Preparation method of Incone1625 nickel base alloy powder for selective laser melting technology

A technology of laser selective melting and nickel-based alloys, which is applied in the field of additive manufacturing, can solve the problems of macroscopic component segregation and low material utilization rate, and achieve the effects of avoiding adverse effects, reducing production costs, and fast cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the Inconel625 nickel base alloy powder that is used for laser selective melting technique comprises the following steps:

[0036] (1) Smelting: Put the Inconel625 nickel-based alloy raw material into a vacuum induction furnace for smelting, and the smelting temperature is controlled at 1450°C. After smelting, an Inconel625 nickel-based alloy bar is obtained. The alloy composition ratio is: Ni: 62%, Cr: 22%, Mo: 9%, Nb: 4.0%, Fe: 2.5%, Al: ≤0.4%, Ti: ≤0.4%, Mn: ≤0.5%, Si: ≤0.5%, C: ≤0.1%, P: ≤0.015% , S: ≤0.015%;

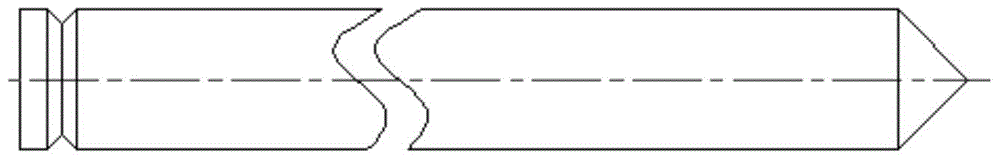

[0037] (2) Processing: Inconel625 nickel-based alloy bar according to figure 1 The structure is processed into a cylindrical rod with a cone angle of 80°;

[0038] (3) Atomization: Vacuum electrode induction melting is performed on the processed Inconel625 nickel-based alloy rod, and the descending speed of the rod is controlled at 20mm / min. Under the impact of the air flow, the atomization forms fine droplets. The atomization gas...

Embodiment 2

[0042] The preparation method of the Inconel625 nickel base alloy powder that is used for laser selective melting technique comprises the following steps:

[0043] (1) Smelting: Put the Inconel625 nickel-based alloy raw material into a vacuum induction furnace for smelting, and the smelting temperature is controlled at 1500 ° C. After smelting, an Inconel625 nickel-based alloy bar is obtained. The alloy composition ratio is: Ni: 62%, Cr: 22 %, Mo: 9%, Nb: 3.6%, Fe: 3.5%, Al: ≤0.4%, Ti: ≤0.4%, Mn: ≤0.5%, Si: ≤0.5%, C: ≤0.1%, P: ≤ 0.015%, S: ≤0.015%;

[0044] (2) Processing: Inconel625 nickel-based alloy rods are processed according to the attached figure 1 Processed into a cylindrical rod with a cone angle of 75°;

[0045] (3) Atomization: Vacuum electrode induction melting is performed on the processed Inconel625 nickel-based alloy rod, and the descending speed of the rod is controlled at 30mm / min. Under the airflow, atomize to form fine droplets. The atomization gas is hig...

Embodiment 3

[0049] The preparation method of the Inconel625 nickel base alloy powder that is used for laser selective melting technique comprises the following steps:

[0050] (1) Smelting: Put the Inconel625 nickel-based alloy raw material into a vacuum induction furnace for smelting, the smelting temperature is controlled at 1550°C, and the Inconel625 nickel-based alloy bar is obtained by smelting. The alloy composition ratio is: Ni: 62%, Cr: 22% , Mo: 9%, Nb: 3.2%, Fe: 4.5%, Al: ≤0.4%, Ti: ≤0.4%, Mn: ≤0.5%, Si: ≤0.5%, C: ≤0.1%, P: ≤0.015 %, S: ≤0.015%;

[0051] (2) Processing: Inconel625 nickel-based alloy rods are processed according to the attached figure 1 Processed into a cylindrical rod with a cone angle of 90°;

[0052] (3) Atomization: Vacuum electrode induction melting is carried out on the processed Inconel625 nickel-based alloy rod, and the descending speed of the rod is controlled at 40mm / min. Under the airflow, atomize to form fine droplets. The atomization gas is high-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com