Method for producing wastewater denitrification carbon source through lactic acid fermentation of kitchen waste

A food waste and lactic acid fermentation technology, which is applied to chemical instruments and methods, fermentation, anaerobic digestion, etc., can solve the problem of high cost of additional carbon sources, achieve efficient resource utilization, convenient operation, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

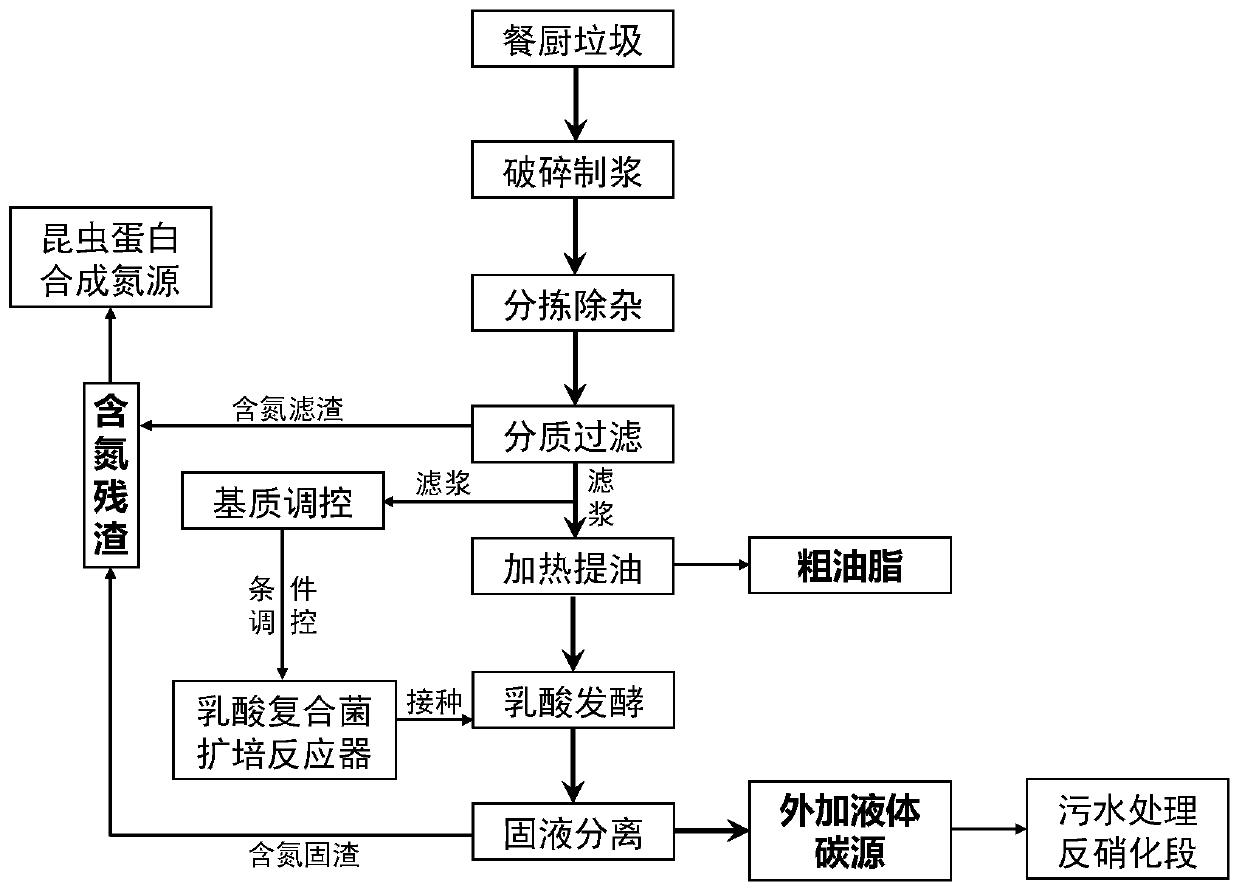

Method used

Image

Examples

Embodiment 1

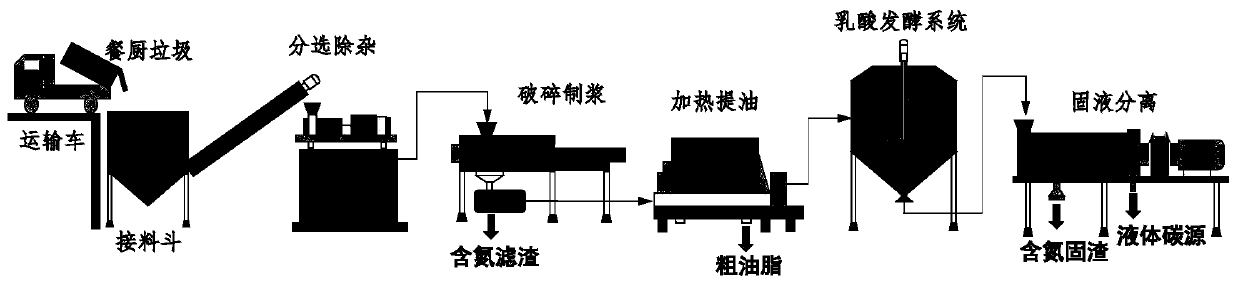

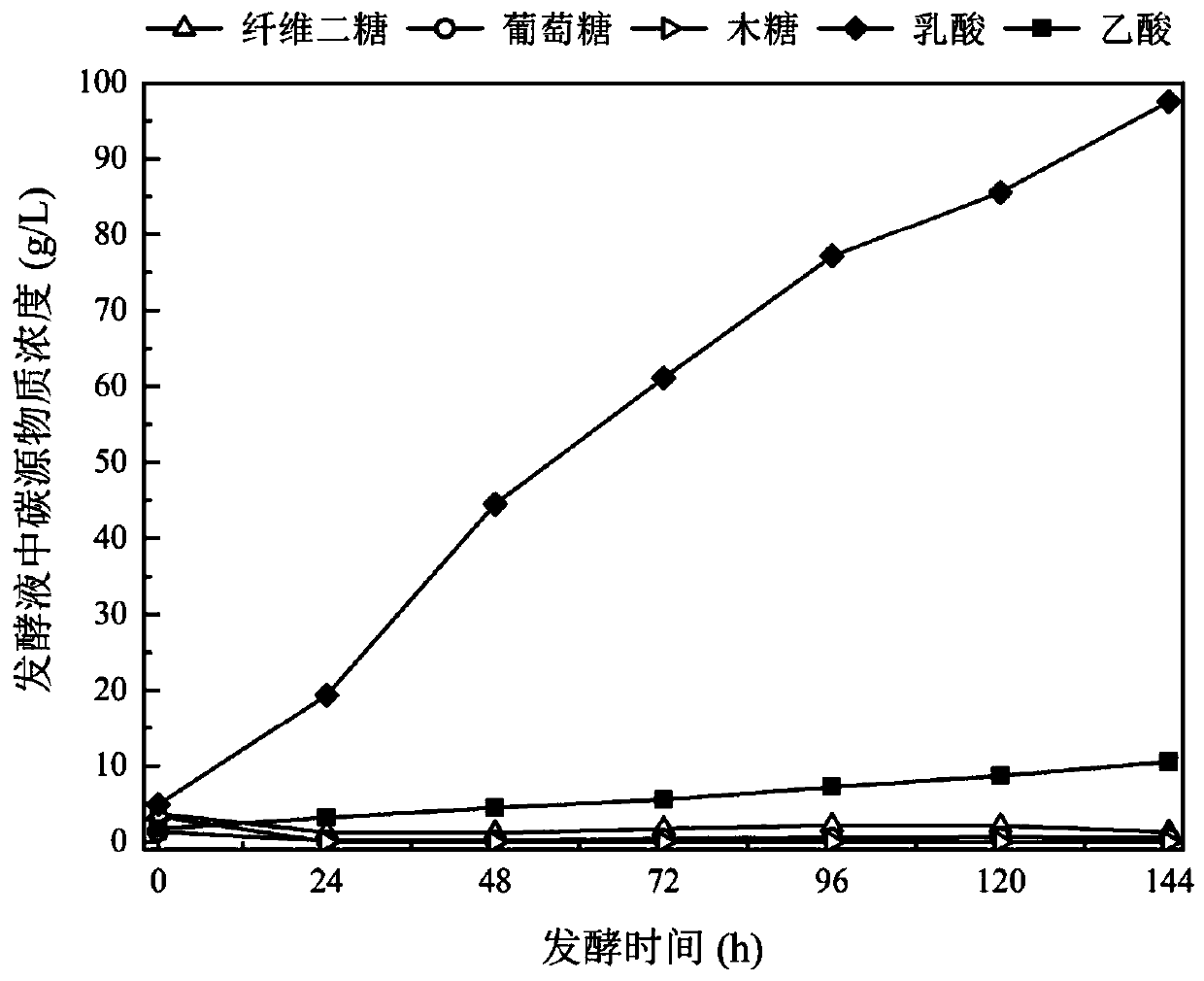

[0036] The food waste collected and transported by the municipal government is sorted to remove metals, plastics, etc., mixed with water according to the solid-to-liquid ratio of 1:1 (w / v), injected into the pulverizer for crushing and refining, and the coarse refining is passed through the filter screen (Φ1mm ) for quality and phase separation. The filter residue intercepts about 40% of the protein in the kitchen waste, and the protein content of the filter residue on a dry basis is 32.52%, which can be collected and reused. The filtered food waste slurry cooking tank is heated at 80°C for 60 minutes, and 75% of the waste oil in the food waste is extracted and recovered by a three-phase separator. After the oil is extracted, the garbage slurry is injected into the anaerobic fermentation tank, and the slurry in the continuous food waste lactic acid complex bacteria expansion reactor is extracted as the inoculum, the inoculation ratio is 10% (v / v), the initial pH value is adjus...

Embodiment 2

[0038] Sequencing batch SBR reactor, effective volume 8L, hydraulic retention time 6h, operation mode 120min aerobic, 180min anoxic, 60min static. The initial concentration of ammonia nitrogen in the reactor was 45mg / L, and the addition of food waste lactic acid fermentation liquid carbon source directly increased the COD concentration of the influent water to 400mg / L, adjusted the COD / TN ratio of 9, and converted the ammonia nitrogen in the water body to nitrate nitrogen 21.9 after aeration for 2 hours mg / L, no nitrite nitrogen; after anoxic denitrification treatment for 3 hours, no nitrate nitrogen and nitrite nitrogen were detected in the effluent, the concentration of ammonia nitrogen was 2.0mg / L, and the concentration of COD in the effluent was 48mg / L. For the change of nitrogen concentration, see Figure 4 . Denitrification rate up to 6.43NO 3- mg / (gMLVSS·h) -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com