Energy saving magnetic head and control method thereof

An electromagnetic head and valve technology, applied in electromagnetic relays, electromagnets with armatures, detailed information of electromagnetic relays, etc., can solve problems such as waste of energy and equipment loss, reduce temperature rise, prolong service life, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

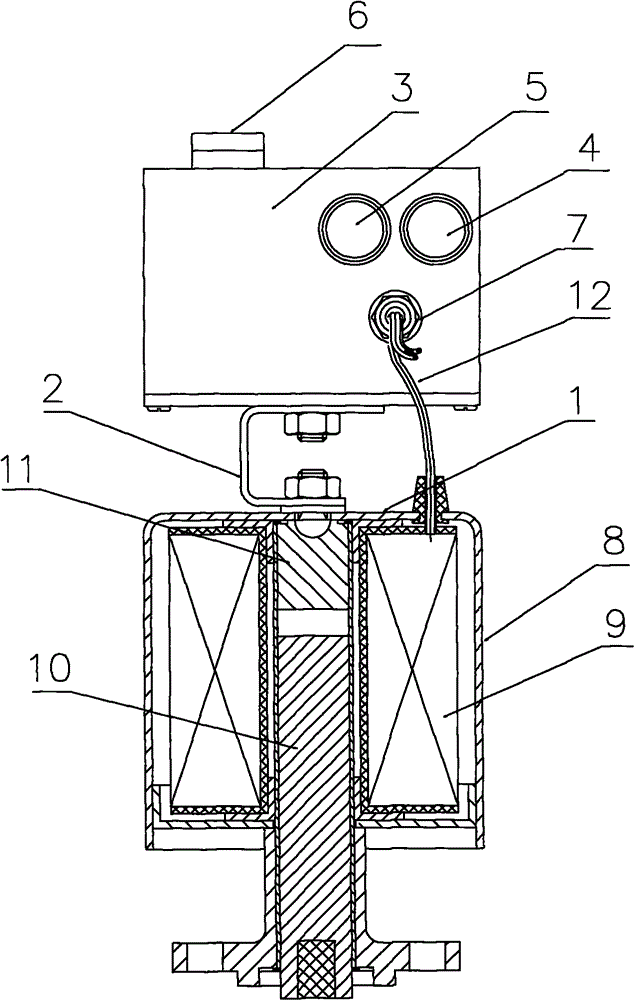

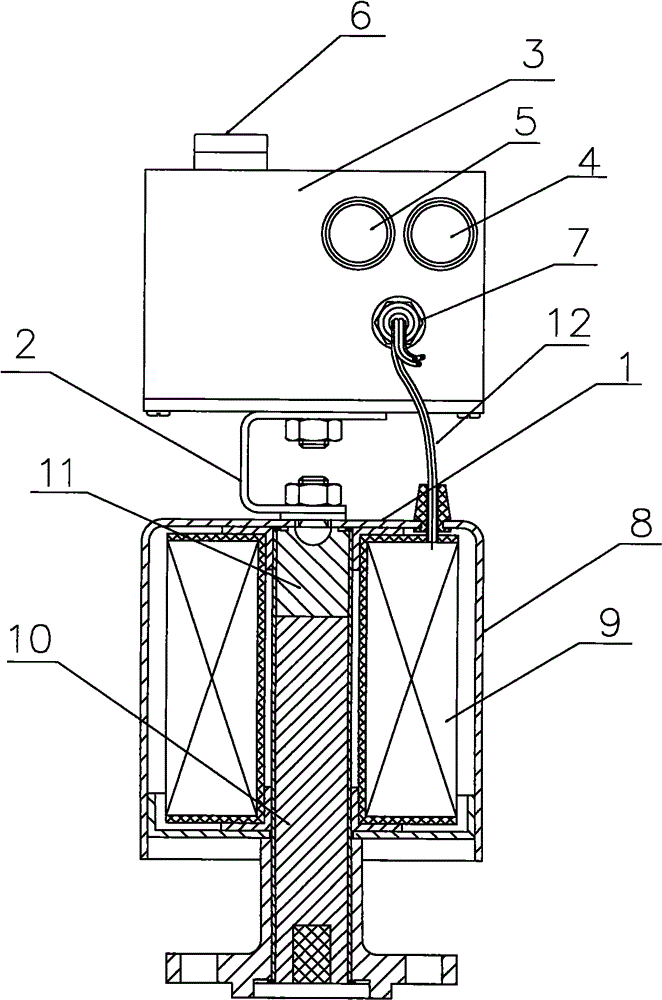

[0035] see figure 1 and figure 2 , an embodiment of the present invention includes a magnetic head main body 1 and a magnetic head control circuit, the magnetic head main body includes a magnetically conductive shell 8, a moving iron core 10, a static iron core 11 and a coil 9 that cooperate with each other, and the magnetically conductive There is an iron core passage in the shell, the static iron core is fixedly installed on the upper end of the iron core passage, the moving iron core is slidably connected in the iron core passage, the static iron core and the moving iron core There is a working air gap between them, the coil is arranged around the passage of the iron core, and the magnetically permeable shell is also provided with a through hole for the wire 12 to pass through.

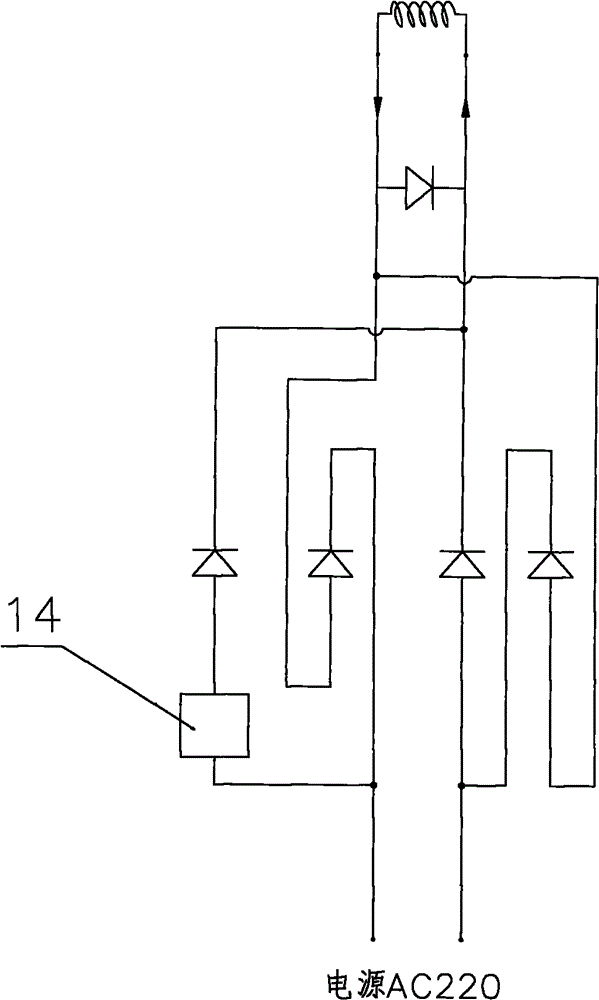

[0036] The energy-saving electromagnetic head also includes an electric c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com