Automatic X-ray metal detection and rubber cutting machine

A metal detection and glue cutting machine technology, applied in metal processing and other directions, can solve the problems of low work efficiency, high labor intensity, time-consuming and laborious, etc., and achieve the effect of improving operating efficiency, low operating burden, and high degree of operation automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

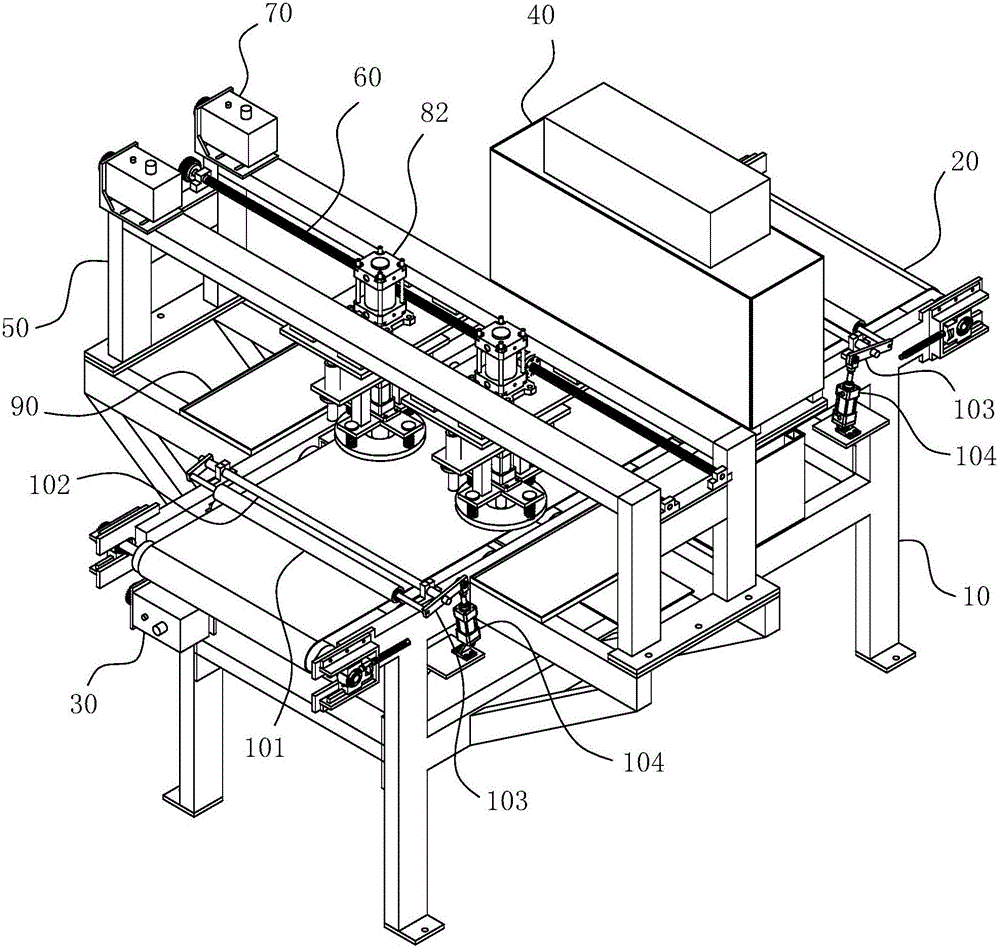

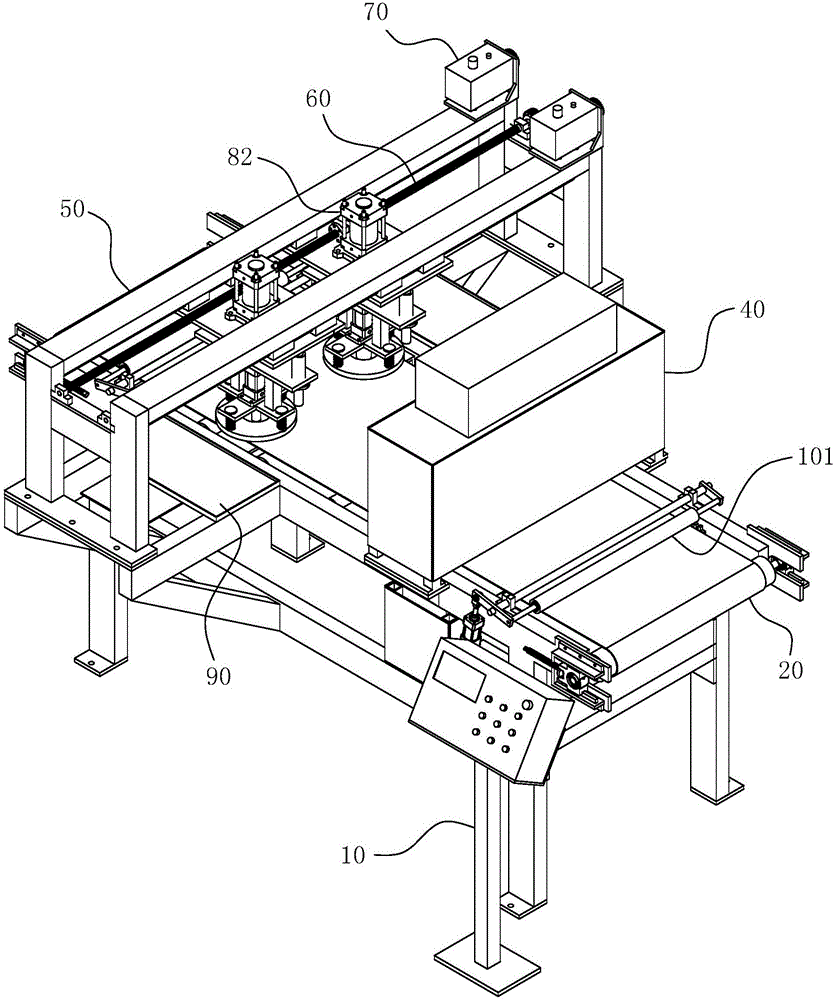

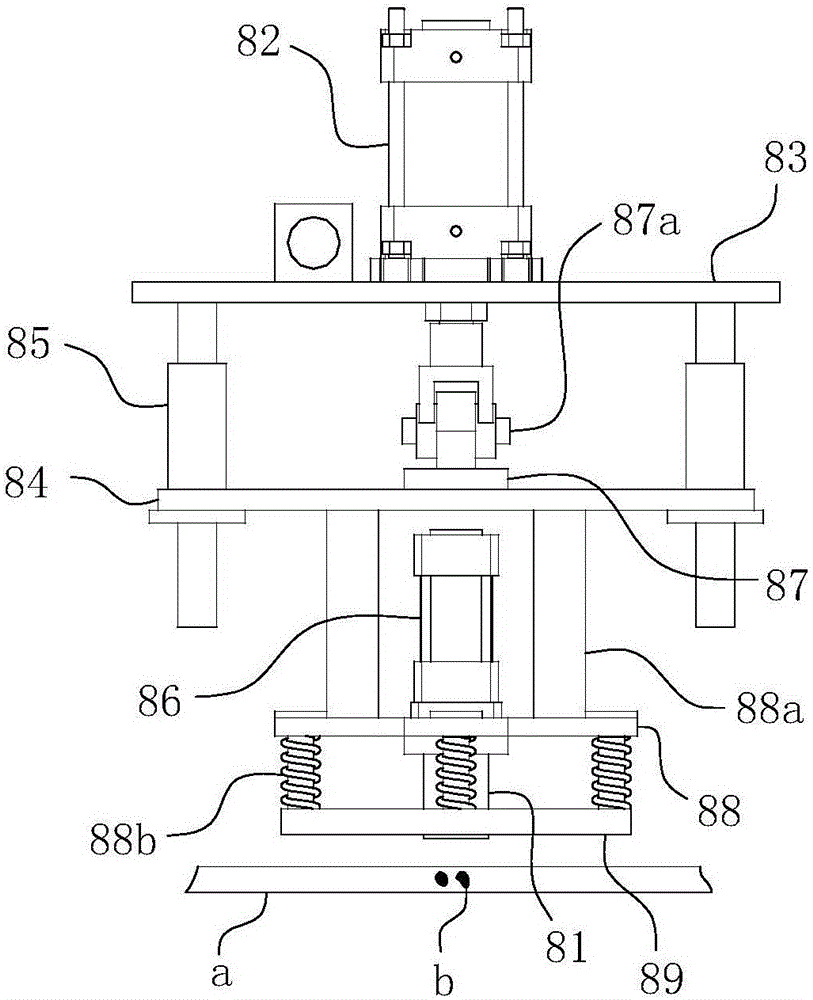

[0041] For ease of understanding, combined here Figure 1-8 Concrete structure and workflow of the present invention are described as follows:

[0042] The working principle of the present invention:

[0043] Such as Figure 1-2 As shown, the present invention utilizes the transmission characteristics of X-rays to perform perspective detection on the advancing rubber material a. The detection results are digitally imaged by CKD, the size and position of the metal are determined, and the results are displayed on the screen. If metal b is detected, an alarm signal will be given, and the data will be transmitted to the PLC, and the servo will control the walking position of the cutter structure. If multiple sets of cutting knives with different calibers are designed, there will be a determination of the metal size in this process. When it is greater than a set value, the servo will control the movement of the large-diameter cutter, and vice versa, the servo will control the sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com