Free radical initiator modified hot melt adhesive composition including functionalized polyethylene and propylene-alpha-olefin polymer

A technology of hot melt adhesive and olefin polymer, applied in the direction of graft polymer adhesive, adhesive type, adhesive, etc., can solve problems such as inappropriateness, achieve good fiber tearability, good thermal stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0093] test program

[0094] The test programs used for the examples include the following programs. All ratios and percentages are by weight unless otherwise indicated.

[0095] thermal stability

[0096] thermal conditioning program

[0097] A 200 gram (g) sample of the hot melt composition was placed in a 400 milliliter (ml) PYREX glass beaker and held at 350°F (177°C) for 24 hours, 48 hours, 72 hours, and 96 hours.

[0098] Gardner color

[0099] The samples were conditioned according to the thermal conditioning procedure and then tested (in the molten state) to determine the Gardner color by comparing the color of the sample against the Gardner color standard described in ASTM D-1544. The comparison was performed using a Gardner Delta comparator equipped with lighting, available from Pacific Scientific, Bethesda, Maryland.

[0100] Clarity

[0101] The samples were conditioned according to the thermal conditioning procedure and then visually inspected fo...

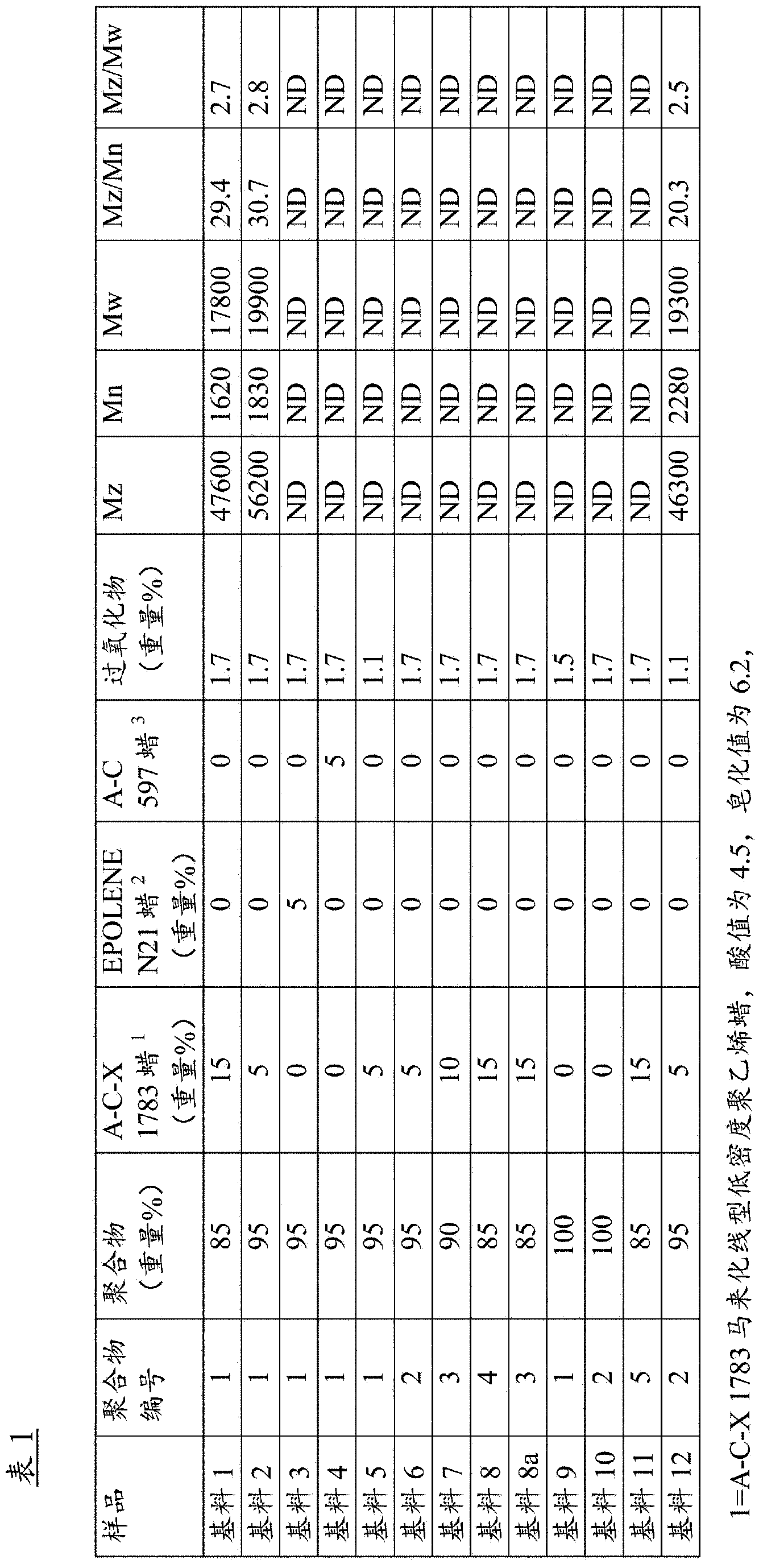

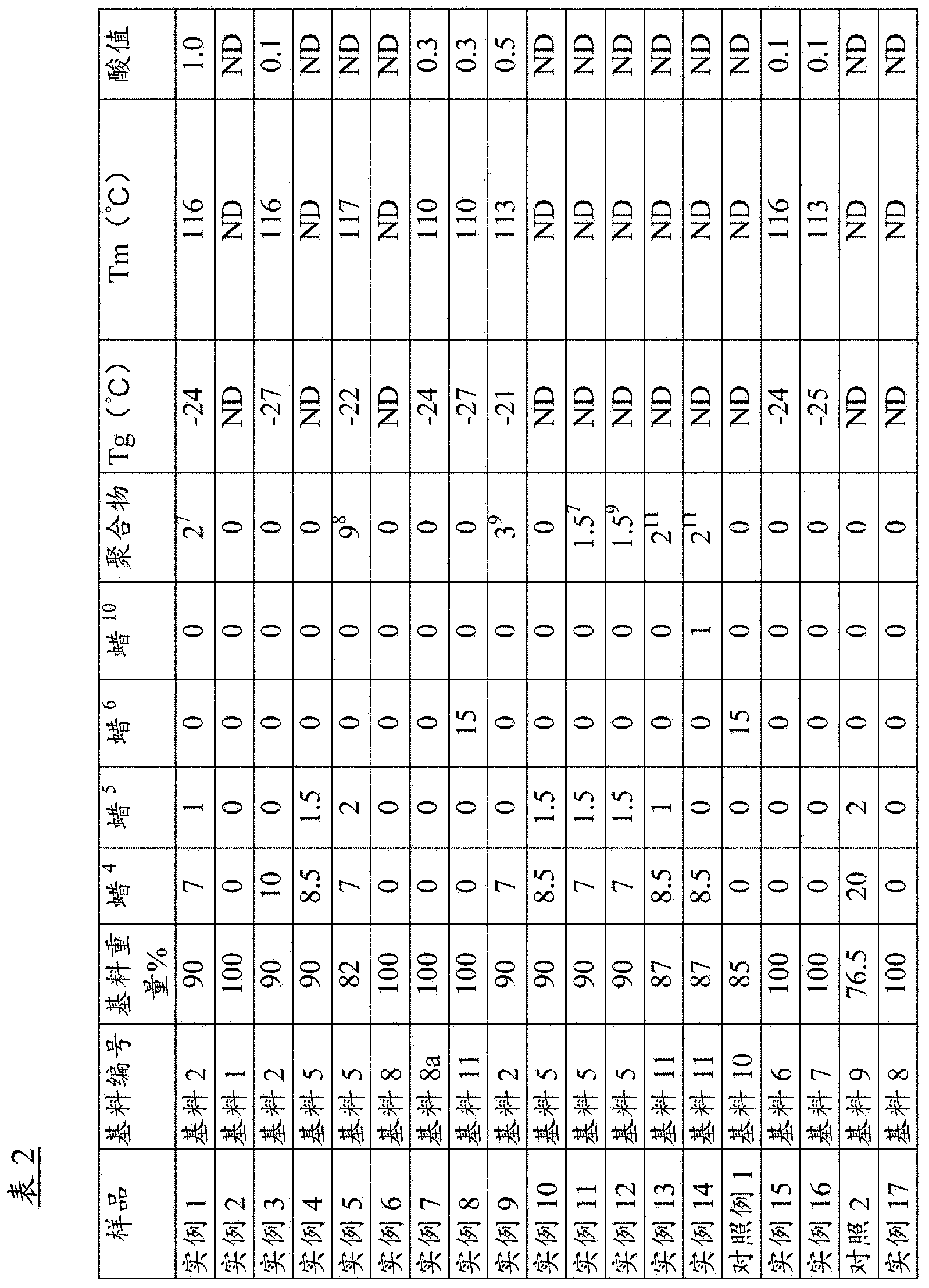

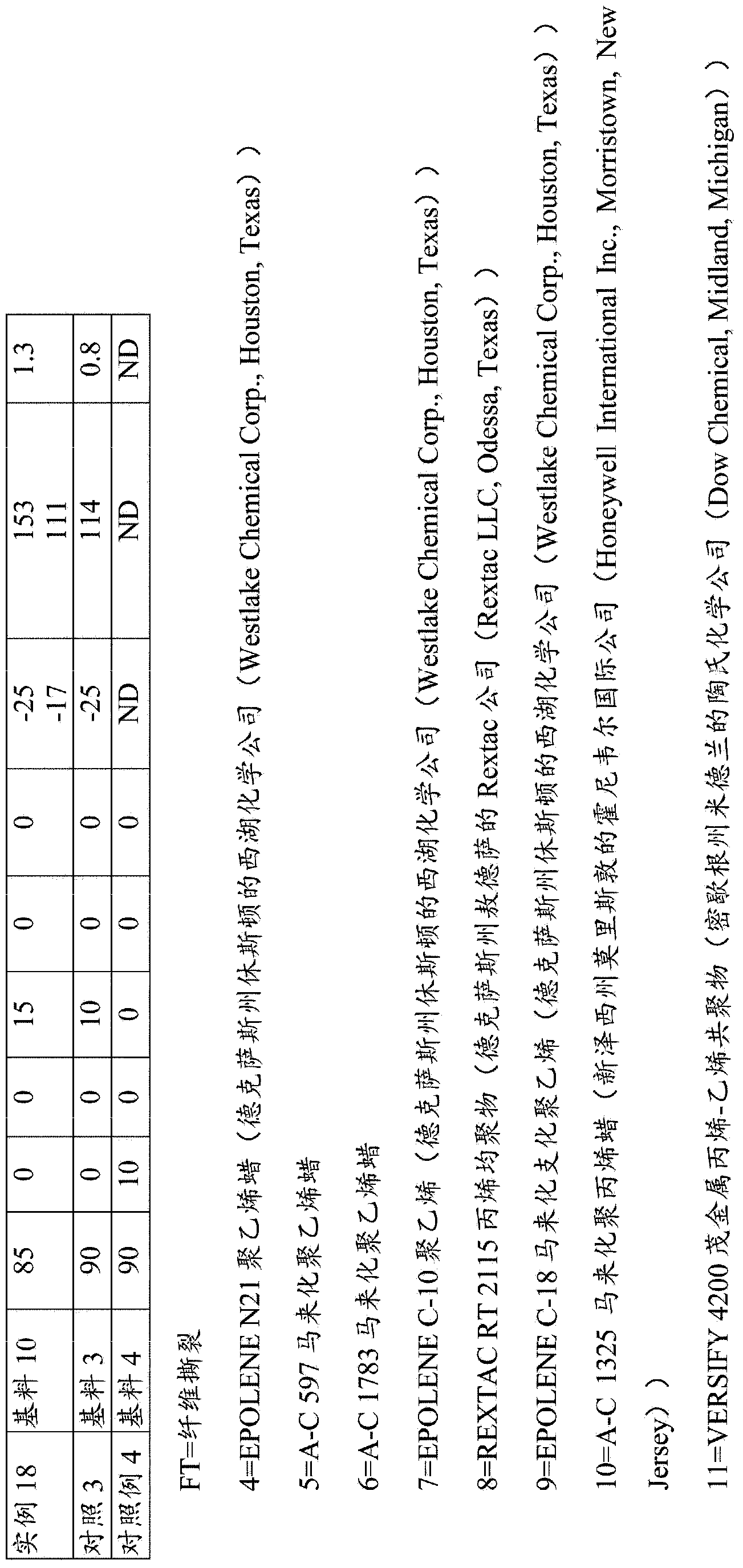

example 1-18

[0132] The hot-melt adhesive compositions of Examples 1-18 were prepared from bases 1, 2, 5, 6, 7, 8, 8a, 10, 11 and 12 by mixing the base with 1.0% by weight of IRGAFOS168 antioxidant, 0.5% by weight % of IRGANOX 1010 antioxidant and optional additional components (eg, waxes and polymers) were melt blended in the amounts shown in Table 2 (weight %). The hot melt adhesive compositions of Examples 1-14 were tested according to the Viscosity, Fiber Tear, and Set Time Test Methods and the results are shown in Table 3. The initial clarity and the observed clarity after 48 hours and 96 hours at 350°F (177°C) are also recorded in Table 3.

[0133]

[0134]

[0135]

[0136]

example 19

[0138] Radiation curable hot melts were prepared by treating a composition comprising the following components with 1.0 weight percent LUPEROX 101 organic peroxide under vacuum at a pressure of about 29 inches of mercury (Hg) and a temperature of about 175°C to about 190°C Adhesive composition: 70.85% by weight of a propylene-α-olefin copolymer of 65% by weight propylene and 35% by weight butene having a viscosity of 6,500 cps at 190°C, 4.48% by weight of A-C-X1783 maleated linear low Density polyethylene wax, 3.00% by weight adipic acid and 0.45% by weight IRGANOX 1010 antioxidant, treatment time was about 45 minutes. The resulting reaction product was then mixed with 3% by weight of IRGACURE184, 10.00% by weight of EASTOTAC H-100E tackifier, 8.52% by weight of N21 polyethylene wax, 1.20% by weight of AC596 maleated polypropylene wax and 0.50% by weight of IRGANOX1010 anti- Oxidants combine.

[0139] The composition is then exposed to UV radiation having a wavelength of 280n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com