Functionalized polyvinyl alcohol hydrogel and preparation method thereof

A polyvinyl alcohol, functionalized technology, applied in chemical instruments and methods, inorganic chemistry, water pollutants, etc., can solve problems such as limiting industrial application and subsequent treatment of adsorbents, achieving good regeneration and reusability, and beneficial to the environment. The effect of sustainable development and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of functionalized polyvinyl alcohol:

[0036] 1. Maleinized Polyvinyl Alcohol

[0037] (1) Add 20 mL of maleic anhydride / dimethyl sulfoxide solution with a concentration of 5% to 10% dropwise into 100 mL of 5% to 10% polyvinyl alcohol dimethyl sulfoxide solution, and let stand for 0.5 to 2 hours.

[0038] (2) Put the above solution under an 8W low-pressure mercury lamp to irradiate (light intensity 10w / m 2 ) 0.5-6h, after drying, maleic anhydrided polyvinyl alcohol is obtained.

[0039] 2. Amino Acid Functionalized Polyvinyl Alcohol

[0040] (1) Add 250mL of NaOH solution with a concentration of 0.4mol / L to a 500mL three-necked flask, swell 3g of polyvinyl alcohol for 6 hours, add 30mL of epichlorohydrin, mix well, stir and react at 60°C for 1 to 10 hours, cool and pump Filter, wash with ethanol and water, and dry to obtain epoxidized polyvinyl alcohol particles.

[0041] (2) After fully swelling 0.5g of epoxidized polyvinyl alcohol particl...

example 1

[0049] Weigh 2g Mercapto-functionalized polyvinyl alcohol , 0.26g of sodium alginate (Qingdao Xiangyu Seaweed Co., Ltd.) and 95mL of deionized water were added to a three-necked flask, heated in a boiling water bath, mechanically stirred for 2 hours to make it completely mixed, and the mixture was heated in a water bath at 80°C. Add 2 g of chitosan (Hangzhou Fuli Biotechnology Co., Ltd.) and mechanically stir for 6 h (the weight ratio of polyvinyl alcohol and chitosan is 50:50). Drop the above-prepared mixed solution into 3% calcium chloride-boric acid saturated solution with a syringe to prepare composite hydrogel beads with a particle size of 2 to 3 mm, soak for 24 hours, and finally rinse with deionized water for 3 times and soak in water .

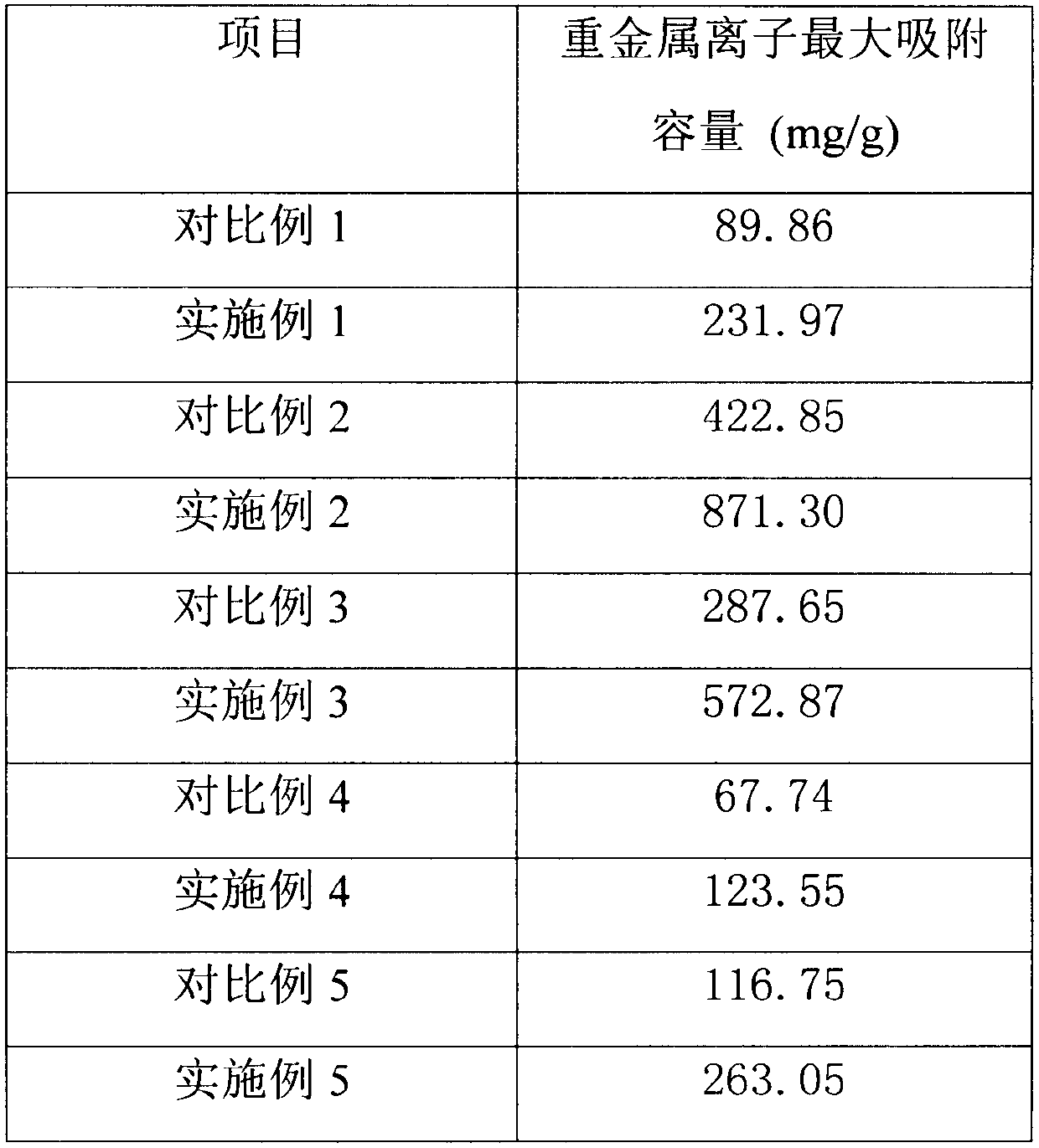

[0050] After testing, the hydrogel was tested for Cu 2+ The adsorption capacity is listed in Table 1.

Embodiment 2

[0055] Under the same other conditions of Example 1, the weight ratio of thiol-functionalized polyvinyl alcohol and chitosan was changed to 70:30 to prepare a hydrogel.

[0056] After testing, the hydrogel was tested against Pb 2+ The adsorption capacity is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com