Functionalized polyvinyl alcohol adsorbent for managing heavy metal pollution in water and preparation method thereof

A polyvinyl alcohol, functionalized technology, applied in the direction of water pollutants, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems that have not been seen yet, achieve fast adsorption rate, good enrichment and recovery, and improve adsorption performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

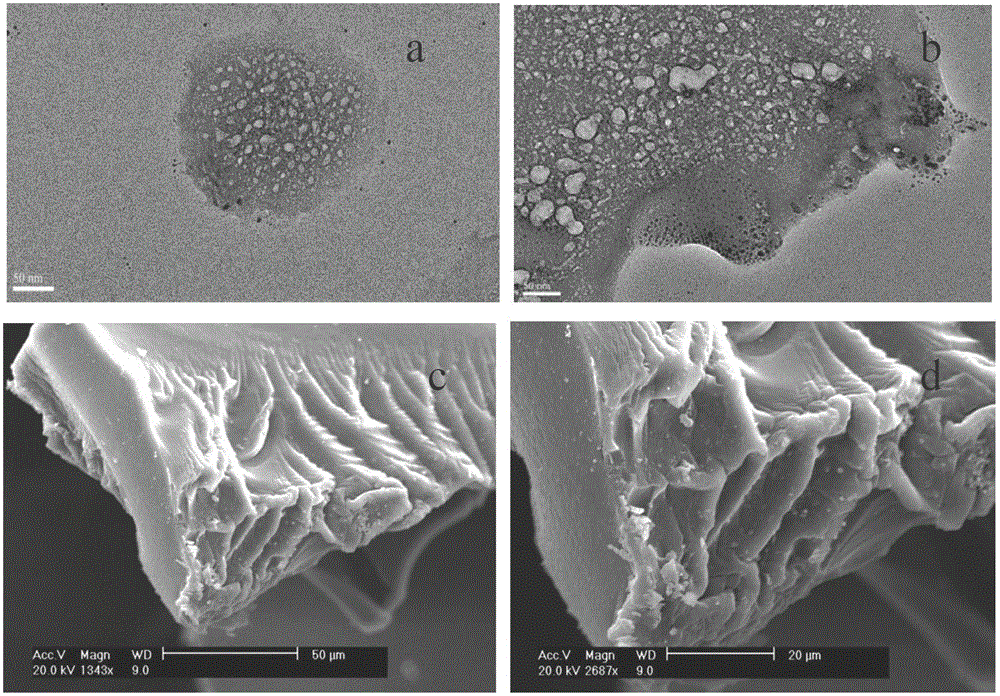

Image

Examples

Embodiment 1

[0035] In this embodiment, a functionalized polyvinyl alcohol adsorbent for controlling heavy metal pollution in water bodies is a polyvinyl alcohol-maleic anhydride polymer prepared from polyvinyl alcohol, maleic anhydride, and butyl acetate, which is swollen and carbonized The polymer particle that obtains after processing, its preparation method is as follows:

[0036] (1) Weigh 40g of maleic anhydride and dissolve in 180g of butyl acetate, and react with 30g of polyvinyl alcohol in a flask at a temperature of 90°C for 6h, filter; pour the precipitate into 300mL of sodium hydroxide containing 3wt% In sodium hydroxide ethanol solution, react at 90°C for 3 minutes, filter; wash the precipitate with absolute ethanol and dry at 50°C to obtain polyvinyl alcohol-maleic anhydride polymer;

[0037] (2) Weigh 50 g of polyvinyl alcohol-maleic anhydride polymer, place in 150 g of dichloroethane and stir and swell for 15 h;

[0038] (3) Add 600 g of concentrated sulfuric acid to the s...

Embodiment 2

[0042] In this embodiment, a functionalized polyvinyl alcohol adsorbent for controlling heavy metal pollution in water bodies is a polyvinyl alcohol-maleic anhydride polymer prepared from polyvinyl alcohol, maleic anhydride, and butyl acetate, which is swollen and carbonized The polymer particle that obtains after processing, its preparation method differs from embodiment one in that:

[0043] The consumption of step (1) maleic anhydride is 60g.

[0044] The contents of hydroxyl group and carboxyl group in the obtained functionalized polyvinyl alcohol adsorbent were 0.6595mmol / g and 0.9590mmol / g, respectively.

Embodiment 3

[0046] In this embodiment, a functionalized polyvinyl alcohol adsorbent for controlling heavy metal pollution in water bodies is a polyvinyl alcohol-maleic anhydride polymer prepared from polyvinyl alcohol, maleic anhydride, and butyl acetate, which is swollen and carbonized The polymer particle that obtains after processing, its preparation method differs from embodiment one in that:

[0047] The consumption of step (1) maleic anhydride is 30g.

[0048] The contents of hydroxyl group and carboxyl group in the obtained functionalized polyvinyl alcohol adsorbent were 1.4790mmol / g and 0.4022mmol / g, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com