Lithium extracting unit adopting flowing electrode, extending device and continuous operating method

A technology of flowing electrodes and flow channels, which is applied in the field of lithium ion collection, can solve the problems of low continuous operation efficiency, limited electrode/lithium-containing brine contact area, and difficult operation, so as to increase the degree of operation automation, realize processing capacity, and avoid Toggle fluid effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

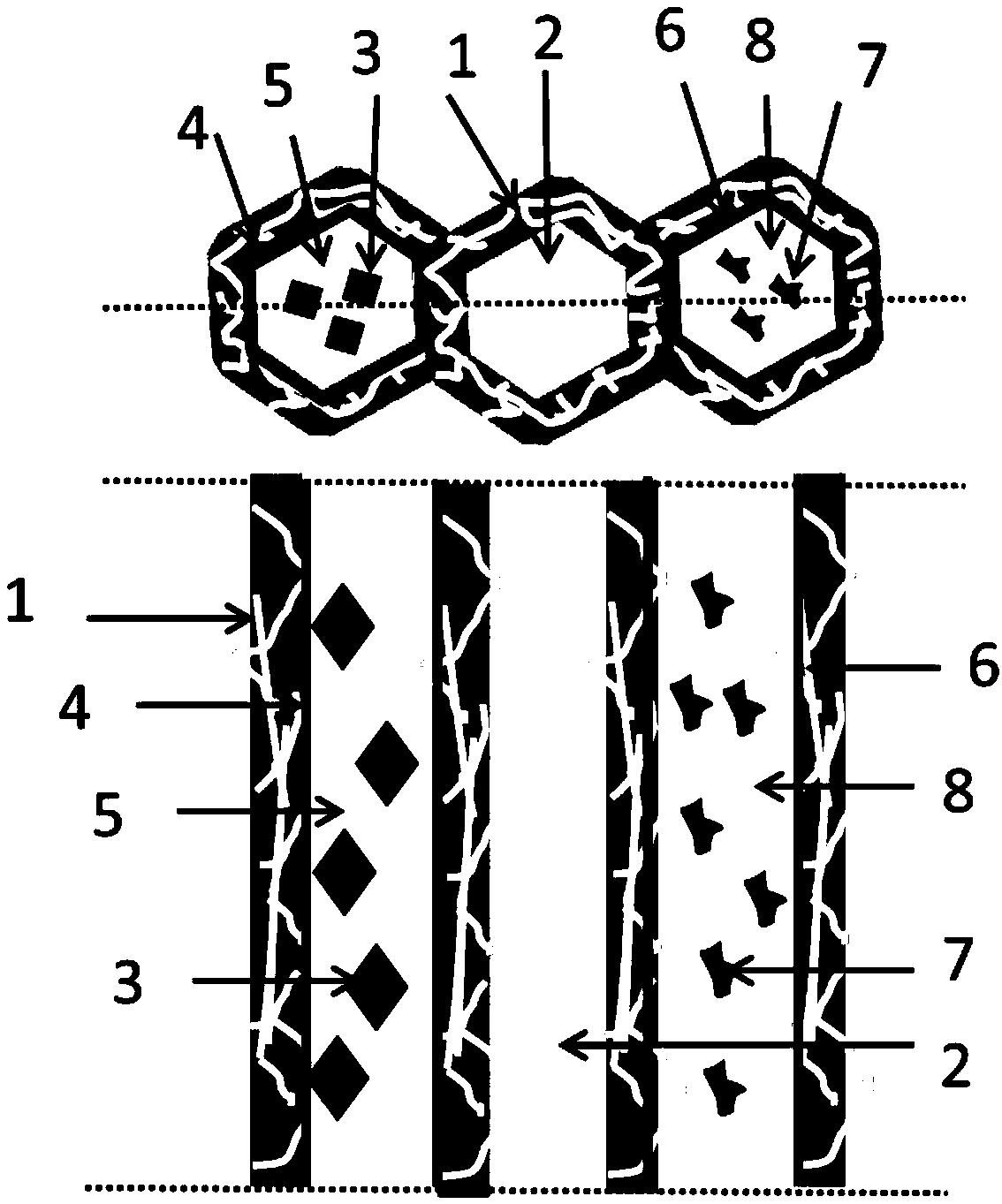

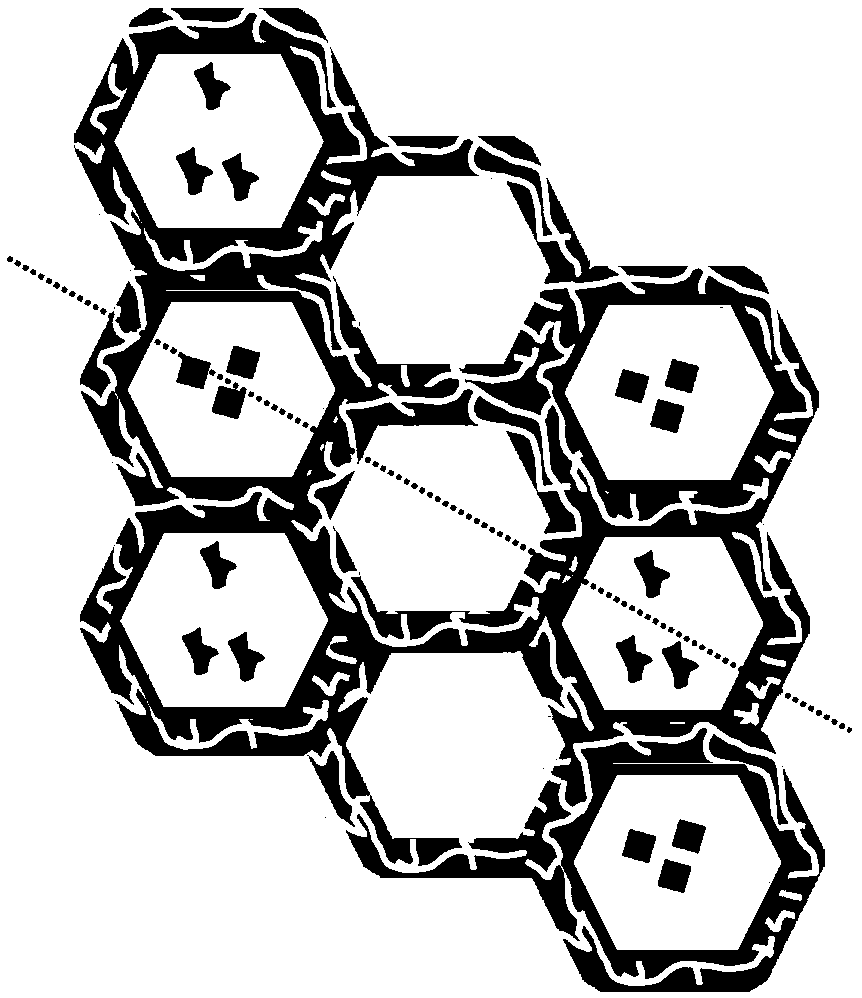

Embodiment 1

[0064] Example 1: The lithium intercalation and delithiation active material in the lithium intercalation and desorption flow electrode slurry is lithium manganate, the carbon particles in the carbon particle flow electrode slurry are activated carbon, and the applied voltage between the positive and negative electrode current collectors is controlled at 1.2V. The channel flow rate is 3ml / min, the scale is the smallest unit (three channels), the lithium ion extraction efficiency is 17umol / min, and the energy utilization efficiency is 9.6%. The solution temperature of the lithium-containing brine channel and the recovery solution channel is 20° C., and the pH value is 6.8.

Embodiment 2

[0065] Example 2: The lithium intercalation and desorption active material in the lithium intercalation and desorption flow electrode slurry is lithium manganate, and the carbon particles in the carbon particle flow electrode slurry are activated carbon. The voltage applied between the positive and negative current collectors is controlled at 1.2V, the single-channel flow rate is 3ml / min, the scale is three groups of smallest units (nine channels), the lithium ion extraction efficiency is 72umol / min, and the energy utilization efficiency is 33%. The temperature of the solution in the lithium-containing brine channel and the recovery solution channel is 25° C., and the pH value is 6.8.

Embodiment 3

[0066] Embodiment 3: The lithium intercalation and deintercalation active material in the lithium intercalation and desorption flow electrode slurry is lithium nickel molybdenum manganese oxide, and the carbon particles in the carbon particle flow electrode slurry are activated carbon. The applied voltage between the positive and negative current collectors is controlled at 1.2V, the single-channel flow rate is 2ml / min, the scale is three groups of smallest units (nine channels), the lithium ion extraction efficiency is 86umol / min, and the energy utilization efficiency is 29%. The solution temperature of the lithium-containing brine channel and the recovery solution channel is 15° C., and the pH value is 7.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com