Local surface heat treatment process for bar parts

A technology of surface heat treatment and local heating, applied in the direction of heat treatment furnace, heat treatment equipment, improvement of process efficiency, etc., can solve the problems of intolerance to wear, low hardness, affecting service life, etc., to improve the quenching effect and wear resistance. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

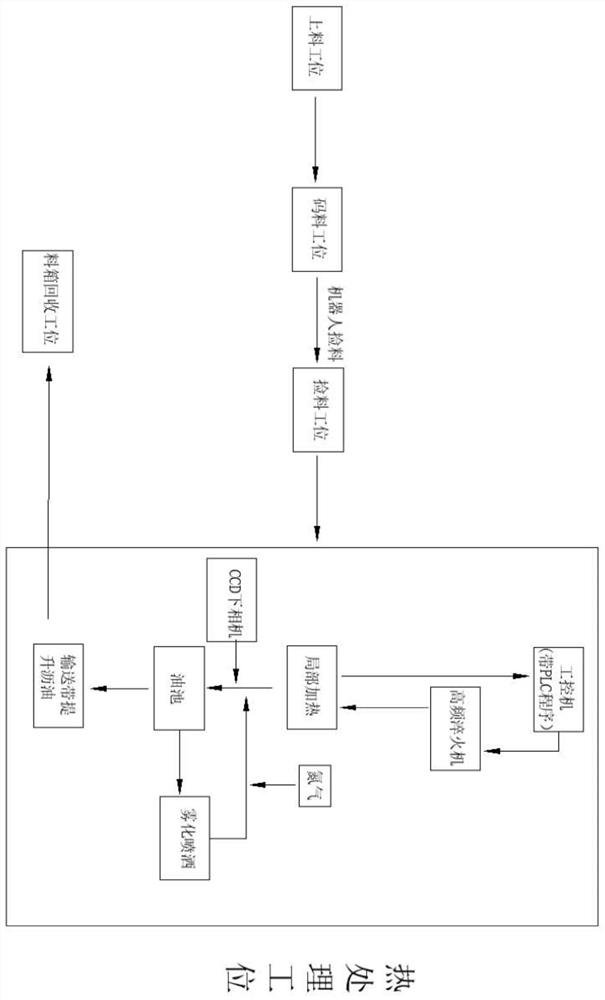

[0024] The local surface heat treatment process of bar parts includes a loading station, a stacking station, a picking station, a heat treatment station and a bin recovery station arranged in sequence. The heat treatment station mainly includes the following steps:

[0025] S1. The industrial computer with PLC control program controls the local heating of the high-frequency quenching machine to the bar parts, and manually adjusts the power of the high-frequency quenching machine, and the power of the manual manual high-frequency quenching machine is 3kW;

[0026] S2. Use the electromagnet on the heat treatment station to absorb the bar parts for heat treatment. The electromagnet is also controlled by the PLC control program, and the current of the high frequency quenching machine is changed by adjusting the resistance on the high frequency quenching machine , thereby changing the suction force of the electromagnet, and the suction force of the electromagnet is 10gf;

[0027] S...

Embodiment 2

[0035] The local surface heat treatment process of bar parts includes a loading station, a stacking station, a picking station, a heat treatment station and a bin recovery station arranged in sequence. The heat treatment station mainly includes the following steps:

[0036] S1. The industrial computer with PLC control program controls the local heating of the high-frequency quenching machine to the bar parts, and manually adjusts the power on the high-frequency quenching machine, and the power of the manual manual high-frequency quenching machine is 4kW;

[0037] S2. Use the electromagnet on the heat treatment station to absorb the bar parts for heat treatment. The electromagnet is also controlled by the PLC control program, and the current of the high frequency quenching machine is changed by adjusting the resistance on the high frequency quenching machine , thereby changing the suction force of the electromagnet, and the suction force of the electromagnet is 20gf;

[0038] S...

Embodiment 3

[0046] The local surface heat treatment process of bar parts includes a loading station, a stacking station, a picking station, a heat treatment station and a bin recovery station arranged in sequence. The heat treatment station mainly includes the following steps:

[0047] S1. The industrial computer with PLC control program controls the local heating of the high-frequency quenching machine to the bar parts, and manually adjusts the power on the high-frequency quenching machine, and the power of the manual manual high-frequency quenching machine is 5kW;

[0048]S2. Use the electromagnet on the heat treatment station to absorb the bar parts for heat treatment. The electromagnet is also controlled by the PLC control program, and the current of the high frequency quenching machine is changed by adjusting the resistance on the high frequency quenching machine , thereby changing the suction force of the electromagnet, and the suction force of the electromagnet is 30gf;

[0049] S3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com