Method for preparing high bulk density molybdenum powder

A technology of bulk density and molybdenum powder, applied in the field of preparation of molybdenum powder with high bulk density, can solve the problems of unfavorable industrial scale production, small powder loading, difficulty in separation of balls, etc. The effect of packing density and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

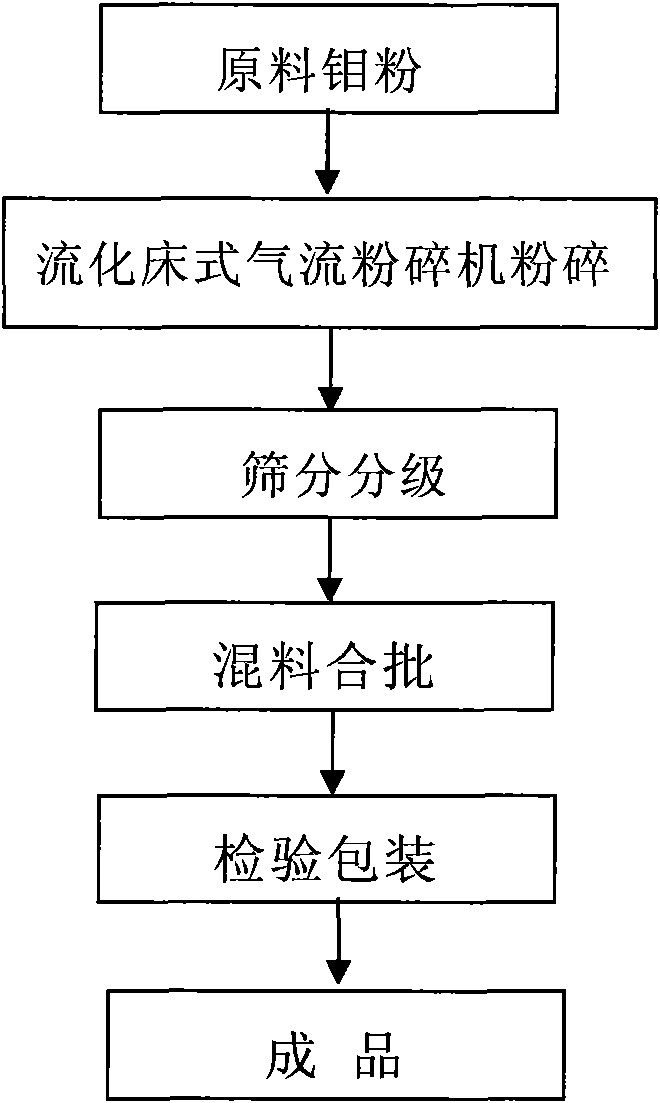

[0014] A kind of preparation method of high bulk density molybdenum powder as shown in Figure 1, its preparation process is: take common molybdenum powder as raw material, the chemical composition of the raw material molybdenum powder that the present invention selects meets the requirement of GB / T3461-2006 standard, molybdenum The Fischer particle size of the powder is greater than 4.0μm, and the bulk density is 0.9-1.2g / cm 3 ; Ordinary molybdenum powder is installed in the material storage box of the fluidized bed airflow mill, and the molybdenum powder is subjected to fluidized bed airflow pulverization treatment with purified and dried nitrogen. The purity of the nitrogen after purification and drying is greater than 99.99%. Less than -45°C, pressure at 0.15-0.7MPa; online sieving and grading of the pulverized molybdenum powder, the mesh number of the rotary vibration sieve is 160 mesh, 200 mesh, 250 mesh or 325 mesh, take The next product is the product; the molybdenum po...

Embodiment 1

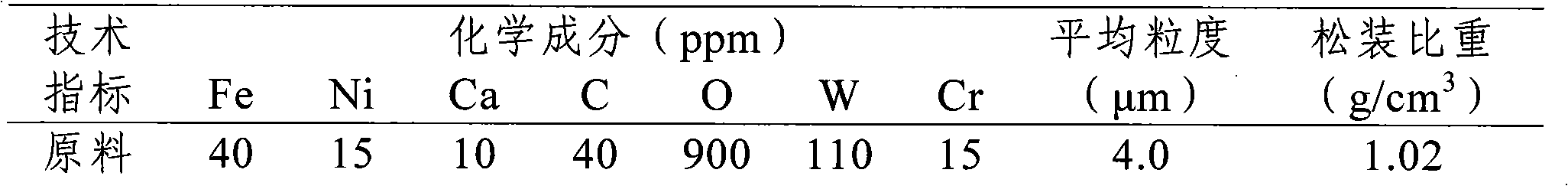

[0020] Take 500 kg of molybdenum powder that meets the GB / T3461-2006 standard, its average Fischer particle size is 4.0 μm, and its bulk density is 1.02 g / cm 3 . Send the prepared molybdenum powder into the material storage box of the fluidized bed jet mill according to the process requirements, and set the pressure of the gas source-purified and dried nitrogen to 0.15MPa. Turn on the linkage switch of the fluidized bed jet mill, and the fluidized bed jet mill starts to run; start the rotary vibrating sieve switch, and start sieving. The mesh size of the sieve is 200 mesh. After running for 3 hours, all the molybdenum powders are processed. Turn off the power. The processed molybdenum powder is mixed and batched in a double-cone mixer, and the mixing time is 1 hour, and the molybdenum powder of the present invention is obtained after inspection and packaging. Table 1 shows the detection results of common raw material molybdenum powder and high bulk density molybdenum powder ...

Embodiment 2

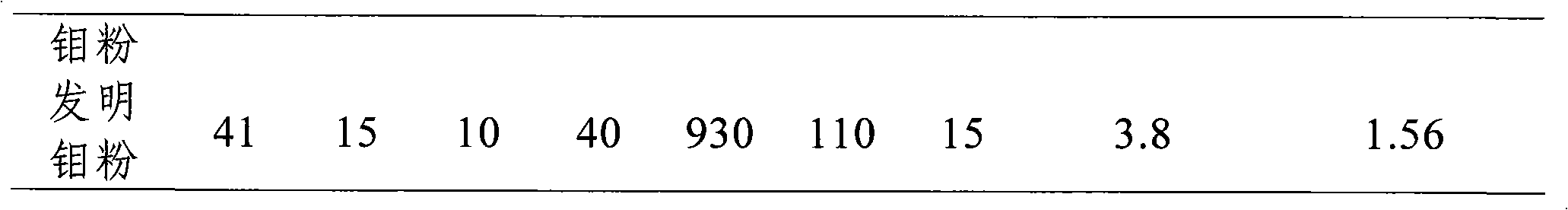

[0025] Take 500 kg of molybdenum powder that meets the GB / T3461-2006 standard, its average Fischer particle size is 4.8 μm, and its bulk density is 1.12 g / cm 3 . Send the prepared molybdenum powder into the material storage box of the fluidized bed jet mill according to the process requirements, and set the pressure of the gas source-purified and dried nitrogen to 0.5MPa. Turn on the linkage switch of the fluidized bed jet mill, and the fluidized bed jet mill starts to run; start the rotary vibrating sieve switch, and start sieving. The sieve mesh is 250 mesh. After running for 2 hours, all the molybdenum powders are processed. Turn off the power. The processed molybdenum powder is mixed and batched in a double-cone mixer, and the mixing time is 1 hour, and the molybdenum powder of the present invention is obtained after inspection and packaging. Table 2 shows the detection results of common raw material molybdenum powder and high bulk density molybdenum powder prepared in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com