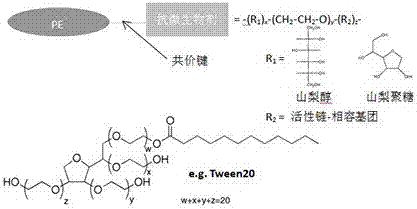

Functionalized polyethylene resin with antibacterial properties and preparation method thereof

A functionalized thermoplastic resin technology, applied in botany equipment and methods, biocides, plant growth regulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

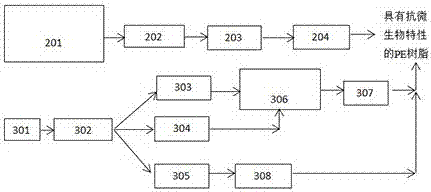

Method used

Image

Examples

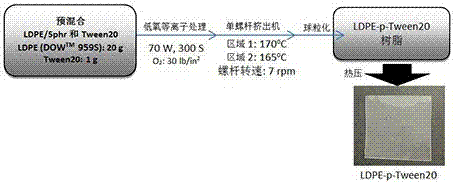

Embodiment 1

[0028] refer to image 3 As shown, this example uses low density polyethylene resin (model: DOWTM 959S) as the thermoplastic resin, which is pre-mixed with TWEEN® 20 as an antimicrobial agent before it is plasma treated. In this example, LDPE resin and TWEEN ® The dry weight ratio between 20 is LDPE resin: TWEEN® 20=20:1, that is: every 20g of LDPE resin and 1g of TWEEN® 20. Do a premix. In order to protect the functional groups introduced into the LDPE resin by the plasma, the plasma treatment step is performed in a near-vacuum (eg, 30 psi oxygen content) environment. In this embodiment, the power of the plasma machine is 70W, and the duration of the plasma treatment is 300s. TWEEN after plasma treatment ® The 20 conjugates are extruded in a single-screw extruder, which has two temperature control zones (zone 1 and zone 2), and the temperatures of zone 1 and zone 2 are set to 170°C respectively and 165° C., and the screw speed of the single-screw extruder was 7 rpm. T...

Embodiment 2

[0030] refer to Figure 4 As shown, the preparation method of this embodiment is to first mix LDPE resin with TWEEN ® 20 premixed, then using the same plasma treatment conditions as in Example 1 to obtain a TWEEN ® 20 conjugates (in Figure 4 and Figure 7 is marked as "p-LDPE-Tween ® 20" or "L1") and film samples prepared with this conjugate; at the same time, first take 20 mL of chitosan with a concentration of 0.05 g / mL (ie: 1 g of chitosan ) was mixed with 50 g of plasma-treated LDPE resin, then extruded, and then hot-pressed at 50 °C for 1 h to obtain a LDPE-chitosan conjugate (in Figure 4 and Figure 7 labeled as "p-LDPE-chitosan" or "L2") and film samples prepared from the conjugate. Conjugate L2 can be further mixed with L1, and then extruded to form another conjugate. The specific steps are as follows: first, the conjugate L2 was washed with water, and dried at 60°C; next, the conjugates L1 and L2 were mixed according to the dry weight ratio of 1:1, and the...

Embodiment 3

[0033] This embodiment discloses a radio frequency plasma machine (the model is GUARDER® GDR-150-T, produced in Shandong), the radio frequency plasma machine is equipped with a drum, and the size of the drum is 400(Φ)×450(L) mm , the speed is 50Hz (counterclockwise). The RF plasma machine has a power of 500W at 13.56MHz. The plasma treatment step is performed in an environment with very low oxygen content (eg, 200 sccm O2 @ 70 Pa) to protect the functional groups introduced by the plasma onto the LDPE backbone. The plasma treatment steps include: first, take 2.5kg of LDPE particles into the rotating cylinder with mesh on the plasma machine, and set the operating conditions required by this embodiment; secondly, achieve hypoxic reaction by decompressing the reaction chamber of the plasma machine Environment; Next, just as the oxygen content described in this embodiment, control the pressure to inject an appropriate amount of oxygen into the reaction chamber; Then, select a sui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com