Ring-shaped lead rail of vertical type lathe

A technology of vacuum suction cups and precision lathes, applied in the directions of sealing, clamping, and supporting of engines, can solve problems such as workpiece deformation and affect processing quality, and achieve the effects of convenient operation, improved operation automation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

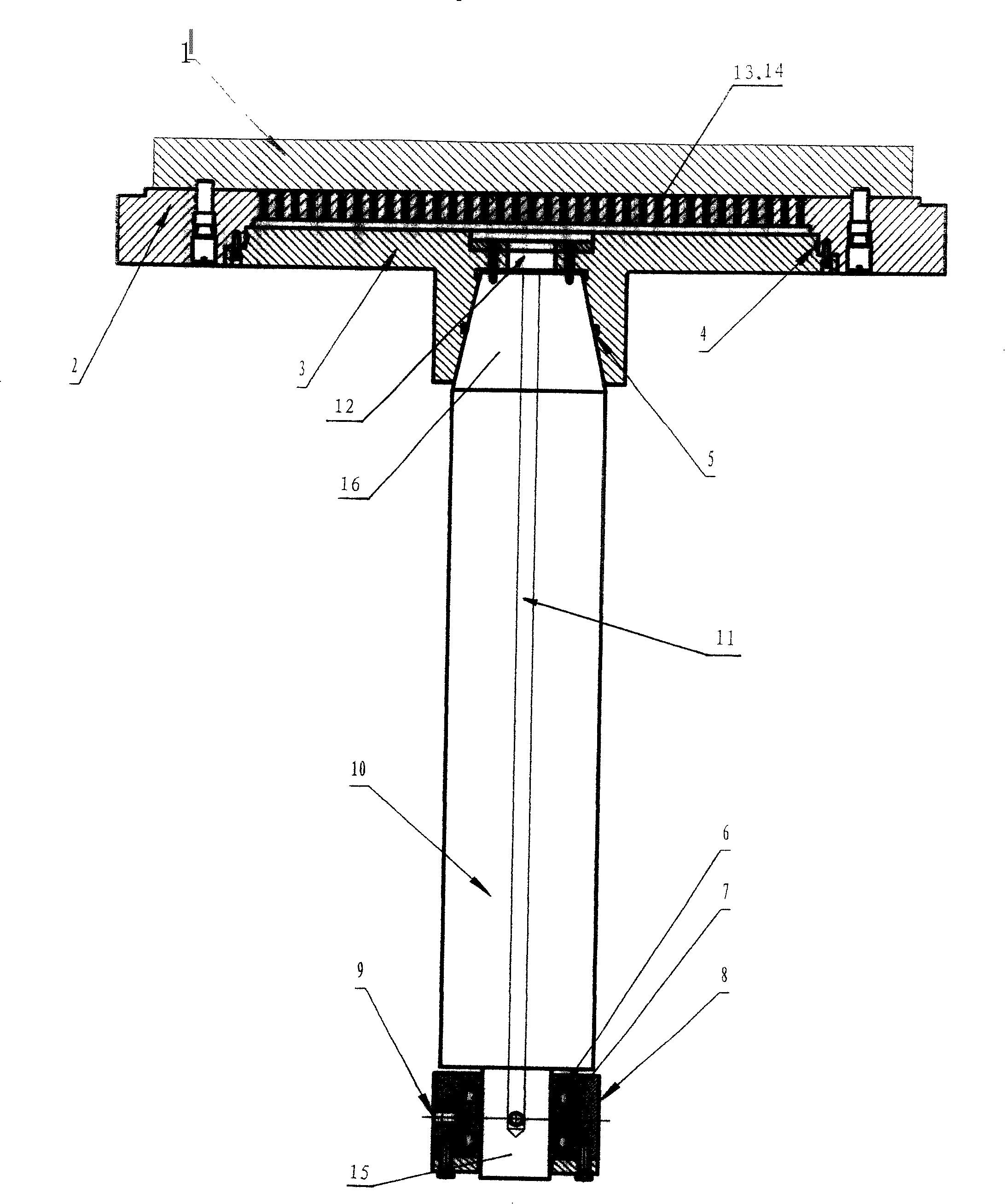

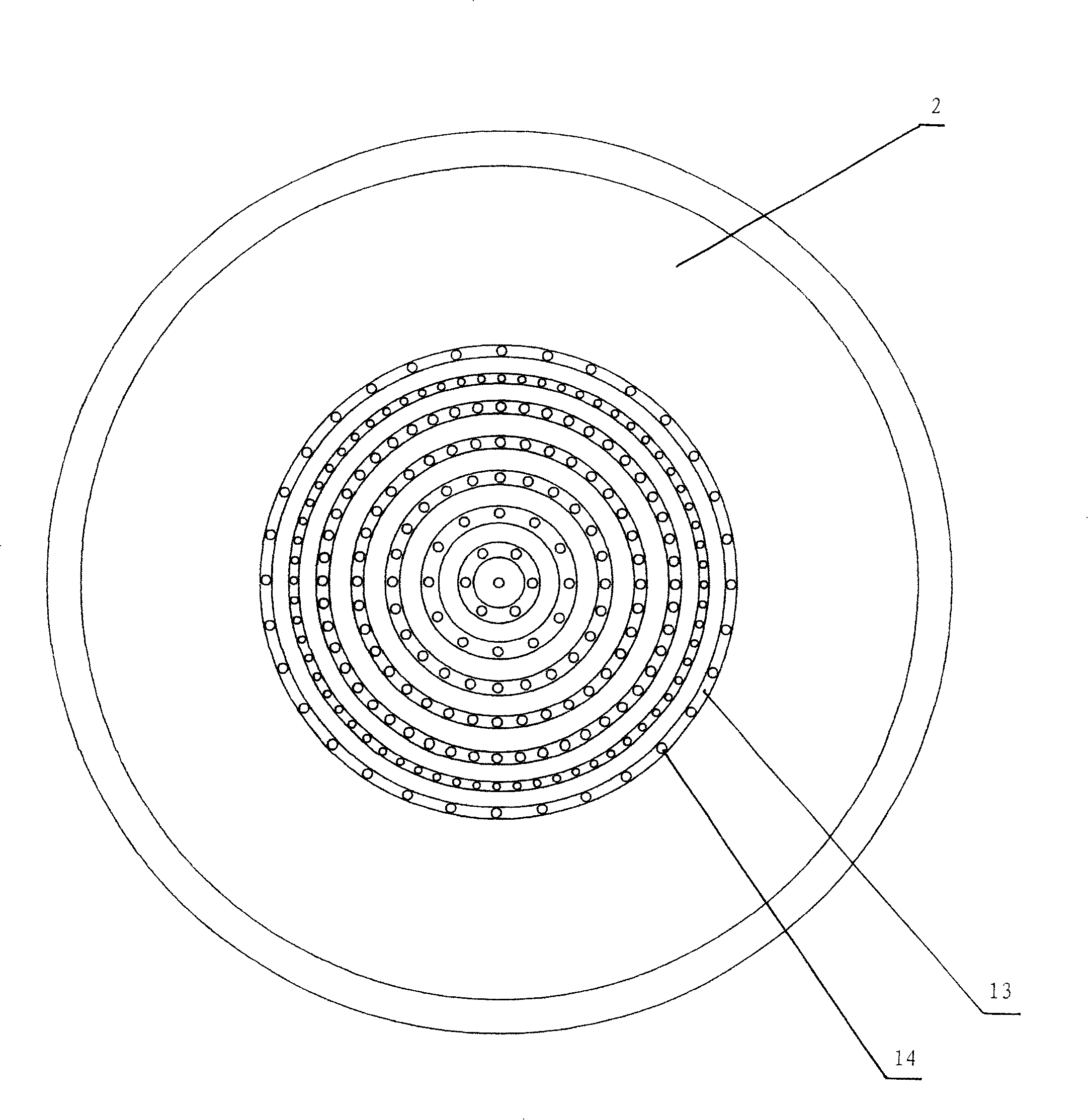

[0010] figure 1 , figure 2 One embodiment of the invention is shown. There is a vacuum pipeline 11 at the axis of the machine tool spindle 10, and a connecting jacket 8 connected to an external vacuum system pipeline is installed at the tail portion 15 of the machine tool spindle. The exhaust port 9 connecting the axial vacuum pipeline and the external vacuum system pipeline is equipped with a vacuum chassis 3 at the end 16 of the machine tool spindle, a vacuum chamber 12 is provided between the vacuum chassis and the machine tool spindle, and a vacuum suction cup is installed outside the vacuum chassis 2. There are multiple concentric ring grooves 13 on the surface of the vacuum chuck, and there are multiple suction ports 14 on the concentric ring grooves. The workpiece 1 is adsorbed on the vacuum chuck, and it is installed on the contact surface between the end of the machine tool spindle and the vacuum chassis. There is a static sealing ring 5, and a static sealing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com