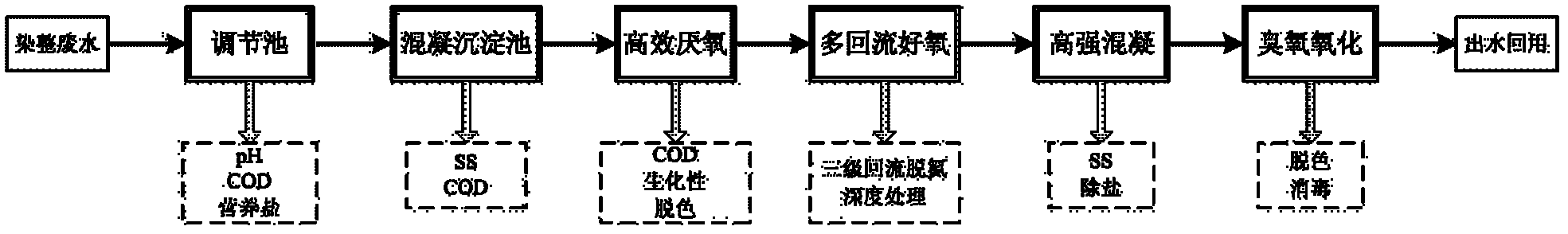

Method for recycling textile dyeing and finishing wastewater

A technology for textile dyeing and finishing and wastewater recycling, which is applied in the field of water pollution control research to achieve high industrial application prospects, high water quality and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

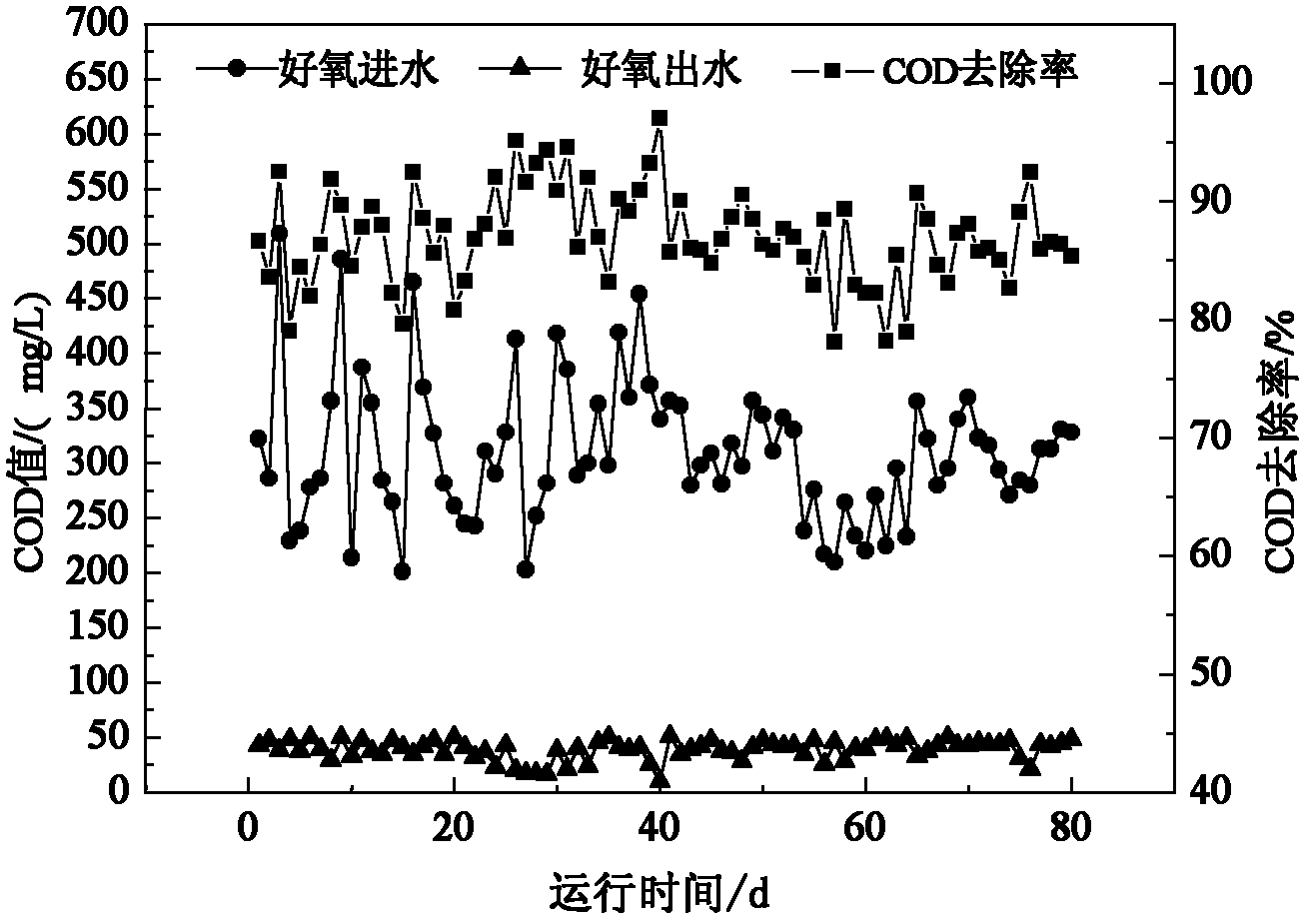

[0047] The multistage circulating aerobic treatment system used in the embodiment of the present invention is composed of anaerobic / anoxic reaction pool A and aerobic reaction pool O in series according to the mode of A-O-A-O-A-O-A, anaerobic / anoxic reaction pool A (effective volume 10L) and The effective volume ratio of the aerobic reaction tank O (effective volume 5L) is 2:1,

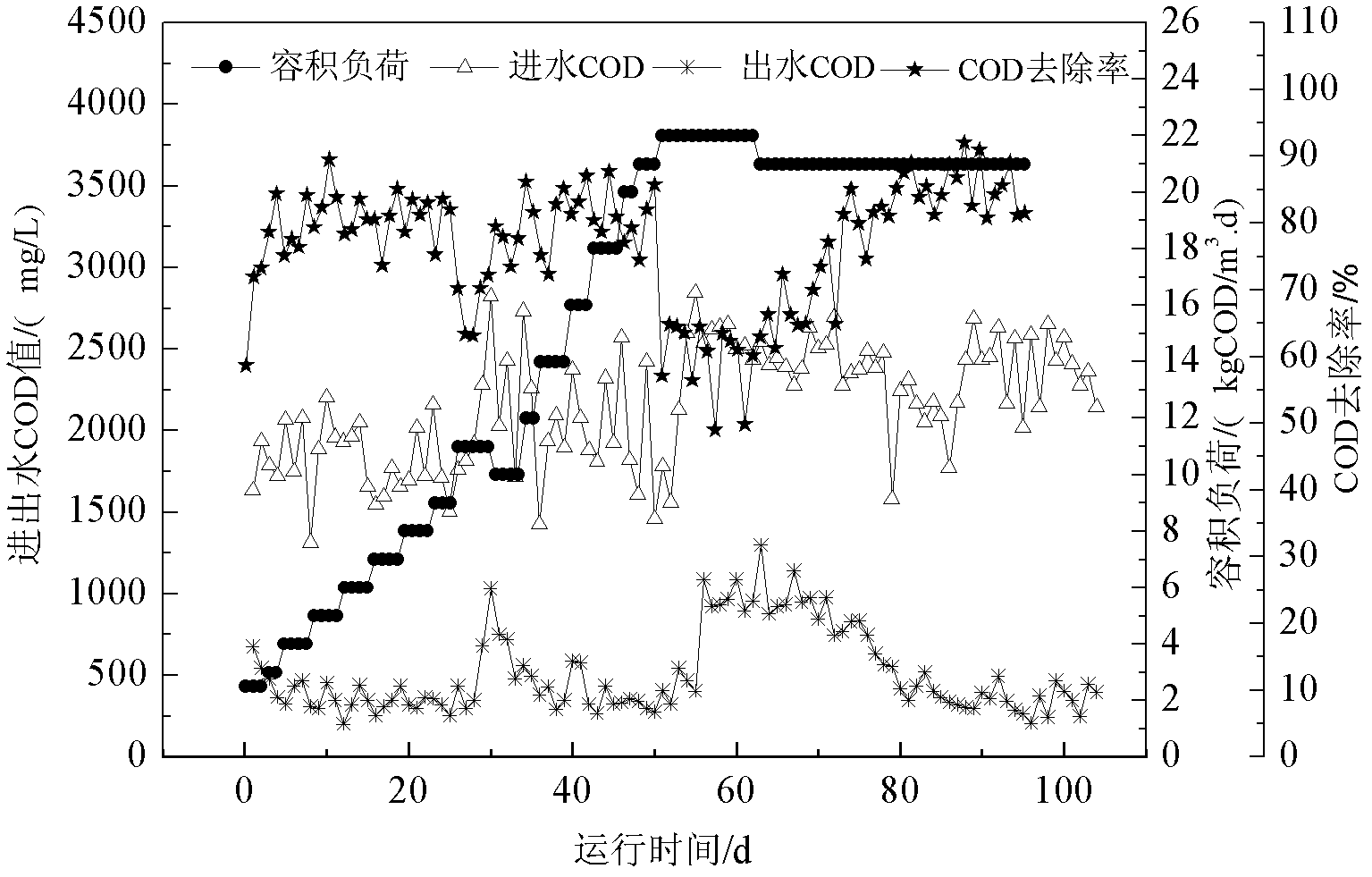

[0048] Inoculate the anaerobic granular sludge in the IC reactor (effective volume 50L), and then pass the debugging wastewater into it. Under the condition of neutral pH value, in the anaerobic environment, the sludge is acclimated at 20-40℃, and the COD of the wastewater is adjusted. The concentration starts from 200mg / L and increases the concentration every day (100mg / L increase rate per day) until the raw water enters. The PCR-DGGE method is used to detect the microbial ecology in the wastewater, and to track the IC reactor effluent and biogas production. When the IC reactor The effluent COD can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com