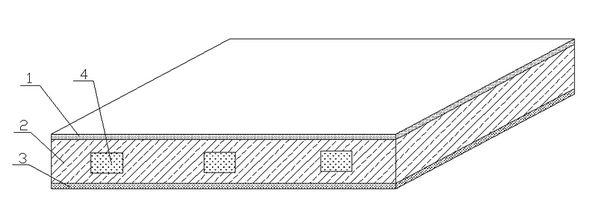

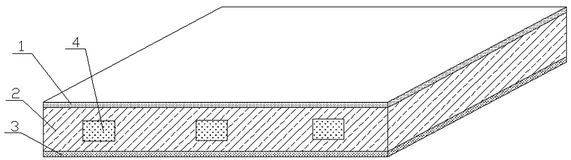

[0010] figure 1 A new type of environmentally friendly wood-plastic floor is shown. Its production method is to use bamboo fiber and polyethylene as the base material, add plastic fillers, reinforcing agents, flame retardants and processing aids, and then granulate after high-speed mixing. Extrude, cool, cut, then fill activated carbon 4 into the middle groove of the wood-plastic layer 2, and then bond together with the lower plastic layer 3 at high temperature, and finally stick the decorative film 1 on the wood-plastic layer 2.

[0011] The mass ratio of bamboo fiber to polyethylene is 1:1-1:4.

[0012] The middle grooves of the wood-plastic layer 2 are 3 to 5 grooves evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com